Super-hydrophilic low-yellowing organic silicon softening agent and preparation method thereof

A silicone softener, super-hydrophilic technology, applied in the directions of improved hand-feeling fibers, textiles and papermaking, fiber processing, etc., can solve the problems of poor stability of amino silicone oil emulsion, affecting wearing comfort, oil drifting and sticking rollers, etc. To achieve the effect of simple and easy preparation method, easy industrial production and low yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

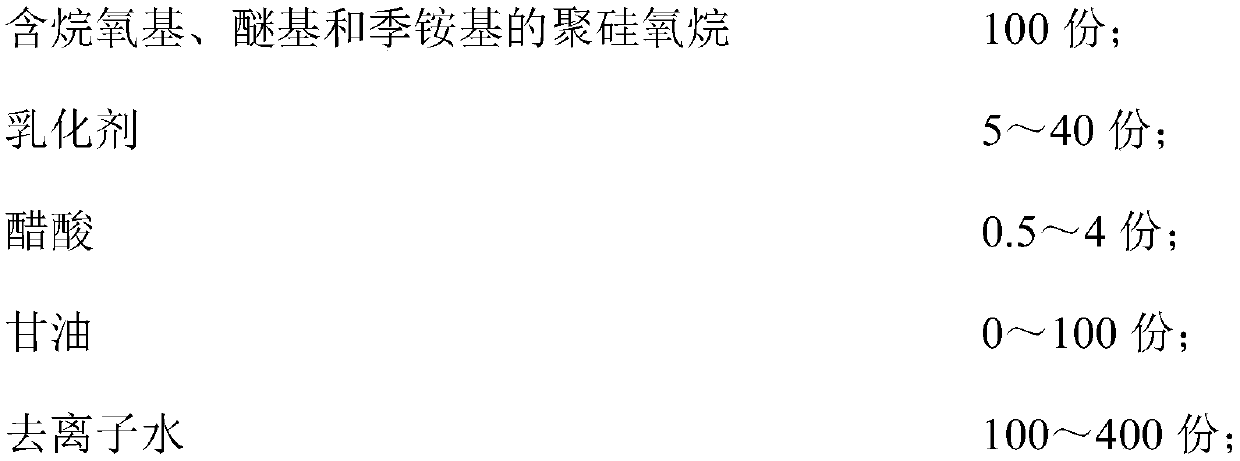

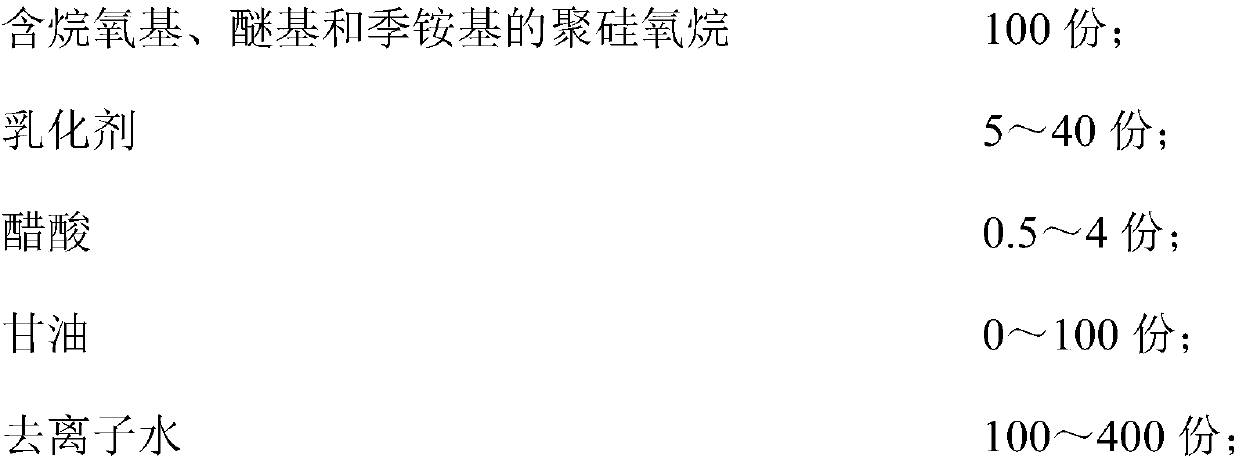

Method used

Image

Examples

Embodiment 1

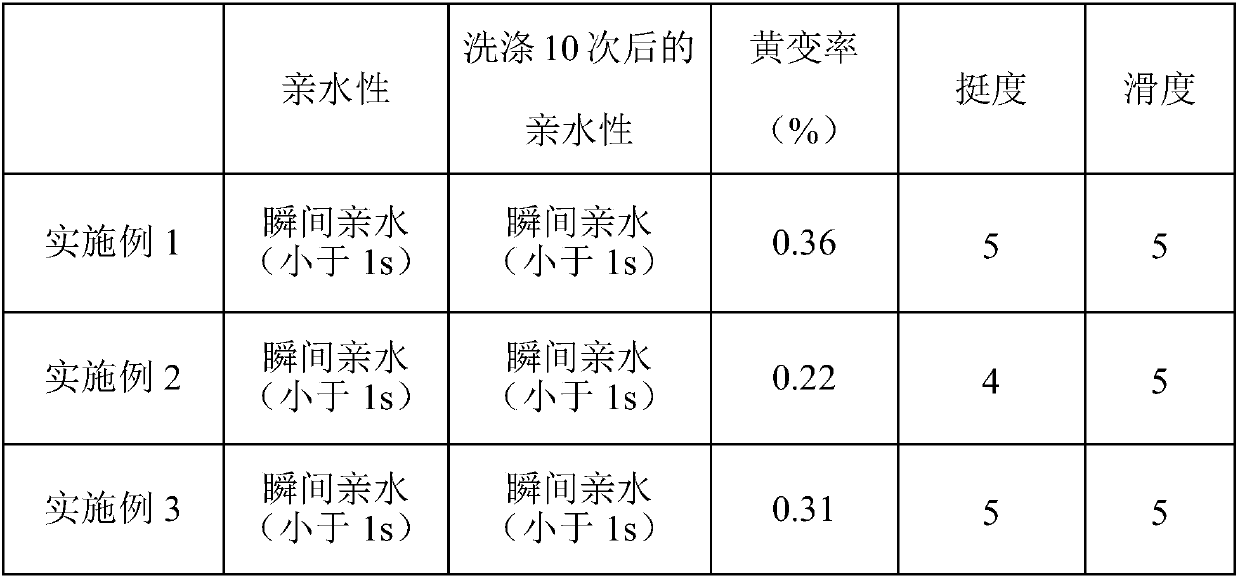

[0020] 100 mass parts [(CH 3 O) 3 SiO 1 / 2 ] 0.05 (CH 3 R 3 SiO 2 / 2 ) 0.002 [(CH 3 ) 2 SiO 2 / 2 ] 0.8 (CH 3 -SiO 3 / 2 ) 0.14 (SiO 4 / 2 ) 0.008 , where R 3 for -CH 2 CH 2 CH 2 OCH 2 CH(OH)CH 2 (CH 3 ) 2 N + -[CH(CH 3 )CH 2 O] 6 [CH 2 CH 2 O] 39 CH 2 CH(CH 3 )N + (CH 3 ) 2 , and 10 parts by mass of XL-40 and 10 parts by mass of AEO-9 emulsifier were added to the emulsification tank, stirred for 30 minutes, then added acetic acid to adjust the pH value to 5-6, and finally added 5 parts by mass of glycerin and 100 parts by mass of deionized water to continue stirring After 10 minutes, a super-hydrophilic low-yellowing silicone softener with a solid content of 55.5% was prepared. The properties of the samples are shown in Table 1 and Table 2.

Embodiment 2

[0022] 100 mass parts [(CH 3 O) 3 SiO 1 / 2 ] 0.5 (CH 3 R 3 SiO 2 / 2 ) 0.008 [(CH 3 ) 2 SiO 2 / 2 ] 0.4 (CH 3 -SiO 3 / 2 ) 0.088 (SiO 4 / 2 ) 0.004 , where R 3 for -CH 2 CH 2 CH 2 OCH 2 CH(OH)CH 2 (CH 3 ) 2 N + -[CH(CH 3 )CH 2 O] 6 [CH 2 CH 2 O] 39 CH 2 CH(CH 3 )N + (CH 3 ) 2 , and 5 parts by mass of XL-70 emulsifier were added to the emulsification kettle, stirred for 5 minutes, then added acetic acid to adjust the pH value to 5-6, and finally added 40 parts by mass of glycerin and 400 parts by mass of deionized water and continued to stir for 40 minutes to obtain a solid content of 26.6% ultra-hydrophilic low-yellowing silicone softener. The properties of the samples are shown in Table 1 and Table 2.

Embodiment 3

[0024] 100 mass parts [(CH 3 O) 3 SiO 1 / 2 ] 0.3 (CH 3 R 3 SiO 2 / 2 ) 0.01 [(CH 3 ) 2 SiO 2 / 2 ] 0.6 (CH 3 -SiO 3 / 2 ) 0.076 (SiO 4 / 2 ) 0.014 , where R 3 for -CH 2 CH 2 CH 2 OCH 2 CH(OH)CH 2 (CH 3 ) 2 N + -[CH(CH 3 )CH 2 O] 6 [CH 2 CH 2 O] 13 CH 2 CH(CH 3 )N + (CH 3 ) 2 , and 6 parts by mass of TO-5 and 9 parts by mass of TO-9 emulsifiers were added to the emulsification tank, stirred for 15 minutes, then added acetic acid to adjust the pH value to 5-6, and finally added 20 parts by mass of glycerin and 200 parts by mass of deionized water to continue stirring After 15 minutes, a super-hydrophilic low-yellowing silicone softener with a solid content of 40.3% was prepared. The properties of the samples are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com