Composite functional fabric with multiple cotton-hemp blends and functional fibers

A technology of functional fibers and composite functions, applied in the textile field, can solve the problems of rough surface of hemp fabric, rough fiber length and fineness, poor fiber cohesion, etc., to increase comfort and coloring power, and stabilize fabric structure , Improve the effect of internal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

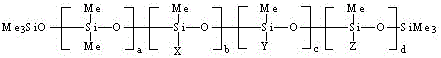

Image

Examples

Embodiment 1

[0018] Blend hemp fiber, bamboo fiber and wool fiber into 50S warp yarn at a ratio of 1:1:1 for use; blend cotton fiber, bamboo fiber and wool fiber at a ratio of 2:1:1 into 60S weft yarn for use. Adopt rapier loom to weave, and weaving speed is 160r / min, and opening time is 300 °.

Embodiment 2

[0020] Blend hemp fiber, bamboo fiber, and wool fiber into 50S warp yarn at a ratio of 2:1:1 for use; blend cotton fiber, bamboo fiber, and wool fiber at a ratio of 4:1:1 into 60S weft yarn for use. Adopt rapier loom to weave, and weaving speed is 180r / min, and opening time is 305 °.

Embodiment 3

[0022] Blend hemp fiber, bamboo fiber, and wool fiber at a ratio of 3:1:1 into 50S warp yarn for use; blend cotton fiber, bamboo fiber, and wool fiber at a ratio of 6:1:1 into 60S weft yarn for use. Adopt rapier loom to weave, and weaving speed is 200r / min, and opening time is 320 °.

[0023] The warp and weft yarns described in Examples 1 to 3 were prepared by the following steps: soaking bamboo fibers and wool fibers in acetone, and simultaneously performing ultrasonic vibration treatment, dehydrating and drying after washing, to obtain mixed fibers; mixing the mixed fibers with Hemp fibers are mixed in proportion and twisted into mixed yarns to obtain warp yarns; mixed fibers and cotton fibers are mixed in proportion and twisted into mixed yarns to obtain weft yarns.

[0024] In order to give full play to the functionality of the hemp fiber and increase the comfort and coloring strength of the yarn, in the preparation steps of the warp and weft yarns, one cotton and linen s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com