All-solid-state battery and preparation method thereof

A technology of all-solid-state batteries and solid-state electrolytes, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve problems such as consumption, hidden dangers of explosion, ignition of organic electrolytes, etc., to improve ion conductivity and for the first time Coulombic efficiency, improvement of cycle life and power life, and the effect of battery safety performance guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

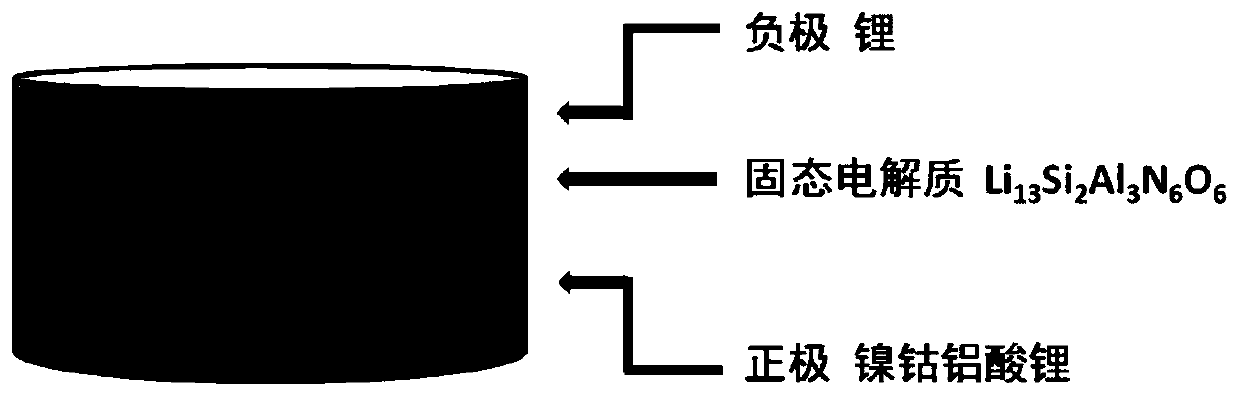

[0064] This embodiment provides an all-solid-state battery, the preparation method of which comprises:

[0065] (1) 70g lithium nickel cobalt aluminate (LiNi 0.8 co 0.1 al 0.1 o 2 ) cathode material and 30g Li 13 Si 2 al 3 N 6 o 6 The solid electrolyte powder is mixed and cast into a 5mm thick film with collodion;

[0066] (2) After the casting film is dried, it is punched into a positive electrode sheet with a diameter of 10mm for use;

[0067] (3) 20g Li 13 Si 2 al 3 N 6 o 6 The solid electrolyte powder is cast into a 1mm thick film with collodion;

[0068] (4) After the casting film is dried, it is punched into a solid electrolyte sheet with a diameter of 10mm;

[0069] (5) The solid electrolyte sheet is stacked on the positive electrode sheet and hot-pressed and sintered together, the sintering pressure is 300MPa, the sintering temperature is 300°C, and the sintering time is 10min;

[0070] (6) Cold-press the lithium negative electrode material with a diame...

Embodiment 2

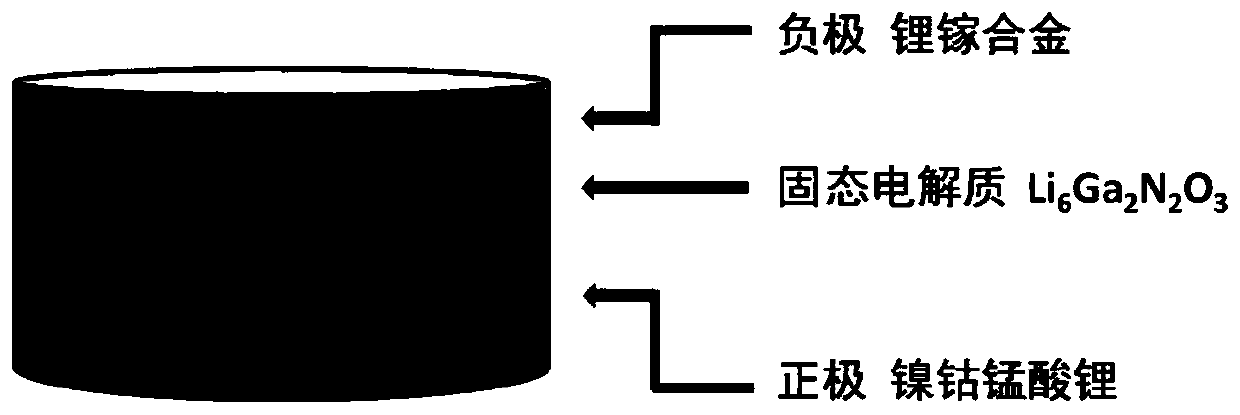

[0073] This embodiment provides an all-solid-state battery, the preparation method of which comprises:

[0074] (1) 70g lithium nickel cobalt manganate (LiNi 0.8 co 0.1 mn 0.1 o 2 ) cathode material and 30g Li 6 Ga 2 N 2 o 3 The solid electrolyte powder is mixed and cast into a 5mm thick film with collodion;

[0075] (2) After the casting film is dried, it is punched into a positive electrode sheet with a diameter of 10mm for use;

[0076] (3) 20g Li 6 Ga 2 N 2 o 3 The solid electrolyte powder is cast into a 1mm thick film with collodion;

[0077] (4) After the casting film is dried, it is punched into a solid electrolyte sheet with a diameter of 10 mm;

[0078] (5) The solid electrolyte sheet is stacked on the positive electrode sheet and hot-pressed and sintered together, the sintering pressure is 300MPa, the sintering temperature is 300°C, and the sintering time is 10min;

[0079] (6) cold-press the lithium-gallium alloy negative electrode material with a diam...

Embodiment 3

[0082] This embodiment provides an all-solid-state battery, the preparation method of which comprises:

[0083] (1) 70g magnesium chromate positive electrode material and 30g Mg 5 SnBi 2 Se 9 The solid electrolyte powder is mixed and cast into a 5mm thick film with collodion;

[0084] (2) After the casting film is dried, it is punched into a positive electrode sheet with a diameter of 10mm for use;

[0085] (3) 20g Mg 5 SnBi 2 Se 9 The solid electrolyte powder is cast into a 1mm thick film with collodion;

[0086] (4) After the casting film is dried, it is punched into a solid electrolyte sheet with a diameter of 10 mm;

[0087] (5) The solid electrolyte sheet is stacked on the positive electrode sheet and hot-pressed and sintered together, the sintering pressure is 300MPa, the sintering temperature is 300°C, and the sintering time is 10min;

[0088] (6) cold-press the tin-bismuth alloy negative electrode material with a diameter of 10mm and a thickness of 2mm on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com