Bearing

A technology of supporting parts and bridging parts, which is applied in the field of supporting parts, can solve problems such as inability to assemble, large construction space, narrow construction space setting of supporting parts, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

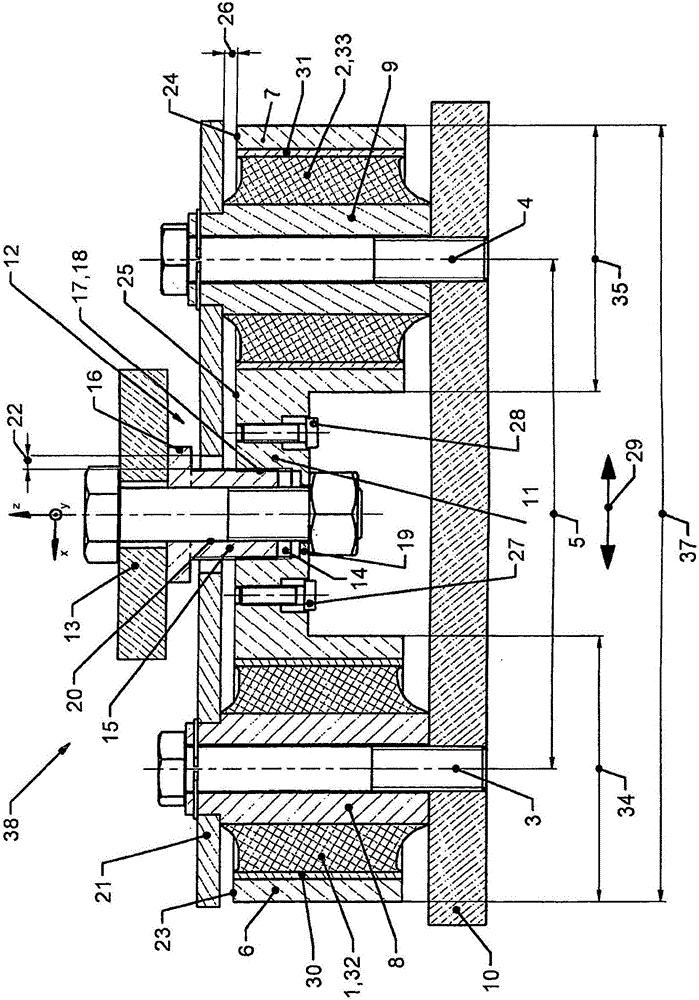

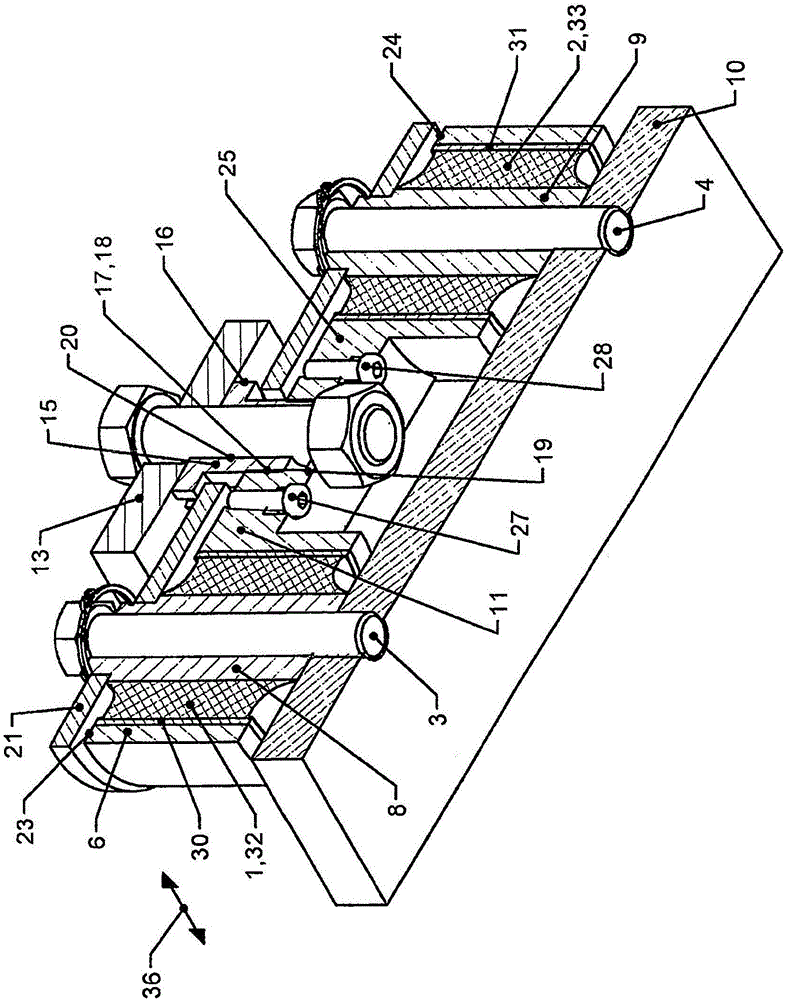

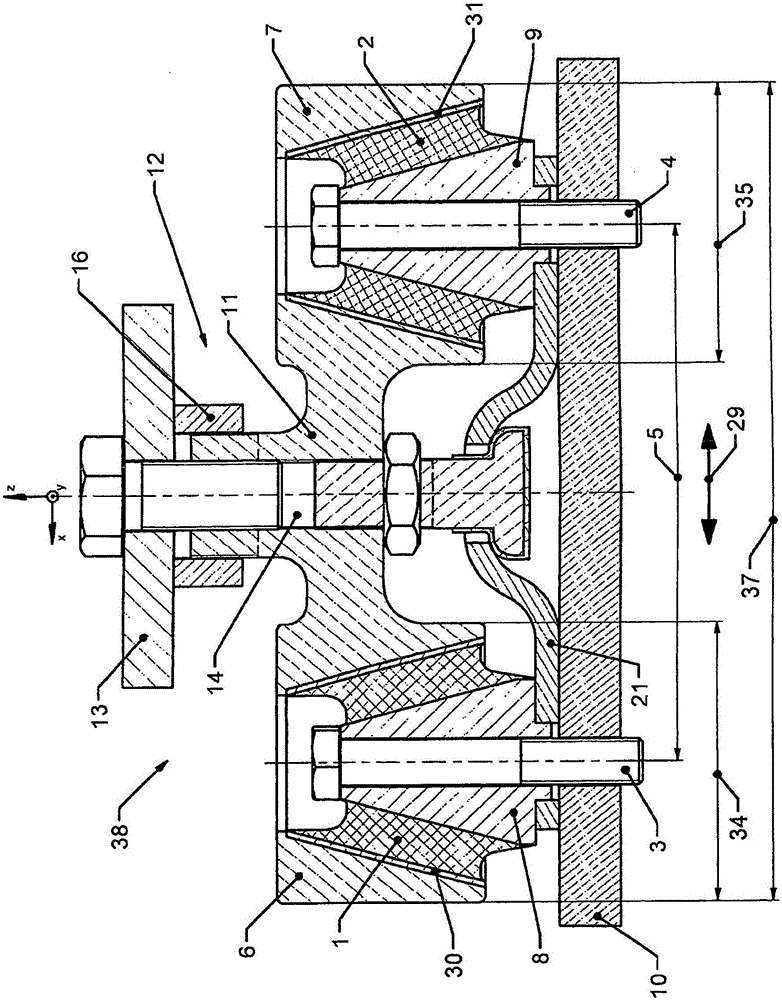

[0037] exist figure 1 and figure 2 A first embodiment of a support according to the invention is shown in .

[0038] The bearing comprises two rubber bushings 1 , 2 which are formed rotationally symmetrically about a vertical axis of rotation 3 , 4 . The rubber bushings 1, 2 comprise respective bushing cores 8, 9, respective outer sleeves 30, 31 and respective hollow cylindrical elastic bodies 32, 33 made of elastic material. The bushing cores 8 , 9 and the outer sleeves 30 , 31 are each made of metallic material in this embodiment.

[0039]Each rubber bush 1 , 2 is arranged in a bush carrier 6 , 7 , wherein the bush carriers 6 , 7 are arranged adjacent to each other at a distance 5 from one another in the longitudinal direction 29 of the carrier. The bushing supports 6 , 7 are connected to one another by a bridge 11 , wherein in the illustrated exemplary embodiment the two bushing supports 6 , 7 and the bridge 11 transition into one another in one piece and are made of on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com