Red mud harmless comprehensive recycling technology suitable for Bayer process

A technology of Bayer method and red mud, which is applied in the field of silicate, can solve the problem of high alkalinity in red mud, achieve the effect of improving recovery rate and reducing radioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The source of red mud in the present invention is Bayer process red mud, and its main chemical composition is: Al 2 o 3 : 22~25%; Si0 2 : 16~19%; Fe 2 0 3 : 32~39%; CaO: 0~2%; Na 2 O:8~13%;TiO 2 :7~9%;

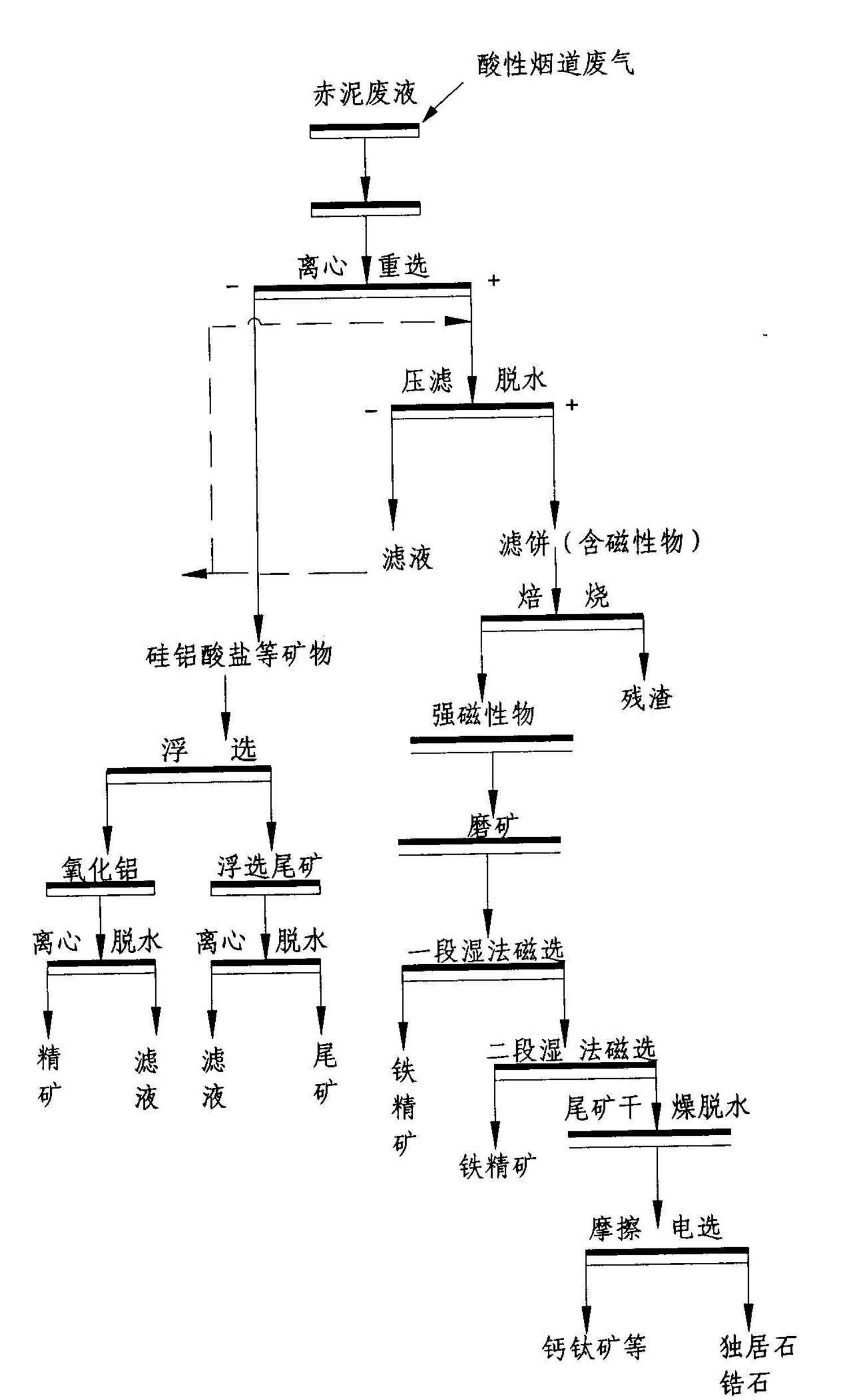

[0052] Such as figure 1 Shown, the technological process of the present embodiment is as follows:

[0053] 1) Removal of free alkali in red mud: Red mud contains a large amount of free alkaline substances, so it has strong alkalinity. Since alkaline red mud will damage the equipment in the subsequent process, it must be removed free base. Therefore, before the red mud enters the separation system, the acidic flue gas from the power plant near the alumina plant is first collected to neutralize the red mud tailings slurry acidically. The pH value is 7.5-9, and it will exist in the red mud in the form of attached liquid. The alumina and sodium oxide in the mud are removed to reduce the alkalinity of the red mud and create conditions for the subsequent utilization ...

Embodiment 2

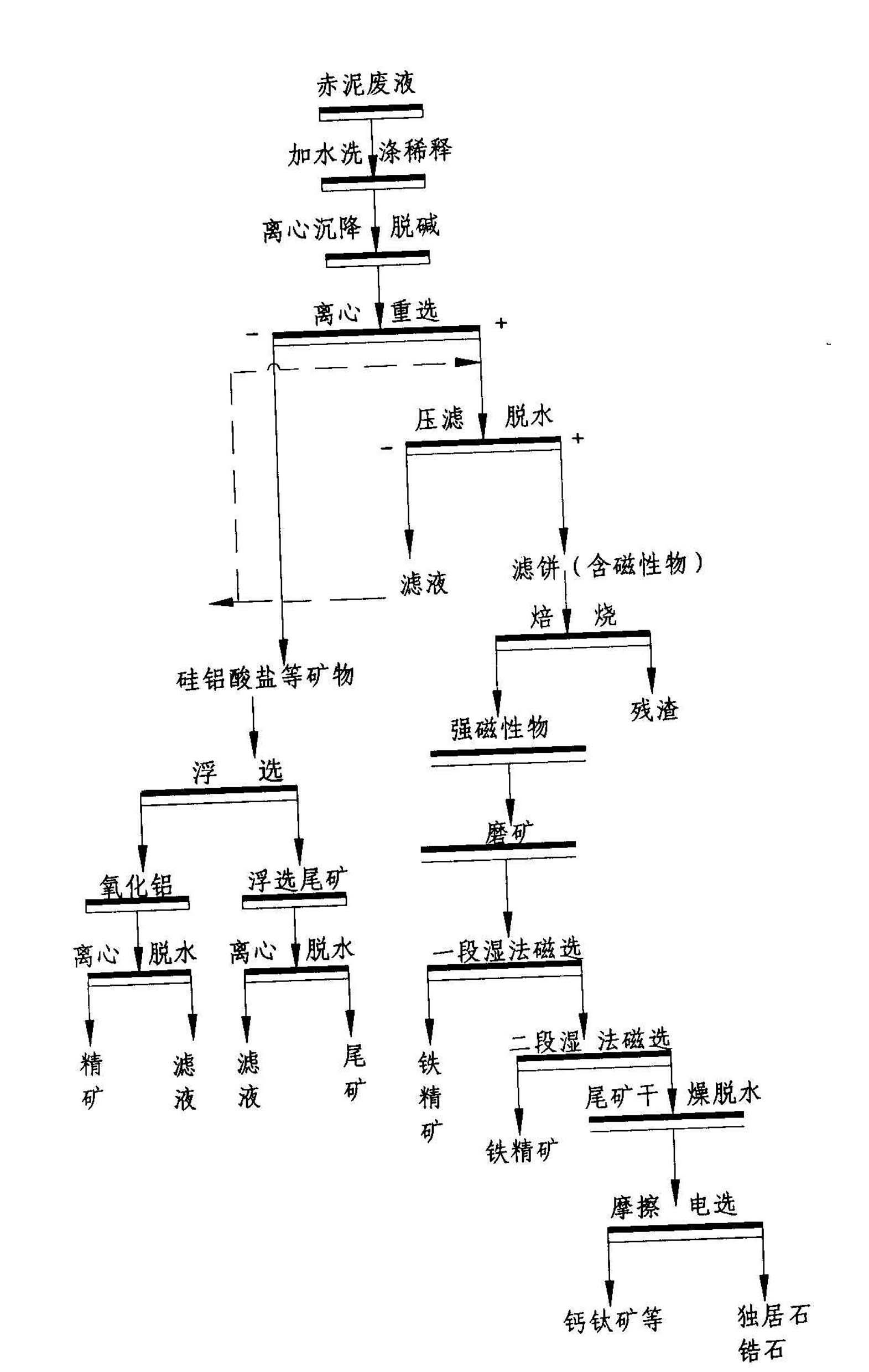

[0065] Such as figure 2 As shown, based on the same principle and method, for the red mud dealkalization mode, the present invention can replace the red mud dealkalization process in the process of Example 1 with the following process system:

[0066] The red mud slurry from the red mud tailings dam is washed and diluted, and the diluted red mud slurry is centrifugally settled to separate most of the solution after settling, and then the bottom flow after settling is subjected to reverse washing for many times, and the The alumina and sodium oxide present in the red mud in the form of attached liquid are removed to reduce the alkalinity of the red mud and create conditions for subsequent red mud recovery. In this way, the purpose of removing alkaline substances in red mud can also be achieved.

[0067]

Embodiment 3

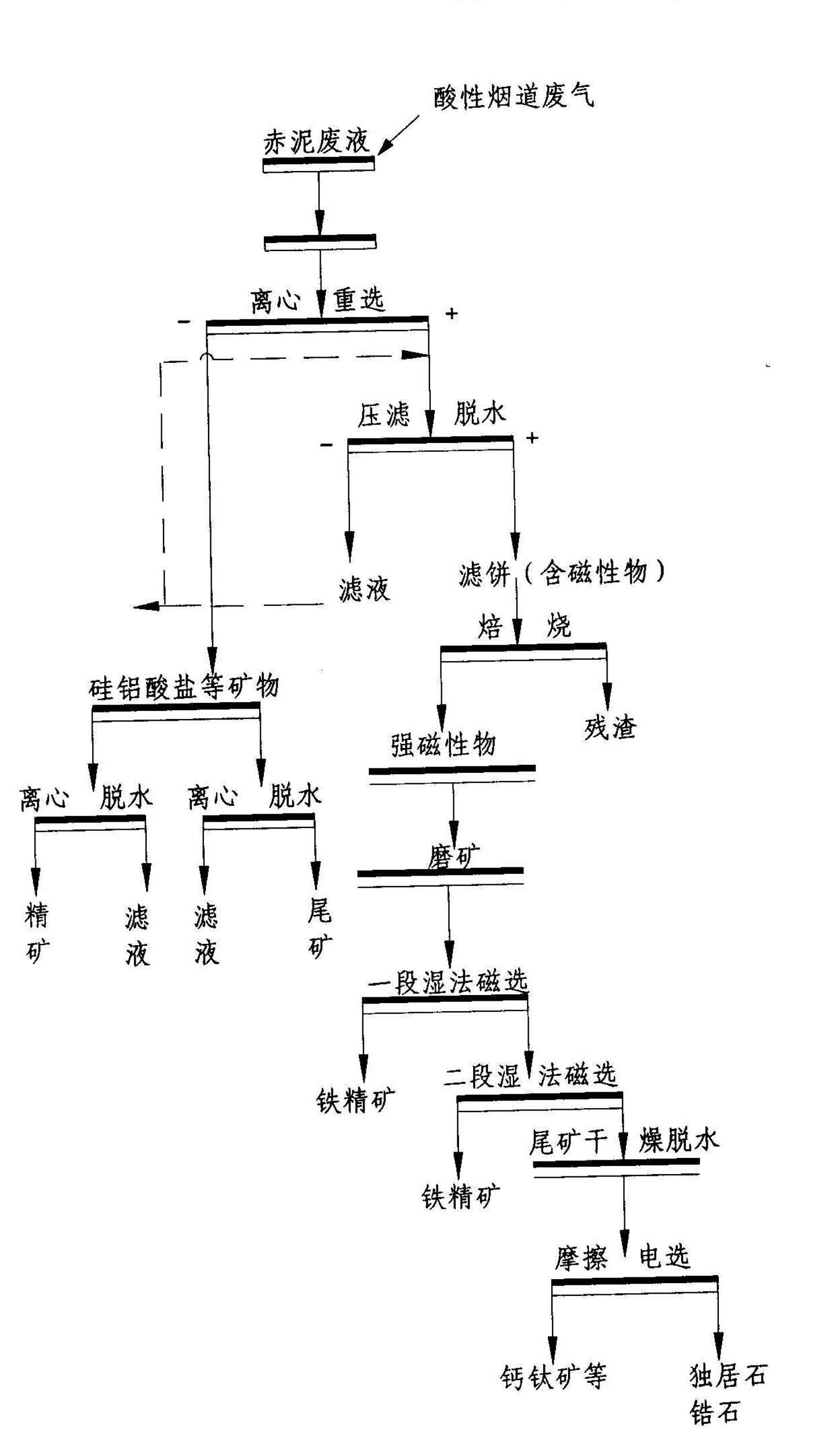

[0069] Such as image 3 As shown, based on the same principle and method, for the flotation process of red mud, the present invention can replace the red mud flotation process and the dehydration process after flotation in the process of Example 1 with the following process system:

[0070] Minerals with a smaller specific gravity produced after re-election, when the diaspore contained in it (mainly becomes Al 2 o 3 ) is less than 10%, this part of the minerals can be directly dehydrated, that is, the flotation ring is saved, and the minerals with a small specific gravity produced after re-election are subjected to centrifugal dehydration or dehydration by pressure filtration, and the minerals after dewatering are used as products Stored and removed water can be used as circulating water. This can also achieve the purpose of the present invention.

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com