Method for manufacturing natural-like stone ceramic tile with clear color and luster and boundary

A technology of imitating natural stone and manufacturing method, applied in the field of manufacturing of building decoration materials, can solve the problems of chaotic colors, blurred boundaries, uneven cloth, etc., and achieve the effects of natural texture, high density and lower firing temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

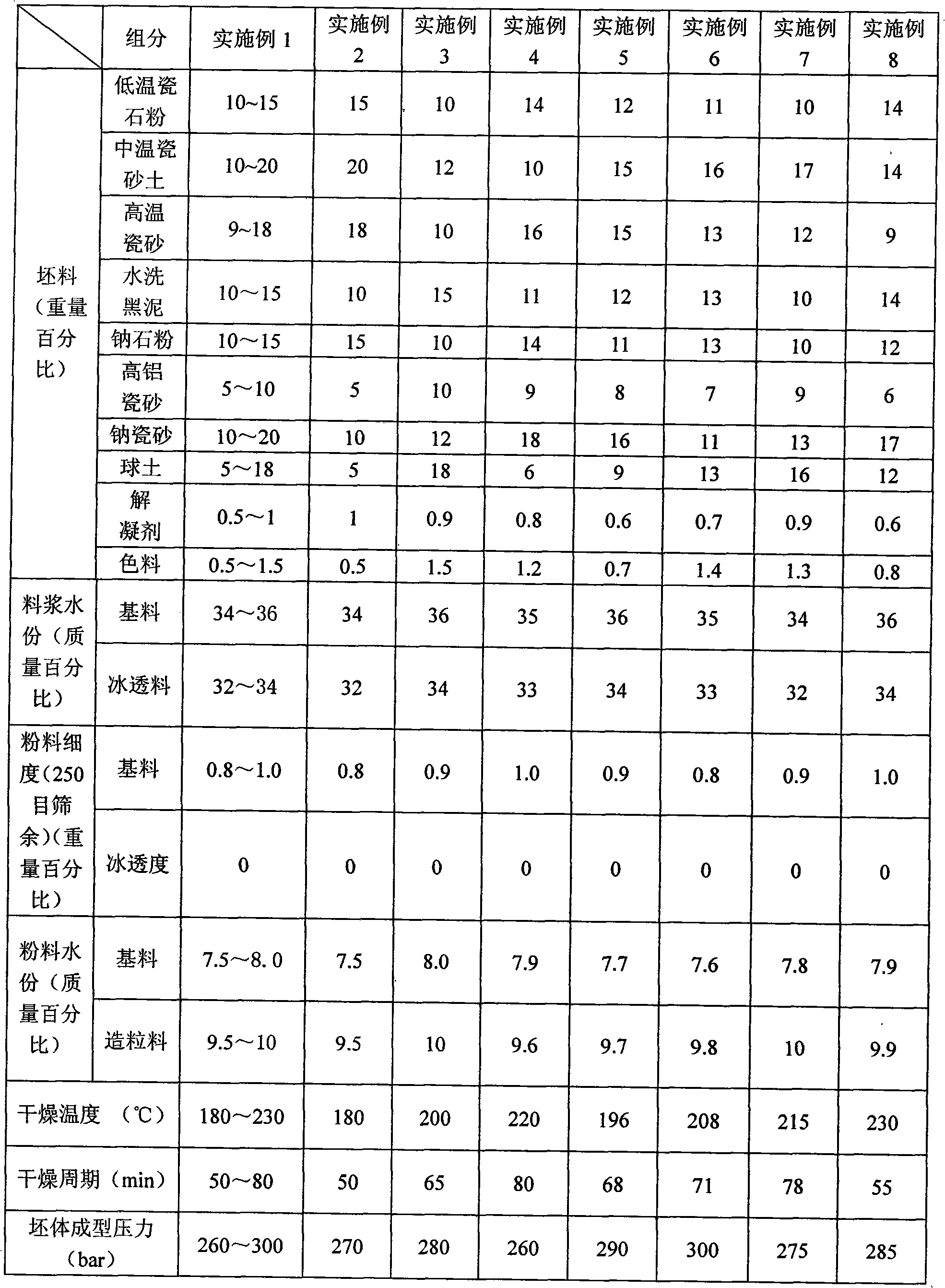

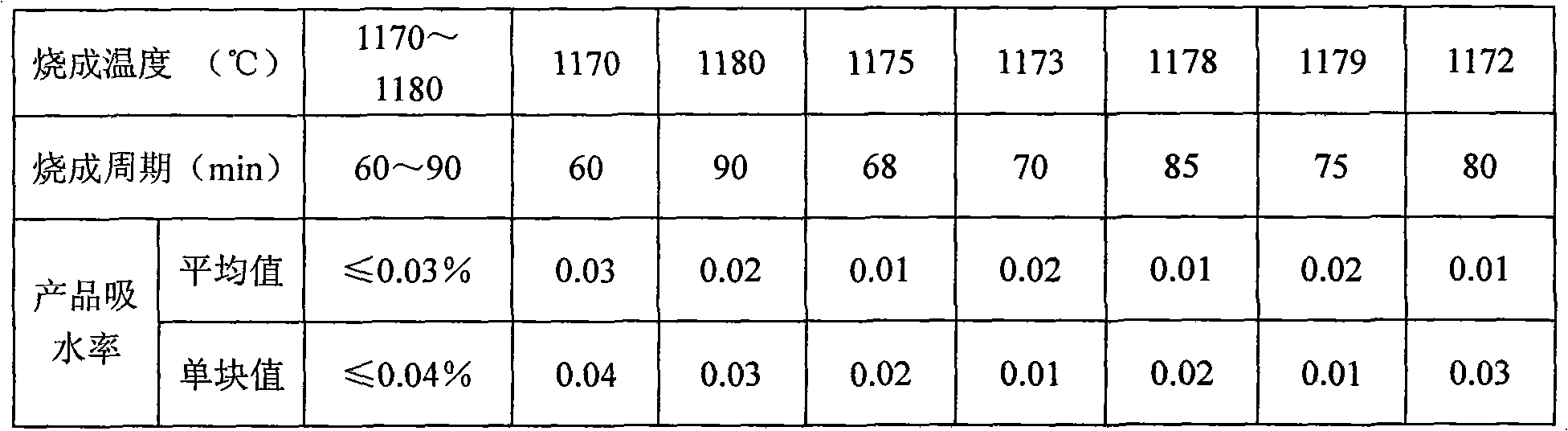

[0038] Below in conjunction with specific embodiment the present invention is described in further detail:

[0039]

[0040]

[0041] Process flow:

[0042] Material selection→batching→ball milling→color mixing→milling→cloth pressing→drying→firing→polishing→checking→packing→warehousing.

[0043] A spraying micron antifouling coating process is added between the cloth pressing process and the drying process.

[0044] The fabric pressing process adopts the waterfall three-time fabric impact blanking process. The process flow:

[0045] Powder crushing→full-automatic computer-controlled vertical blanking→line micro-powder cloth falls on the mold→base material cloth→press molding.

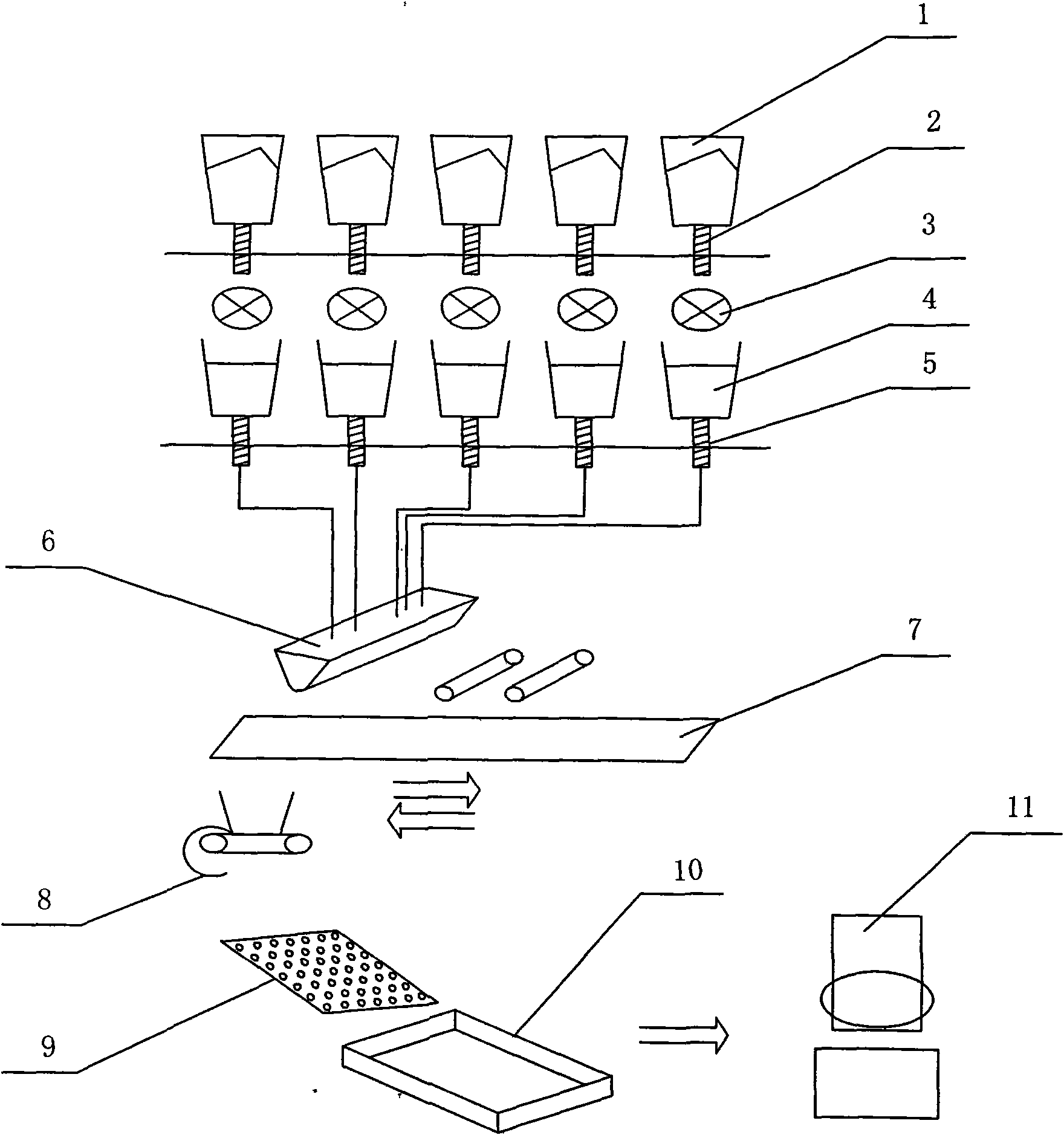

[0046] The material distribution device (partial) of the waterfall three-time material impact blanking process is as follows: figure 1 shown.

[0047] exist figure 1 Among them, the waterfall-type three-time material impact blanking process is as follows: the computer control system of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com