Molten salt reactor thorium fuel cyclic utilization method

A molten salt reactor and thorium fuel technology, applied in the direction of reactor fuel elements, reactor fuel materials, reactors, etc., can solve the problem of thorium fuel utilization scheme relying on online processing, etc., to suppress neutron absorption, increase fission contribution and reduce super The effect of the production of uranium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

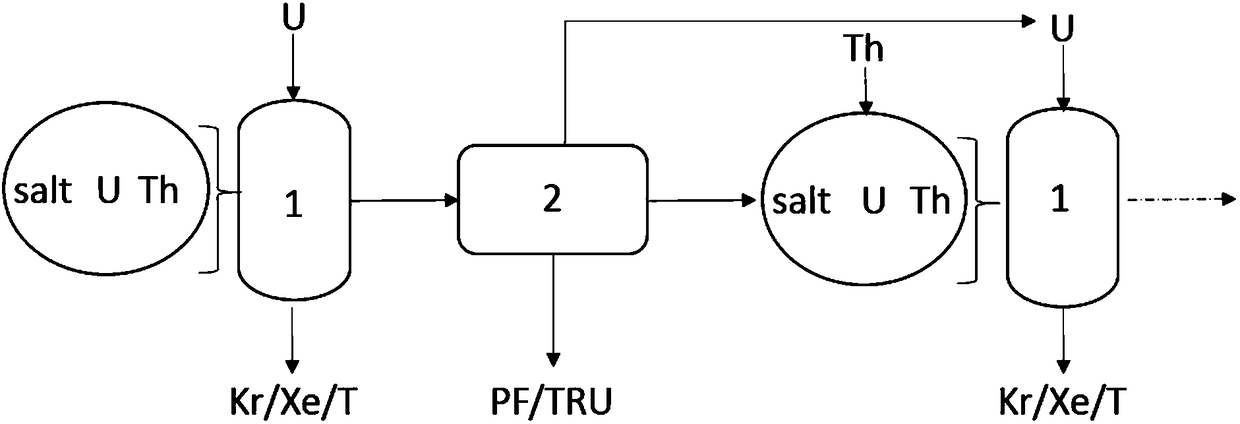

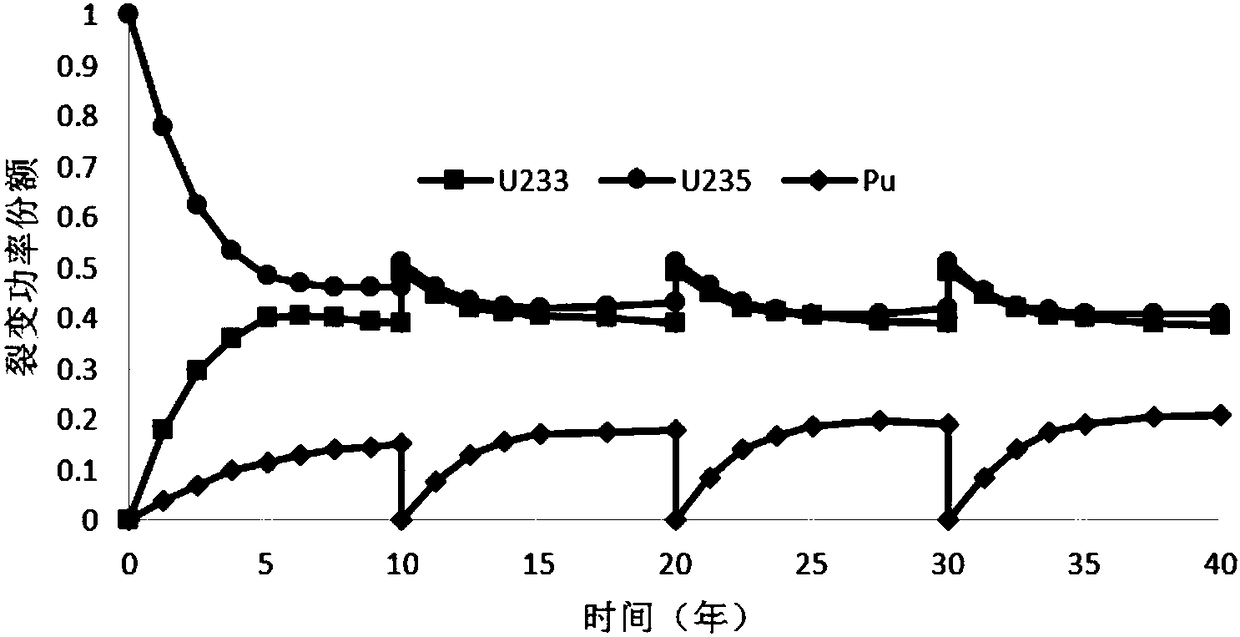

[0031] Such as figure 1 As shown, the fuel molten salt of molten salt reactor 1 is LiF-BeF 2 -UF 4 -ThF 4 , the initial molar ratio is 70.0:18.0:1.0:6.0, the abundance of Li-7 is 99.995%, and the enrichment degree of uranium is 20%. The core of the molten salt reactor 1 adopts a graphite moderator module with a structural outline of a hexagonal prism. The distance between the sides of the module is 19.5 cm. The core is a cylinder with a diameter close to the height. The diameter of the cylinder is 5 m. The ratio to the total volume of the core is 5%.

[0032] During the operation of molten salt reactor 1, UF is continuously replenished 4 Fuel was fed at an average rate of 33 mol U / day / GWe to compensate for burnup reactivity, while fission gases were continuously removed by helium bubbling.

[0033] After 10 years of operation, the core spent fuel is put into the decay tank, and after cooling for 5 years, it enters the reprocessing system 2 for off-line processing. The fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com