Reactor core structure, molten-salt pebble bed reactor and fuel management and reactor core loading method of molten-salt pebble bed reactor

A core structure and molten salt technology, applied in the direction of reactor fuel elements, fuel elements, reactors, etc., can solve the problems of complex purification of fuel balls, insufficient reliability of devices, and complex devices, so as to reduce the risk of reactor control and maintain the reactor Effect of core stability and fewer loading times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] (1) Core structure

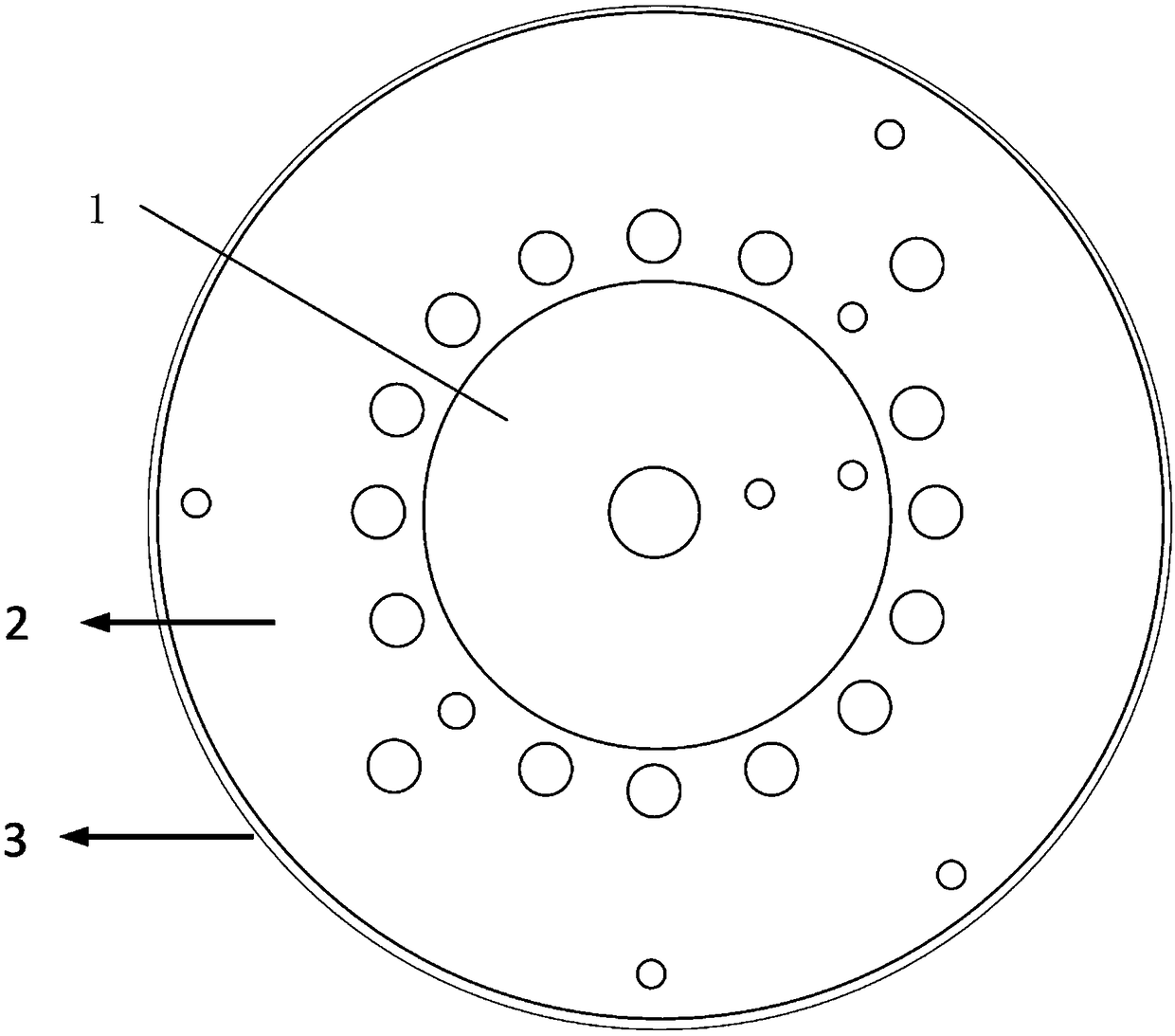

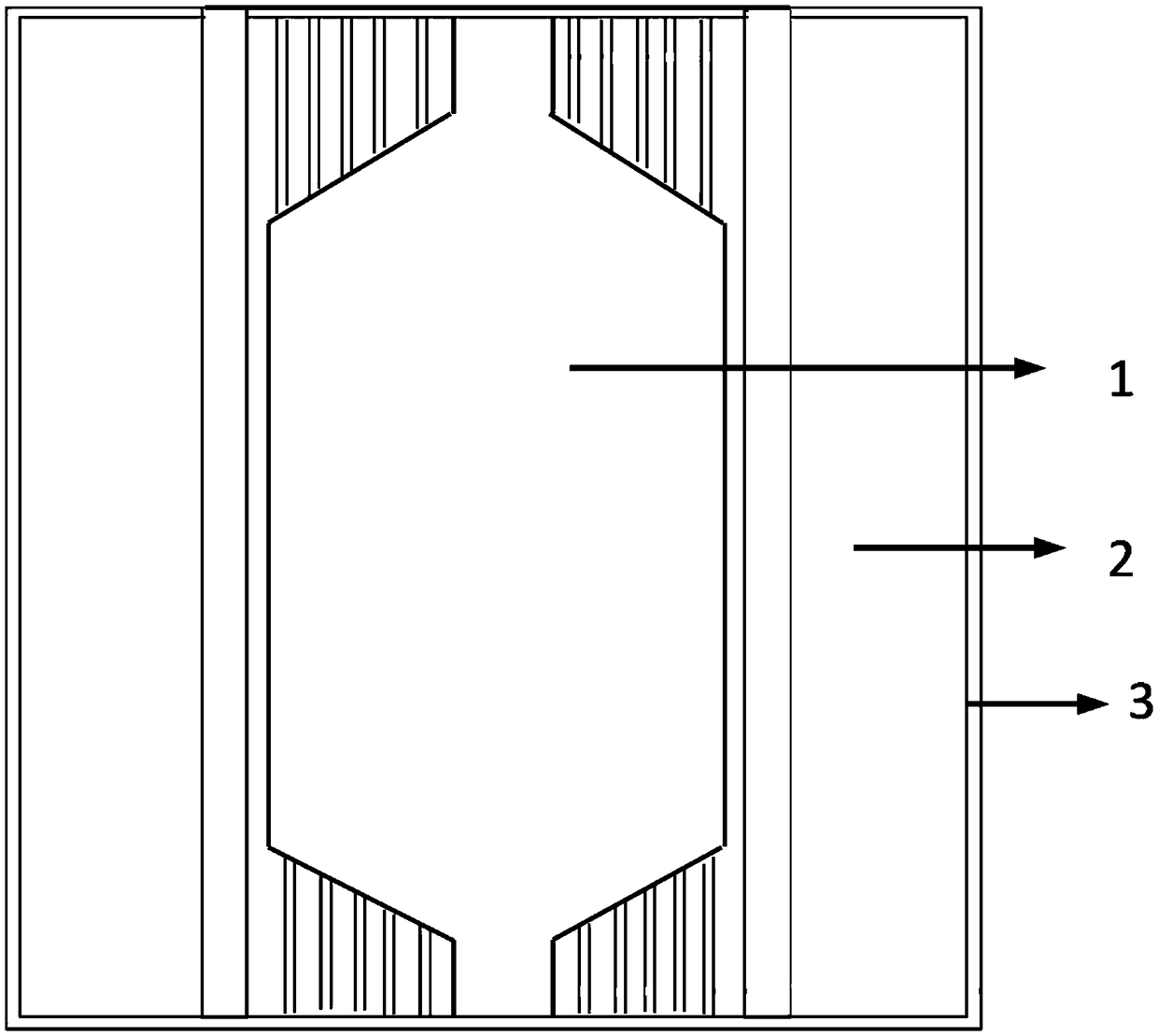

[0073] Such as figure 1 and figure 2 In the shown core structure, the active zone 1 of the core structure is provided with a feed inlet at the bottom and a discharge outlet at the top, the density of the fuel balls in the active zone 1 is less than the density of the molten salt in the active zone 1, and the activity Zone 1 is capable of accommodating fuel loads greater than the preset number of days of full power operation.

[0074] The above core structure also includes graphite balls with the same size and density as the fuel balls; the fuel balls, graphite balls and molten salt all enter the active zone 1 through the feed port. Fuel balls, graphite balls and molten salt are all discharged from the active area 1 through the discharge port.

[0075] In the above core structure, the molten salt in the molten salt pebble bed reactor is fluorine salt, and the fluorine salt is 2LiF-BeF 2 Molten salt, 2LiF-BeF 2 Molten salt made of LiF and BeF 2...

Embodiment 2

[0119] (1) The core structure is the same as in Embodiment 1

[0120] (2) molten salt pellet bed heap is the same as embodiment 1

[0121] (3) Fuel management and core loading method

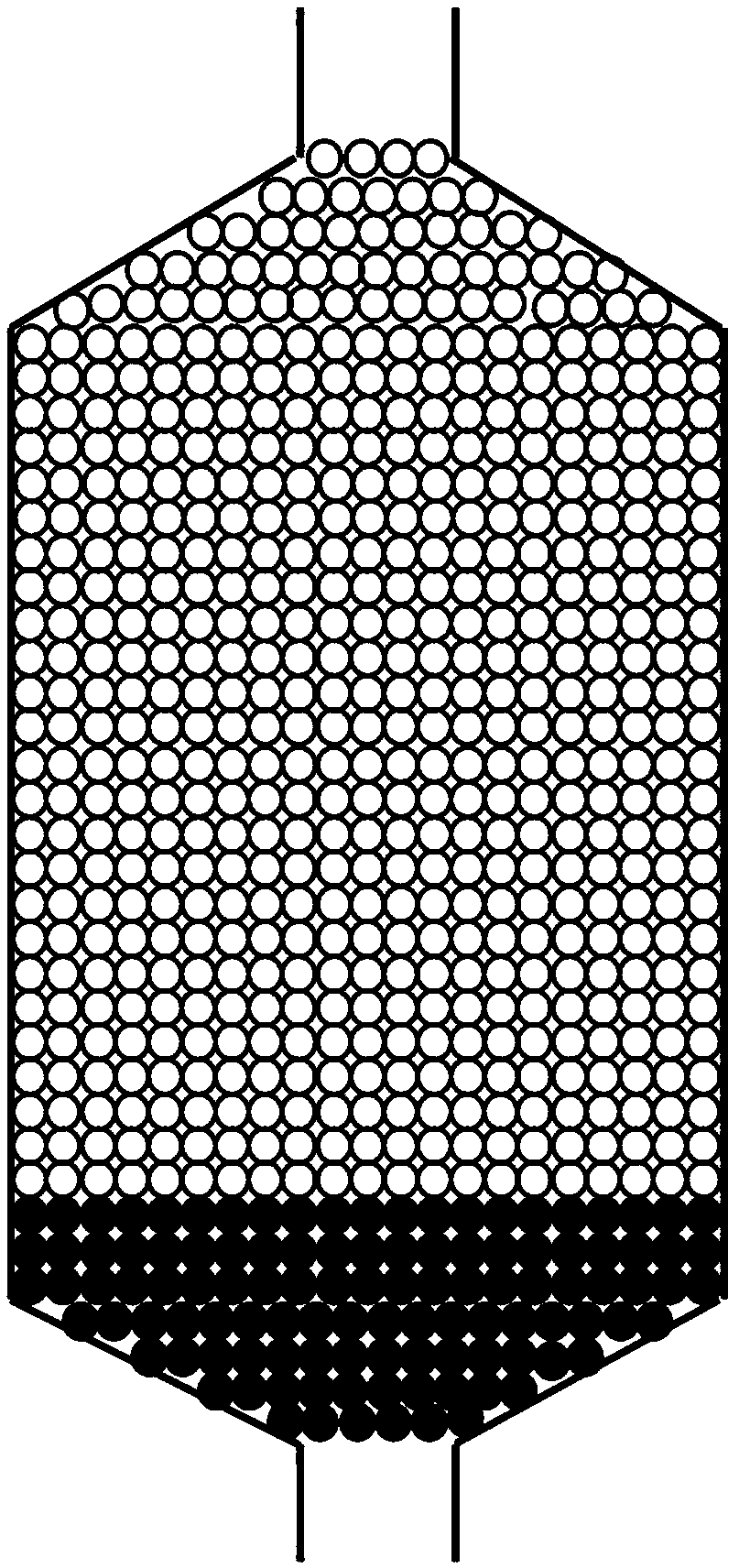

[0122] Such as image 3 Fuel management and core loading method of the molten salt pebble bed reactor shown, fuel management and core loading method in the above molten salt pebble bed reactor (such as figure 1 and figure 2 as shown);

[0123] The fuel management and core loading method includes the following steps:

[0124] S1: Loading fuel spheres into the active area 1; wherein, the loading amount of the fuel spheres is equal to the fuel loading amount equal to the preset number of days of full-power operation;

[0125] S2: According to the critical extrapolation experiment, check whether the core has reached the preset initial backup reactivity;

[0126] After detection, it is found that the preset initial backup reactivity has been reached, and then it is judged whether the active ar...

Embodiment 3

[0135] (1) Core structure

[0136] as 1 and figure 2 In the shown core structure, the active zone 1 of the core structure is provided with a feed inlet at the bottom and a discharge outlet at the top, the density of the fuel balls in the active zone 1 is less than the density of the molten salt in the active zone 1, and the activity Zone 1 is capable of accommodating fuel loads greater than the preset number of days of full power operation.

[0137] The above core structure also includes graphite balls with the same size and density as the fuel balls; the fuel balls, graphite balls and molten salt all enter the active zone 1 through the feed port. Fuel balls, graphite balls and molten salt are all discharged from the active area 1 through the discharge port.

[0138] In the above core structure, the molten salt in the molten salt pebble bed reactor is fluorine salt, and the fluorine salt is 2LiF-BeF 2 Molten salt, 2LiF-BeF 2 Molten salt made of LiF and BeF 2 Composition,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com