Light alloy semisolid slurry preparation technique and device

A technology of semi-solid slurry and preparation process, which is applied in the direction of manufacturing tools, metal processing equipment, casting equipment, etc., to achieve the effect of good universality and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

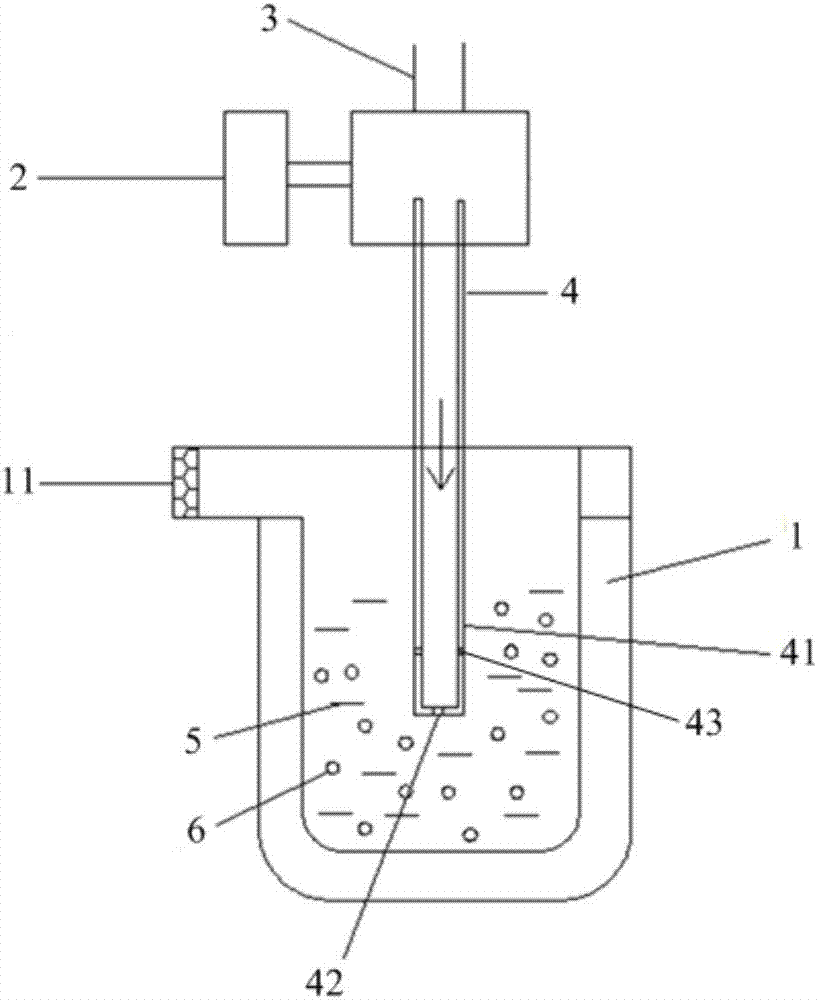

[0050] The invention provides a preparation process of light alloy semi-solid slurry. The stirring equipment is put into the slurry container, the liquid alloy is stirred, and the processing gas is passed into it. When the temperature of the alloy liquid drops to the solid-liquid temperature range, the The light alloy semi-solid slurry;

[0051] Wherein, the processing gas enters the alloy liquid through the ventilation hole on the stirring device under a predetermined pressure, the rotation speed of the stirring device is not lower than 800 revolutions per minute, and the diameter of the ventilation hole is not more than 2 mm, which can be used in pulping. Simultaneously refining the semi-solid slurry.

[0052] The preparation process of the semi-solid slurry can be used in continuous die-casting production, the container for holding the slurry can be a spoon of a die-casting machine, and the prepared die-casting product can be subjected to T6 heat treatment to improve mechan...

Embodiment 1

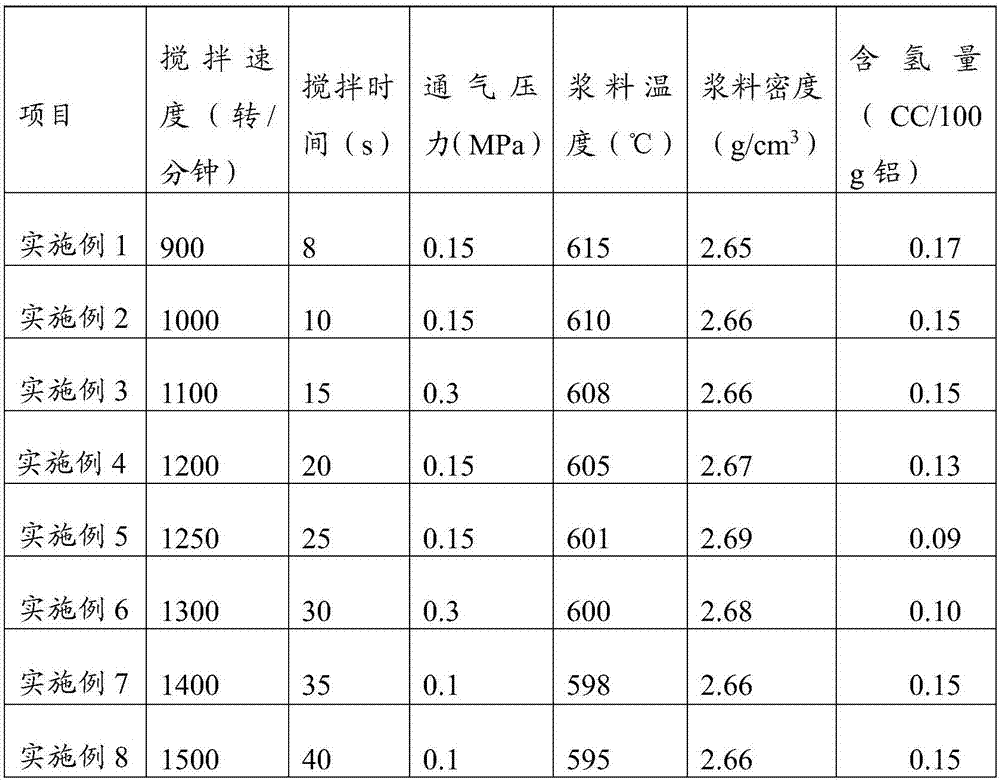

[0057] combine figure 1 , Example 1 Use a slurry making device for continuous die casting, use a slurry container to scoop 5kg of aluminum alloy liquid, put the stirring device into the slurry container, stir the aluminum alloy liquid at 670 ° C, and pass argon into it Air, control the rotation speed of the stirring rod to 900 rpm, the pressure of argon gas to 0.15 MPa, the flow rate to 13 L / min, and the aeration and stirring time to 8 s to prepare a semi-solid slurry at a temperature of 615 °C. Wherein, the diameter of the stirring rod is 30 mm, 5 ventilation holes are distributed on the bottom surface of the stirring rod, and 10 ventilation holes are distributed on the circumferential surface 8 mm from the bottom surface of the stirring rod, and the diameter of the ventilation holes is 0.8 mm.

Embodiment 2

[0059] combine figure 1 , Example 2 Use a slurry making device for continuous die casting, use a slurry container to scoop up 12kg of aluminum alloy liquid, put the stirring device into the slurry container, stir the aluminum alloy liquid at 670 ° C, and pass argon into it Air, control the rotation speed of the stirring rod to 1000 rpm, the pressure of argon gas to 0.15MPa, the flow rate to 13L / min, the aeration and stirring time to 10s, and a semi-solid slurry at a temperature of 610°C was obtained. Wherein, the diameter of the stirring rod is 53 mm, 4 ventilation holes are distributed on the bottom surface of the stirring rod, 8 ventilation holes are distributed on the circumferential surface 6 mm away from the bottom surface of the stirring rod, and the diameter of the ventilation holes is 1.2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com