Rolled steel side edge cleaning equipment for producing elevator guide rail bracket

A technology for elevator guide rails and cleaning equipment, which is applied to metal processing equipment, grinding/polishing equipment, devices for fixing grinding wheels, etc. Improve the effect of rust removal and polishing and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

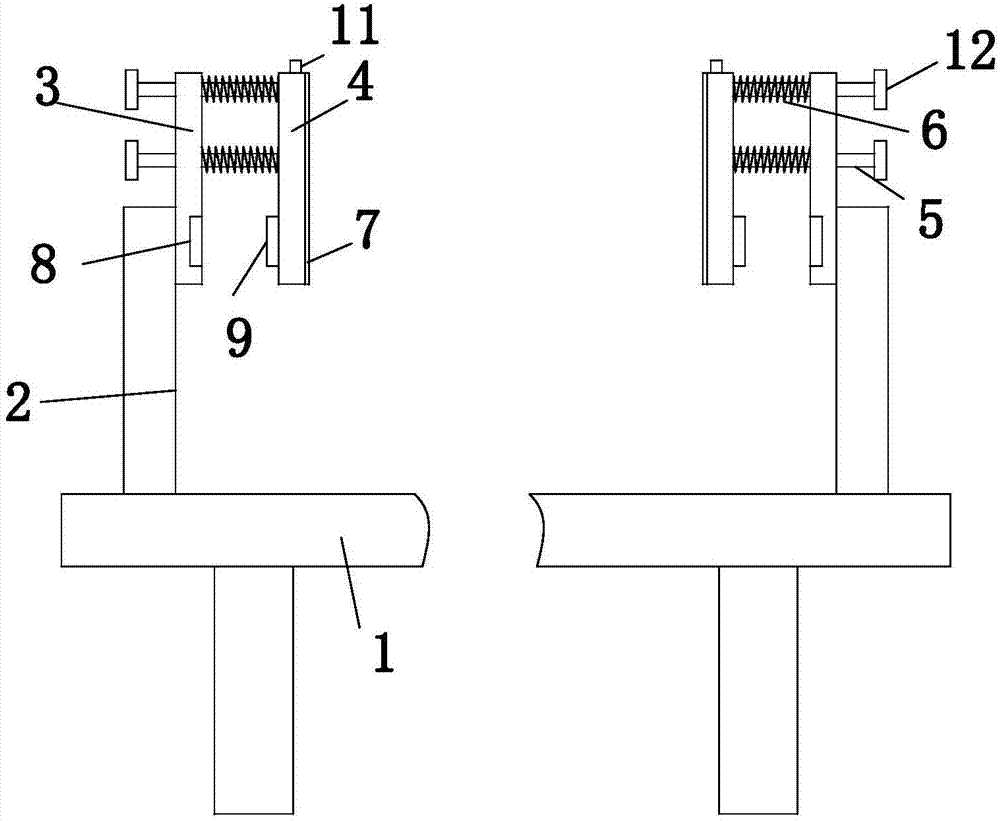

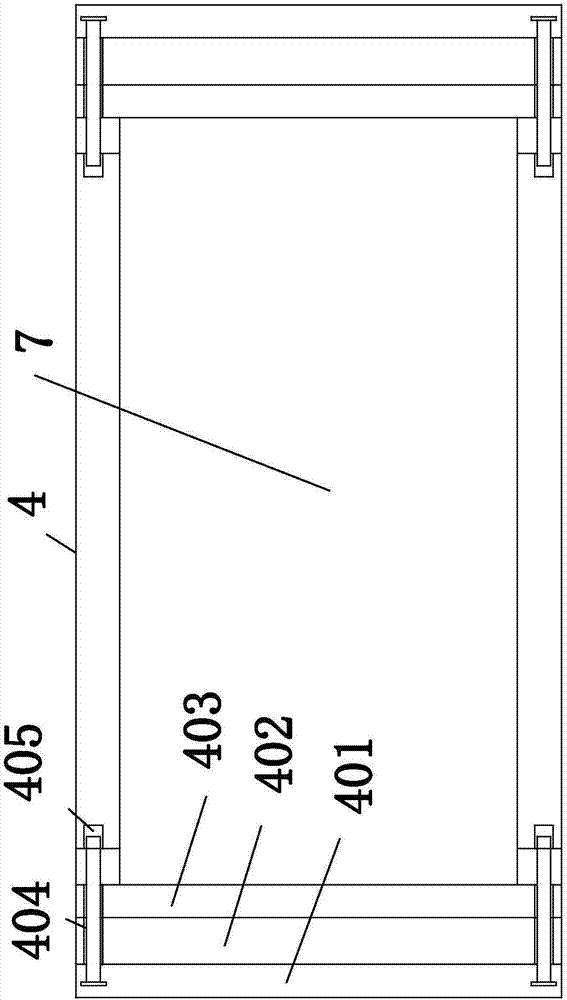

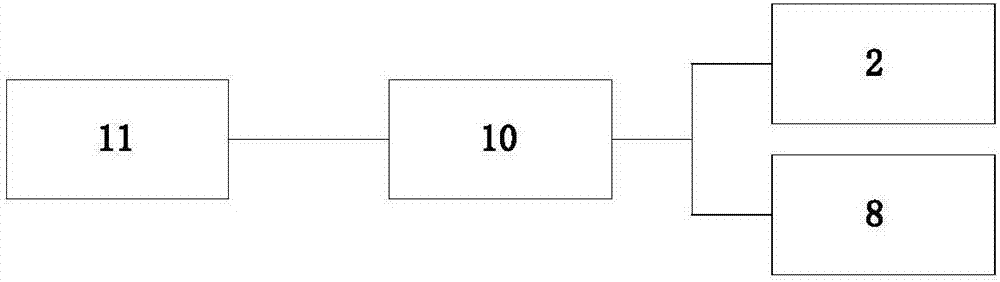

[0015] Example. A coiled steel side cleaning device for producing elevator guide rail brackets, which is composed of Figure 1 to Figure 3 As shown, including a frame 1, the front and rear sides of the frame 1 are provided with hydraulic elevating rods 2, and each hydraulic elevating rod 2 is provided with a grinding mechanism, and the described grinding mechanism includes a device arranged on the hydraulic elevating rod 2 There are a fixed plate 3 and a friction plate 4, a guide column 5 is provided between the friction plate 4 and the fixed plate 3, a compression spring 6 is set on the guide column 5, and sandpaper 7 is provided on the surface of the friction plate 4; the fixed plate 3 An electromagnet 8 is also provided on the friction plate 4, and an iron block 9 corresponding to the electromag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com