Horizontal type oil-gas separator for diesel engine

A technology for oil and gas separators and diesel engines, which is applied to machines/engines, mechanical equipment, engine components, etc. It can solve the problems of setting to the application number, only side air intake, and no down air intake, etc., to increase the filtering effect. , The effect of controlling pressure and improving intake efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

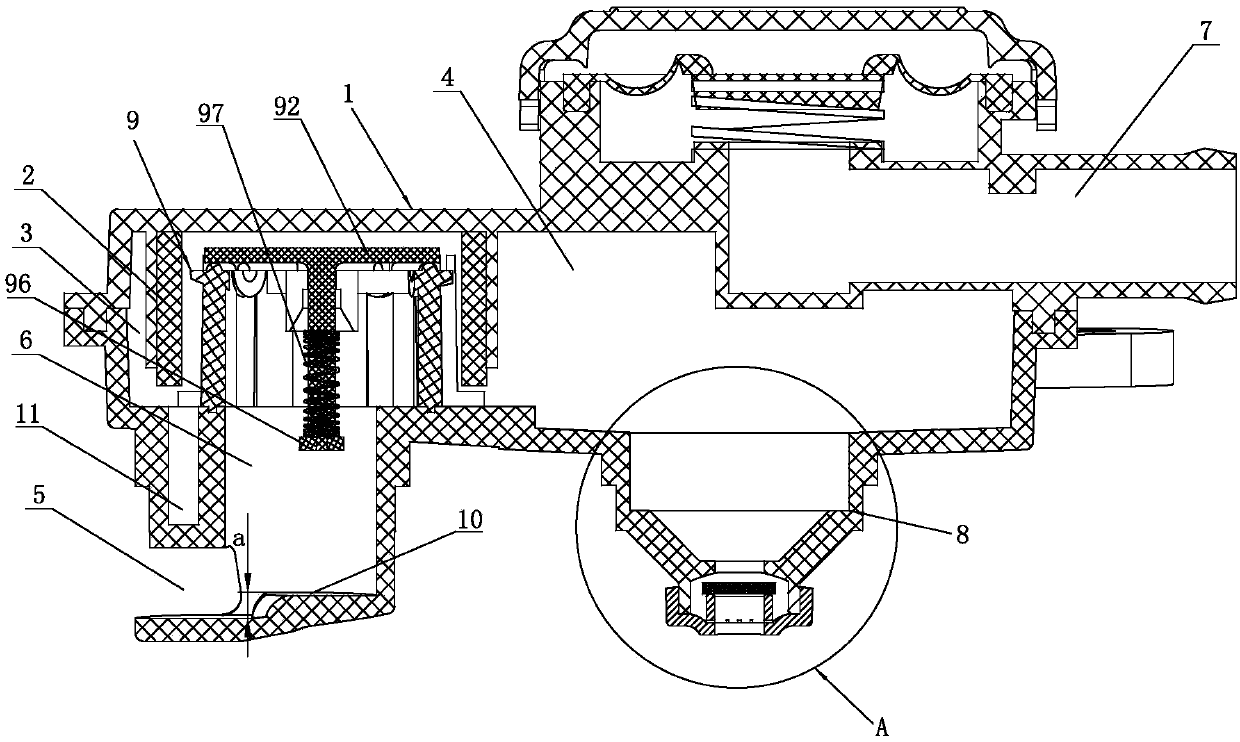

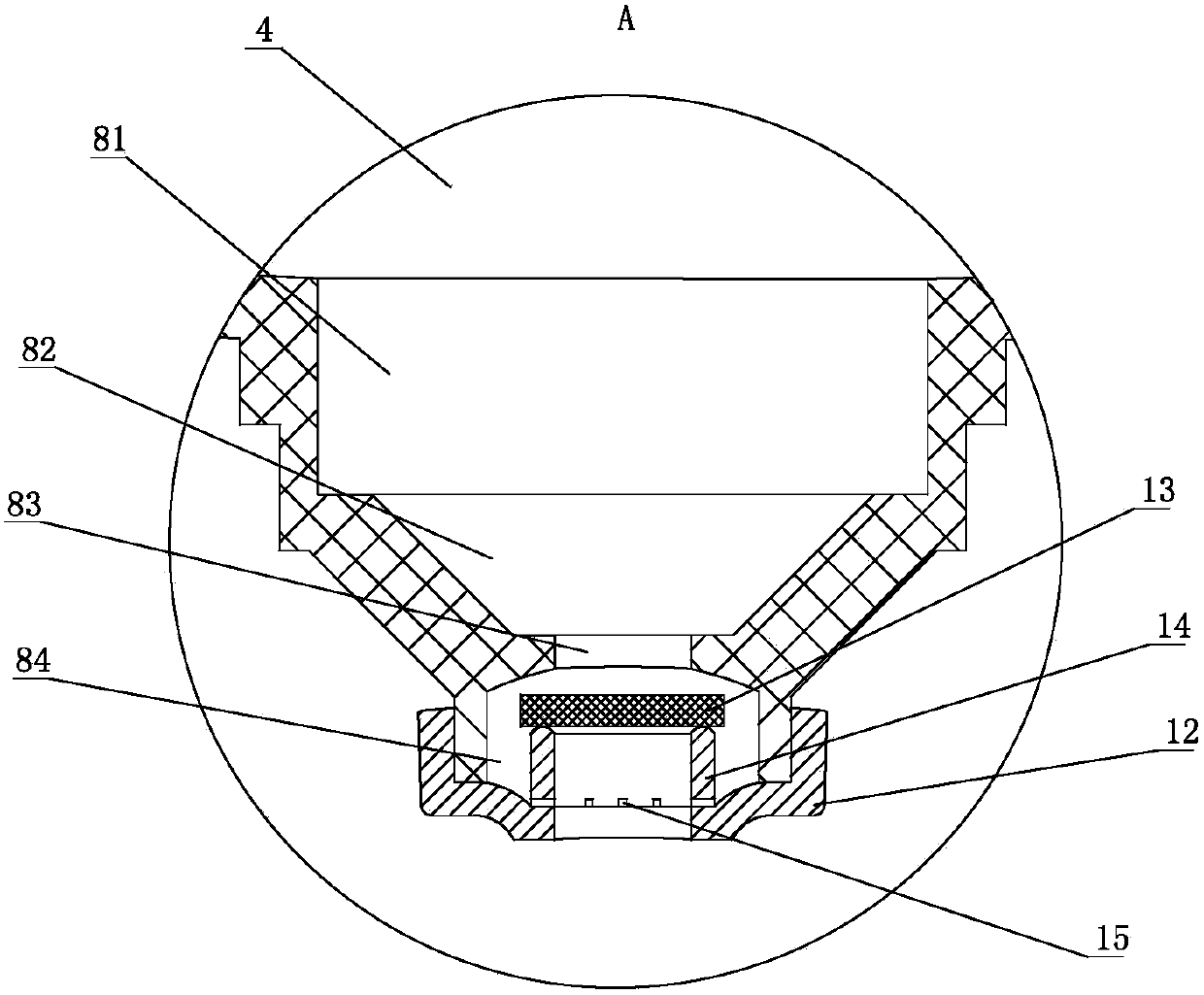

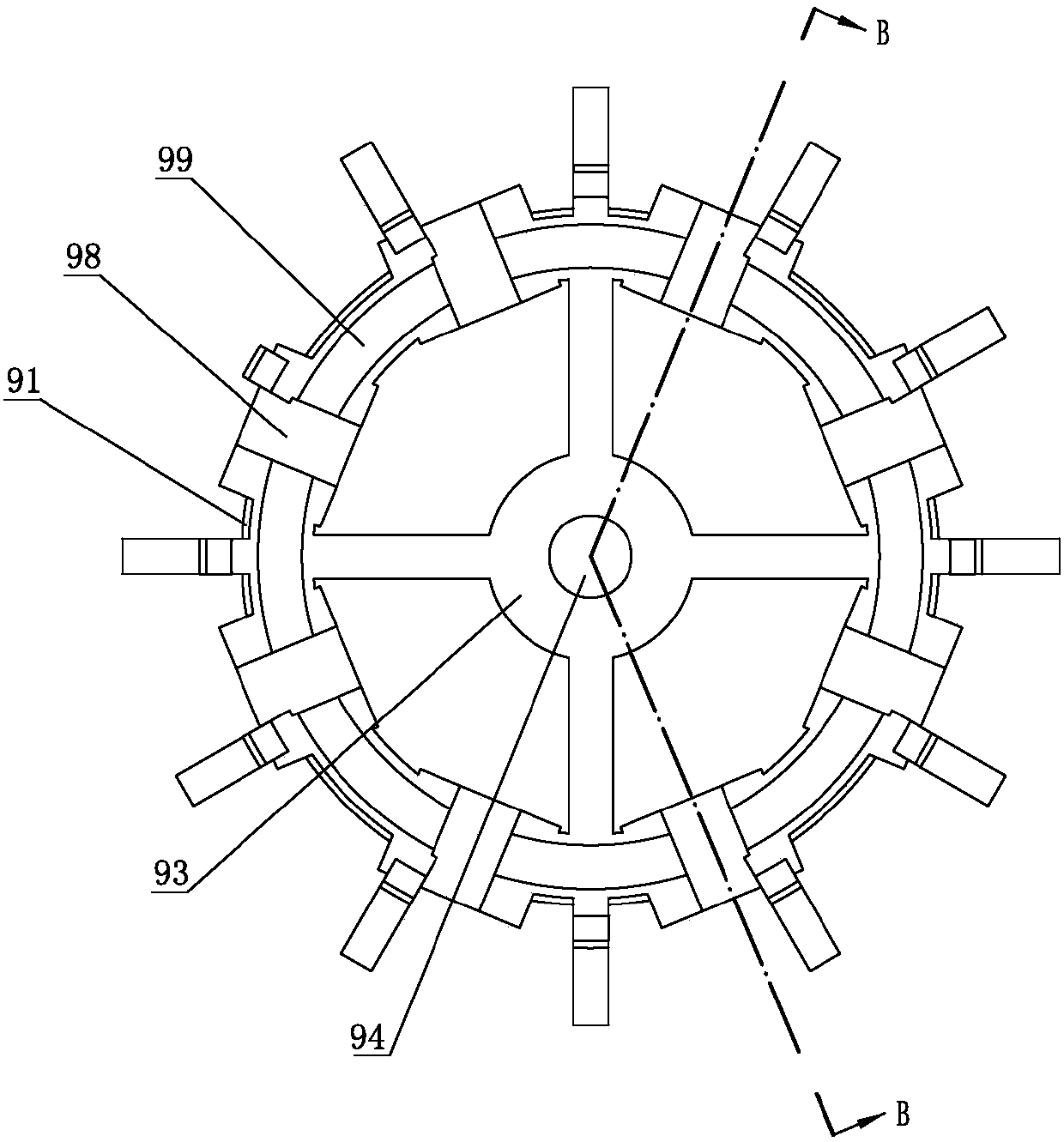

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the present invention provides a horizontal oil-gas separator for diesel engines, which includes a housing 1 and a filter element 2. The housing 1 is divided into upper and lower parts, which facilitates the injection molding of the housing 1 after being set up in this way. After the upper and lower parts are welded A housing 1 is formed, and the filter element 2 is an existing filter element; the housing 1 is provided with a filter chamber 3 and a buffer chamber 4, the volume of the buffer chamber 4 is 1.5 to 3 times the volume of the filter chamber 3, and the filter chamber 3 is located in the transverse direction of the buffer chamber 4 One side of the filter chamber 3 communicates with the buffer chamber 4; the bottom of the filter chamber 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com