Multi-purpose cooperative rotary cut radial self-rotation slit type inner concave multi-blade coreless drill bit

A self-rotating, multi-purpose technology, used in drill bits, drilling equipment, earth-moving drilling, etc., can solve problems such as large hole diameter changes, large powder discharge, chipping, etc., to ensure consistent hole size and protect drill bit steel. body, the effect of reducing the degree of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

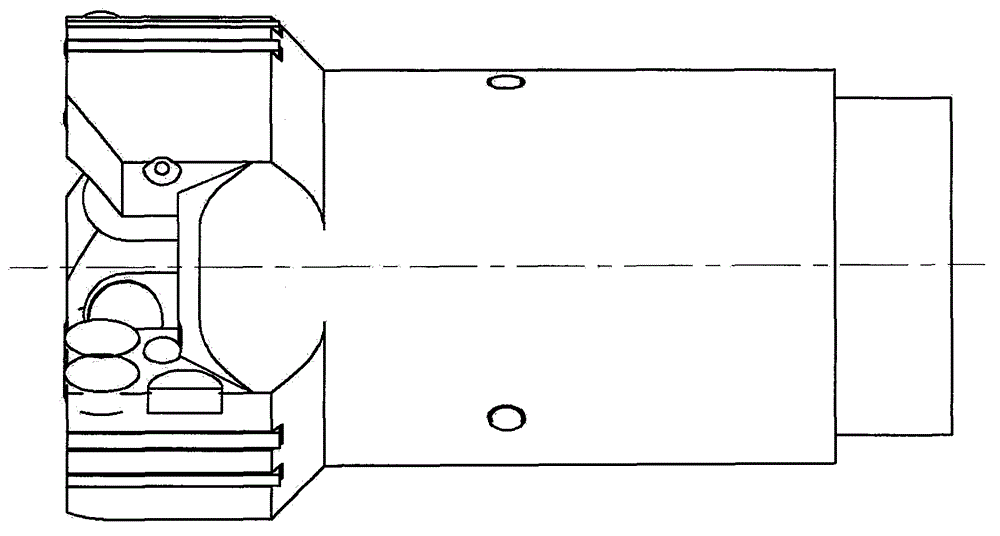

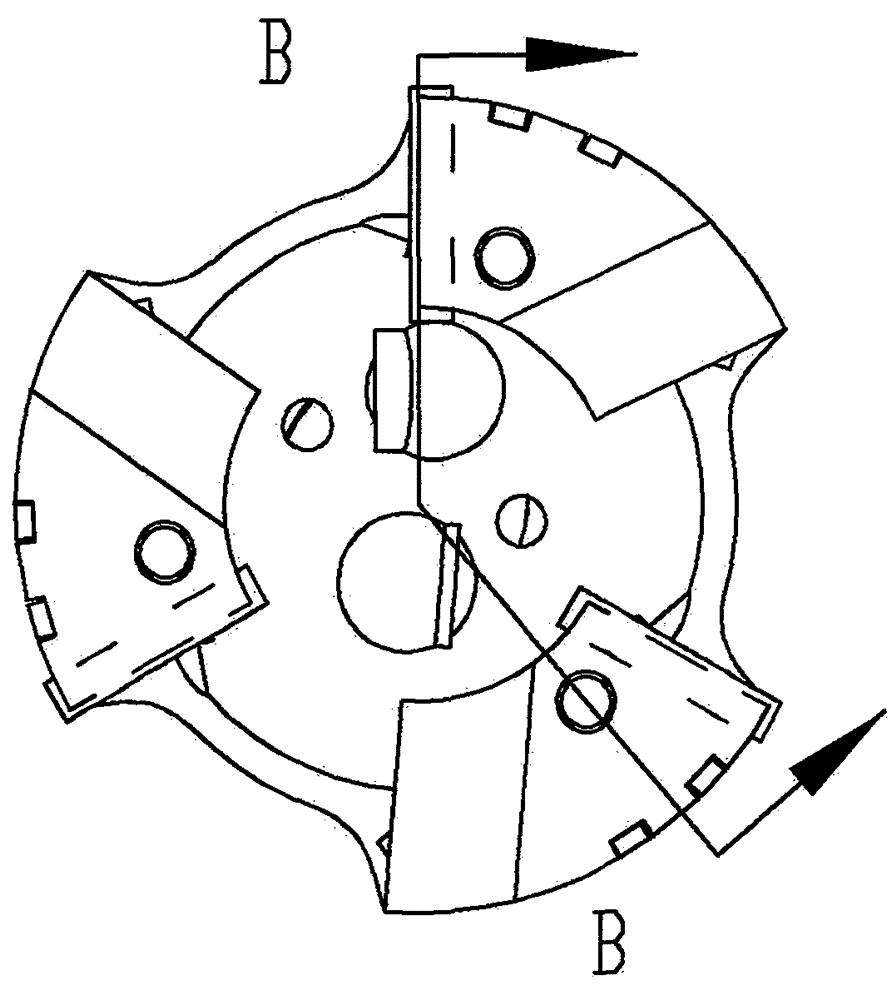

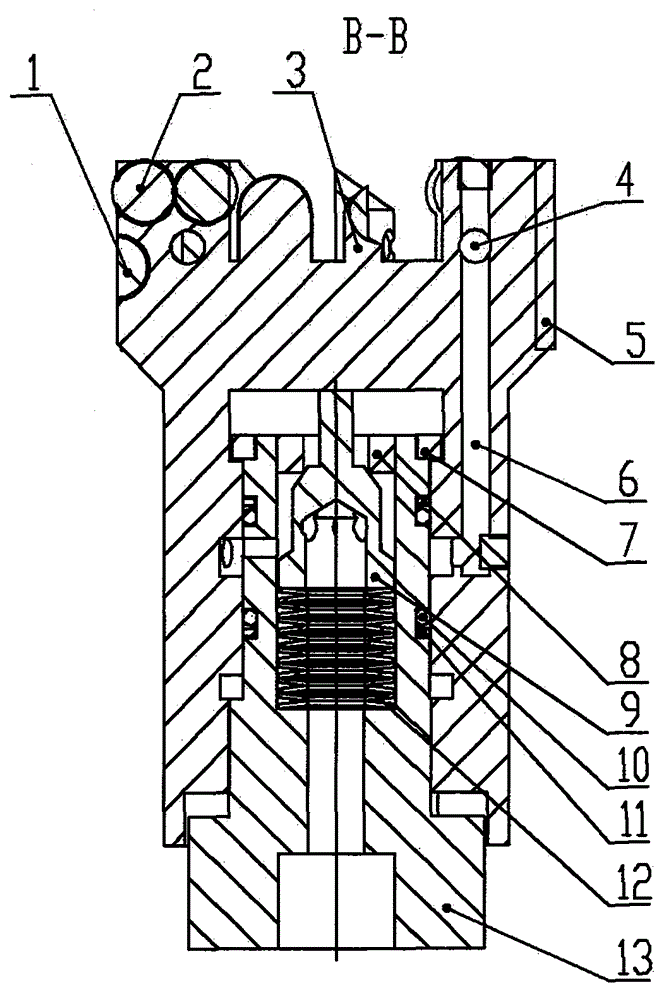

[0028] As shown in the figure: the multi-purpose combined rotary cutting radial self-rotation slotting type concave multi-wing coreless drill bit is transformed into a new PDC bit body 3 and joint body 13 split assembly structure, which is characterized in that: the new PDC bit 3 includes A special alloy crown is designed. On the basis of the original concave multi-wing coreless drill design, the original outer circumference is maintained. Six diamond composite sheets 2 are arranged in parallel on the three wing plates, and each wing plate has There are two pieces, and there are two pillars in the concave, each of which has a diamond composite sheet. This is a two-layer drilling structure in which the outer circumference of the composite sheet is rotary cut and the inner composite sheet is broken. Added that the second layer on each wing plate has a half diamond composite sheet 1, so that the total number is increased by one and a half pieces. Effectively alleviate the wear d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com