Patents

Literature

33results about How to "Excellent resistance to chloride ion penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-permeability liquid rubber spray coating

InactiveCN102329566AHigh bonding strengthImprove waterproof and anti-seepage performanceUnspecified rubber coatingsConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

The invention discloses a high-permeability liquid rubber spray coating, and relates to the technical field of spray coatings. The high-permeability liquid rubber spray coating comprises a component A and a component B, wherein the component A is anionic liquid rubber asphalt emulsion; the component B is a coagulant solution; the component A has the solid content of liquid rubber asphalt emulsion of 50-75 weight percent, and comprises the following components in percentage by mass: 1 to 35 percent of rubber emulsion, 10 to 50 percent of asphalt emulsion, 0.01 to 2 percent of anionic dispersing agent, 0.01 to 2 percent of anionic surfactant, 0.1 to 10 percent of fatty alcohol-polyoxyethylene ether, 0.1 to 10 percent of alkali resistant wetting agent OEP-70 and 0.1 to 10 percent of alkali resistant wetting agent AEP; and the component B is an aqueous solution at the concentration of 3-18 percent, which is prepared by mixing calcium chloride and composite aluminum-iron polymer in percentage by mass. The wetting agents are added into the spray coating, and the coating has high permeability and wider application range.

Owner:DALIAN MEICHENTE TECH

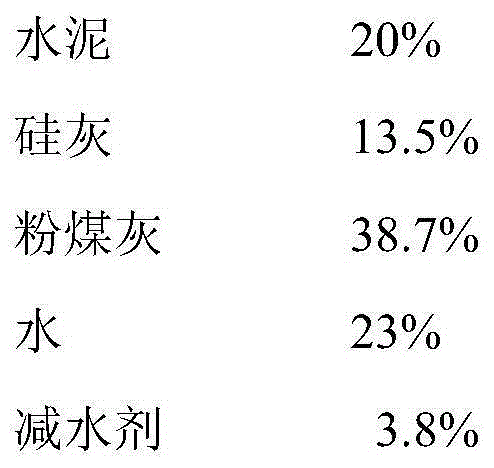

Ultrahigh-performance cement-based composite material

InactiveCN105198339AMeet the requirements of construction mobilityHigh strengthFreezing thawingHigh intensity

The invention relates to an ultrahigh-performance cement-based composite material. Particle gradation of a polynary gelling material and particle gradation of aggregates are optimized, and a water reducer and other additives are used, so the compressive strength under 28d standard curing reaches 170MPa or above on the premise that concrete has good fluidity. The material has the following technical advantages: construction fluidity requirements are met under a low water-binder ratio; under standard curing conditions, the strength of the concrete in 7d age reaches 120MPa or above, and the strength of the concrete in 28d age reaches 170MPa or above; compared with RPC which only can be used to produce prefabricated parts, the composite material can be stirred and constructed in any occasions without hot curing or pressure forming; the impermeability, the carbonization resistance, the chloride ion penetration resistance and the freeze thaw cycle resistance of the composite material are better than those of common concrete; and the composite material can be used to produce member products with the cross section being 50% (or more) than the common concrete member products.

Owner:浙江宏日泰耐克新材料科技有限公司

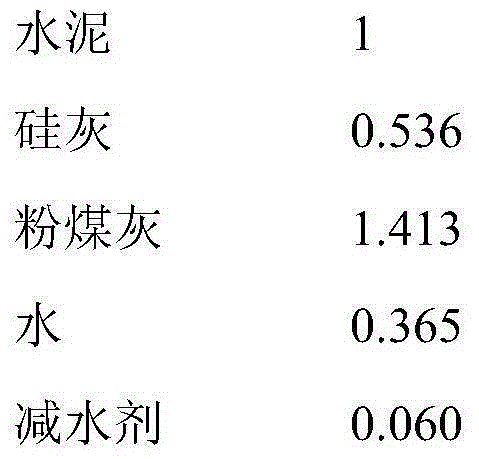

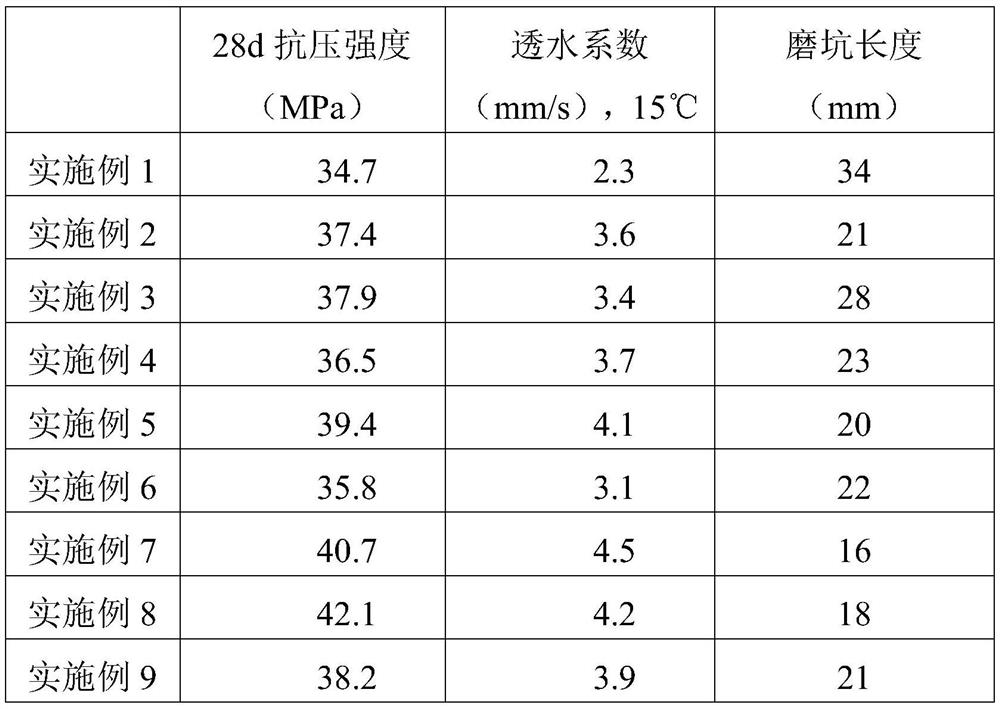

Ultra-high performance cement-based impact wear resistant material

The invention relates to an ultra-high performance cement-based impact wear resistant material. By optimizing the grain gradation of a multi-element cementing material and the grain gradation of an aggregate, and using a water reducing agent and other chemical admixtures, the material provided by the invention can be employed to perform surface coating on a newly constructed concrete structure or an impact wear damaged old concrete structure, and the impact wear resistance of a hydraulic structure can be improved by means of the high impact wear resistance of the material itself and the good adhesion of a concrete substrate. The material has the technical advantages that: the impact wear resistance is significantly superior to that of ordinary concrete; the weatherability and durability are significantly superior to those of an organic impact wear resistant coating material; by optimizing the grain gradation of the cementing material and the grain gradation of the aggregate, the material can meet the construction liquidity requirements under a low water-binder ratio; under standard curing conditions, the material can reach high strength of more than 150MPa after 28 days; and the anti-permeability, carbonization resistance, chloride ion penetration resistance, freezing-thawing cycle resistance and other properties are superior to those of ordinary concrete.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

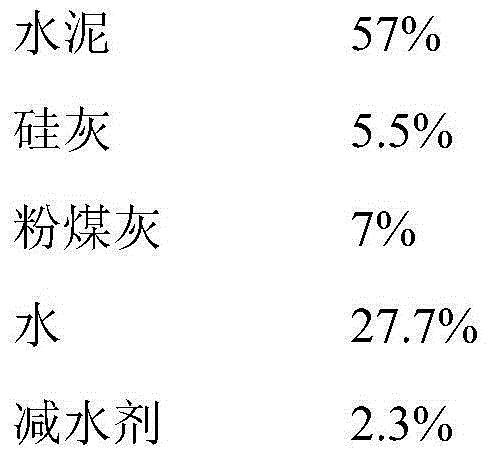

Ultra-high performance cement base composite material

InactiveCN103922662AMeet the requirements of construction mobilityHigh strengthChemical admixtureCarbonization

The present invention relates to a light weight and high strength cement base composite material. According to the present invention, particle size distribution of a multi-component cementing material and particle size distribution of an aggregate are optimized, and a reducing agent, a thickener and other chemical admixtures are used to make the material can concurrently achieve bulk density of significantly lower than bulk density of the ordinary concrete and a compressive strength of more than 20 MPa; the technical advantages of the material comprise that: in the case of the bulk density of less than or equal to 1650 kg / m<3>, the 28 d standard maintenance compressive strength of more than or equal to 20 MPa is achieved, and the construction fluidity requirements can be met in the case of the low water-binder ratio by optimizing the particle size distribution of the cementing material and the particle size distribution of the aggregate; and the hardened material has characteristics of compact surface, excellent impermeability, excellent carbonization resistance, chloride ion erosion resistance, and other durable performances.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

High-durability damping concrete and preparation method thereof

The invention discloses a high-durability damping concrete and a preparation method thereof, and relates to several concretes and a preparation method thereof. The invention solves the problems of low damping capability and poor durability of the conventional concrete structure material per se. The high-durability damping concrete is prepared by stirring and mixing cements, rubber powder, water, medium sand, stones, and adding fibers and silicon powder. In the invention, c the loss factors of the high-durability damping concrete are improved by about 80-200 percent compared with that of pain concrete under the condition of different frequencies. After maintenance for 28 days, the concrete prepared by using the method has chloridion-resistant permeability and carbonizing-resistant capability both superior to that of blank concretes.

Owner:刘铁军

Ultrahigh-performance cement-based abrasion-resistant material

The invention relates to an ultrahigh-performance cement-based abrasion-resistant material, which has the features that the material can be used for performing surface coating on a newly built concrete structure or an old concrete structure damaged due to erosion and abrasion by means of optimizing the grain composition of multi-component cementing materials and the grain composition of aggregates and utilizing the chemical admixtures, such as a water reducing agent and the like, and the scour and wear resistance of a hydraulic structure is improved through the high scour and wear resistance of the material itself and the excellent bonding of concrete base materials. The technical advantages of the material include that scour and wear resistance of the material is significantly better than that of ordinary concrete; weather resistance and durability of the material are significantly better than those of organic scour and wear-resistant coating materials; a low water-binder ratio is obtained by means of optimizing the grain composition of the cementing materials and the grain composition of the aggregates, so that the requirements on construction mobility are satisfied; under the condition of standard maintenance, the material reaches the high strength of above 150 MPa during the concrete age of 28 days; the impervious performance, carbonation resistance, chloride-ion penetration resistance as well as freezing-thawing cycle resistance and the like of the material are better than those of the ordinary concrete.

Owner:浙江宏日泰耐克新材料科技有限公司

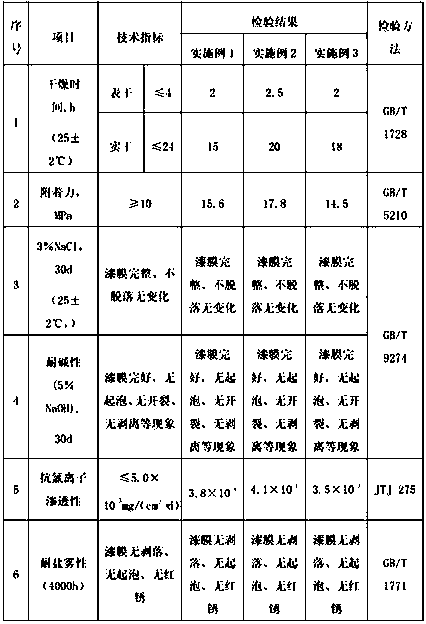

Underwater-curing long-acting anticorrosive coating for marine steel structures, and preparation method thereof

ActiveCN107603423ACuring shrinkage is smallGood film-forming performance and adhesionAnti-corrosive paintsEpoxy resin coatingsSolventCorrosion

The invention discloses an underwater-curing long-acting anticorrosive coating for marine steel structures, and a preparation method thereof. The coating comprises a component A and a component B according to a weight ratio of 1.5:1 to 3:1; the component A comprises, by weight, 20-50 parts of phenolic modified epoxy resin, 3-8 parts of an active diluent, 25-55 parts of a filler, 0.2-1 part of a thixotropic agent, 0.3-1 part of a wetting dispersant, 0.3-0.8 part of an antifoaming agent and 0.3-1 part of a coupling agent; and the component B comprises, by weight, 20-70 parts of a curing agent Iand 30-80 parts of a curing agent II. A paint film produced by using the coating can be fast cured in a wet and even water environment, contains no solvents, has no pollution to the environment, and has good application properties. The coating has the advantages of excellent water curing and underwater curing performances, excellent corrosion resistance, excellent chloride ion permeation resistance, excellent adhesion, and excellent impact resistance.

Owner:洛阳双瑞防腐工程技术有限公司

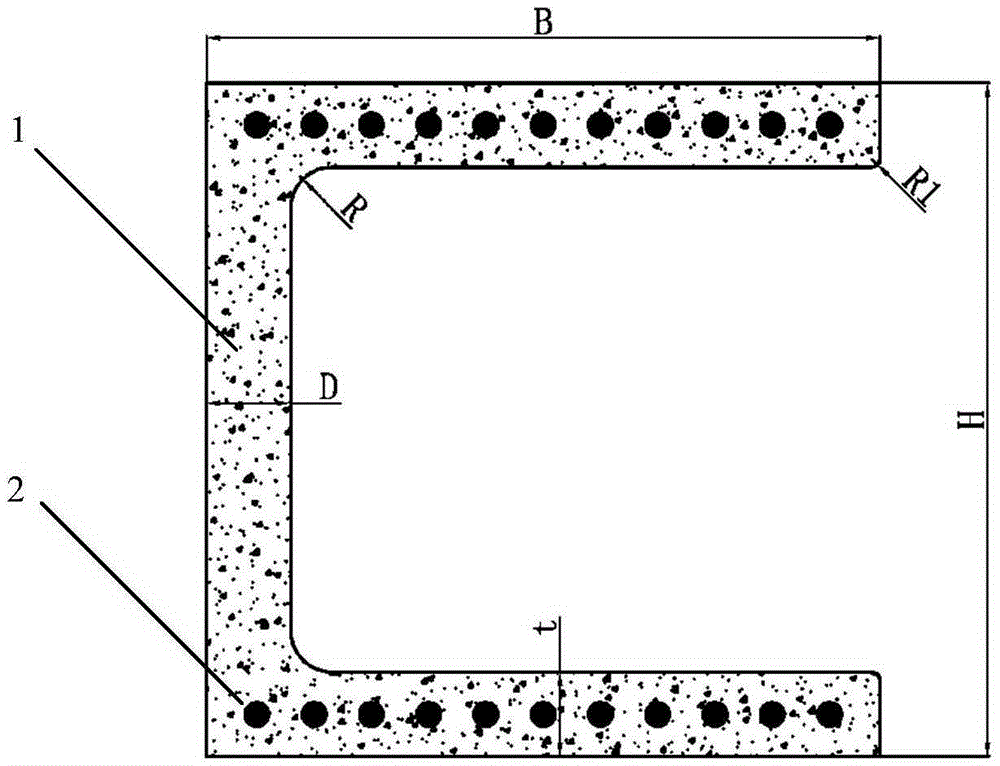

Ultrahigh-performance cement-based H-shaped profile

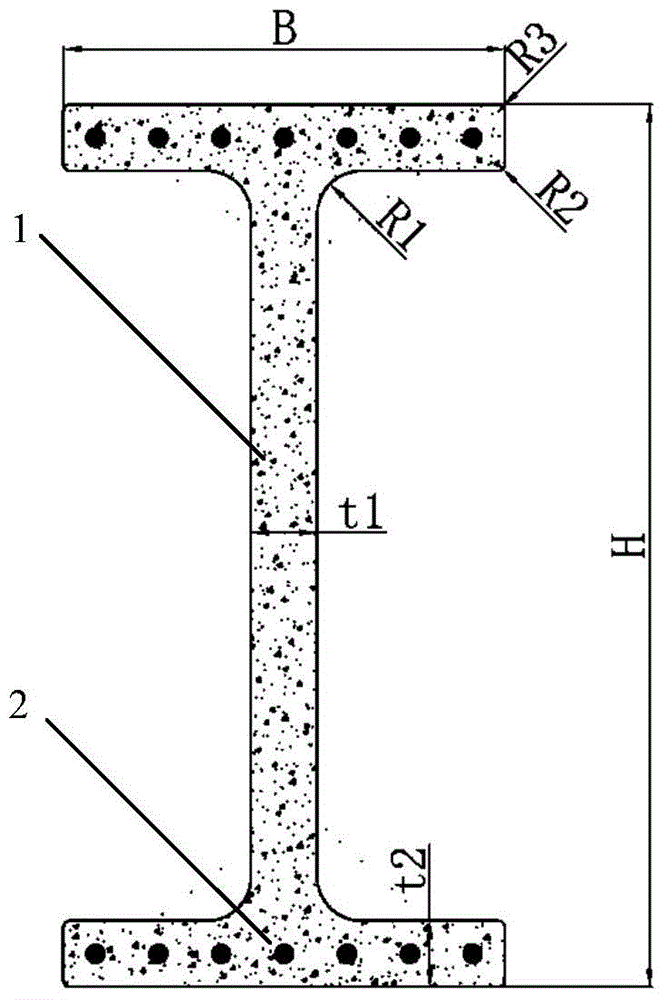

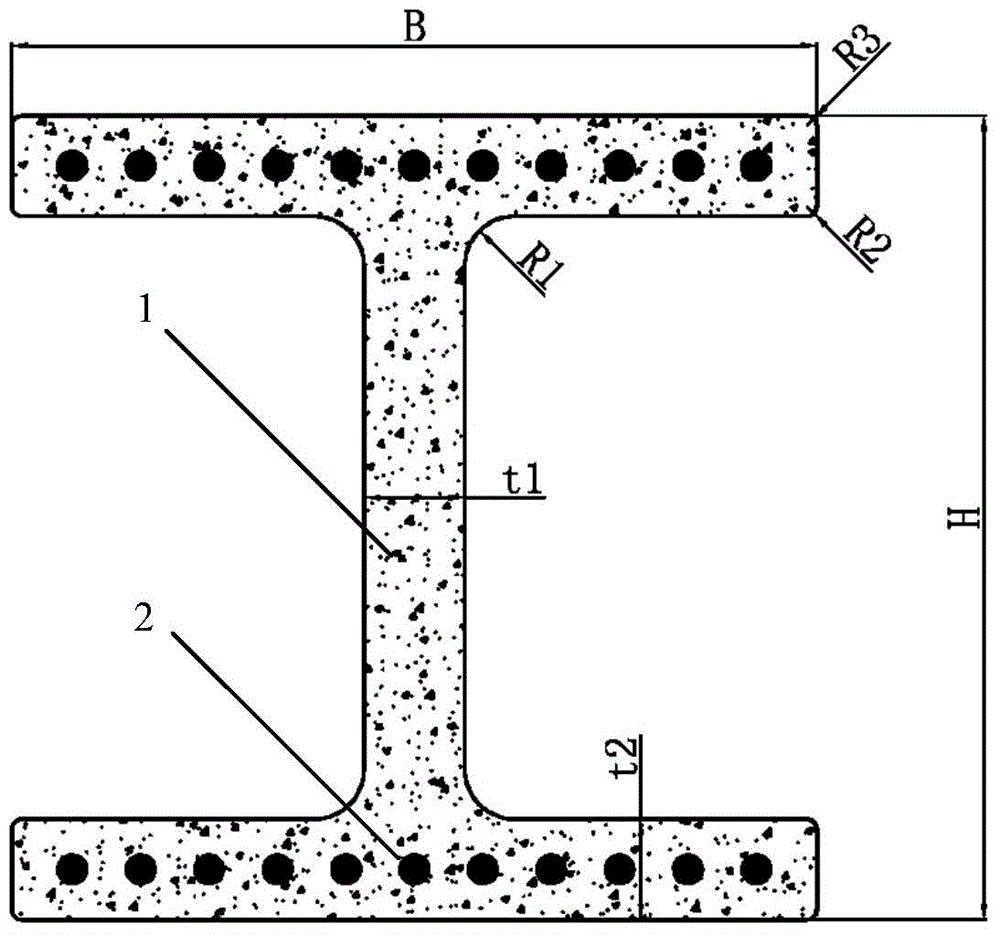

InactiveCN104018619AHigh corrosion resistance and fire resistanceMeet the requirements of construction mobilityStrutsGirdersCompressive strengthUltimate tensile strength

The invention relates to an ultrahigh-performance cement-based H-shaped profile poured by using an ultrahigh performance cement-based composite material. The cement-based H-shaped profile satisfies the requirement that H / B is equal to 0.8-3, t1 / B is equal to 0.03-0.2, t2 / H is equal to 0.03-0.2, R1 / B equal to 0.05-0.5, R2 / t2 is equal to 0.1-0.5 and R3 / R2 is smaller than or equal to 1. According to the ultrahigh-performance cement-based composite material, the grain composition of a multi-element cementing material and the grain composition of aggregates are optimized, and chemical additives are added, so that the compressive strength of concrete reaches over 170MPa under 28d of standard curing on the premise of good flowability. Through technologies such as fibers, and reinforcement, the cement-based profile obtains the material member performance similar to profile steel and is applied to structures of beams, columns, piles and the like of assembled buildings, and the buildings have light weight and construction speed similar to steel structures and have anticorrosive and fireproof performance higher than steel structure profiles.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

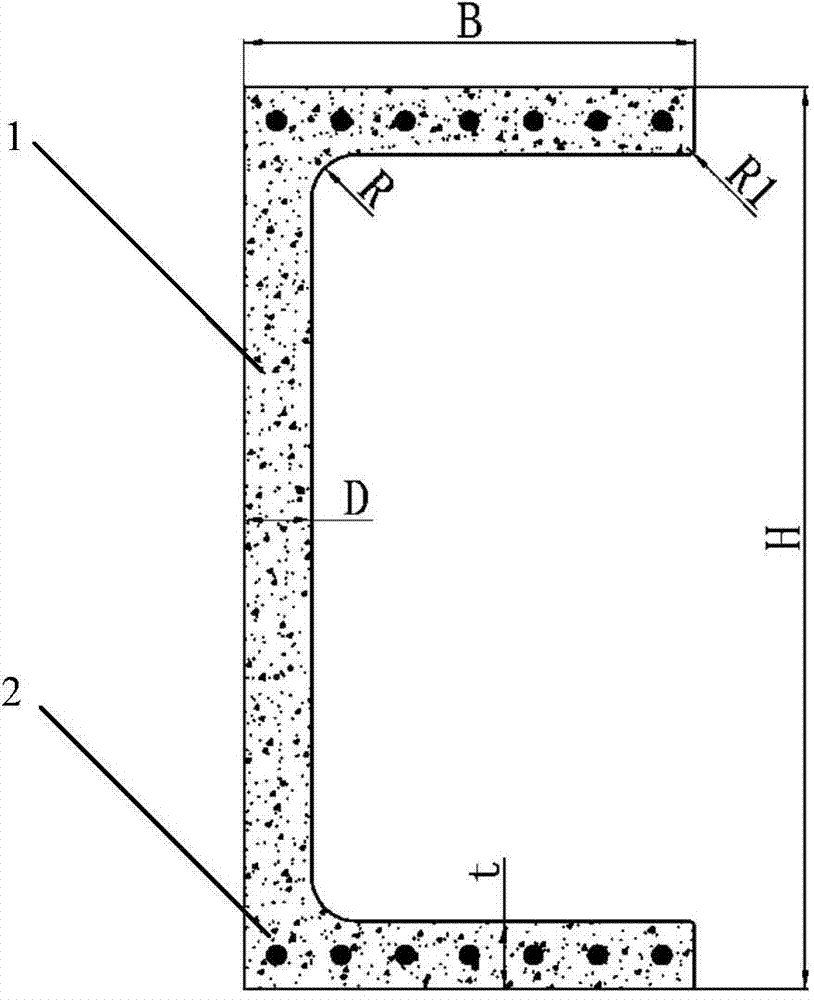

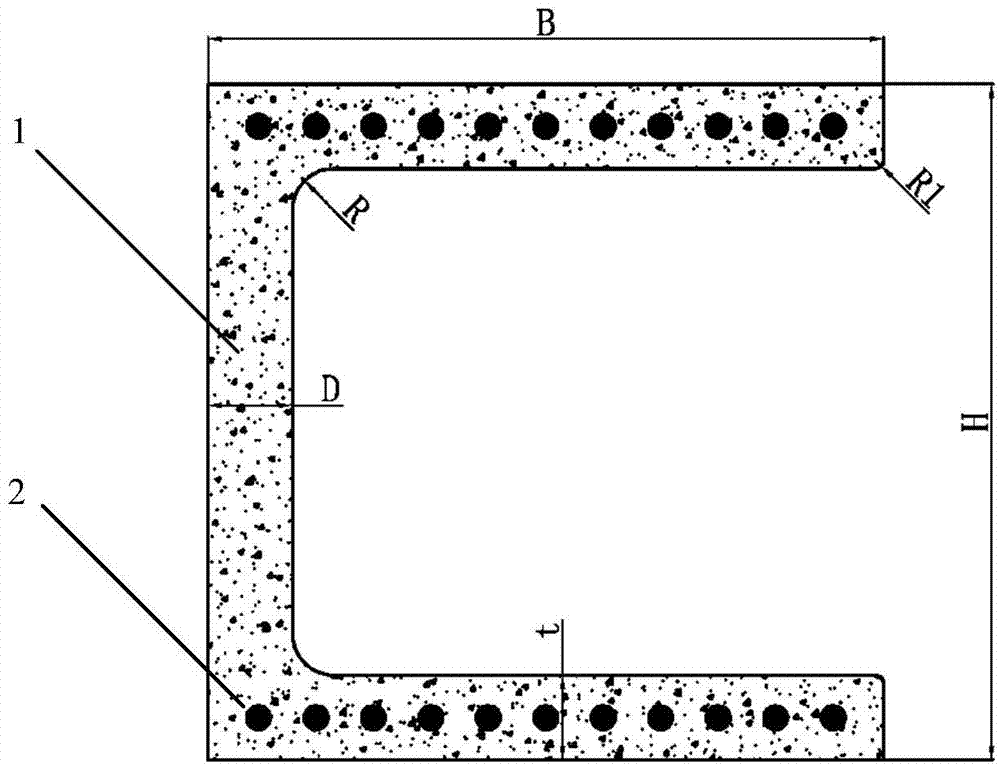

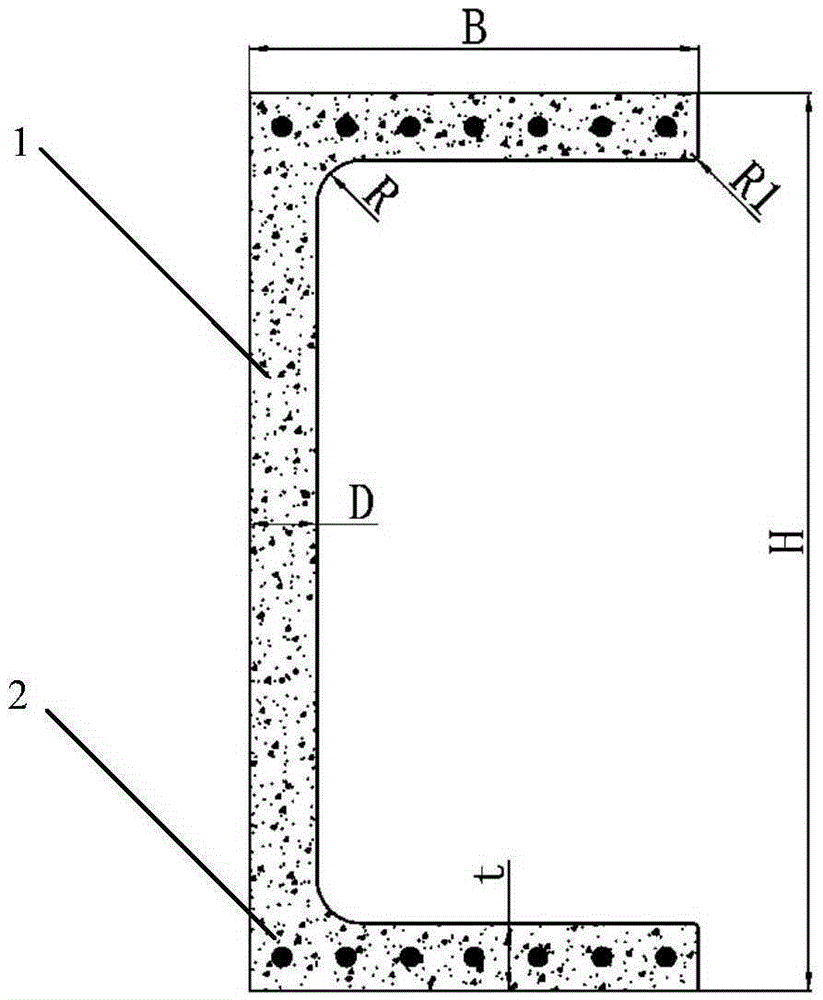

Ultra-high performance cement based groove type profile

InactiveCN103938794AHigh corrosion resistance and fire resistanceMeet the requirements of construction mobilityStrutsSolid waste managementFire resistanceConstruction aggregate

The invention relates to an ultra-high performance cement based groove type profile cast from an ultra-high performance cement based composite material. The cement based groove type profile meets the conditions of: H / B=0.8-3; D / B=0.1-0.5; t / H=0.05-0.5; R / B=0.05-0.5; and R1 / t=0.1-0.5. By optimizing the grain gradation of a multi-element cementing material and the grain gradation of an aggregate, and using a water reducing agent and other chemical additives, under the premise that concrete has good flowability, the ultra-high performance cement based composite material involved in the invention can reach compressive strength of over 170MPa under 28d standard curing. By means of fiber reinforced reinforcement and other technologies, the ultra-high performance cement based composite material enables the ultra-high performance cement based profile to acquire material component properties similar to those of section steel. By applying the profile provided by the invention to beams, columns, piles and other structures of prefabricated buildings, the buildings can have a construction speed similar to that of a steel structure, but can have higher corrosion resistance and fire resistance than steel structure profiles.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

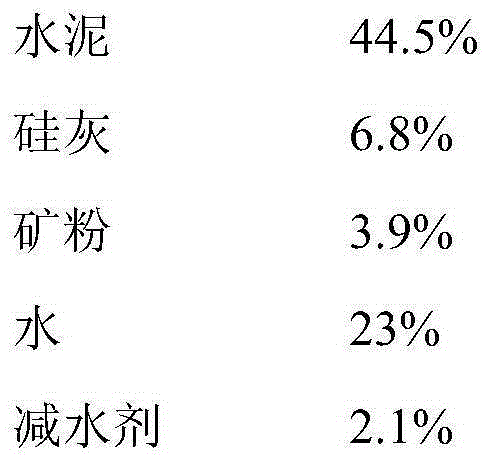

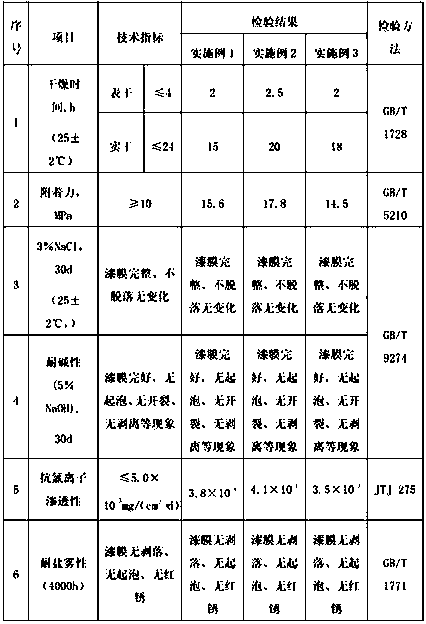

Polymer cement waterproof coating with high corrosion resistance and preparation method thereof

InactiveCN111087868AIncreased durabilityImprove corrosion resistanceConjugated diene hydrocarbon coatingsChloropene polymer coatingsIon permeabilityPolymer emulsion

The invention discloses a polymer cement waterproof coating with high corrosion resistance and a preparation method thereof. The high-corrosion-resistance polymer cement waterproof coating comprises the following raw materials: cement, quartz sand, a coupling agent, a defoaming agent, a water reducing agent, a dispersing agent, a pigment and a polymer emulsion. The polymer cement waterproof coating prepared by the invention is excellent in acid and alkali resistance, sulfate resistance and seawater corrosion resistance and high in bonding strength with a concrete base material, and still has high bonding strength after being corroded by acid, alkali and salt; the polymer cement waterproof coating prepared by the invention has excellent chloride ion permeability resistance, high density andlow water absorption rate; the polymer cement waterproof coating prepared by the invention can be constructed by using a blade coating, picture brushing or roll coating method, is easy to operate andpopularize, can be directly constructed on a humid basal plane, and is relatively low in cost.

Owner:WUHAN POLYTECHNIC UNIVERSITY

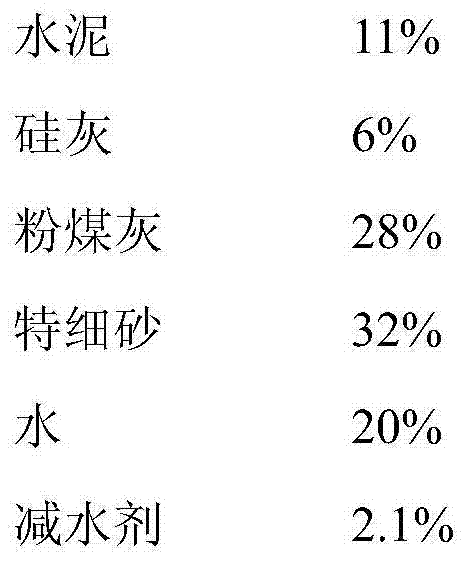

High-strength high-durability modified concrete structure repairing material

The invention discloses a high-strength high-durability modified concrete structure repairing material. The repairing material is prepared from, by mass, 10-11% of cement, 6-7% of sand, 21-38% of coarse aggregate, 16-20% of modifier, 5-7% of silica fume and 34-38% of water. By adding the modifier and silica fume, the strength and durability of concrete are improved. Compared with traditional concrete materials, the repairing material has the advantages that working performance is high, strength is high, interface bonding performance is high, price is low, durability is high, and the repairing material can be widely applied to repair work of water conservancy projects and various industrial and civil buildings.

Owner:夏学云

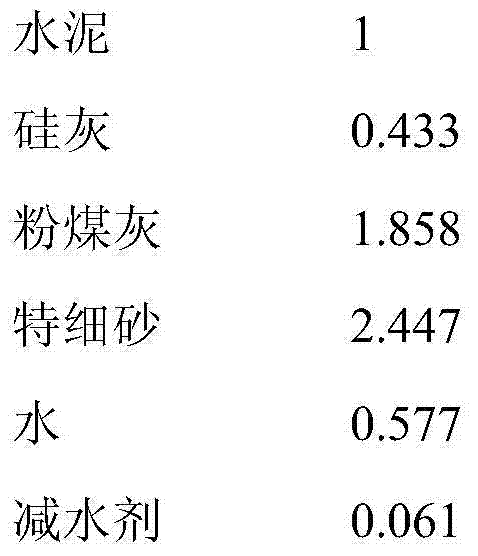

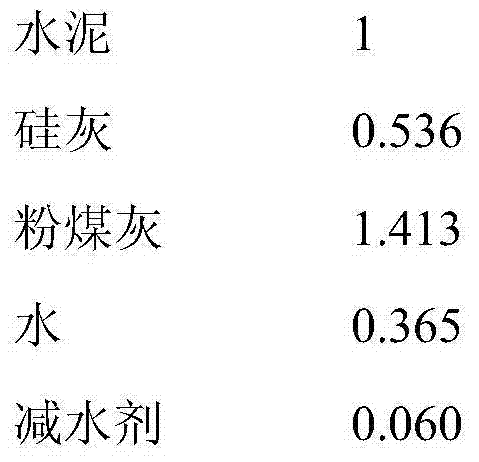

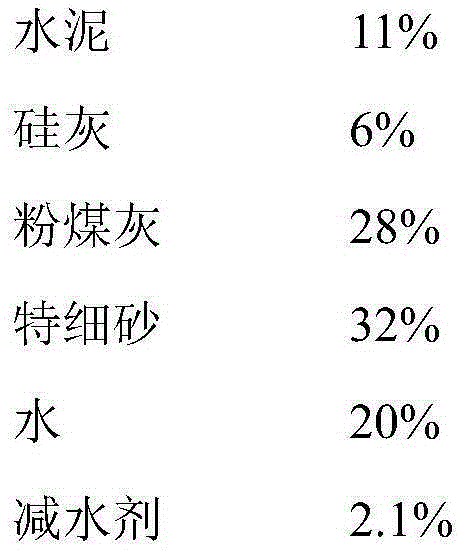

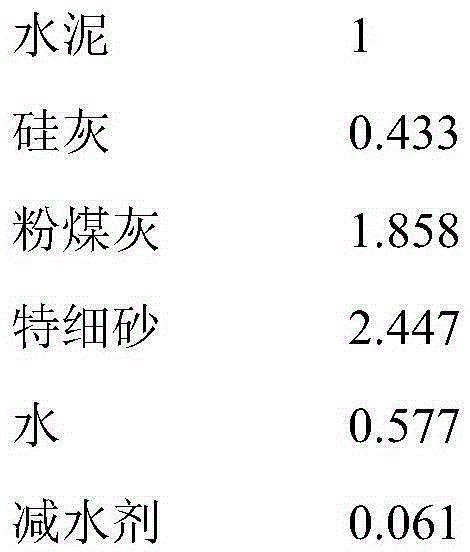

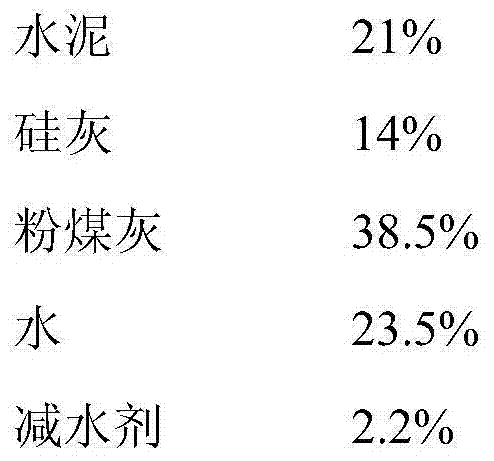

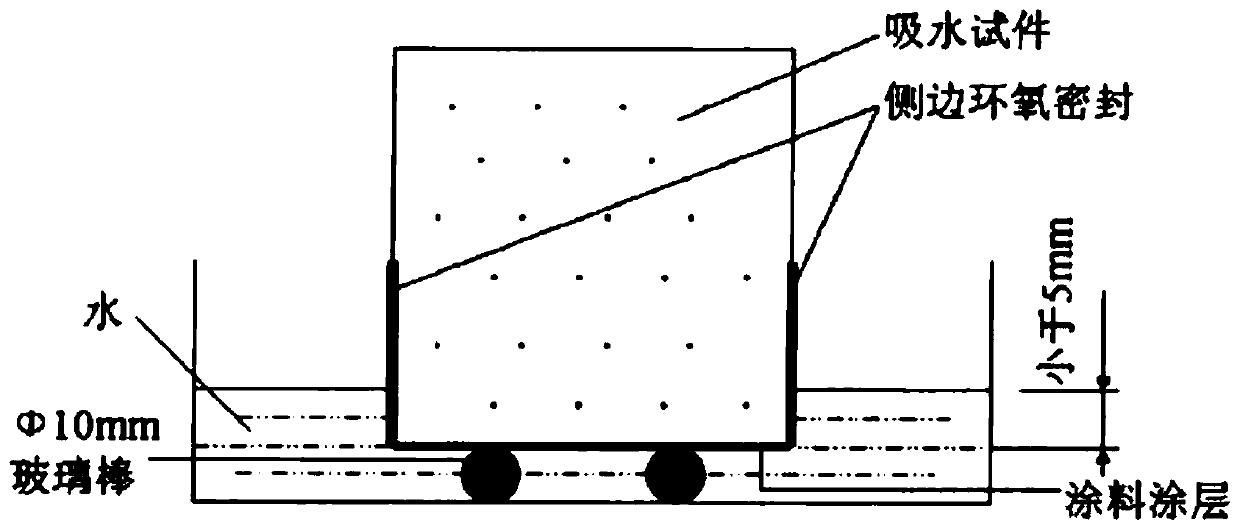

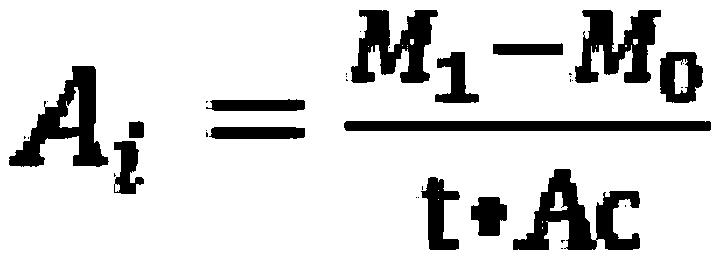

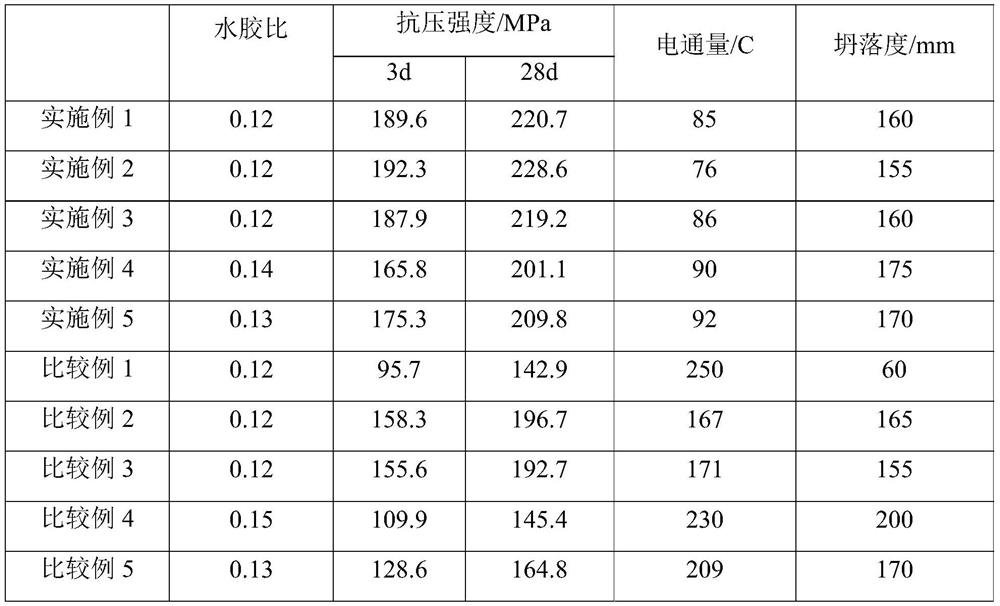

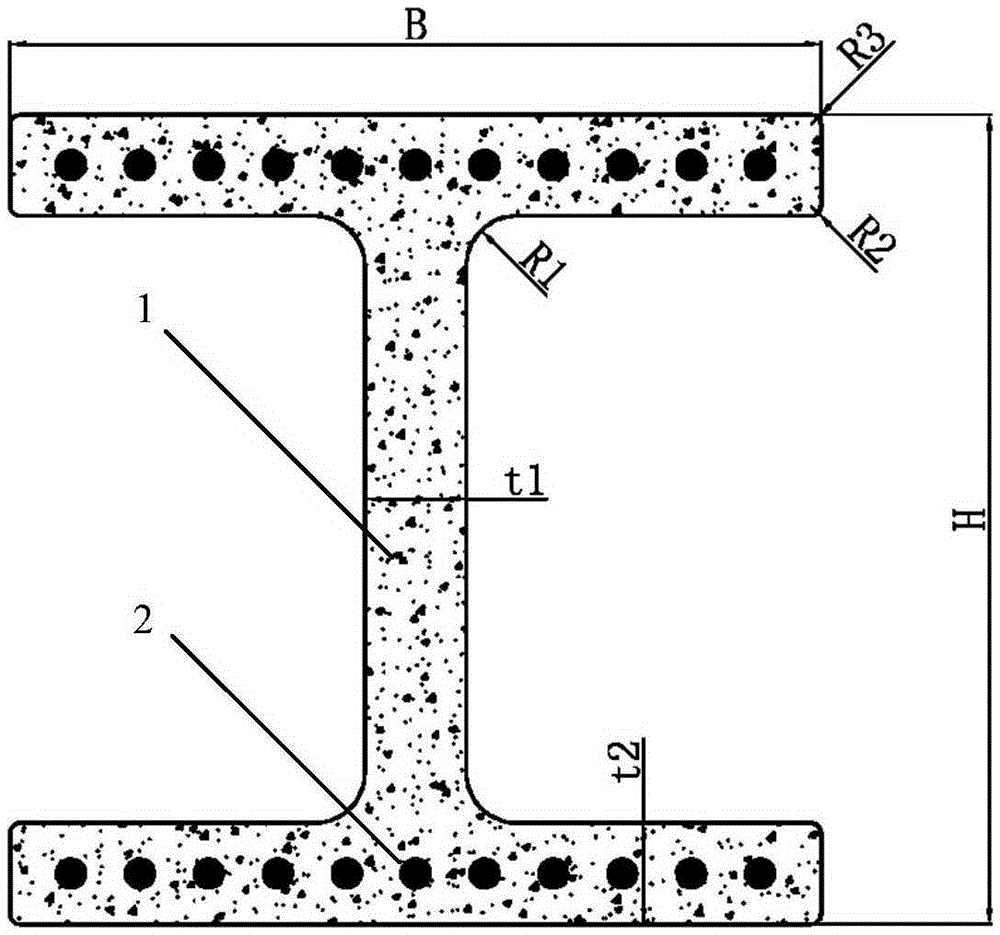

Ultra-high performance concrete with low water-binder ratio and preparation method thereof

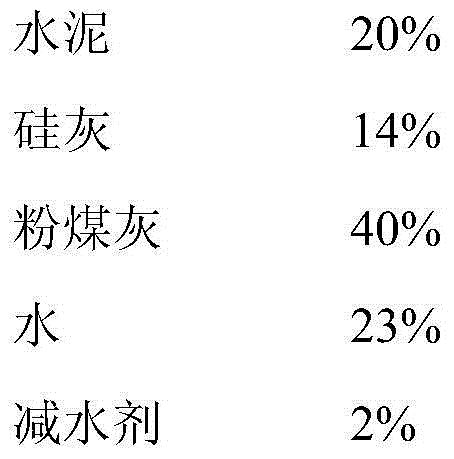

InactiveCN111925173AExcellent resistance to chloride ion penetrationHigh compressive strengthSuperplasticizerCarboxylic acid

The invention discloses ultra-high performance concrete with a low water-binder ratio and a preparation method thereof. The ultra-high performance concrete with the low water-binder ratio contains cement, silica fume, fly ash, mineral powder, sand, steel fibers, additives and water which are independently stored or stored in a mixed mode, wherein the weight ratio of the cement to the silica fume to the coal ash to the mineral powder to the sand to the steel fibers to the admixture to the water is 500: (20-200): (20-70): (200-400): (600-1300): (150-400): (15-45): (18-120); the additive containsa polycarboxylate superplasticizer, a defoaming agent and water in a weight ratio of 30: (0.05-0.12): (30-60); the polycarboxylate superplasticizer at least meets the following conditions that the water reducing rate is not lower than 30%, and the solid content is not lower than 40%. The ultra-high performance concrete with the low water-binder ratio has excellent mechanical properties, fluidity,chloride ion penetration resistance and an ultra-low water binder ratio, and meanwhile, the preparation method has the advantages of being simple and convenient to operate and simple in process.

Owner:安徽精公检测检验中心有限公司

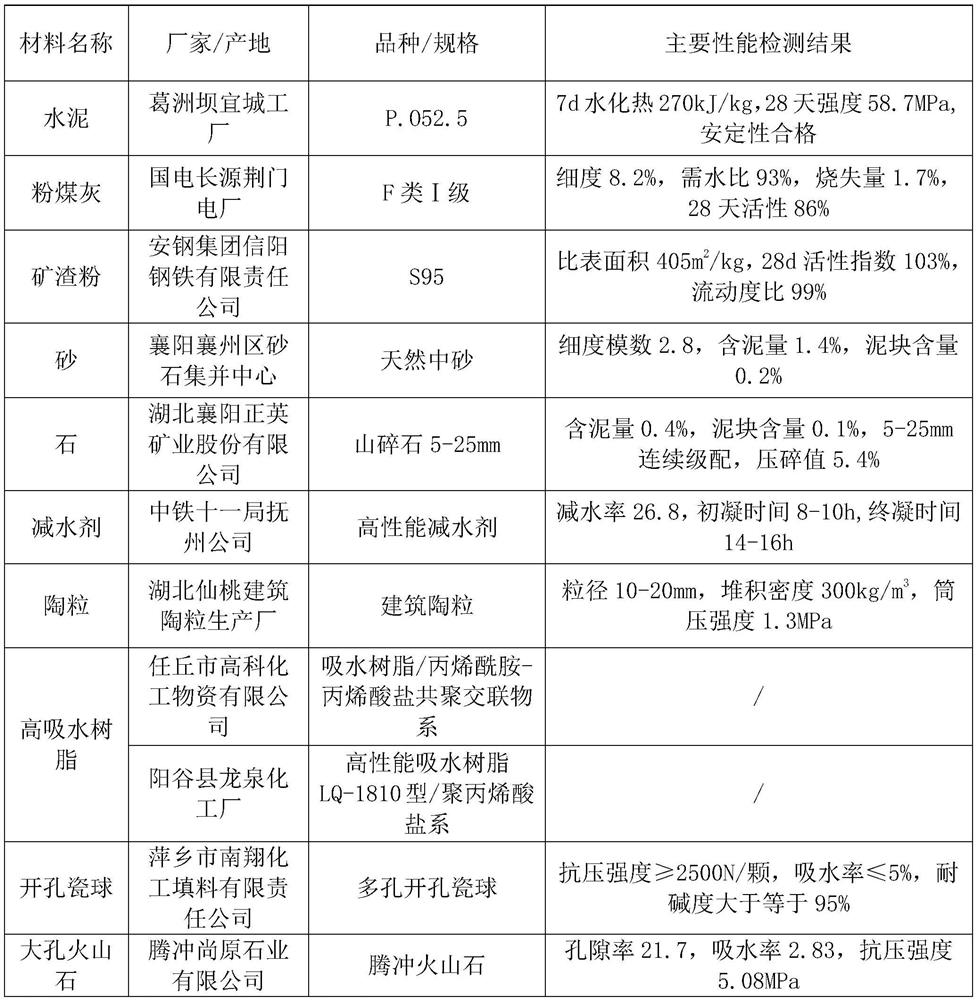

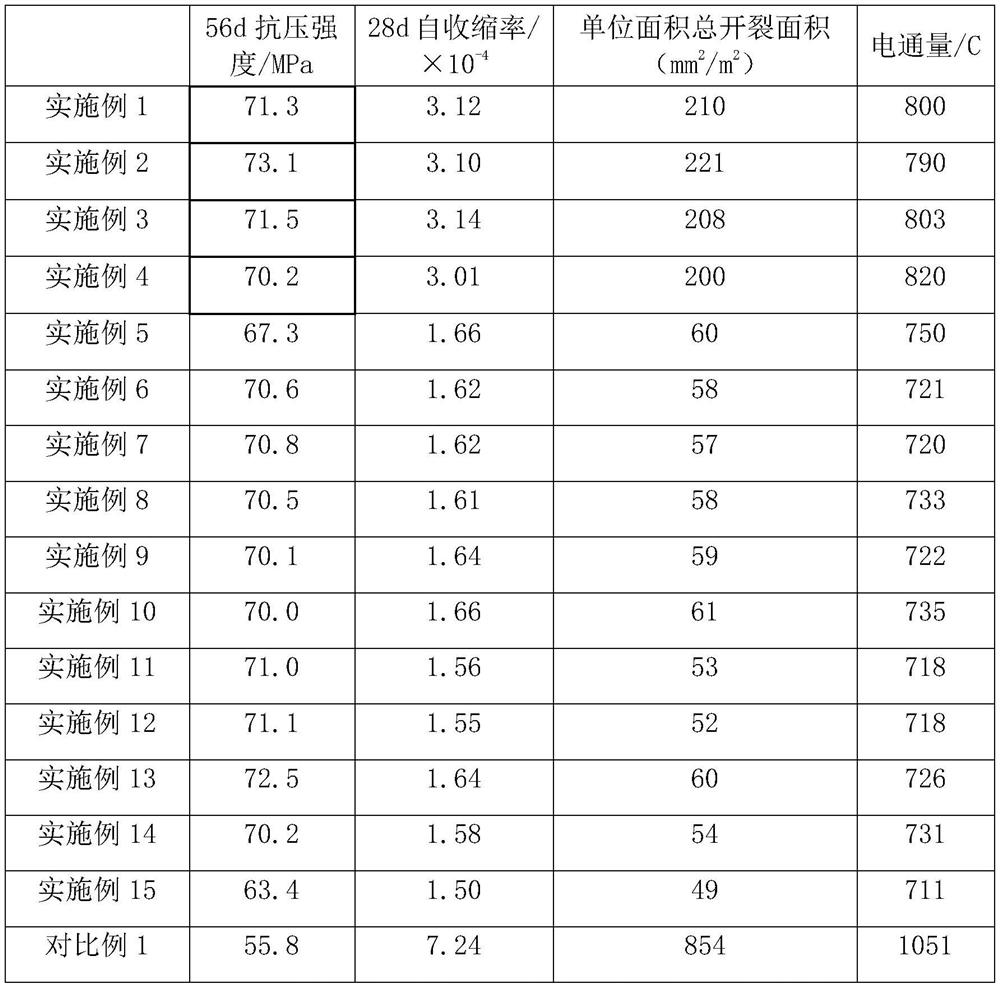

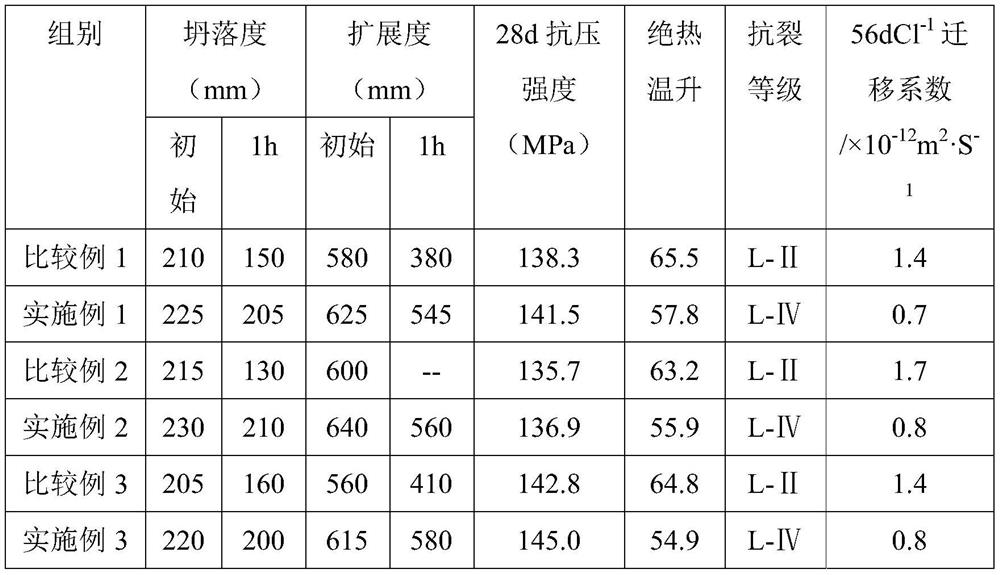

Mass concrete and preparation method thereof

The invention relates to the field of concrete, and particularly discloses mass concrete as well as a preparation method and application thereof. The mass concrete is prepared from the following raw materials in parts by weight: 340-355 parts of cement; 40 to 45 parts of fly ash; 100 to 110 parts of mineral powder; 680 to 720 parts of fine aggregate; 1080 to 1100 parts of coarse aggregate; 7-9 parts of a water reducing agent; and 135 to 145 parts of water. The preparation method comprises the following steps: weighing the cement, the fly ash, the mineral powder, the fine aggregate and the coarse aggregate in proportion, and uniformly mixing and stirring to obtain a first mixture; and weighing the water reducing agent and the water according to the proportion, adding the weighed water reducing agent into the water, uniformly mixing, adding the water doped with the water reducing agent into the first mixture, and uniformly stirring to obtain the mass concrete. The mass concrete has the advantages that the crack generation probability is reduced, and the crack generation amount is reduced.

Owner:襄阳嘉众和建材实业有限公司

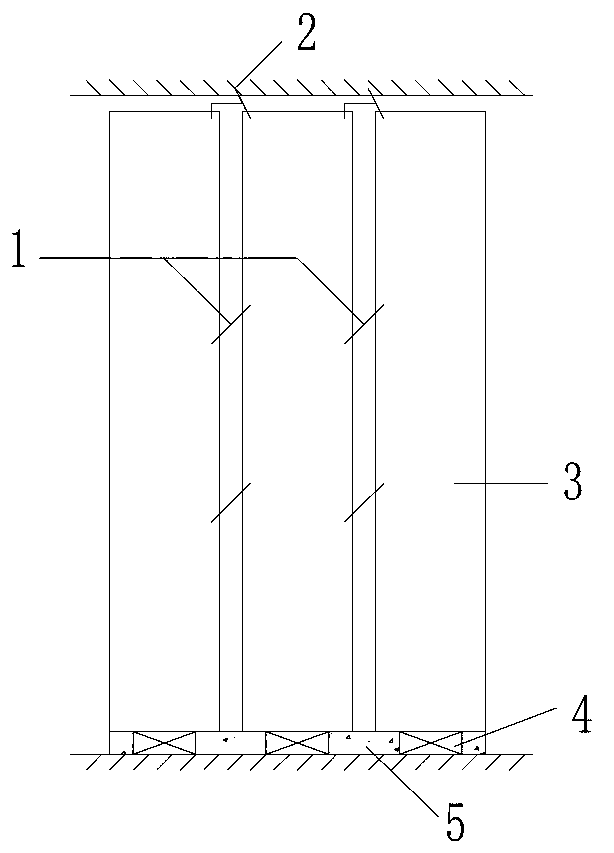

Non-bearing type light thin-wall damping partition wall

The invention provides a non-bearing type light thin-wall damping partition wall which comprises a wall board formed by an ultrahigh toughness cement-based composite material; the mortar matrix of the ultrahigh toughness cement-based composite material comprises cement, water, fine aggregate, pulverized fuel ash, silica fume, granulated blast-furnace slag and metakaolin, and the mass ratio among the components of the mortar matrix is 1: (0.27-2.2): (0-3): (0-6.9): (0-0.3): (0-0.55): (0-0.4), wherein the maximum particle size of the fine aggregate is not larger than 0.55mm, and the weights of the pulverized fuel ash, the silica fume, the granulated blast-furnace slag and the metakaolin are not equal to 0 at the same time; furthermore, chopped fiber is added into the mortar matrix, and volume dosage of the chopped fiber is 1-3% of that of the wall board; and the slump cone expansion diameter range of the mortar matrix with the chopped fiber is 60-70mm. The non-bearing type light thin-wall damping partition wall effectively replaces the traditional wall board material, and has the advantages of being high in strength, thin in thickness, fire-resistant, impervious, good in durability, low in thermal conductivity, low-carbon, energy-saving and the like.

Owner:ZHEJIANG UNIV

Waterproof heat insulation environment-friendly mortar and preparation method thereof

The invention discloses waterproof heat insulation environment-friendly mortar prepared from the following raw materials in parts by weight: 5-8 parts of silicon carbide, 20-24 parts of aluminum oxide micro powder, 20-30 parts of a polyacrylate emulsion, 20-25 parts of silicon micro powder, 100-130 parts of perlite, 80-100 parts of tourmaline negative ion powder, 2-4 parts of stearic acid, an appropriate amount of water, 20-25 parts of an auxiliary agent and 130-140 parts of cement. The mortar disclosed by the invention is excellent in adhesion, crack resistance, frost resistance, seepage prevention, corrosion protection, chlorine ion penetration resistance, aging resistance and corrosion resistance; by using the tourmaline negative ion powder, the mortar is beneficial for human health, has good heat insulation property, and is suitable for anti-seepage, anticorrosive face protection and repair engineering of steel structures and reinforced concrete structures including industrial terraces, civil buildings and the like. By using the auxiliary agent provided by the invention, the compression resistance and breaking strength of the mortar are improved, and the workability, sagging resistance, thixotropy and sedimentation resistance of the mortar are also improved.

Owner:魏超产

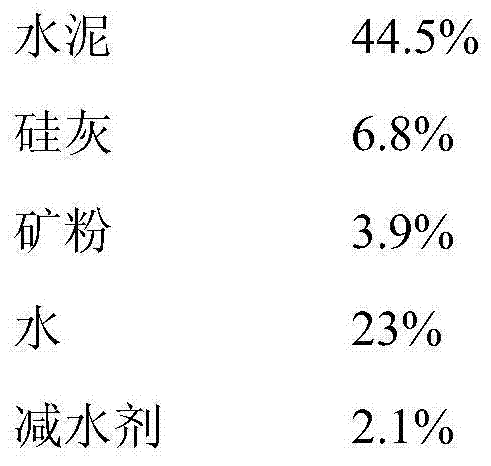

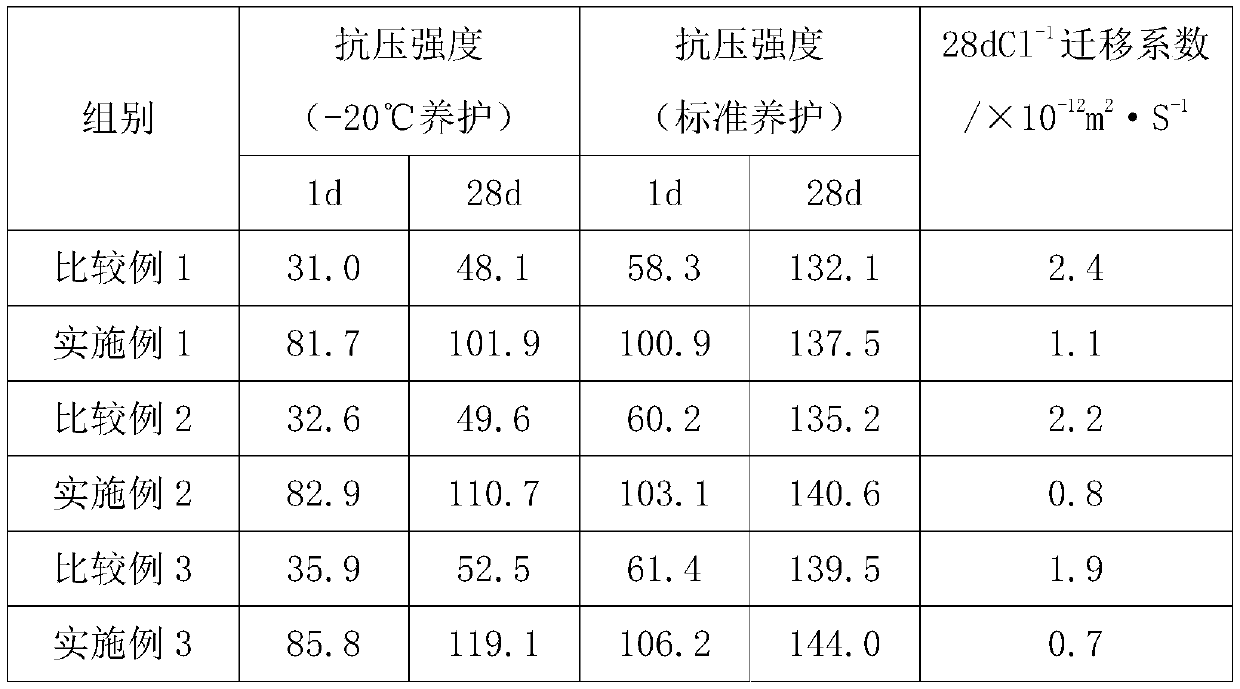

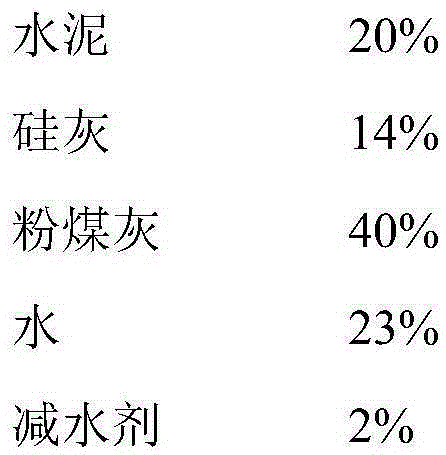

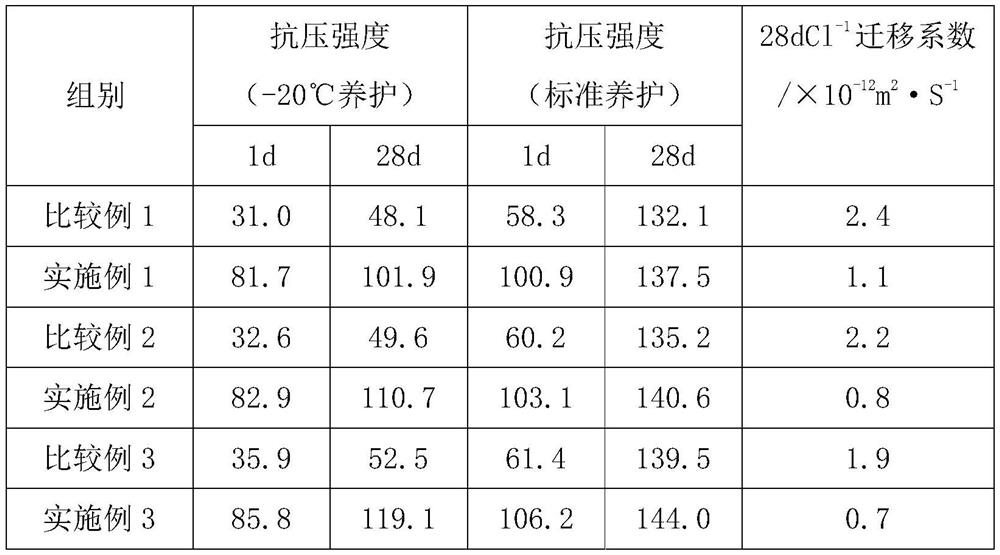

Ultra-high-performance concrete for use in high-cold area and preparation method thereof

ActiveCN110627461AImprove compactnessGood resistance to chloride ion penetrationSilica fumeCold area

The invention provides an ultra-high-performance concrete for use in a high-cold area and a preparation method thereof. The ultra-high-performance concrete comprises the following raw materials in parts by weight: 450-650 parts of Portland cement, 200-450 parts of high aluminate cement, 50-100 parts of silica fume, 5-50 parts of nano-silica, 1000-1300 parts of sand, 35-200 parts of steel fiber, 20-45 parts of water reducer, 2-10 parts of antifreezing agent, 0.2-2.0 parts of early strength agent, and 180-210 parts of water. Compared with the prior art, the ultra-high-performance concrete for use in a high-cold area provided in the invention can be used for construction in a high-cold area at -20 DEG C, and can gain strength rapidly. Moreover, the concrete is high in compactness, and has excellent anti-chlorine ion permeation performance and excellent mechanical properties.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

High-strength wear-resisting mortar

High-strength wear-resisting mortar is characterized by being prepared from, by mass, 5.0-10.0% of superfine wear-resisting composite micro-powder (micro-sphere), 0.08-0.10% of steel-plastic fiber, 0.10-0.16% of additive, 1.3-2.7% of polymer gelatine powder, 69-74% of fine aggregate and 13.75% of cement through technological combination.The technological process mainly comprises the steps of material drying, pre-dispersion, fiber dispersion and vacuum sealed storage.The high-strength wear-resisting mortar has the excellent bonding property, cracking resistance, freezing resistance, seepage resistance, corrosion resistance, chloride penetration resistance and aging resistance of polymer cement mortar, and also has ultrahigh strength, scour-grind resistance, cracking resistance and gas etching resistance.

Owner:辽宁省水利水电科学研究院有限责任公司

Ultra-high performance cement-based groove type profile

InactiveCN105421659AHigh corrosion resistance and fire resistanceMeet the requirements of construction mobilityStrutsGirdersCompressive strengthFire resistance

The invention relates to an ultra-high performance cement-based groove type profile poured by an ultra-high performance cement-based composite material. The cement-based groove type profile meets H / B=0.8-3, D / B=0.1-0.5, t / H=0.05-0.5, R / B=0.05-0.5 and R1 / t=0.1-0.5. According to the ultra-high performance cement-based composite material, by optimizing the grain composition of multi-element cementing materials and the grain composition of aggregates and using a water reducing agent and other chemical additives, the compressive strength of the concrete reaches 70 MPa or above under 28 d standard curing on the premise that the concrete has the good fluidity; the ultra-high performance cement-based profile obtains the material component performance similar to that of profile steel through the fiber reinforcement and other technologies, the ultra-high performance cement-based profile is applied to the beam, column, pile and other structures of a prefabricated building, and therefore the building has the building speed similar to that of a steel structure, but has the corrosion and fire resistance higher than that of the steel structure profile.

Owner:浙江宏日泰耐克新材料科技有限公司

Ultra-high performance cement-based H-shaped section bar

InactiveCN105386563AHigh corrosion resistance and fire resistanceMeet the requirements of construction mobilityStrutsGirdersCompressive strengthFire resistance

The invention relates to an ultra-high performance cement-based H-shaped section bar which is formed by pouring an ultra-high performance cement-based composite material. The cement-based H-shaped section bar meet requirements as follows: H / B is equal to 0.8-3; t1 / B is equal to 0.03-0.2; t2 / H is equal to 0.03-0.2; R1 / B is equal to 0.05-0.5; R2 / t2 is equal to 0.1-0.5; and R3 / R2 is smaller than or equal to 1. According to the ultra-high performance cement-based composite material, the grain composition of a multi-component cementitious material and the grain composition of an aggregate are optimized, and by means of chemical additives, on the premise that concrete has excellent fluidity, the compressive strength reaches more than 170 MPa under the 28 d standard. Through technologies of fibers, reinforcing bars and the like, the cement-based section bar obtains performance of a material component similar to section steel and is applied to structures such as beams, columns, piles and the like of a fabricated building, so that the building has portability and construction speed which are similar to the portability and the construction speed of a steel structure but corrosion resistance and fire resistance which are higher than the corrosion resistance and the fire resistance of a steel-structure section bar.

Owner:浙江宏日泰耐克新材料科技有限公司

Composition used as concrete maintenance assistant

The invention relates to a composition used as a concrete maintenance assistant. The composition comprises, by weight, 100 parts of trihexadecenoin, 0.01-0.05 parts of 1-butylsulfonic acid-3-methylimidazolium tetrafluoroborate, 0.01-0.05 parts of N-butyl-N-methylpiperidine bis(trifluoromethanesulfonyl)imide salt, 1-5 parts of disodium laureth (1~4) sulfosuccinate and 1000 parts of tetrahydrofuran.

Owner:张玲

High-strength pervious concrete and preparation method thereof

The invention discloses high-strength pervious concrete and a preparation method thereof, and the high-strength pervious concrete comprises the following raw materials: cement, gravel, polypropylene fiber, a water reducing agent, a retarder and water. The modified zeolite powder, the acrylate emulsion and the sulfamate water reducing agent are added, after the concrete mixture is added, the cement particles are dispersed, the workability of the cement particles can be improved, the unit water consumption is reduced, and the flowability of the concrete mixture is improved; the concrete is high in coagulation strength, and has excellent adhesion, crack resistance, freezing resistance, seepage resistance, corrosion resistance, chloride ion permeation resistance, aging resistance and corrosion resistance.

Owner:WUHAN TEXTILE UNIV

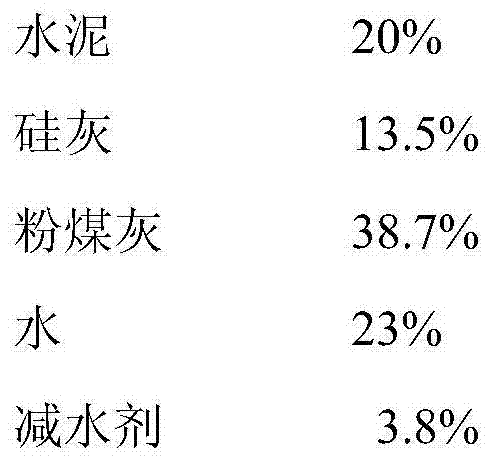

A kind of marine ultra-high performance concrete and preparation method thereof

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

Marine reinforced concrete anticorrosion paint and preparation method thereof

InactiveCN101255291BLong-term heavy-duty anti-corrosionImprove adhesionAnti-corrosive paintsSpecial surfacesReinforced concreteLacquer

The invention discloses a kind of reinforced concrete anticorrosive paint in marine engineering and preparation method, comprising prime paint and surface paint, wherein the prime paint is composed of post agent of prime paint and curing agent of prime paint and the surface paint comprises post agent and curing agent of surface paint. The preparation method comprises: preparation technique of prime paint and preparation technique of surface paint, wherein the preparation technique of prime paint is composed of preparation technique of post agent of prime paint and preparation technique of curing agent of prime paint and the preparation technique of surface paint comprises preparation techniques of post agent and curing agent of surface paint. The invention can provide long anticorrosion to steel and concrete structure which is difficult to be kept for a long time in bad environment such as ocean, with excellent oil resistant and anti-chemicals performance, and good cathodic protectioncompatibility performance. The paint can be solidified and dried to form film in water with stronger ornament property.

Owner:NINGBO DADA CHEM CO LTD

A high-strength wear-resistant mortar

High-strength wear-resisting mortar is characterized by being prepared from, by mass, 5.0-10.0% of superfine wear-resisting composite micro-powder (micro-sphere), 0.08-0.10% of steel-plastic fiber, 0.10-0.16% of additive, 1.3-2.7% of polymer gelatine powder, 69-74% of fine aggregate and 13.75% of cement through technological combination.The technological process mainly comprises the steps of material drying, pre-dispersion, fiber dispersion and vacuum sealed storage.The high-strength wear-resisting mortar has the excellent bonding property, cracking resistance, freezing resistance, seepage resistance, corrosion resistance, chloride penetration resistance and aging resistance of polymer cement mortar, and also has ultrahigh strength, scour-grind resistance, cracking resistance and gas etching resistance.

Owner:辽宁省水利水电科学研究院有限责任公司

A kind of ultra-fine powder-based ultra-high toughness lightweight concrete and preparation method thereof

The invention discloses an ultra-high toughness lightweight concrete based on ultra-fine powder. Each component and its weight parts include: 600-750 parts of sulfoaluminate cement, 100-150 parts of ultra-fine powder, silica fume 50-70 parts, 75-100 parts of glass microspheres, 90-110 parts of expanded perlite, 5-10 parts of copper-coated microwire steel fibers, 25-35 parts of high water-reducing and viscosity-reducing polycarboxylate water-reducing agent, water 220-250 parts; the superfine powder is mixed with calcium carbide slag powder, fly ash and mineral powder as the main raw materials. The ultra-high-toughness lightweight concrete obtained by the invention can effectively take into account light weight, high strength and ultra-high toughness, and can ensure high strength and high toughness while reducing self-weight, and is suitable for fields such as ultra-high-rise structures; and the preparation method involved is relatively simple and expensive. Low, suitable for promotion and application.

Owner:中建西部建设新疆有限公司 +1

A kind of long-acting anti-corrosion coating for underwater curing marine steel structure and preparation method thereof

ActiveCN107603423BReduce curingReduce adhesionAnti-corrosive paintsEpoxy resin coatingsPolymer scienceSolvent free

The invention discloses an underwater-curing long-acting anticorrosive coating for marine steel structures, and a preparation method thereof. The coating comprises a component A and a component B according to a weight ratio of 1.5:1 to 3:1; the component A comprises, by weight, 20-50 parts of phenolic modified epoxy resin, 3-8 parts of an active diluent, 25-55 parts of a filler, 0.2-1 part of a thixotropic agent, 0.3-1 part of a wetting dispersant, 0.3-0.8 part of an antifoaming agent and 0.3-1 part of a coupling agent; and the component B comprises, by weight, 20-70 parts of a curing agent Iand 30-80 parts of a curing agent II. A paint film produced by using the coating can be fast cured in a wet and even water environment, contains no solvents, has no pollution to the environment, and has good application properties. The coating has the advantages of excellent water curing and underwater curing performances, excellent corrosion resistance, excellent chloride ion permeation resistance, excellent adhesion, and excellent impact resistance.

Owner:洛阳双瑞防腐工程技术有限公司

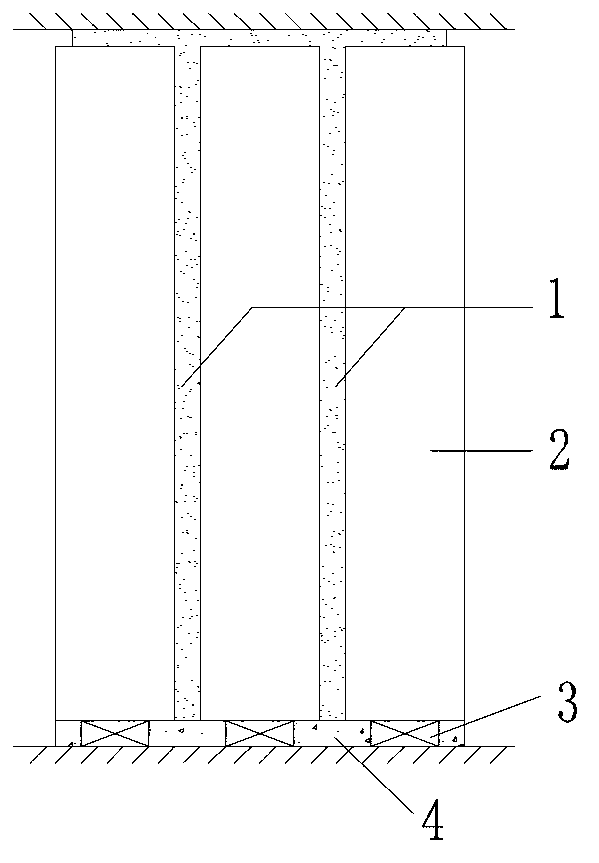

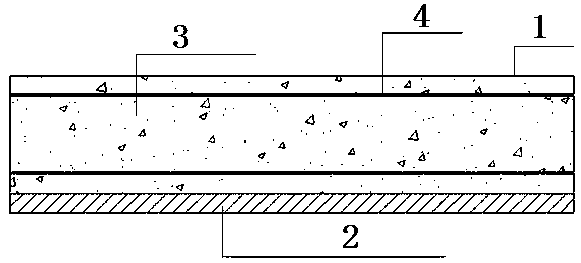

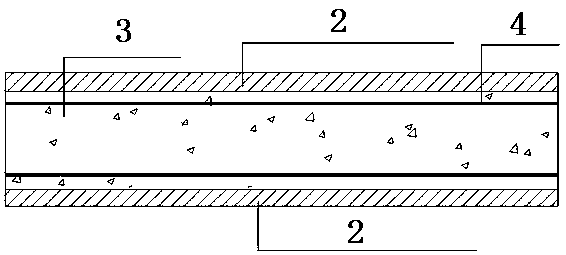

Low-shrinkage ultra-high-strength concrete-reinforced concrete combined structure and construction method thereof

PendingCN110468954ASimple structureReduce rust damageBuilding insulationsHigh strength concreteReinforced concrete

The invention relates to a low-shrinkage ultra-high-strength concrete-reinforced concrete combined structure which comprises a reinforced concrete layer, wherein low-shrinkage ultra-high-strength concrete protection layers are cast on the single side or the double sides of the reinforced concrete layer. The low-shrinkage ultra-high-strength concrete-reinforced concrete combined structure has the advantages that the structure is simple; the corrosion damage of steel bars is effectively delayed; and interface cracks caused by inconsistent shrinkage of the ultra-high-strength concrete protectionlayers and the reinforced concrete layer can be inhibited.

Owner:FUZHOU UNIV

Marine reinforced concrete anticorrosion paint and preparation method thereof

InactiveCN101255290BImprove adhesionImprove matchLayered productsAnti-corrosive paintsReinforced concreteLacquer

The invention discloses a kind of reinforced concrete anticorrosive paint in marine engineering and preparation method, comprising prime paint, intermediate layer paint, surface paint, wherein the prime paint is composed of post agent of prime paint and curing agent of prime paint, the intermediate layer paint comprises post agent of intermediate layer and curing agent of intermediate layer, and the surface paint comprises post agent and curing agent of surface paint. The preparation method comprises: preparation technique of prime paint, preparation technique of intermediate layer paint andpreparation technique of surface paint, wherein the preparation technique of prime paint is composed of preparation technique of post agent of prime paint and preparation technique of curing agent ofprime paint, the preparation technique of intermediate layer paint comprises preparation technique of post agent of intermediate layer and preparation technique of curing agent of intermediate layer,and the preparation technique of surface paint comprises preparation techniques of post agent and curing agent of surface paint. The invention can provide long anticorrosion to steel and concrete structure which is difficult to be kept for a long time in bad environment such as ocean. The paint can be solidified and dried to form film in water with stronger ornament property.

Owner:NINGBO DADA CHEM CO LTD

A kind of granite stone powder concrete whose strength grade is not greater than C40 and its preparation method

ActiveCN103803916BFill in the gapsImprove interface structureCinker content reductionCrack resistanceChloride penetration

The invention discloses granite stone powder concrete having strength grade not more than C40 and a preparation method of the granite stone powder concrete. The granite stone powder concrete is mainly prepared from a cementing material, water, sand, gravels and an admixture, wherein the cementing material is a mixture of cement and granite stone powder or a mixture of cement, mineral powder and granite stone powder, and the admixture is a water reducing agent. The granite stone powder concrete has early crack resistance, chloride penetration resistance and carbonation resistance, which are superior to those of the traditional concrete under a condition of meeting the strength requirement.

Owner:QINGDAO QINGJIAN NEW MATERIAL GRP CO LTD

A kind of ultra-high performance concrete applied in the alpine region and its preparation method

The invention provides an ultra-high-performance concrete used in alpine regions and a preparation method thereof, comprising the following raw materials in parts by weight: 450-650 parts of Portland cement, 200-450 parts of peraluminate cement, and 50-100 parts of silica fume , 5-50 parts of nano-silica, 1000-1300 parts of sand, 35-200 parts of steel fiber, 20-45 parts of water reducing agent, 2-10 parts of antifreeze, 0.2-2.0 parts of early strength agent and 180-210 parts of water share. Compared with the prior art, the ultra-high-performance concrete prepared in the invention can be constructed in a cold region of -20°C and can quickly gain strength. Moreover, it has high compactness, excellent resistance to chloride ion penetration and excellent mechanical properties.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com