Polymer cement waterproof coating with high corrosion resistance and preparation method thereof

A waterproof coating and polymer technology, applied in chloroprene homopolymer coatings, anti-corrosion coatings, polyurea/polyurethane coatings, etc., to achieve the effects of improved comprehensive performance, excellent seawater corrosion resistance, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

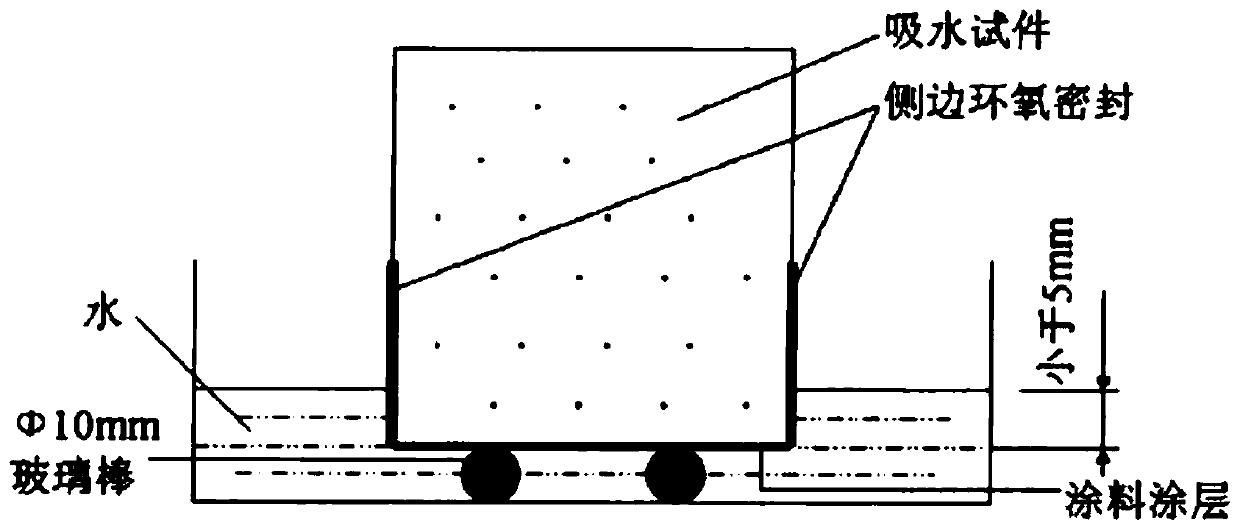

Image

Examples

preparation example Construction

[0032] In the embodiment of the present invention, the preparation method of the polymer cement waterproof coating includes:

[0033] First stir the cement and quartz sand evenly, add the homogeneous mixture of polymer emulsion and coupling agent, dispersant and pigment, stir for 3-5 minutes, then add defoamer and continue to stir for 1-3 minutes, and finally add water reducing agent and stir 1-3 minutes, after the stirring stops, let it stand for 1-3 minutes to obtain the polymer cement waterproof coating with high corrosion resistance.

Embodiment 1

[0035] This embodiment provides a polymer cement waterproof coating with high corrosion resistance.

[0036] The composition of the polymer cement waterproof coating of this embodiment is: 60g cement, 23g quartz sand, 109g polymer emulsion (acrylate emulsion: polyurethane emulsion=1:1, by mass percentage), 0.9g coupling agent, 0.3g minus Water agent, 0.3g dispersant, 1.8g defoamer, 0.5g pigment.

[0037] In this embodiment, the cement is 42.5 type ordinary Portland cement, the particle size of the quartz sand is 80-120 mesh; the acrylic emulsion is BP-2181, Beijing Mengtai Weiye Building Material Co., Ltd.; the polyurethane emulsion is PU-2188, Guangdong Guanzhi New Material Technology Co., Ltd.; coupling agent is KH-550, Jiangsu Chenguang Paint Co., Ltd., water reducing agent is FDN-I naphthalene series superplasticizer, Shanghai Yunzhe New Material Technology Co., Ltd.; dispersing agent is six Sodium metaphosphate, Shanghai Yunzhe New Material Technology Co., Ltd.; defoamer is s...

Embodiment 2

[0039] This embodiment provides a polymer cement waterproof coating with high corrosion resistance.

[0040] The composition of the polymer cement waterproof coating of this embodiment is: 60g cement, 23g quartz sand, 131g polymer emulsion (acrylate emulsion: neoprene rubber emulsion=1:1, by mass percentage), 0.9g coupling agent, 0.3 g water reducer, 0.3g dispersant, 2.2g defoamer, 0.5g pigment.

[0041] In this example, the cement is 42.5 type ordinary Portland cement, the particle size of the quartz sand is 80-120 mesh, the acrylic emulsion is the same as in Example 1, and the neoprene emulsion is 511A Beijing Mengtai Weiye Building Materials Co., Ltd. The coupling agent is the same as Example 1, the water reducing agent is the same as Example 1, the dispersant is the same as Example 1, the antifoaming agent is the same as Example 1, and the pigment is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com