Mass concrete and preparation method thereof

A large-volume concrete and porous carrier technology, applied in the field of concrete, can solve the problems of reducing the bearing capacity of engineering structures, affecting the durability of structures, and the large temperature difference between the inside and outside of concrete, so as to reduce the possibility of micro-cracks, less shrinkage cracks, and reduce The effect of cement dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

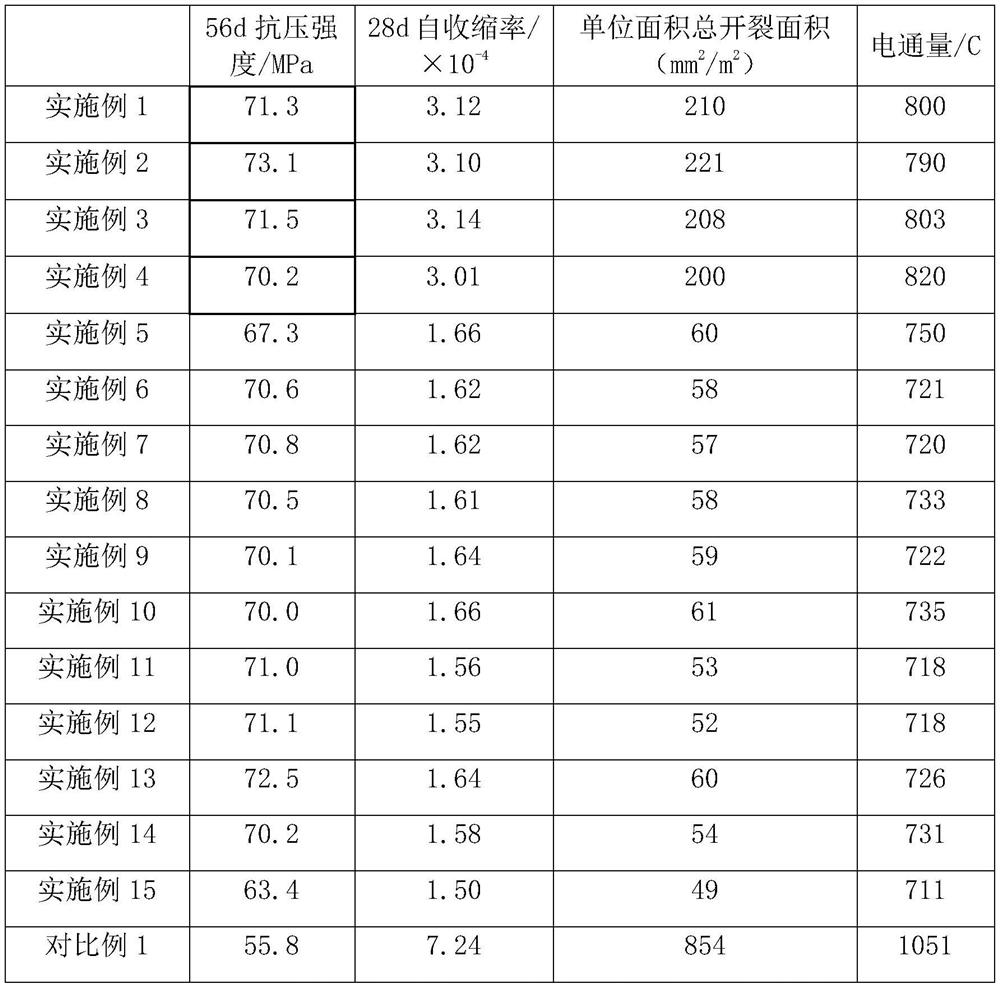

Examples

preparation example 1

[0047] A preparation method of high-strength porous carrier-superabsorbent resin particles, comprising the following steps:

[0048] S1. Weigh 10 kg of super absorbent particles and 50 kg of high-strength porous carrier, put them into a mixer and stir for 3 minutes, and use a 16-mesh screen to screen the stirred mixture of high-strength porous carrier and super-absorbent particles to obtain the remaining high-strength porous carrier;

[0049] S2. Put the remaining high-strength porous carrier into a reservoir filled with sufficient normal temperature water for soaking until the water level in the reservoir is stable, remove the high-strength porous carrier, and use an air separator to perform air separation to obtain High-strength porous carrier-superabsorbent resin particles.

[0050] Among them, the high-strength porous carrier is open-pore ceramic balls, the particle size of the open-pore ceramic balls is 15-25mm, and the pore diameter of the open-pore ceramic balls is 1mm;...

preparation example 2

[0052] A method for preparing high-strength porous carrier-superabsorbent resin particles, the difference from Preparation Example 1 is that before step S2, the remaining high-strength porous carrier obtained in step S1 is wax-sealed, and in step S2, in the reservoir The water temperature is 60°C. Wax sealing includes the following steps:

[0053] Put the sieved high-strength porous carrier into a heating tank filled with 60°C liquid paraffin, take it out after the liquid paraffin is cooled and solidified, put the taken out solidified paraffin into a crusher for extrusion and crushing, so that it is wrapped with high-strength porous The large solidified paraffin of the carrier is divided into small pieces, and then the small pieces of paraffin are put into a vibrating sieve machine for vibratory screening, and the paraffin adhered to the surface of the high-strength porous carrier is vibrated to obtain a high-strength porous carrier with paraffin wax sealing.

preparation example 3

[0055] A method for preparing high-strength porous carrier-superabsorbent resin particles, the difference from Preparation Example 2 is that the superabsorbent resin is an acrylic polymer superabsorbent resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com