Patents

Literature

55 results about "Chloride penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

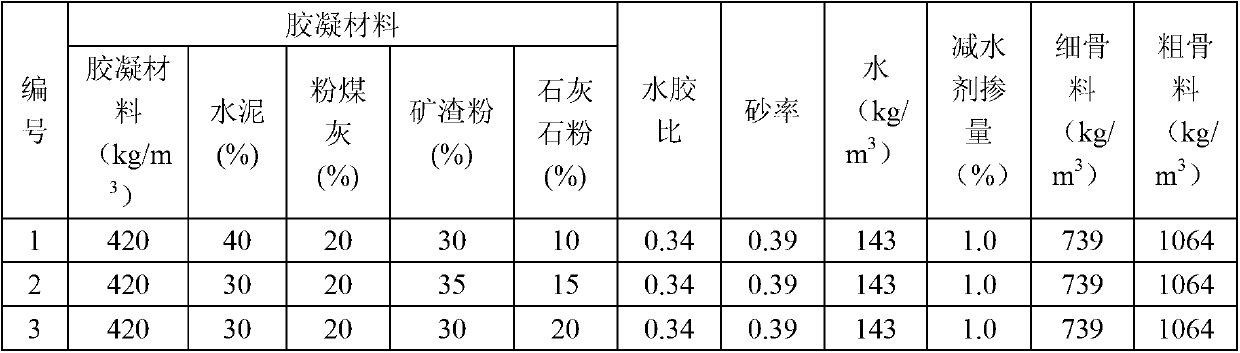

Bare concrete binding material and corrosion-resistant bare concrete utilizing same

InactiveCN103011637AReduce manufacturing costReduce heat of hydrationCement productionSlagChloride penetration

The invention discloses a bare concrete binding material. The bare concrete binding material is prepared by mixing 30-50% of cement, 15-25% of coal ash, 25-35% of slag powder and 10-20% of limestone flour according to weight percentage. According to the bare concrete binding material and the corrosion-resistant bare concrete utilizing the same, through the blending of the limestone flour, the cement can be saved, and the production cost of the concrete can be lowered; due to the blended limestone flour, the hydration heat of the concrete can be decreased, and the anti-cracking capability of the concrete can be improved; and through the blending of two active blending stocks including the coal ash and the slag powder, the chloride penetration resistance of the concrete is improved, and the service life of the structure is prolonged.

Owner:CCCC FOURTH HARBOR ENG INST +3

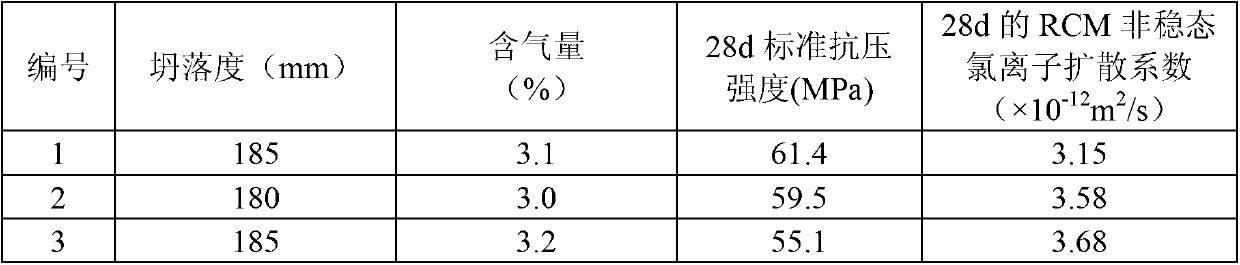

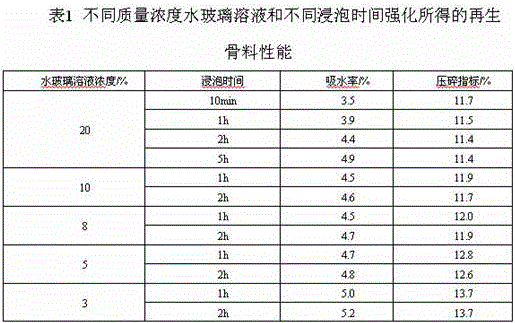

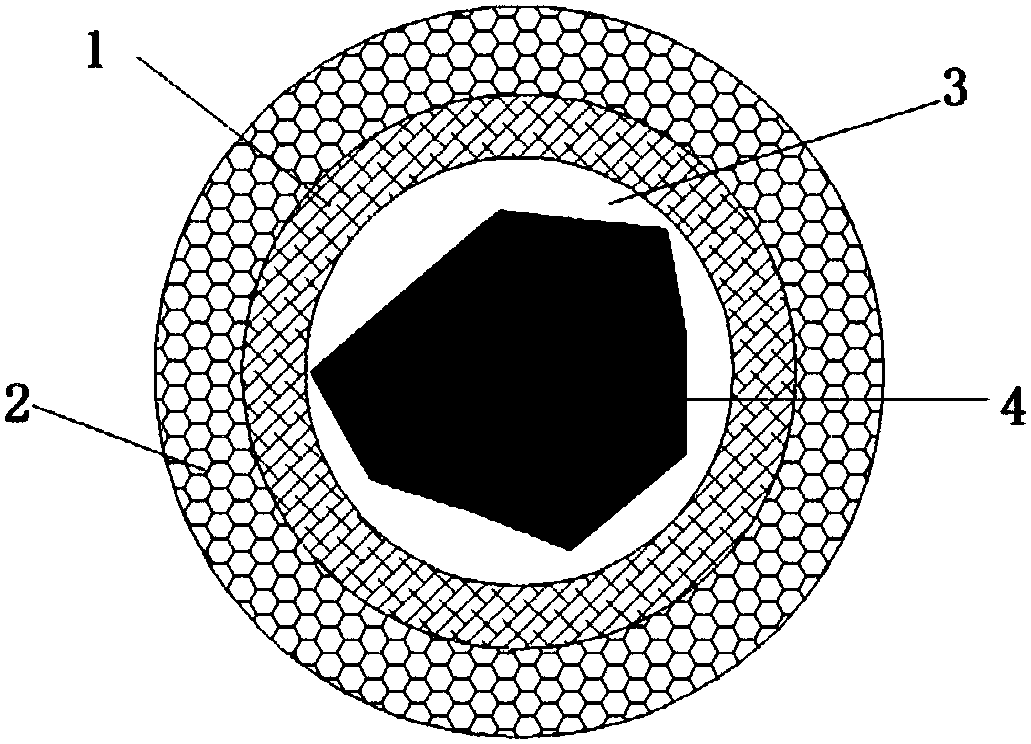

Preparation method of strengthened recycled aggregate and strengthened recycled aggregate concrete

InactiveCN106477929ALow water absorptionHigh compressive strengthSolid waste managementWork performancePotassium

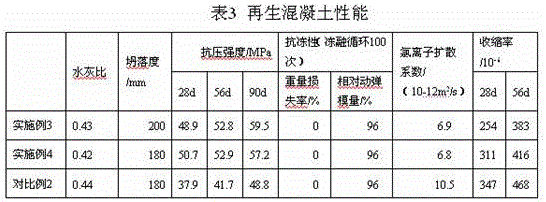

The invention discloses a preparation method of strengthened recycled aggregate and strengthened recycled aggregate concrete. The preparation method comprises the following steps: recycled aggregate is completely soaked in a water glass solution with the mass concentration being 3%-20% and the modulus being 3.0-3.4 for 10 min-5h; alternatively, the recycled aggregate is completely soaked in a potassium methyl silicate with the mass concentration being 1%-15% for 5-10 min. By comparison with recycled aggregate concrete in the prior art, the work performance, the compressive strength and the chloride penetration resistance of the soaked recycled aggregate concrete are all remarkably improved; the recycled aggregate is fished out, dried in air naturally and stacked, and the strengthened recycled aggregate can be obtained. The method has a good modification effect and is low in cost and environment-friendly; the water absorption rate of the strengthened recycled aggregate can be reduced by 50% or higher, and the crush index is reduced 20%. The shrinking percentage of the strengthened recycled aggregate is remarkably reduced, and the freezing resistance is good.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Waterproof and corrosion-resistant coating for coastal region

InactiveCN106047091AGood flexibilityImprove densification performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyChloride penetration

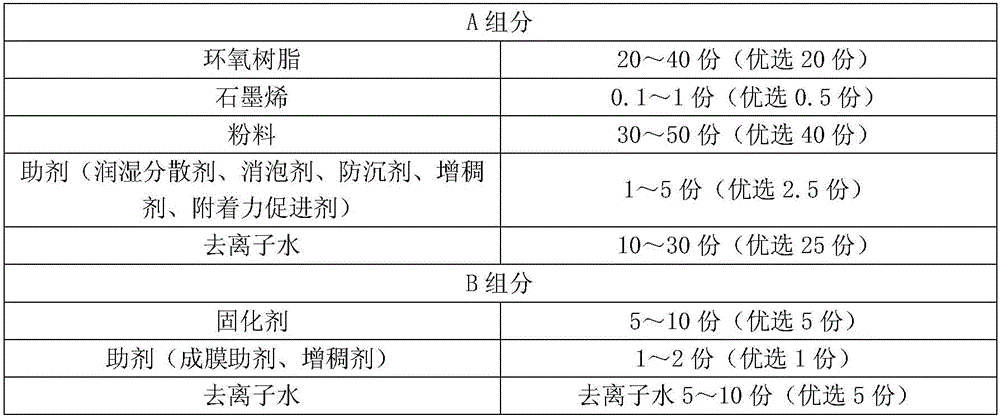

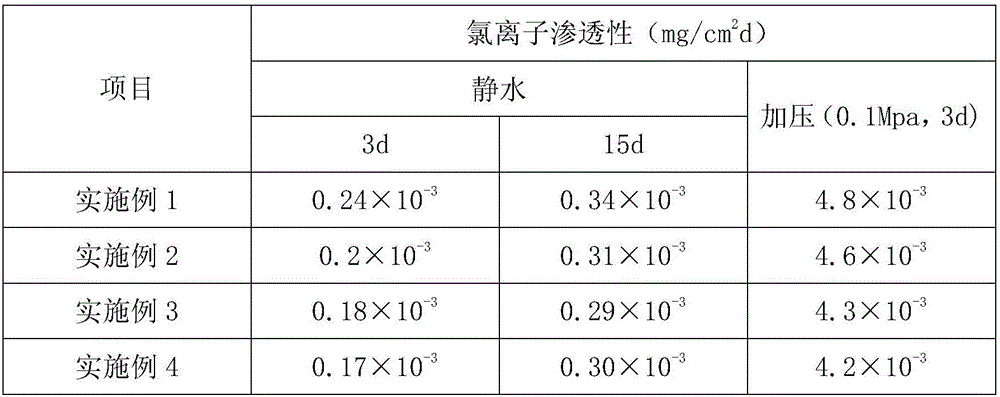

A waterproof and corrosion-resistant coating for a coastal region is characterized by being prepared from a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 20-40 parts of epoxy resin, 0.1-1 part of graphene, 30-50 parts of powder, 1-5 parts of an auxiliary, and 10-30 parts of deionized water; the component B is prepared from the following raw materials in parts by weight: 5-10 parts of an amine curing agent, 1-2 parts of an auxiliary and 5-10 parts of deionized water. The waterproof and corrosion-resistant coating for the coastal region has the advantages of good water resistance, high chloride penetration resistance, good alkali resisting and salt corrosion resisting properties and the like, and is environmentally friendly and odorless, meanwhile, the preparation method is simple, and the waterproof and corrosion-resistant coating can be scraped and can also be sprayed during construction.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

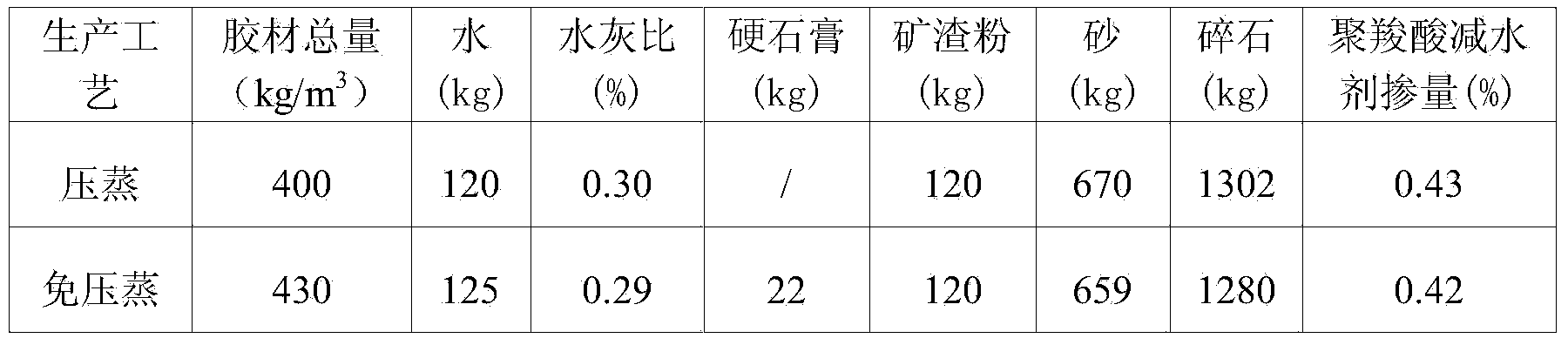

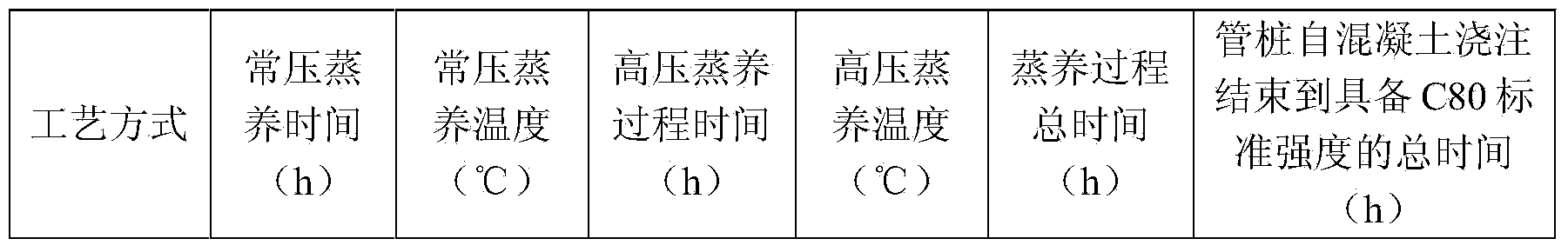

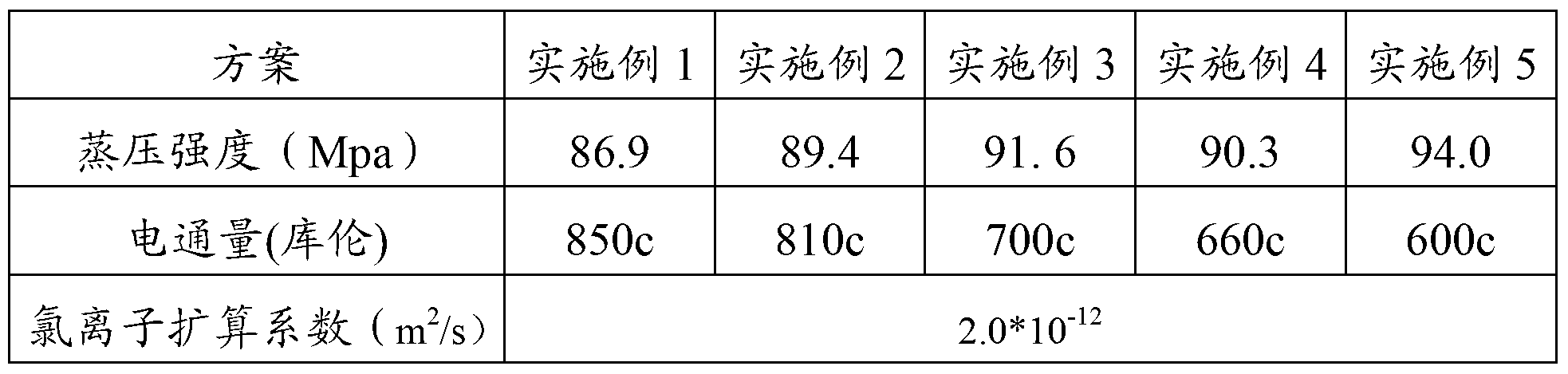

Non-autoclave primary health care (PHC) pipe pile concrete containing early strength composite mineral material and preparation method thereof

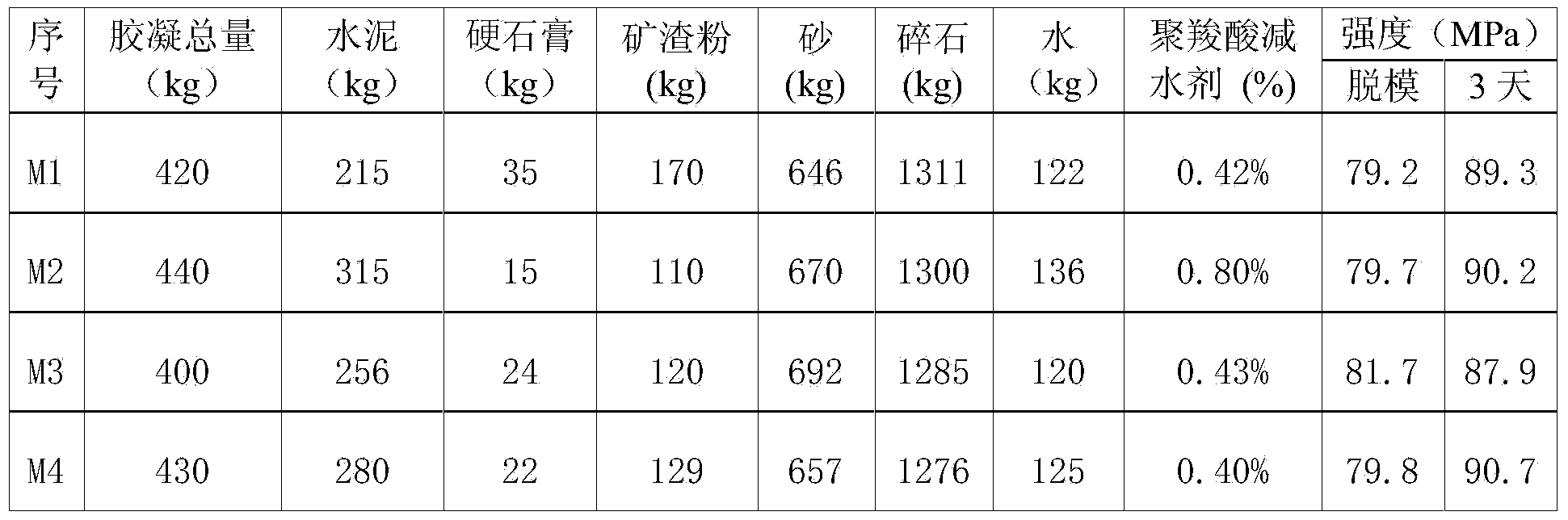

The invention relates to non-autoclave primary health care (PHC) pipe pile concrete. The concrete is characterized by being prepared from the following raw materials: a binding material, a water reducing agent, water, coarse aggregate, and fine aggregate, wherein the binding material is prepared from the following raw materials by mass ratio: 3.0-8.0% of rich calcareous material, 25-40% of rich siliceous material and the balance of cement; the water reducing agent accounts for 0.4-0.8% of weight of the binding material; the water cement ratio of the concrete is 29-31%; the sand ratio is 33-35%; the volume-weight is 2480-2500kg / m<3>. The rich calcareous material and the rich siliceous material are compounded at a ratio of 1:4 or 1:6; the cement is excited to hydrate for the second time; the early strength is improved; the C80 strength grade requirements can be met by one-time atmospheric pressure steam maintenance for 6 hours; the performances, such as the volume stability, the carbonizing resistance, corrosion of reinforcement, the chloride penetration resistance, the freeze-thaw resistance, the acid corrosion resistance, the salt corrosion resistance and the like of the PHC pipe pile concrete are improved and changed, and the late durability of the concrete is improved.

Owner:安徽省恒泰新材料有限公司

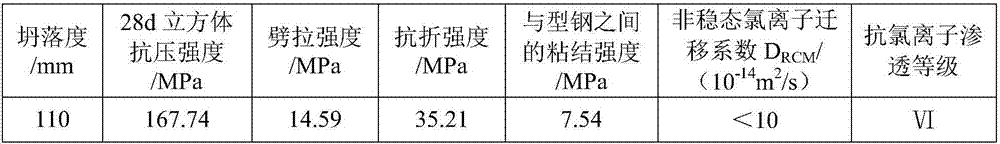

Ultrahigh strength high-performance fiber concrete at C160 strength grade and preparation method thereof

ActiveCN107382205APrevent pulling outImprove energy consumptionSolid waste managementModified carbonCarbon nanotube

The invention discloses an ultrahigh strength high-performance fiber concrete at C160 strength grade and a preparation method thereof. The concrete comprises the following components in parts by weight: 485 parts of cement, 82 parts of water, 1000 parts of macadam, 750 parts of fine aggregate, 70 parts of coal ash, 73 parts of rice hull ash, 102 parts of silica fume, 14.0 parts of water reducer, 9.5 parts of excitant, 1.6 parts of cellulosic fiber, 40 parts of hydroxy modified carbon nano tube dispersion liquid, 37 parts of graphene oxide dispersion liquid and 2.6 parts of de-foaming agent. The prepared concrete has higher toughness, durability, higher bonding strength with profile steel, compressive strength reaching up to 167.74MPa, breaking strength reaching up to 35.21MPa, splitting strength reaching up to 14.59MPa, bonding strength with profile steel reaching up to 7.54MPa and chloride penetration resistance grade at VI-grade. When the ultrahigh strength high-performance fiber concrete is applied to a profile steel concrete combined structure, the cooperative working property between the profile steel and the concrete is effectively exerted and the defects of poor bonding property of the profile steel and the concrete and incapability of fully utilizing the respective mechanical properties of the profile steel and the concrete can be overcome.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Underwater non-dispersible high-performance concrete

The invention provides underwater non-dispersible high-performance concrete, and belongs to the technical field of concrete. The underwater non-dispersive high-performance concrete meets both the underwater non-dispersive performance requirement and the chloride penetration resistance requirement, and has high strength. The underwater non-dispersive high-performance concrete is prepared from 650 kg / m<3> of cementing materials, 625 kg / m<3> of sand, 725 kg / m<3> of broken stone, 16.25 kg / m<3> of flocculating agent, 6.5 kg / m<3> of high-performance water reducing agent and 240 kg / m<3> of water. The cementing materials are prepared from cement and mineral powder in the proportion of 4:1. The underwater non-dispersible high-performance concrete can be applied to underwater concrete structures.

Owner:CCCC FIRST HARBOR ENG

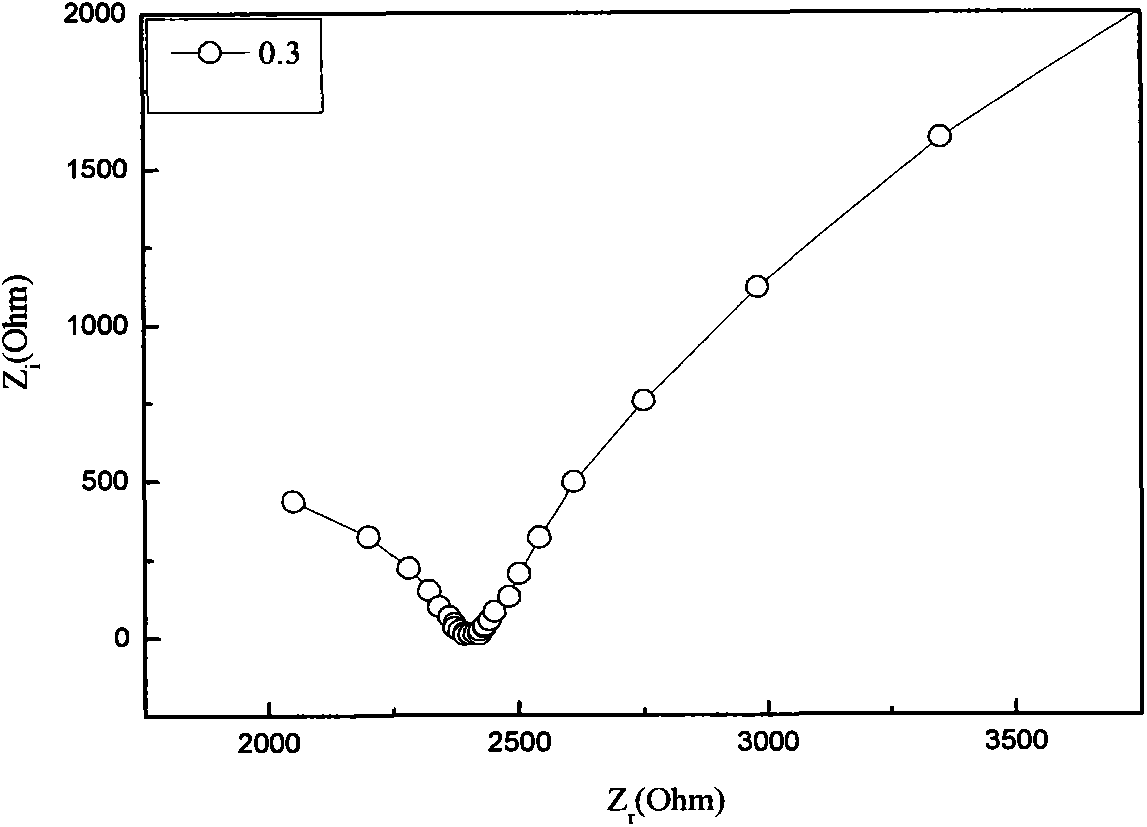

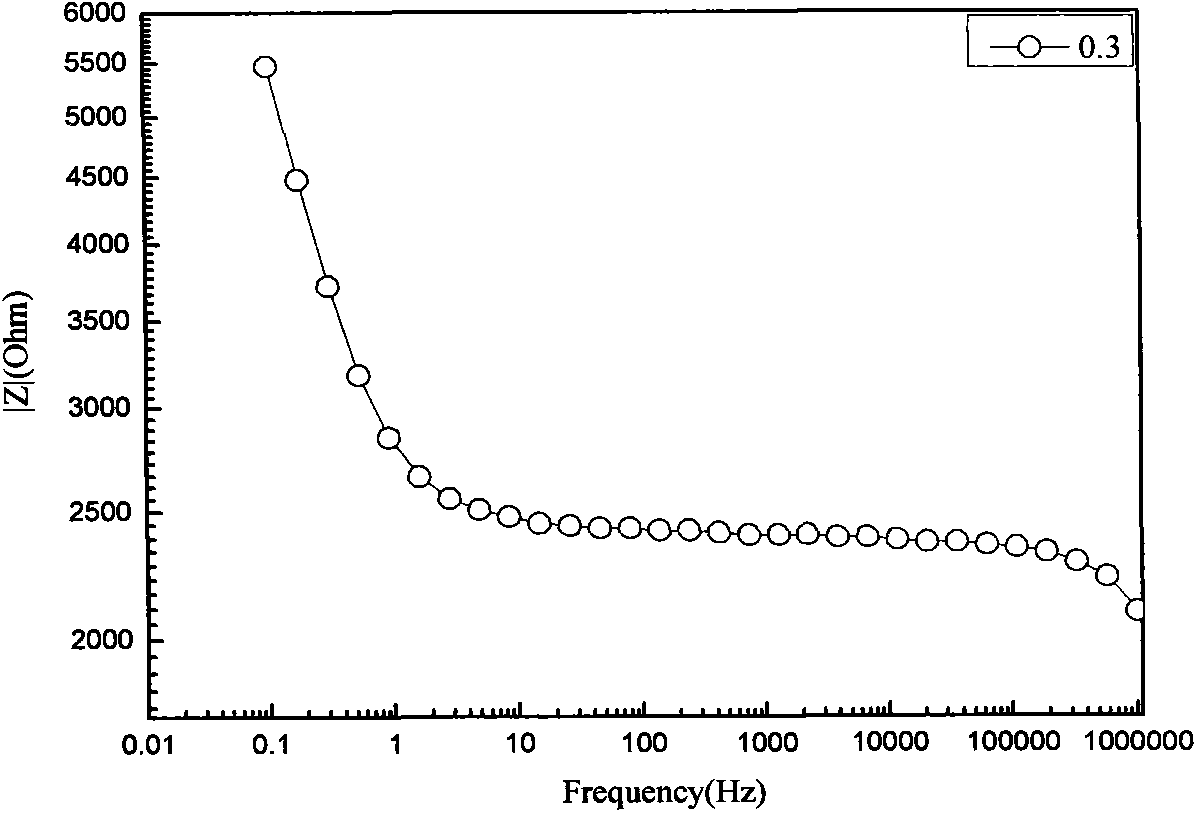

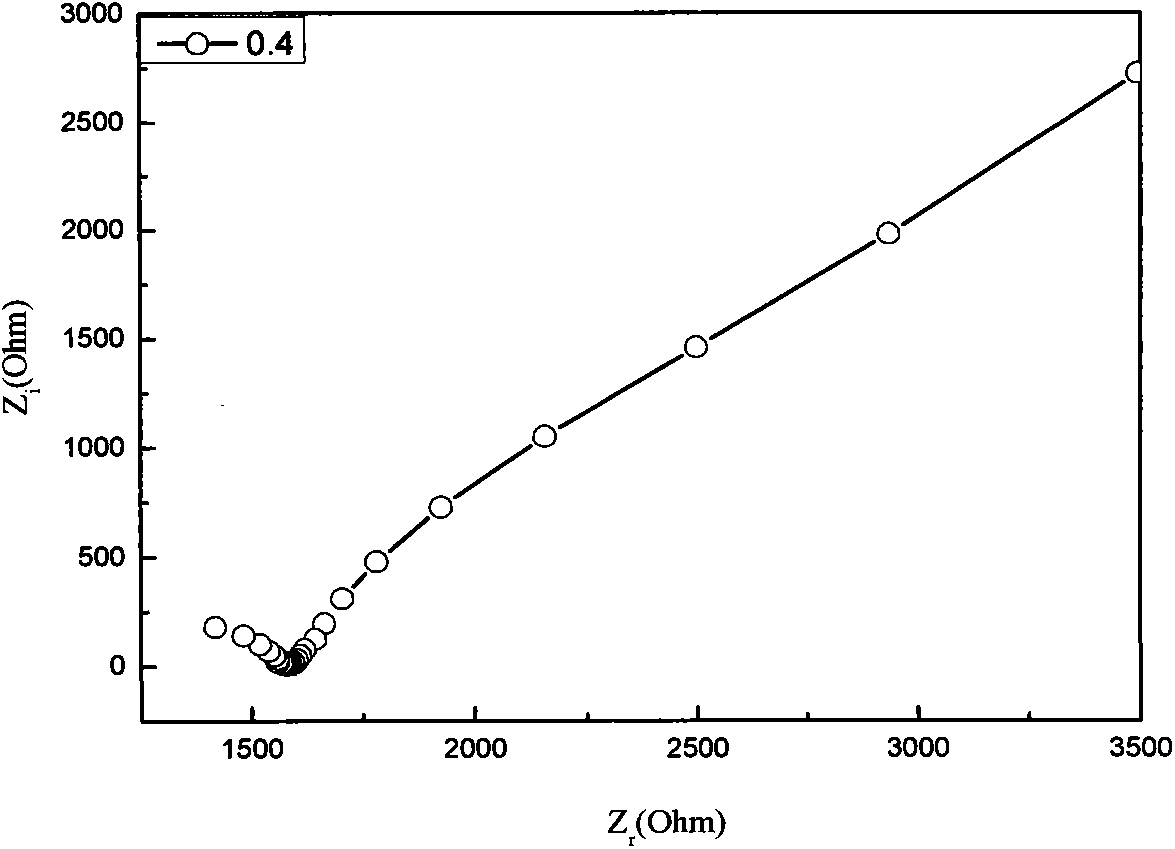

Test method of cement-based material chloride ion penetration depth

ActiveCN103674807AAvoid Reading ErrorsSave manpower for testingSurface/boundary effectPermeability/surface area analysisOnline testSpectroscopy

The invention provides a test method of a cement-based material chloride ion penetration depth. The method uses a mould disclosed in a patent of which the patent number is 'ZL201120473976.2' and used for an electrochemical impedance spectroscopy online test in a cement hydration process to carry out full-course maintenance and a chloride ion penetration test for cement materials. Electrode plates of 40mm*40mm arranged at two ends of the mould are detached during chloride penetration to enable the cement materials to be eroded by the chloride ions; when the test is to be carried out, the electrode plates are mounted at the two ends of the mould to carry out the electrochemical impedance spectrum test; finally the chloride ion penetration depth of the cement materials are reflected and calculated through regular variation of electrochemical parameters. The test method disclosed by the invention has the advantages that the mould and cement test pieces are not easy to damage, repeatable detection is achieved, the error is small and the operation is convenient.

Owner:SHENZHEN UNIV

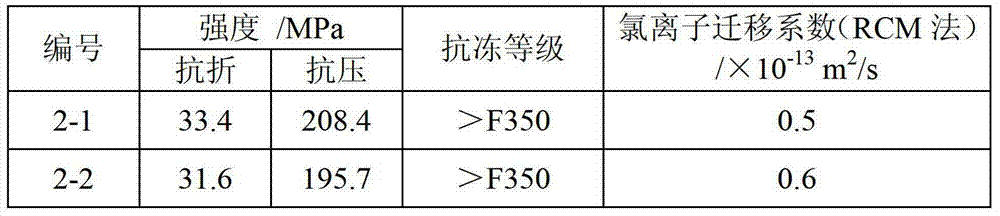

Phosphorus slag-doped active powder concrete and preparation method thereof

The invention discloses phosphorus slag-doped active powder concrete and a preparation method thereof. The preparation method comprises the following steps of: adopting a material compounding technology on the basis of utilizing gelling performances of phosphorus slag powder; and preparing high-compressive strength active powder concentration by using phosphorus slag powder, silica fume, cement, quartz sand and steel fiber under the normal-pressure steam curing condition of 80-95 DEG C. The active powder cement obtained by the preparation method has compressive strength not less than 180MPa, breaking strength not less than 25MPa and belongs to RPC200 level. Meanwhile, the anti-freezing level is not lower than F350, the chloride ion transport coefficient (RCM process) DRCM is not higher than 1.0-10<-13>m<2> / s, and the chloride penetration resistance reaches RCM-V level. Besides, the phosphorus slag-doped active powder concrete has excellent anti-freezing performances and chloride penetration resistance, can be used for prompting high-efficiency utilization of phosphorus slag, and can be used for saving resource and energy and protecting the environment.

Owner:CHINA THREE GORGES UNIV

Compound modified cement concrete internal-maintenance material and preparation method thereof

The invention provides a compound modified cement concrete internal-maintenance material and a preparation method thereof. The maintenance material is prepared by compounding inorganic hydrotalcite-like compounds with organic high water-absorbent resin through an intercalation modification technique. The material preparation by virtue of the preparation method has excellent water retention capacity, the shrinkage of concrete is reduced to a great extent, the compressive strengths in the days 7 and 28 are increased by above 10%, the relatively dynamic elasticity modulus after 300 freezing and thawing cycles is above 80%, the anti-freezing property is obviously improvided, and the chloride penetration resistance and sulfate corrosion resistance are remarkably improved.

Owner:西安华泽道路材料有限公司

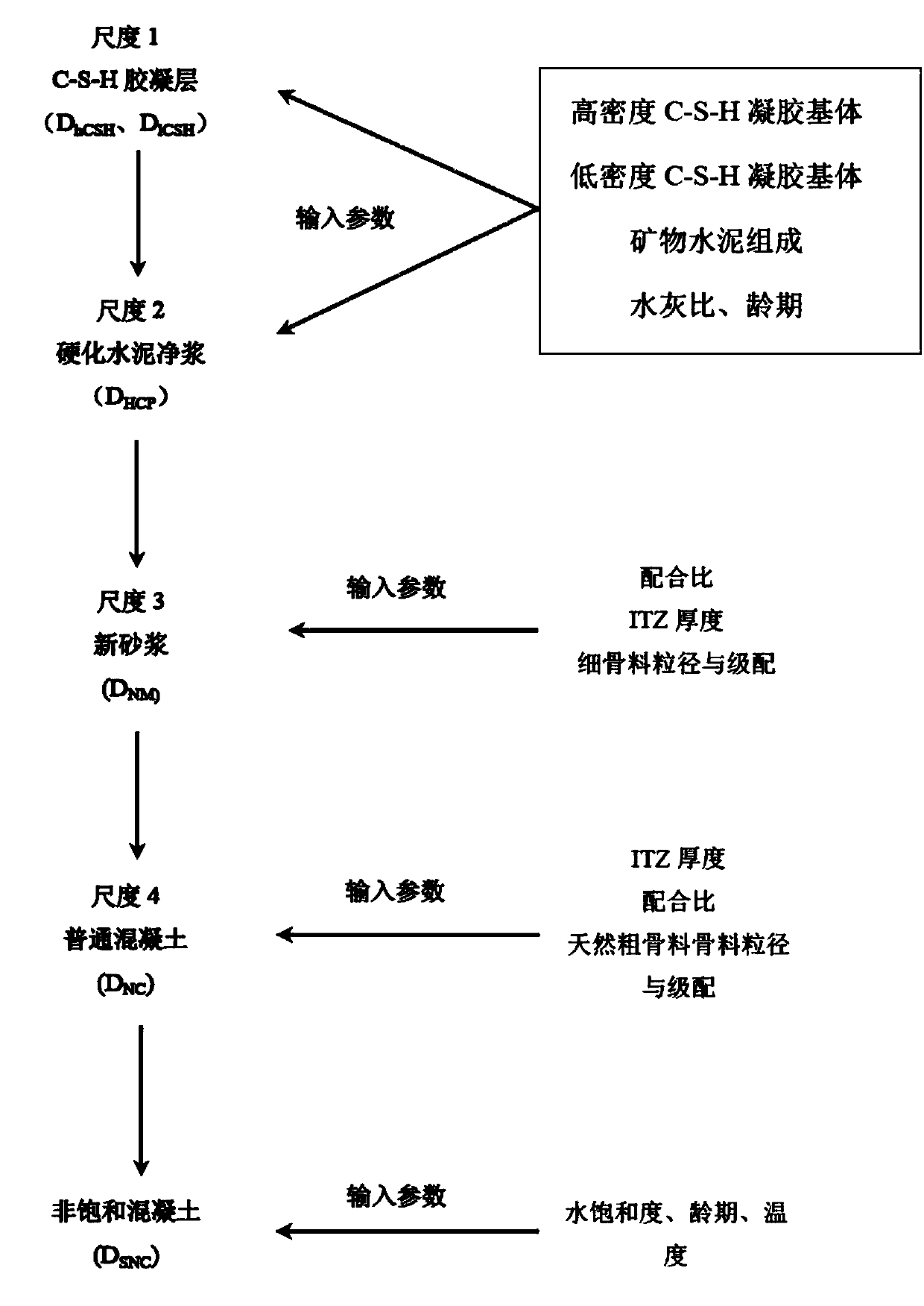

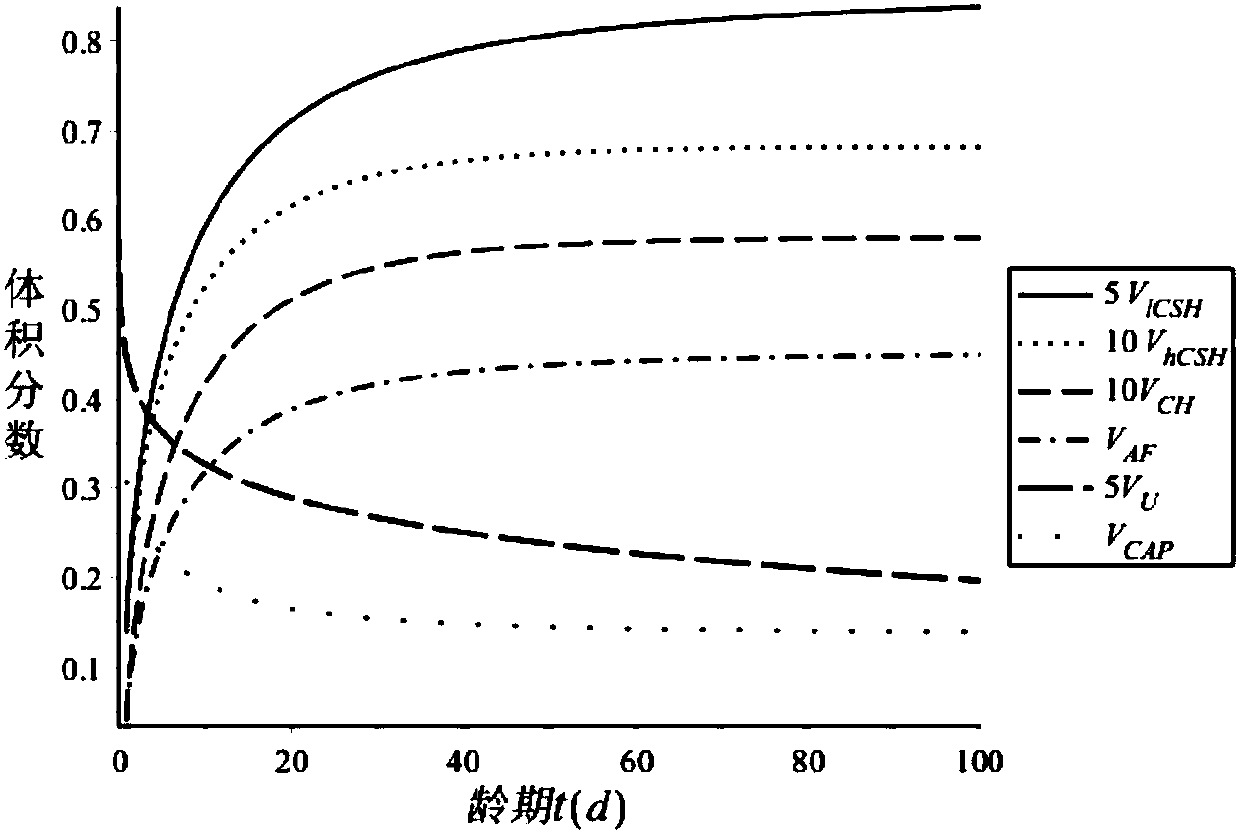

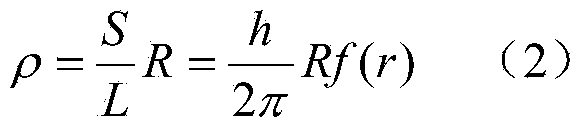

Construction method of multiscale prediction model for chloride ion diffusion coefficient of unsaturated concrete

ActiveCN108333082AEasy to analyzeConvenient researchSurface/boundary effectDiffusionChloride penetration

The invention discloses a construction method of a multiscale prediction model for a chloride ion diffusion coefficient of unsaturated concrete. Concrete is regarded as a cement based composite material formed by different scales of materials, prediction models for chloride ion diffusion coefficients of different scales of cement based materials are constructed sequentially by starting from small-scale hard cement paste to large-scale concrete gradually, and finally, by considering the influence of saturation degree of internal water of the concrete on chloride ion diffusion, the multiscale prediction model for the chloride ion diffusion coefficient of the unsaturated concrete is constructed finally. By considering the influence of the saturation degree of internal water of the concrete onchloride ion diffusion, the chloride ion diffusion coefficient of the unsaturated concrete can be predicted more scientifically, more reasonably and more accurately with the method, and the method has great significance in chloride penetration resistance research and durability design of the concrete under unsaturated conditions.

Owner:GUANGXI UNIV

Preparation technology of high-elastic modulus fiber self-stress recycled concrete

PendingCN109369121AOvercome mechanical propertiesReduced mechanical propertiesGlass fiberSuperplasticizer

The invention discloses a preparation technology of high-elastic modulus fiber self-stress recycled concrete. The high-elastic modulus fiber self-stress recycled concrete is prepared from the following components: recycled coarse aggregate, natural coarse aggregate, natural fine aggregate, cement, a superplasticizer, mixed water, fiber, mineral powder, silica fume and rubber particles, wherein thefiber adopts one of high-elastic modulus fiber such as steel fiber, carbon fiber, basalt fiber and fiberglass. According to the preparation technology disclosed by the invention, expansion of internal microdefects of recycled concrete can be relieved by utilizing the high-elastic modulus fiber, and the bending strength, the tensile strength and the toughness of the recycled concrete can be increased; meanwhile, the fiber per se has higher elastic modulus, so that the elastic modulus of the recycled concrete and the rigidity of components can be increased; the strength of the concrete can be increased by utilizing the mineral powder and the silica fume, and creep of the concrete can be reduced; the ductility of the concrete can be increased by utilizing the rubber particles, chloride penetration resistance and the freezing resistance of the recycled concrete can be improved, and the durability of the recycled concrete can be enhanced.

Owner:WUHAN UNIV

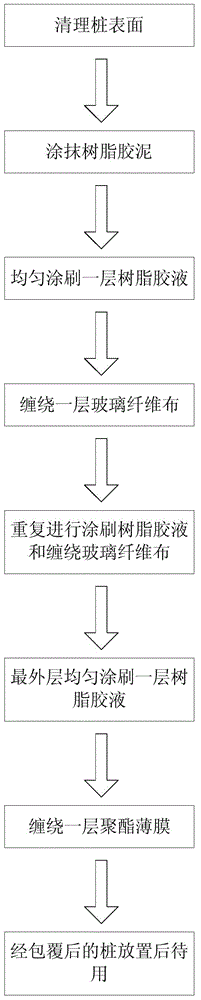

Prestressed reinforced concrete pile foundation anticorrosive material for oceaneering and its construction method

ActiveCN104878743AHigh mechanical strengthLess susceptible to stress crackingProtective foundationBulkheads/pilesGlass fiberReinforced concrete

The invention provides a prestressed reinforced concrete pile foundation anticorrosive material for oceaneering, comprising, by weight, 40% to 60% of resin, 0.3% to 1% of pigment, 1% to 3% of thixotropic agent, 0.3% to 0.7% of ultraviolet absorption agent, 1% to 2.5% of initiator, 0.1% to 1.5% of accelerant and 35% to 55% of glass fiber cloth. The invention further provides a construction method of the prestressed reinforced concrete pile foundation anticorrosive material for oceaneering. The anticorrosive material has the advantages that the construction is convenient, the required thickness of oceaneering pile foundation anticorrosive coating can be achieved only by one-time construction, the construction period is short, and environmental friendliness is allowed; the strength of bonding with the surface of a pile foundation is high, peeling rarely occurs, the corrosion resistance is excellent, the durability is high, and the requirement that chloride penetration resistance of the pile foundation in marine environment lasts for 50 years can be ensured.

Owner:CCCC SHANGHAI THIRD HARBOR SCI RES INST CO LTD +1

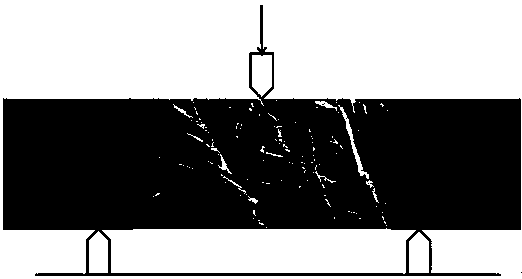

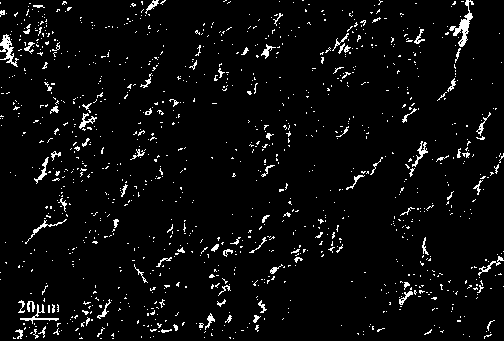

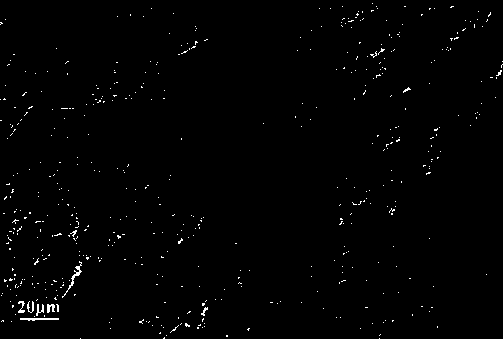

Composite modified concrete and testing method of interfacial transition zone of composite modified concrete

ActiveCN108609952AHigh activityMake up for the lack of early activitySolid waste managementMaterial strength using tensile/compressive forcesMechanical propertyMaterials science

The invention discloses a testing method of an interfacial transition zone of composite modified concrete, and relates to the field of building materials. The composite modified concrete is characterized by comprising the raw materials in parts by weight: 100 parts of cement, 240 to 260 parts of pebbles, 150 to 170 parts of sands, 35 to 45 parts of water, 20 to 30 parts of fly ash, 3 to 12 parts of silicon ash, 0.5 to 2 parts of nanometer materials, and 0.5 to 1.5 parts of a high-effect water reducing agent. According to the method, calcium hydroxide enriched in the interfacial transition zoneof composite modified concrete is properly absorbed through synergism of the nanometer materials and the silicon ash with grain composition and pozzolanic activity, so that C-S-H gel with better adhesive property is produced; in addition, gaps in the interfacial transition zone are properly filled with optimized grain composition, so that the interfacial transition zone of composite modified concrete is effectively improved. Cases prove that the method can effectively improve the bonding strength of the interfacial transition zone and ensure that the interfacial transition zone is dense, thereby improving the mechanical property and chloride penetration resistance property of the concrete.

Owner:UNIV OF JINAN

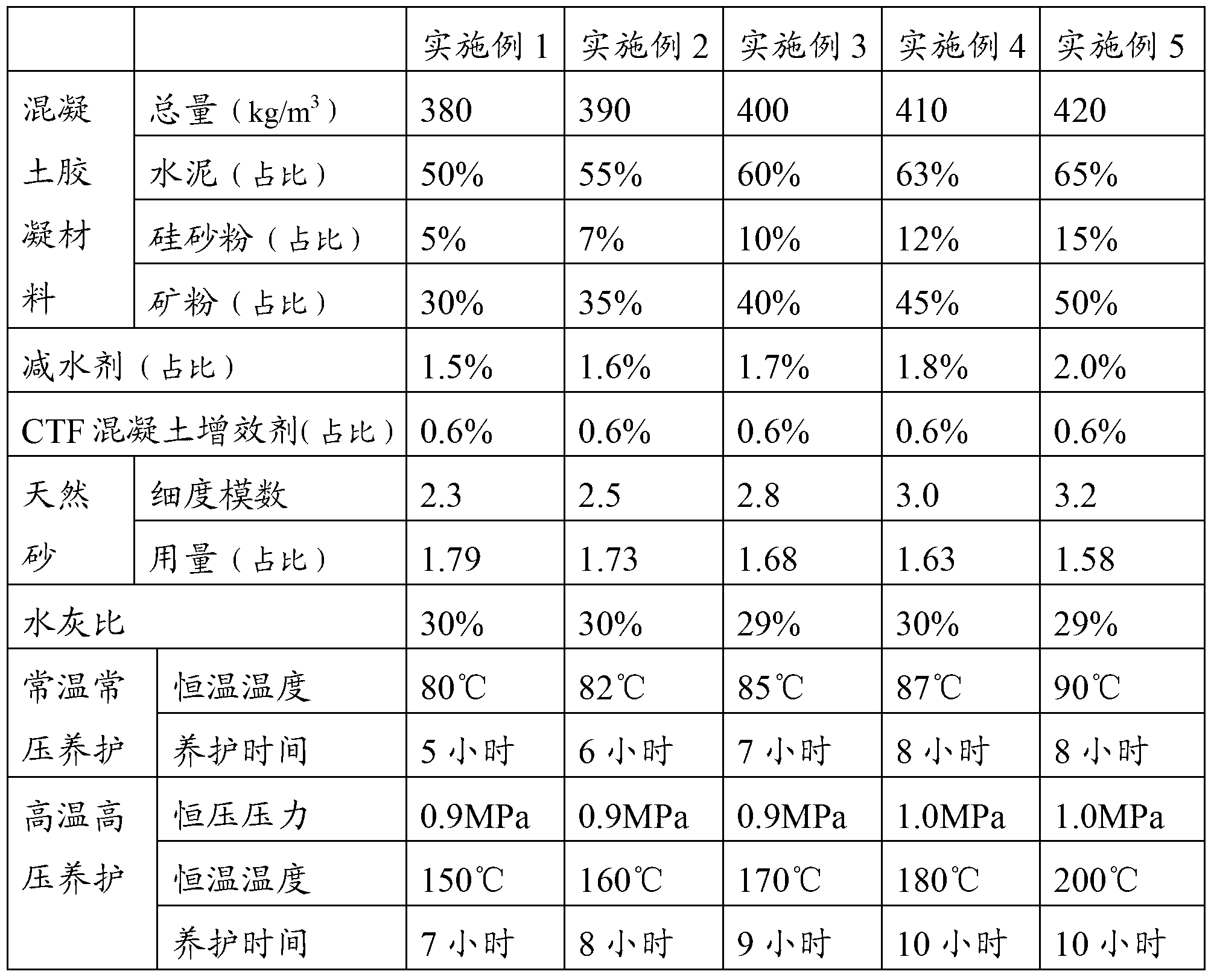

Method for producing precast concrete component

ActiveCN103304188AGuaranteed StrengthFully stimulate the activityCeramic shaping apparatusFineness modulusSilicon dioxide

The invention provides a method for producing a precast concrete component, wherein the following raw materials are utilized by weight: 380-420 kg / m<3> of concrete cementing material, a water reducer, a CTF concrete synergist, and natural sand, wherein the concrete cementing material comprises 50-65% of cement content, 5-15% of silica flour content and 30-50% of mineral powder; the cement is cement with a grade above PII42.5 R; the content of silicon dioxide in the silica flour is greater than or equal to 90%; the content of the water reducer is 1.5-2.0% of the dosage of the concrete cementing material; the water reducer is a naphthalene or polycarboxylic acid water reducer; the content of the CTF concrete synergist is 0.6% of the dosage of the concrete cementing material; the silt content of the natural sand is less than 1.0%, and the fineness modulus of the natural sand is in the range from 2.5 to 3.0; and a water cement ratio is less than 30%. The method provided by the invention is characterized in that a certain quantity of CTF concrete synergist and concrete admixture are blended, so that the properties of the concrete such as chloride penetration resistance, sulphate attack and the like also can be improved while the strength of the concrete is up to the standard; therefore, the precast concrete component can be applied to medium or above corrosive geological conditions.

Owner:FUJIAN JIANHUA CONSTR MATERIALS CO LTD

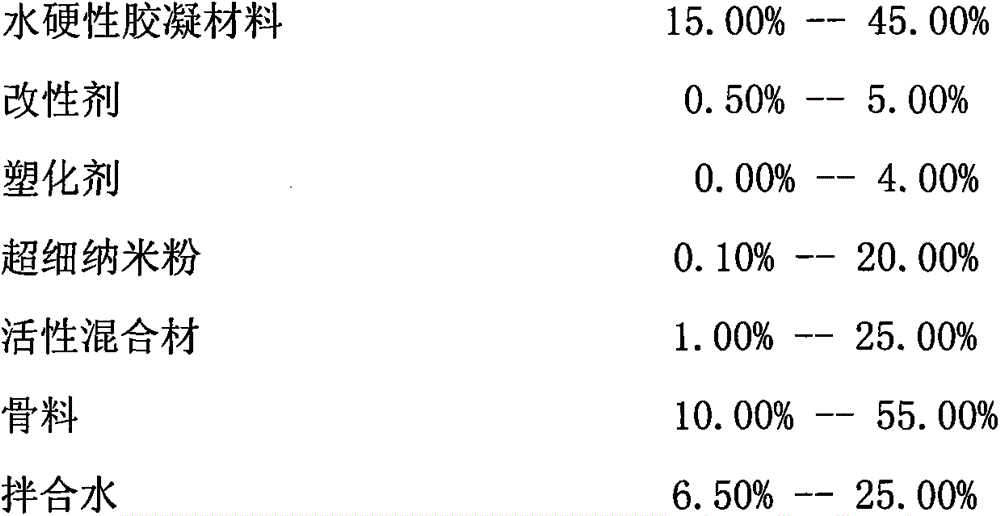

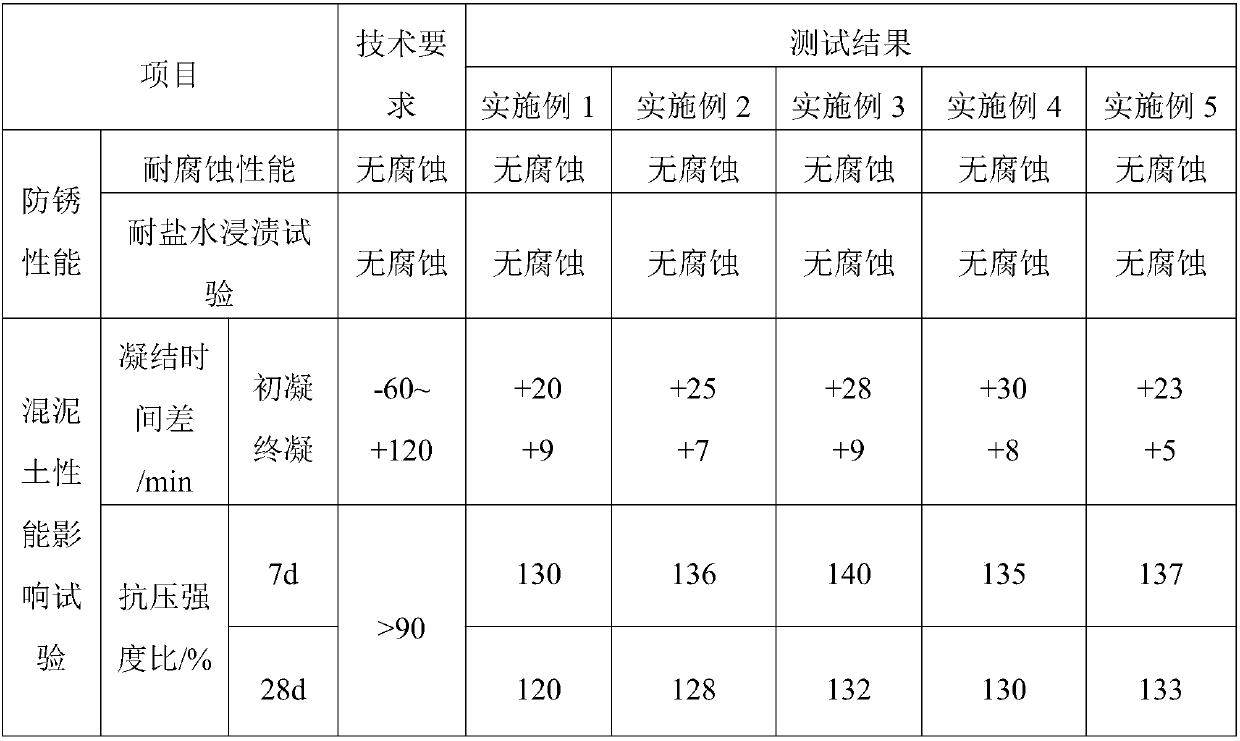

Preparation method of inorganic anti-corrosive paint for steel bar

The invention belongs to the technical field of building materials and particularly relates to an inorganic anti-corrosive paint for a steel bar. The inorganic anti-corrosive paint is prepared from a hydraulic cementing material, a modifying agent, a plasticizer, superfine nanometer powder, an active composite material, aggregates and mixing water at a certain ratio. The inorganic anti-corrosive paint prepared by the method disclosed by the invention is quite good in workability; the surface of the steel bar has a quite good adhesive force and is unlikely to sag after being mechanically sprayed with the inorganic anti-corrosive paint; the paint can be rapidly coagulated; the paint formed after solidification is compact in structure, 30 to 70 MPa in compressive strength in one day, 60-150 MPa in compressive strength in 28 days and 100-1000 coulombs in electric flux, so the paint is quite good in chloride penetration resistance. Besides, the paint and concrete have quite good compatibility and quite high bonding strength which is 1.0-2.0 MPa in 28 days. By adopting mechanical operation, the inorganic anti-corrosive paint for the steel bar, disclosed by the invention, can be used for rapidly performing a large-area anti-corrosive treatment on the steel bar at a construction site and is especially applicable to the anti-corrosive treatment of the steel bar in marine concrete. The preparation method disclosed by the invention is simple, convenient and wide in application.

Owner:汪峻峰

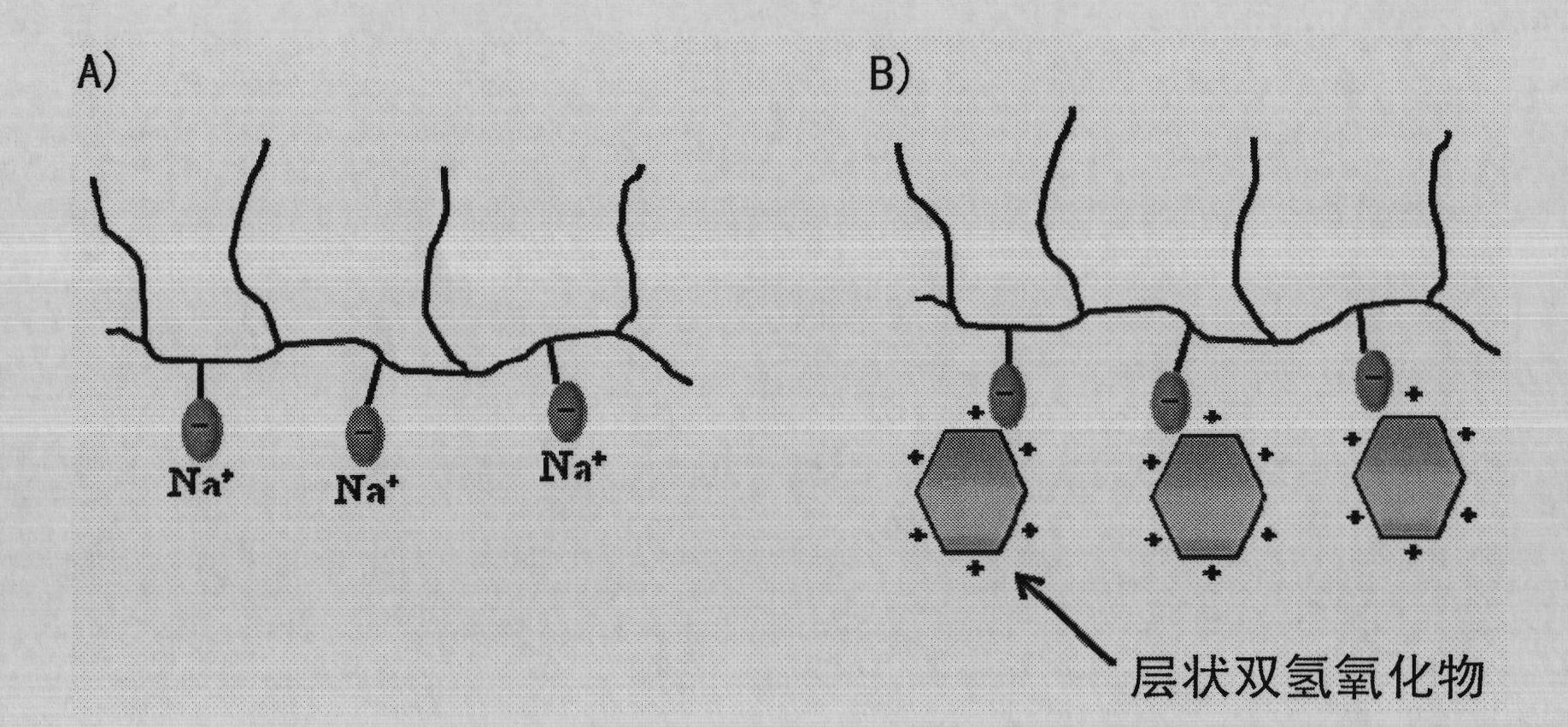

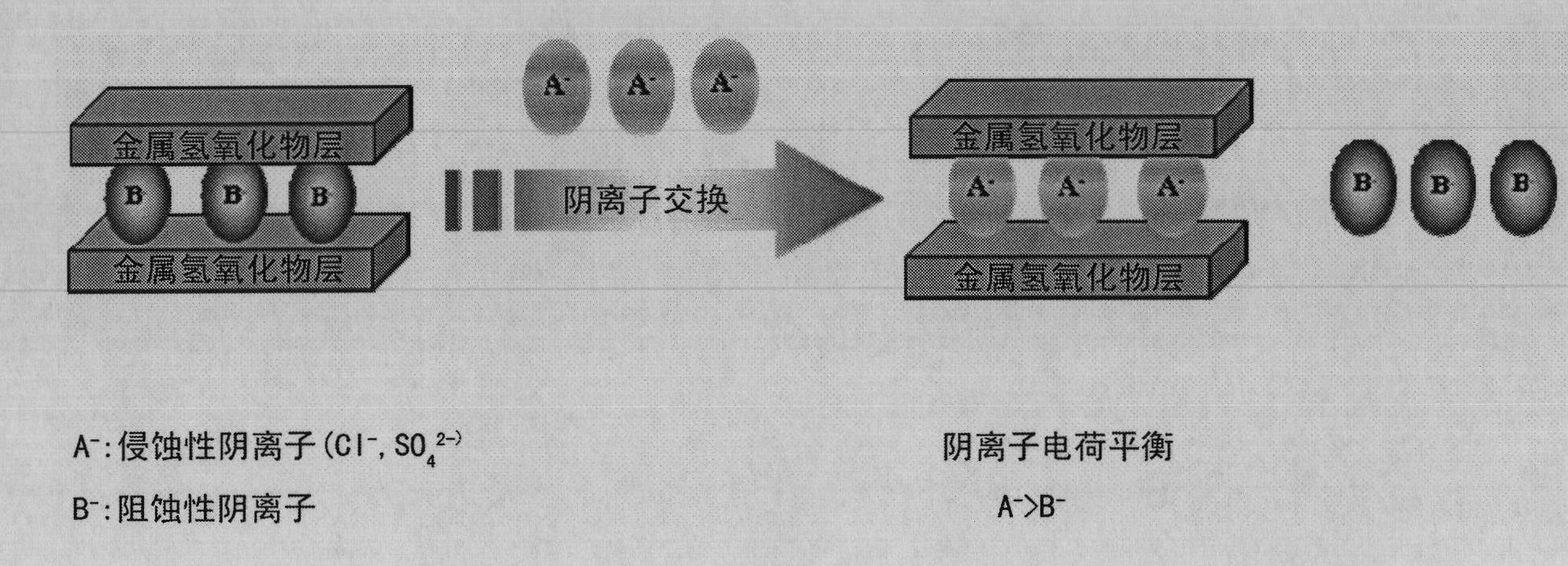

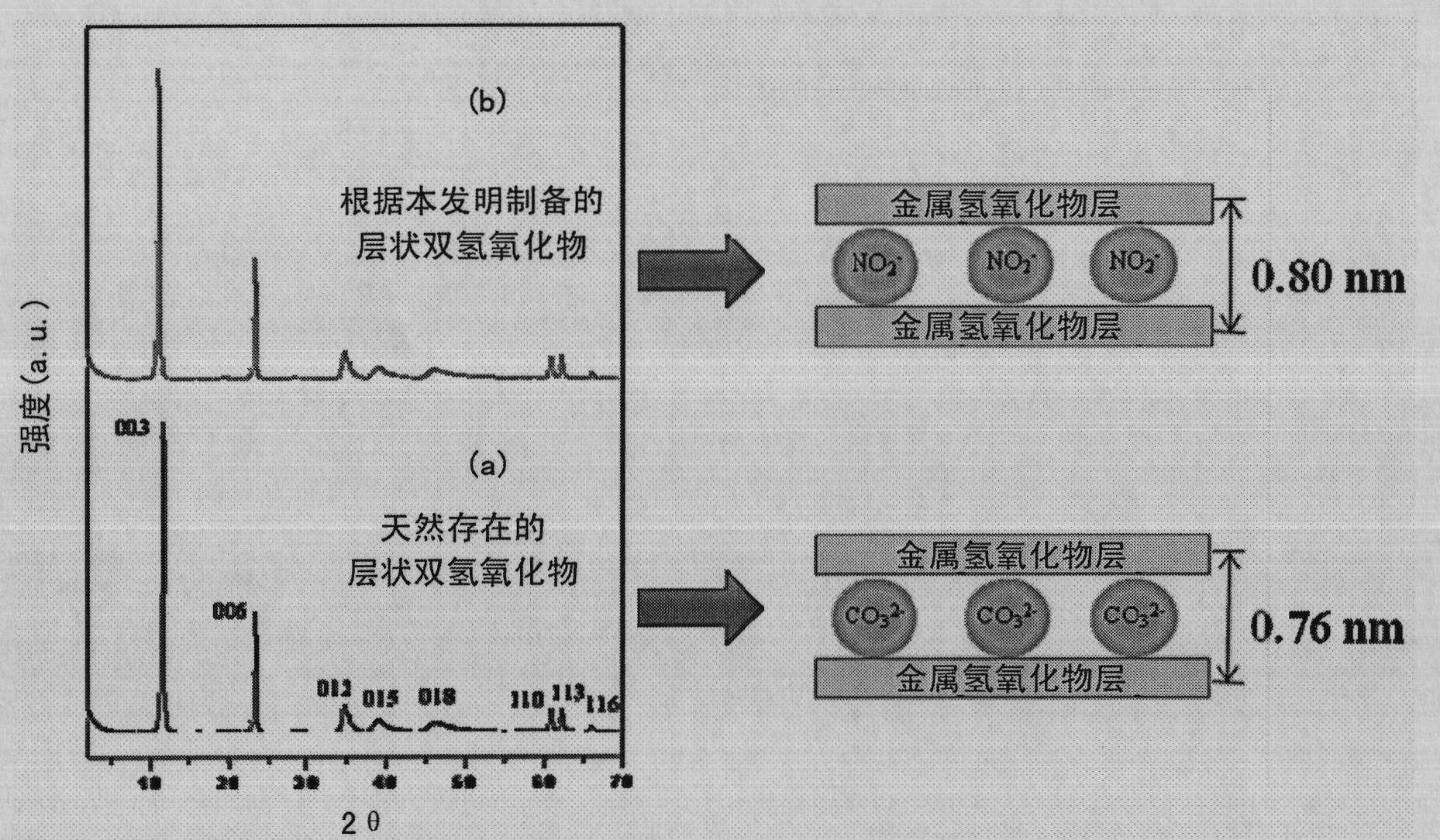

Nano-hybrid concrete chemical admixture for chloride invasion resistance consisting of layered double hydroxide/polyurethane copolymer

The present invention relates to a chloride penetration resistant nano-hybrid concrete chemical admixture comprising layered double hydroxide and polyurethane copolymer. More specifically, nano-hybrid concrete chemical admixture obtained by combining the two compounds at a nano-scale, the layered double hydroxide which exhibits resistance to chloride penetration, and polyurethane copolymer which entails an excellent water reducing ability, durability and workability. In addition, the inorganic / organic hybrid material described herein exhibits high water reducing ability, improved resistance to chloride penetration, and thus can be used as chloride penetration resistant concrete chemical admixture for marine concretes.

Owner:SILKROAD C&T

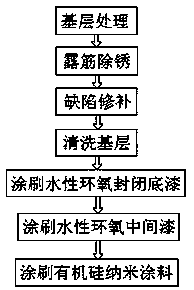

Expressway bridge concrete structure crash barrier nanometer coating method

InactiveCN108035247AMeet permeabilityCorrosiveBridge structural detailsBridge erection/assemblyEpoxySnow melting

The invention provides an expressway bridge concrete structure crash barrier nanometer coating method. The method includes the steps that a concrete crash barrier is treated, a concrete base layer isexposed, and broom-finish treatment is conducted; rust on rusted reinforcing steel bars is removed; two aqueous epoxy seal primers are prepared; one seal primer is painted on the defective inner surface on the concrete base layer, and the other seal primer is painted on the defective inner surface; the primers are air-dried, and a defect is filled and repaired through two types of aqueous epoxy mortar sequentially, polished and washed; the repaired crash barrier concrete surface is coated with the seal primers in a rolling mode; an aqueous epoxy intermediate coat is prepared; a completely-cured sealed layer is coated with the aqueous epoxy intermediate coat, so that an intermediate layer is obtained; silicone nanometer anticorrosive paint is prepared; and the completely-cured intermediatelayer is coated with the silicone nanometer anticorrosive paint, conventional curing is carried out until a nanometer anticorrosive layer is completely cured, and the crash barrier is coated. By the adoption of the coating method, the requirements for carbonization resistance, chloride penetration resistance, sulfate ion erosion resistance, snow melt salt corrosion resistance, scrubbing resistanceand the like of the concrete crash barrier can be fully met.

Owner:甘肃众鼎工程科技有限公司

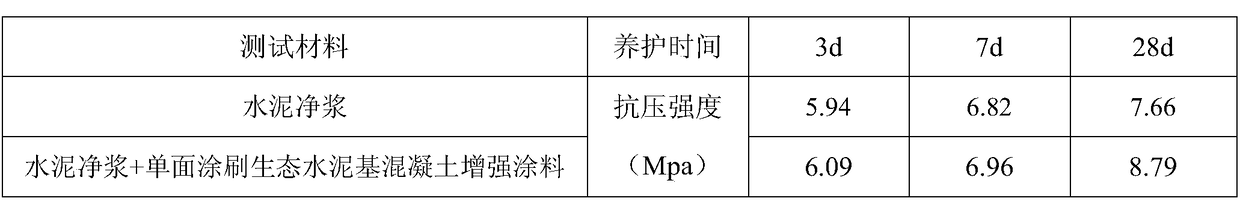

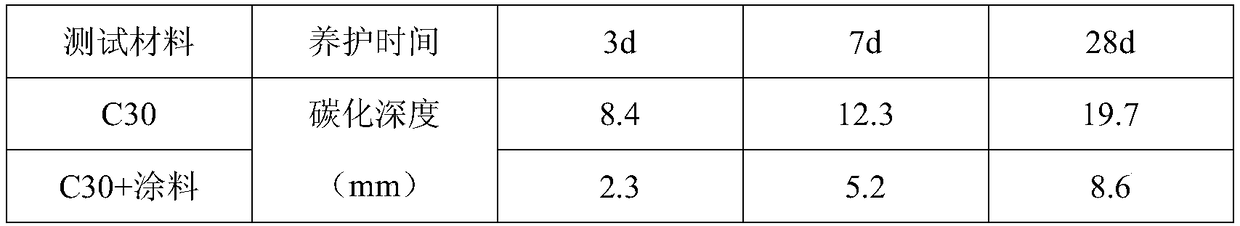

Ecological cement-based concrete reinforcing coating and preparation method thereof

The invention discloses ecological cement-based concrete reinforcing coating and a preparation method thereof. The coating is prepared by mixing a solid-phase component and a liquid-phase component, wherein the solid-phase component comprises, by weight percentage, 35-40% of cement, 5-10% of silica fume, 15-20% of fly ash and 10-15% of limestone flour; the liquid-phase component comprises, by weight percentage, 20-25% of water, 1-5% of water reducing agent and 1-5% of defoaming agent, and the weight percentage sum of the components above is 100%. The cement-based concrete reinforcing coating has the advantages that the cement-based concrete reinforcing coating is simple and environment-friendly in components and harmless to human bodies and environments, the silica fume and the fly ash inthe powder materials are recycled industrial waste, the raw materials are simple, easy to obtain and low in cost, waste recycling has sustainable development significance, and the cement-based concrete reinforcing coating has a quite good crack repairing effect, can effectively improve concrete surface attractiveness and visual effect and can effectively increase concrete structure surface strength, carbonization resistance, water penetration resistance and chloride penetration resistance.

Owner:HOHAI UNIV

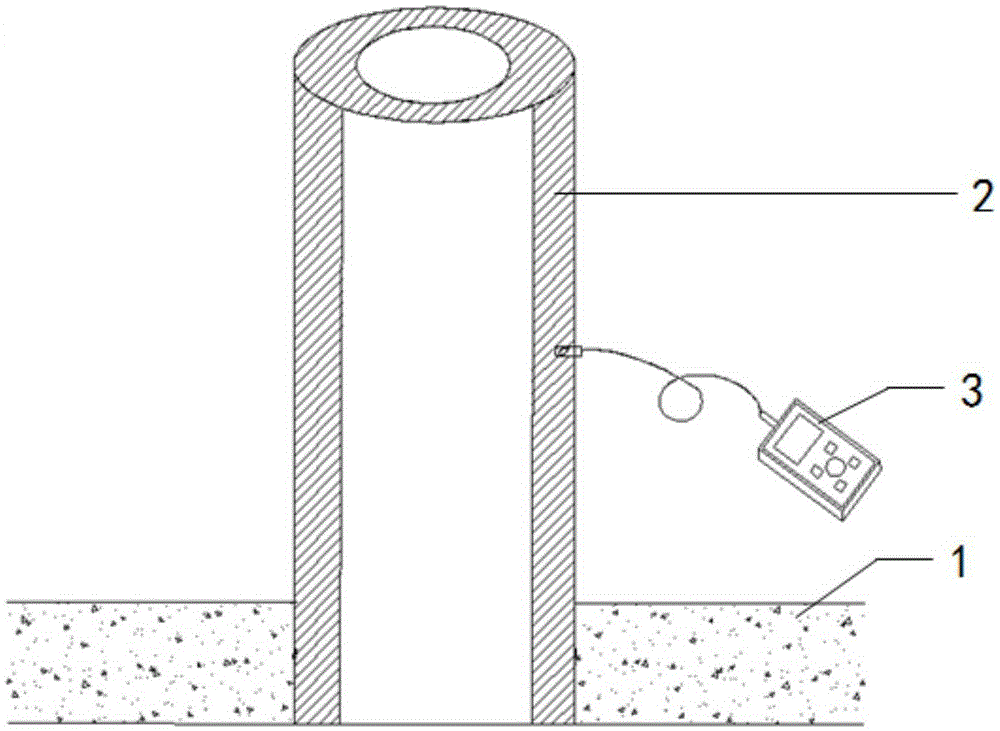

Concrete rust protection and reinforcement device and method based on electroosmosis technology

ActiveCN109944458APrevent penetrationPrevent steel corrosionBuilding repairsBuilding insulationsElectrochemical responseReinforced concrete

The invention discloses a concrete rust protection and reinforcement device and method based on an electroosmosis technology. Nano-silica and methyl sodium silicate are injected into reinforced concrete with an electrochemical reaction technology, the nano-silica penetrates through the concrete sample and forms a protective layer, and chlorine ion penetration is effectively prevented. The injectednano-silica can affect an inner pore system and its densification, and then the protective layer for preventing chloride penetration is formed.

Owner:CHINA UNIV OF MINING & TECH

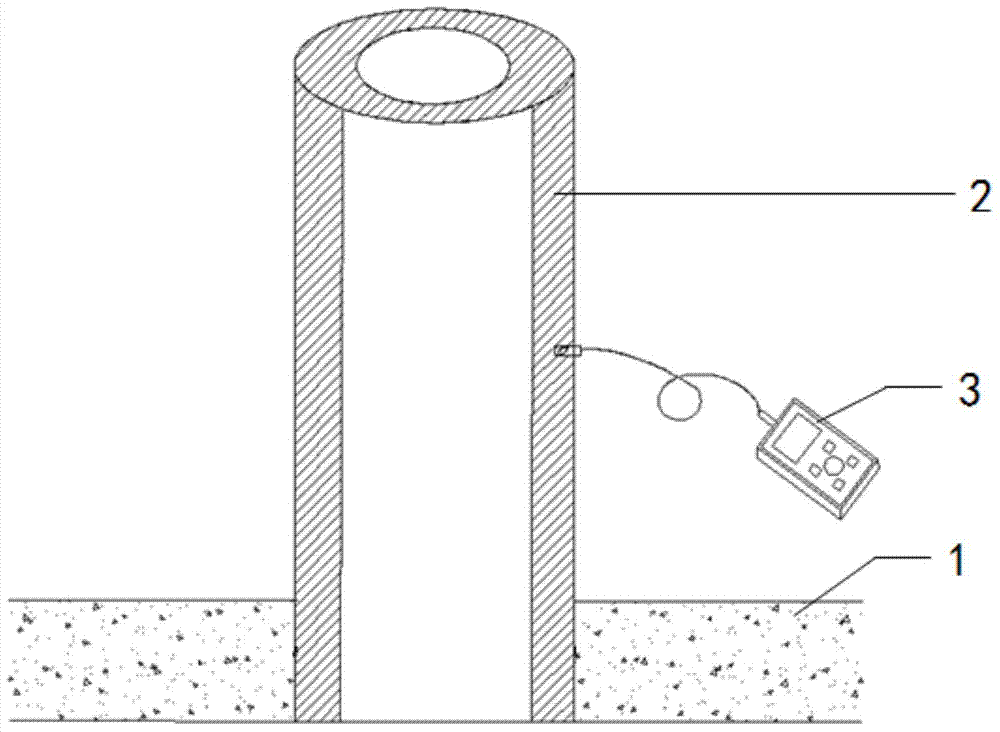

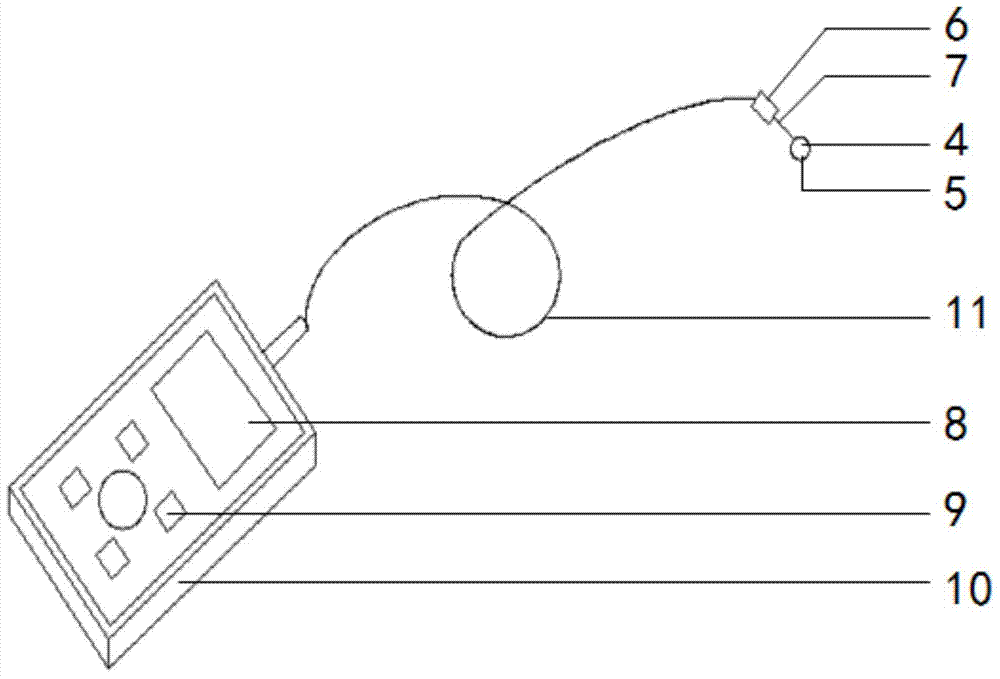

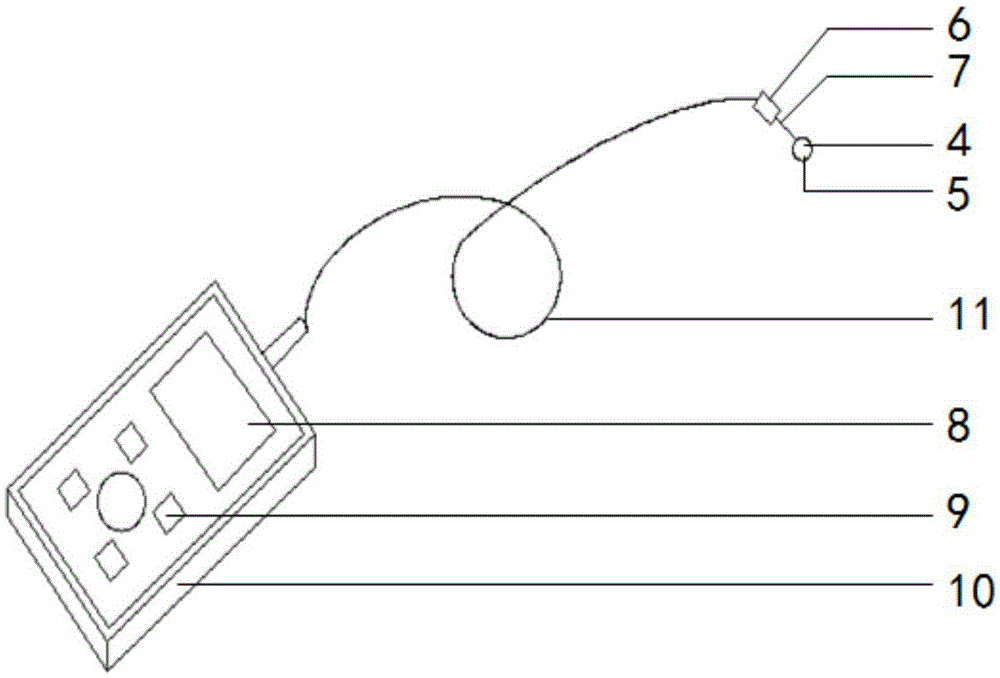

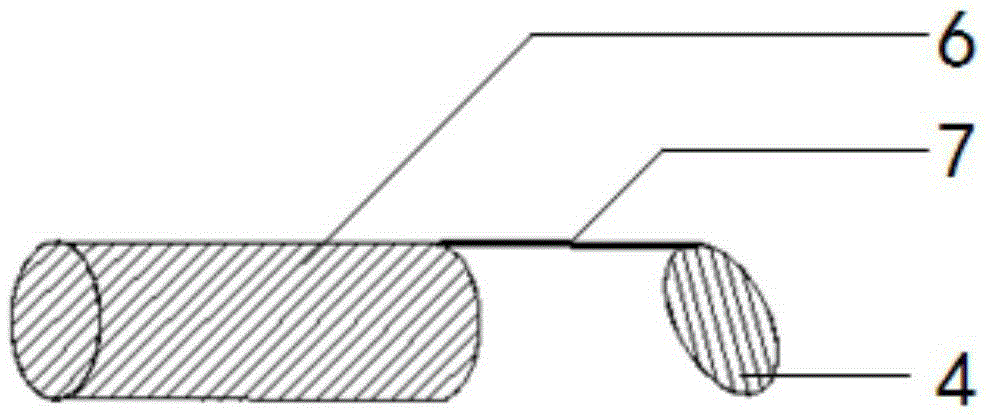

Instrument and method for detecting depths of concrete carbonation and chloride penetration of pole on service

ActiveCN103616382ADamage minimizationClear border of discolorationMaterial analysis by optical meansUsing optical meansReinforced concreteChloride penetration

The invention discloses an instrument and a method for detecting depths of concrete carbonation and chloride penetration of a pole on service. The instrument comprises an imaging device, a camera device and an operating device, wherein the imaging device comprises a convex lens and a bracket fixedly arranged on the convex lens, the camera device comprises a camera and LEDs (Light Emitting Diode), and the operating device comprises a controller, a display screen and a keyboard. The convex lens is fixedly arranged on the bracket which is connected with the camera device through a stainless steel rod, the camera is located in the circumferential center on one side of the camera device, and the LEDs are circumferentially and uniformly distributed around the camera. The camera device is connected with the controller through a video line, the controller is arranged in a shell, and the display screen and the keyboard are arranged on the surface of the shell and are connected with the controller. The method disclosed by the invention overcomes limitation on existing detection methods of depths of concrete carbonation and chloride penetration of the pole on service, protects continuous capacity of the pole on service, and is suitable for particularity of field detection.

Owner:STATE GRID CORP OF CHINA +1

Basement epoxy resin coated steel bar binding method in corrosive environment

InactiveCN108868153AScientific and reasonable constructionIntegrity guaranteedBuilding material handlingEpoxyBasement

Provided is a basement epoxy resin coated steel bar binding method in corrosive environment. The corrosive environment comprises a chemical corrosion environment, a hot wet corrosion environment, anda chloride permeation corrosion environment. The method is characterized by comprising the following steps: a, drawing out position lines of basement epoxy resin coated steel bars; b, transporting theepoxy resin coated steel bar to application positions; c. binding the base plate epoxy resin coated steel bar and the foundation beam epoxy resin coated steel bar; d, binding wall epoxy resin coatedsteel bars. The basement epoxy resin coated steel bar binding method in corrosive environment is scientific and ensures the integrity of the epoxy resin coating on the steel surface, and the effectivesteel banding measures can better exert the anti-corrosion and anti-rust function of the epoxy resin coated steel bar and solve the problem of high damage rate of the epoxy coated steel bar construction.

Owner:MCC5 GROUP CORP SHANGHAI

Low-permeability cement-based grouting material suitable for chloride ions

The invention discloses a low-permeability cement-based grouting material suitable for chloride ions. The low-permeability cement-based grouting material is prepared from the following raw materials by percentages: 39.7-40.7% of 42.5R ordinary portland cement, 39.7-40.7% of river sand, 3.2-3.3% of fly ashes, 2% of silica fume, 0.28% of a water reducing agent, 0.04% of a retarder, 3.18-3.28% of an expanding agent and 9.7-11.9% of water. According to the cement-based grouting material, admixtures such as the river sand, the fly ashes and the silica fume are optimized and combined on the basis of the ordinary portland cement, and supplemented by additives such as the water reducing agent, the retarder and the expanding agent, so that the cement-based grouting material has the advantages of high early strength, high long-term strength, good workability, micro-expansion and no bleeding through a reasonable water-cement ratio, and also has the characteristics of low total chloride ion content, a low electric flux value and high chloride penetration resistance.

Owner:NANTONG VOCATIONAL COLLEGE

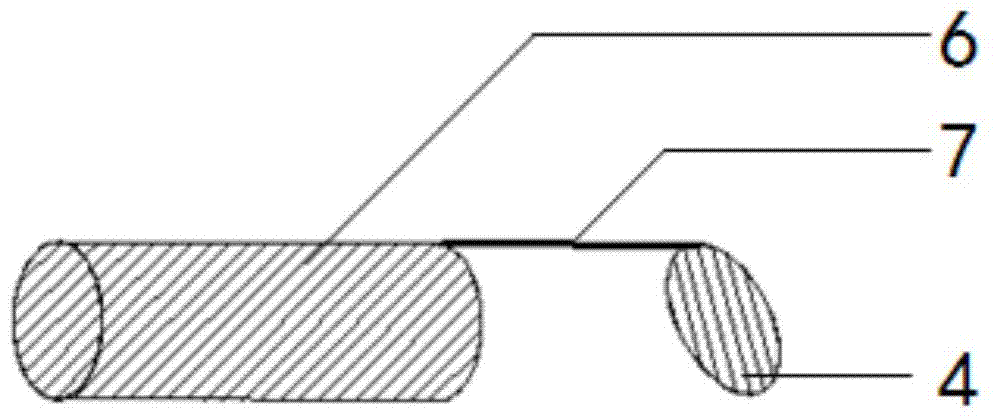

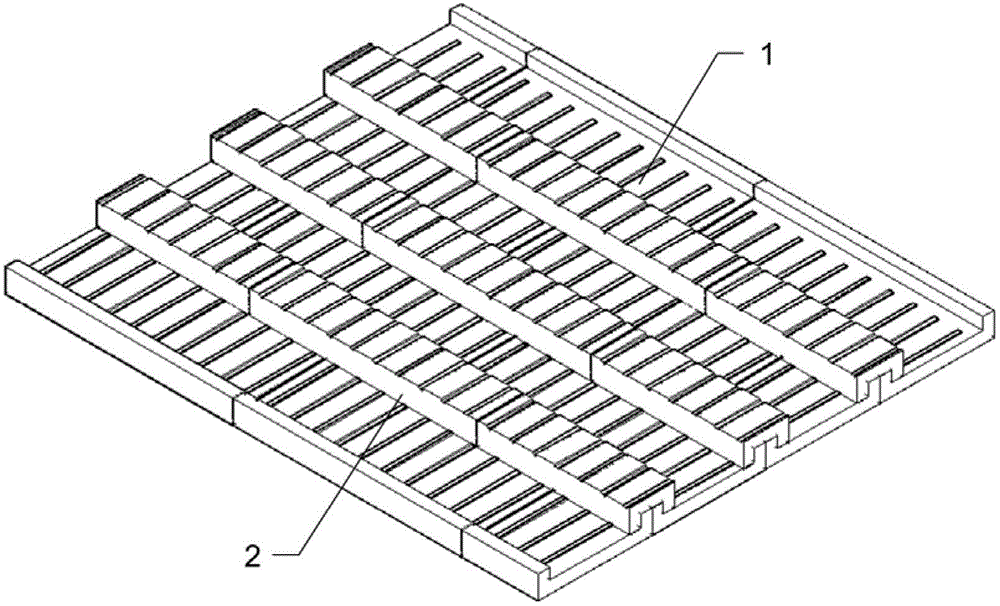

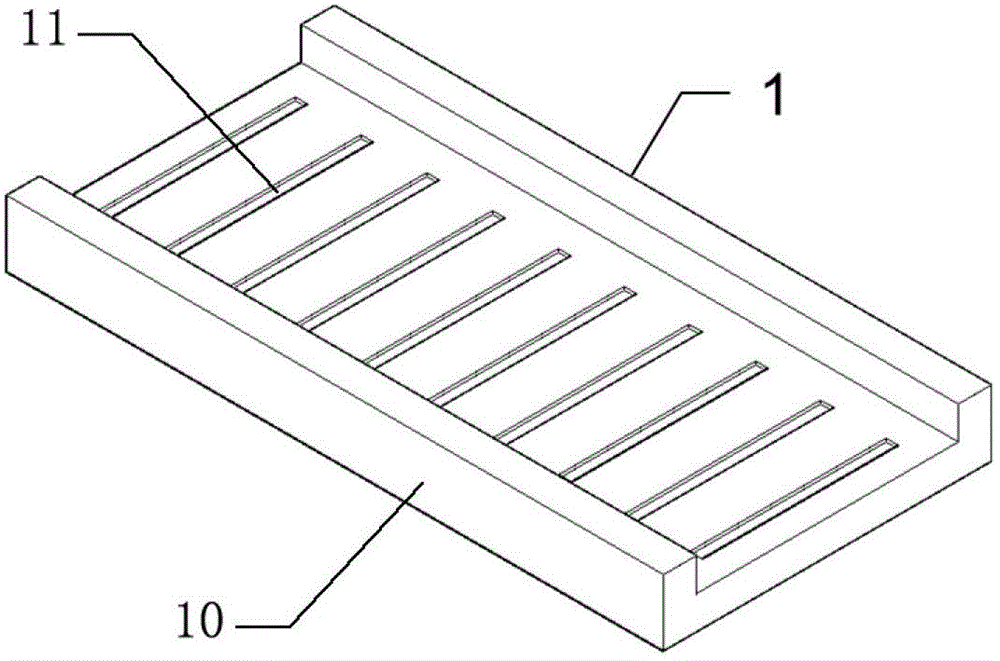

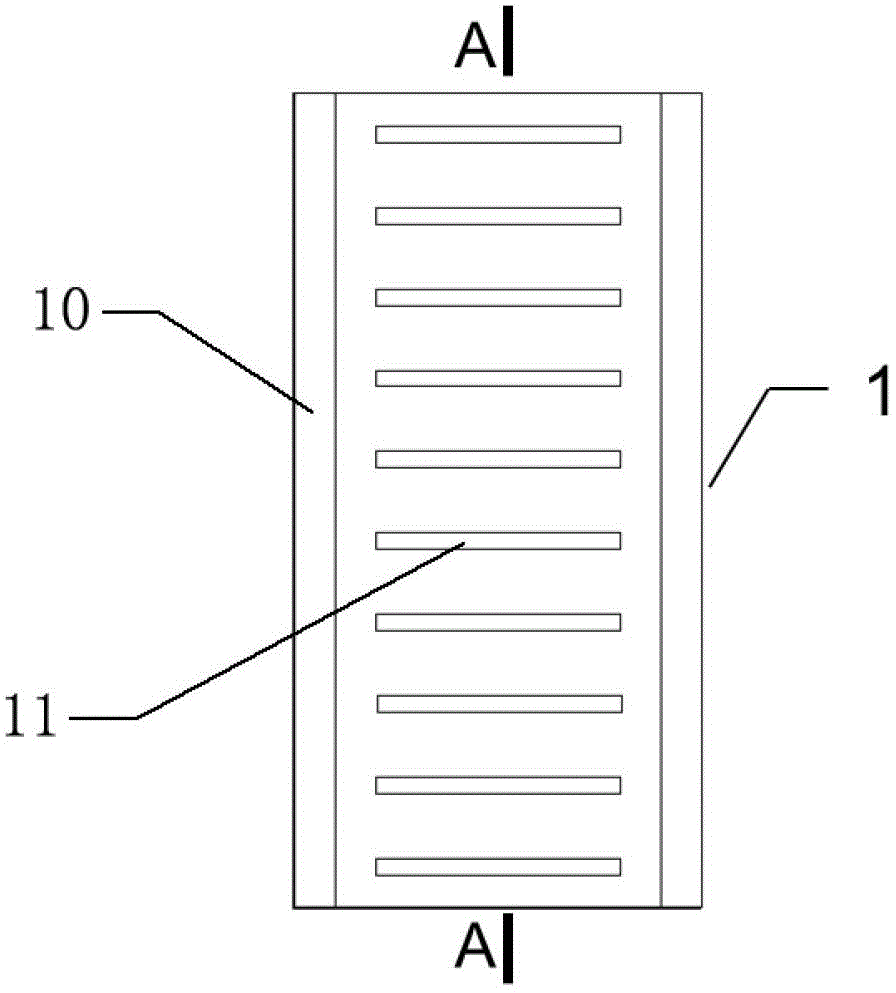

Unidirectional keel embedded assembled anti-cracking impermeable permanent formwork

ActiveCN102720158AImprove and resolve disassemblyImprove and address utilizationGround-workHydraulic engineering apparatusAbsorption capacityKeel

The invention provides a unidirectional keel embedded assembled anti-cracking impermeable permanent formwork. The formwork consists of panels and a connecting piece, wherein the transversal surfaces of the panels and the connecting piece are of concave shapes; the connecting piece is fastened with left and right adjacent panels; and the panels and the connecting piece are manufactured by the following materials: ultrahigh toughness cement-base composite materials (UHTCC), nonmetallic fiber mesh grid and short fiber combined reinforced cement-base composite materials, and steel mesh and short fiber combined reinforced cement-base composite materials. After serving as the formwork at the casting stage, the unidirectional keel embedded assembled anti-cracking impermeable permanent formwork is not removed, but serves as a structural protective plate and an outer protective layer and becomes a permanent formwork, and the engineering cost and the construction strength are reduced. The formwork has the characteristics of high tensile ductility and crack control capacity, high damage tolerance, high energy absorption capacity and the like, and the chloride penetration resistance and water penetration resistance of the formwork are higher than those of the common concrete. By adopting the structure of the panels and the connecting piece, the formwork has the characteristics of convenience in manufacturing and use and the capacity of controlling crack developing.

Owner:ZHEJIANG UNIV

Preparation method of light-weight aggregate concrete

The invention provides a preparation method of light-weight aggregate concrete. The preparation method comprises the following steps: mixing water, cement, sand, plastic-steel fiber, a lightweight aggregate and a water reducer in proportion according to design strength grade specifications, and blending a single mineral admixture in a preset proportion or blending a compound admixture in a presetproportion so as to obtain the light-weight aggregate concrete. Through the technical scheme, the chlorine ion diffusion parameter of the light-weight aggregate concrete with the plastic-steel fiber is effectively reduced, and the chloride penetration resistance of the light-weight aggregate concrete with the plastic-steel fiber is improved.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

An anti-erosion aluminophosphate cement-based gel material suitable for marine engineering

The invention discloses anti-erosion phosphoaluminate cement based cementing material applicable to ocean engineering. The anti-erosion phosphoaluminate cement based cementing material consists of 60-75% of an iron-rich phosphoaluminate cement clinker, 5-15% of coal ash, 3-8% of silicon carbide powder, 2-6% of rubber powder, 3-6% of an anti-alkali glass fiber and 0.5-2% of an aluminum-zirconium coupling agent. By virtue of properties such as early strength, high strength, corrosion prevention, permeation prevention and freezing resistance of iron-rich phosphoaluminate cement, together with materials such as the coal ash, the silicon carbide, the rubber powder, the aluminum-zirconium coupling agent and the anti-alkali glass fiber, the material is good in flashing resistance and abrasion resistance, the properties of a high polymer are sufficiently brought into play, and the chloride penetration resistance and the abrasion resistance of the structure are improved.

Owner:UNIV OF JINAN

Apparatus and method for detecting concrete carbonation and chloride ion penetration depth of electric poles in service

ActiveCN103616382BDamage minimizationClear border of discolorationMaterial analysis by optical meansUsing optical meansReinforced concreteChloride penetration

The invention discloses an instrument and a method for detecting depths of concrete carbonation and chloride penetration of a pole on service. The instrument comprises an imaging device, a camera device and an operating device, wherein the imaging device comprises a convex lens and a bracket fixedly arranged on the convex lens, the camera device comprises a camera and LEDs (Light Emitting Diode), and the operating device comprises a controller, a display screen and a keyboard. The convex lens is fixedly arranged on the bracket which is connected with the camera device through a stainless steel rod, the camera is located in the circumferential center on one side of the camera device, and the LEDs are circumferentially and uniformly distributed around the camera. The camera device is connected with the controller through a video line, the controller is arranged in a shell, and the display screen and the keyboard are arranged on the surface of the shell and are connected with the controller. The method disclosed by the invention overcomes limitation on existing detection methods of depths of concrete carbonation and chloride penetration of the pole on service, protects continuous capacity of the pole on service, and is suitable for particularity of field detection.

Owner:STATE GRID CORP OF CHINA +1

Preparation method of reinforced concrete corrosion inhibitor

The invention provides a preparation method of a reinforced concrete corrosion inhibitor. The preparation method comprises the following steps: mixing 2,4,6-tri(4-carboxyl phenyl)-1,3,5-triazine, 1-(chloromethyl) adamantane and diethyl ether, stirring to react, distilling, conducting suction filtration, washing and drying in vacuum to obtain an ionic liquid, dissolving in deionized water, adding magnesium hydrate, filtering after stirring, distilling at the reduced pressure, and conducting suction filtration to obtain a magnesium salt compound, soaking the magnesium salt compound in an aqueoussolution of sodium monofluorophosphate, stirring, and drying in vacuum to obtain the reinforced concrete corrosion inhibitor. The magnesium ion in the prepared corrosion inhibitor improves the chloride penetration resistance of the concrete; the triazine substance corrosion inhibitor is adsorbed on the surface of a rebar to play a role in inhibiting the corrosion of the rebar; the carboxylate radical and the chloride ion form an adsorption film on the surface of the rebar so as to protect the rebar; and the monofluorophosphate forms a unimolecule protection film on the surface of the rebar, so that the corrosion speed of the rebar is slowed down. In addition, the used materials are nontoxic and harmless, are green, protect the environment, and are environmentally friendly.

Owner:ZHEJIANG DIHENG IND CO LTD

High-strength wear-resisting mortar

High-strength wear-resisting mortar is characterized by being prepared from, by mass, 5.0-10.0% of superfine wear-resisting composite micro-powder (micro-sphere), 0.08-0.10% of steel-plastic fiber, 0.10-0.16% of additive, 1.3-2.7% of polymer gelatine powder, 69-74% of fine aggregate and 13.75% of cement through technological combination.The technological process mainly comprises the steps of material drying, pre-dispersion, fiber dispersion and vacuum sealed storage.The high-strength wear-resisting mortar has the excellent bonding property, cracking resistance, freezing resistance, seepage resistance, corrosion resistance, chloride penetration resistance and aging resistance of polymer cement mortar, and also has ultrahigh strength, scour-grind resistance, cracking resistance and gas etching resistance.

Owner:辽宁省水利水电科学研究院有限责任公司

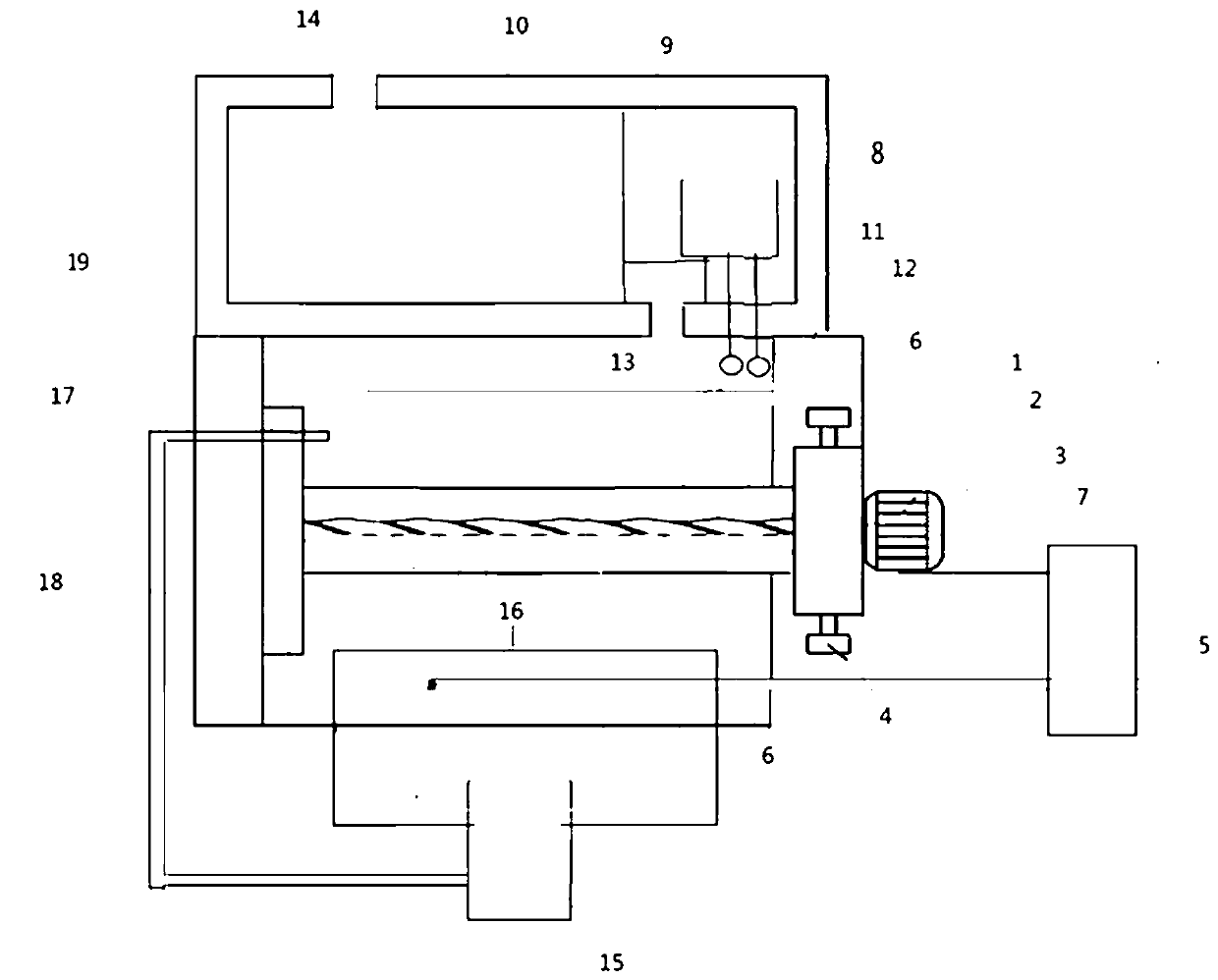

Method for measuring concrete chloride penetration coefficient through electrodeless electrical measuring method

InactiveCN104062220AEliminate measurement errorsAvoid permeability changesPermeability/surface area analysisReinforced concreteChloride penetration

The invention discloses a method for measuring a concrete chloride penetration coefficient through an electrodeless electrical measuring method. The method comprises the steps that hardened concrete with any age is cut into concrete slices; salt saturation treatment is carried out on the vacuum the concrete slices through a sodium chloride solution; the resistivity of the sodium chloride solution and the resistivity of a sodium chloride solution and concrete slice series connection model are respectively tested through an electrodeless resistivity meter, and then the resistivity of the concrete slices is calculated on the basis of a resistivity formula; on the basis of the Nernst-Einstein equation, the penetration coefficient of chloride ions in the concrete slices is calculated. According to the method, the penetration coefficient of the chloride ions in the hardened concrete slices with any age is determined, the problem that the concrete chloride penetration coefficient cannot be accurately measured at present is solved, and the more accurate basis is provided for durability estimation and service life prediction of reinforced concrete.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Strapping method for epoxy-resin-coated column hoops of frame columns under corrosive environments

InactiveCN108868006AScientific and reasonable constructionIntegrity guaranteedBuilding reinforcementsEpoxyStrapping

The invention discloses a strapping method for epoxy-resin-coated column hoops of frame columns under corrosive environments. The corrosive environments include chemical corrosive environments, hot and humid corrosive environments and chloride permeation corrosive environments. The strapping method is characterized by including the following steps of a, strapping the epoxy-resin-coated column hoops of the frame columns; b, alternately arranging hook overlapping portions of the epoxy-resin-coated column hoops along column epoxy-resin-coated vertical ribs, and strapping the hook overlapping portions tightly; c, ensuring that the tip angles and the straight-portion lengths of the epoxy-resin-coated column hoops meet design regulations and requirements. The strapping method for the epoxy-resin-coated column hoops of the frame columns under the corrosive environments has the advantages that reinforcing bars are constructed scientifically and reasonably, completeness of epoxy resin coatingson the surfaces of the reinforcing bars is guaranteed, corrosion and rust resistance of the epoxy-resin-coated reinforcing bars is well developed through effective strapping measures for the reinforcing bars, and the problem of high breakage rate in construction of the epoxy-resin-coated reinforcing bars is solved.

Owner:MCC5 GROUP CORP SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com