Preparation method of reinforced concrete corrosion inhibitor

A technology of reinforced concrete and rust inhibitor, which is applied in the direction of organic chemistry, etc., can solve the problems of environmental pollution, large usage, corrosion of steel bars, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

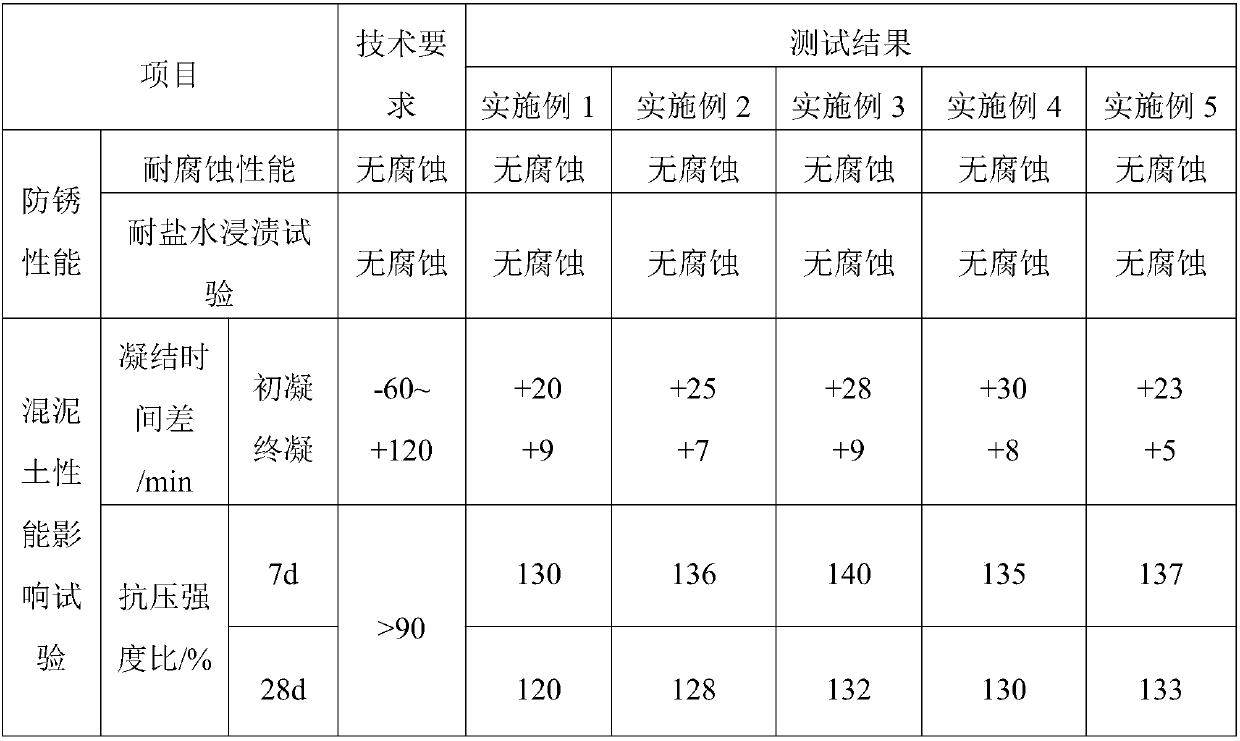

Examples

preparation example Construction

[0019] The invention provides a method for preparing a rust inhibitor for reinforced concrete, comprising the following steps: step a) combining 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine, 1-( Chloromethyl)adamantane and ether are mixed, stirred for reaction, distilled, suction filtered, washed, and vacuum-dried to obtain an ionic liquid; step b) dissolving the ionic liquid in deionized water, adding magnesium hydroxide, and filtering after stirring, The magnesium salt compound is obtained after vacuum distillation and suction filtration; step c) immersing the magnesium salt compound in an aqueous solution of sodium monofluorophosphate, stirring, and vacuum drying to obtain a rust inhibitor for reinforced concrete.

[0020] First, 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine, 1-(chloromethyl)adamantane and ether were mixed and reacted to form an ionic liquid. In step a, the stirring reaction time is preferably 4-8h, more preferably 5-8h. The mass ratio of the 2,4,6-tris(4-carbo...

Embodiment 1

[0032] 1) Preparation of ionic liquid: Weigh 100 g of 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine and 120 g of 1-(chloromethyl)adamantane into a two-necked flask, add Solvent diethyl ether 400g, stirred and reacted at room temperature of 25°C for 4h, immediately after the reaction, distilled under reduced pressure, filtered with suction, the product was washed with acetone and ether for 5 times, and then dried in vacuum at 60°C for 12 hours;

[0033] 2) Preparation of metal magnesium salt: Weigh 50 g of the ionic liquid prepared in step 2) and dissolve it in 200 g of deionized water, then add 10 g of magnesium hydroxide, stir at room temperature for 2 hours, acid-base neutralization reaction occurs, and then By filtering, distillation under reduced pressure, and suction filtration, metal magnesium salt is obtained;

[0034] 3) Ion exchange: Soak the metal magnesium salt prepared in step 3) in a 20% aqueous solution of sodium monofluorophosphate, stir for 40 hours to carry out i...

Embodiment 2

[0036] 1) Preparation of ionic liquid: Weigh 100 g of 2,4,6-tris(4-carboxyphenyl)-1,3,5-triazine and 120 g of 1-(chloromethyl)adamantane into a two-necked flask, add Solvent diethyl ether 500g, stir and react at room temperature of 25°C for 5h, immediately after the reaction, distill under reduced pressure, filter with suction, wash the product with acetone and ether for 6 times, and then dry in vacuum at 60°C for 18 hours;

[0037] 2) Preparation of metal magnesium salt: Weigh 50 g of the ionic liquid prepared in step 2) and dissolve it in 300 g of deionized water, then add 10 g of magnesium hydroxide, stir at room temperature for 2.5 hours, and an acid-base neutralization reaction occurs, Afterwards, by filtering, distillation under reduced pressure, and suction filtration, metal magnesium salt is obtained;

[0038] 3) Ion exchange: soak the metal magnesium salt prepared in step 3) in a 25% aqueous solution of sodium monofluorophosphate, stir for 48 hours to carry out ion ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com