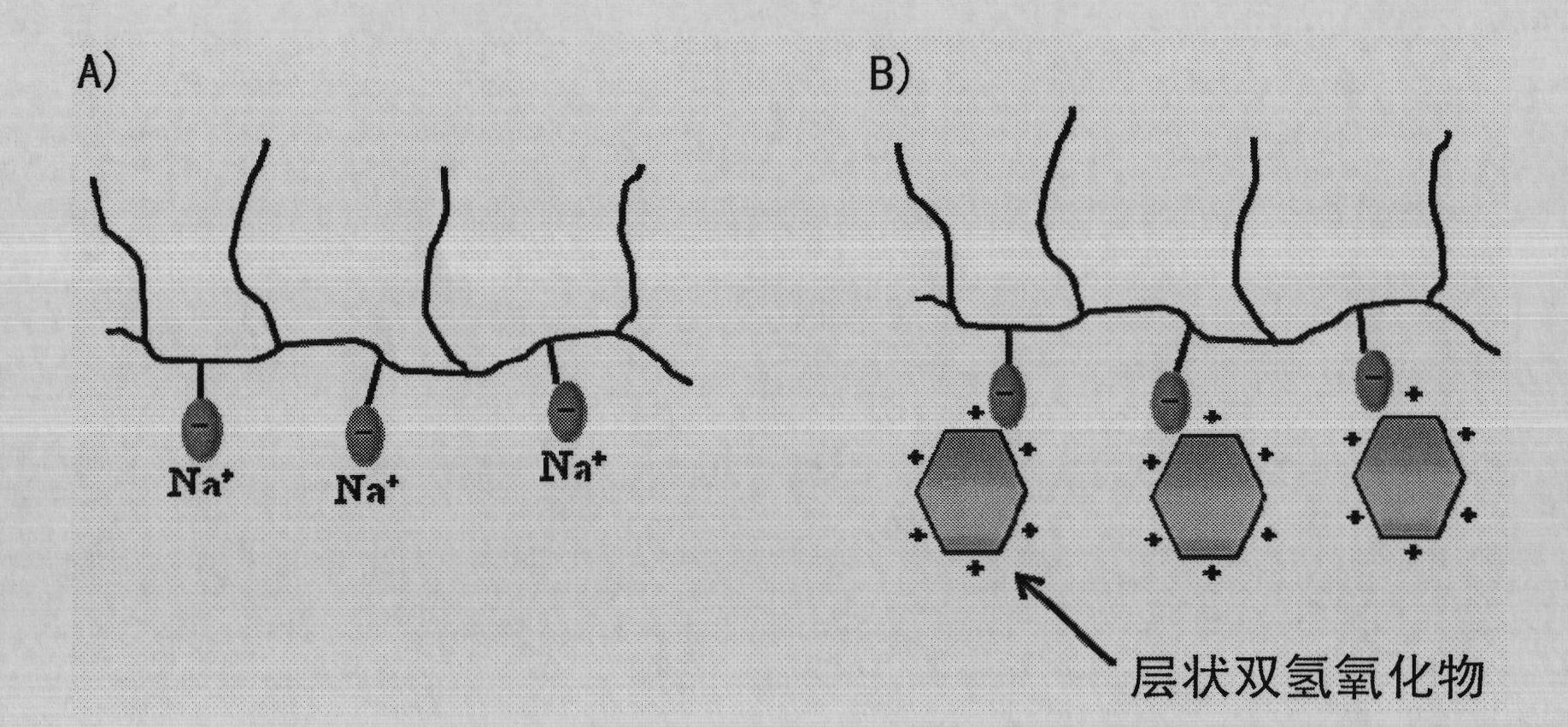

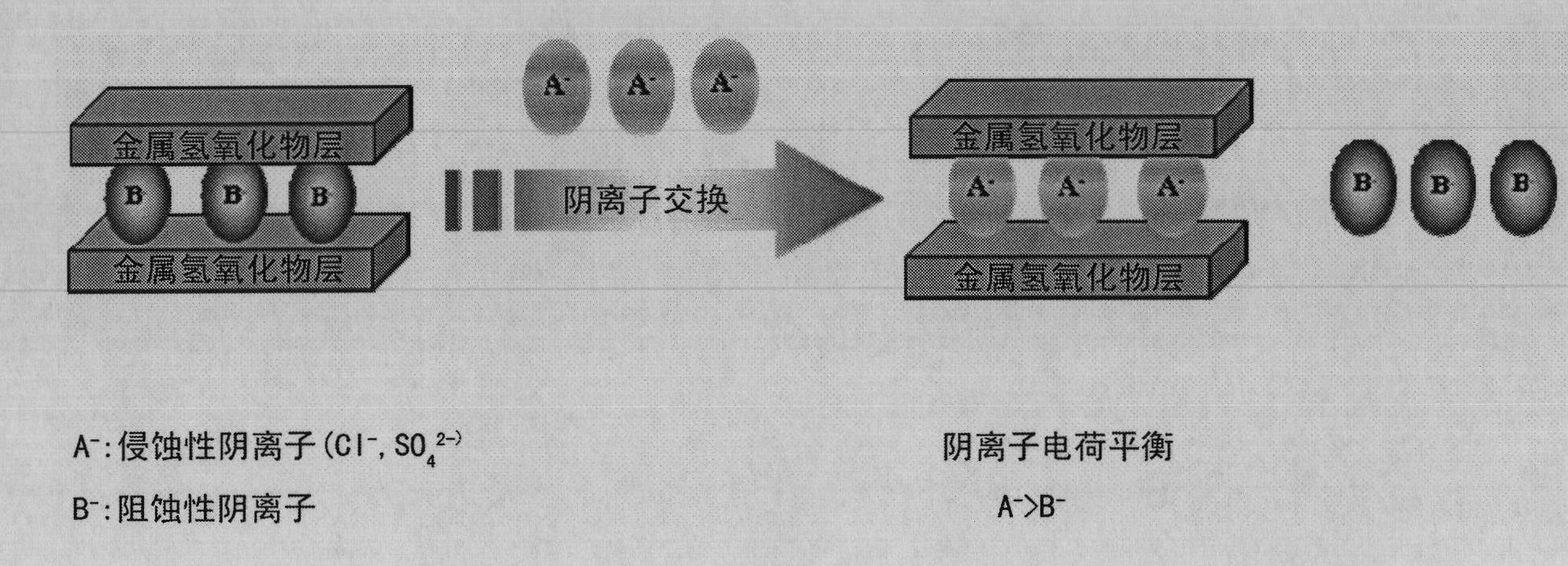

Nano-hybrid concrete chemical admixture for chloride invasion resistance consisting of layered double hydroxide/polyurethane copolymer

A hydroxide and concrete technology, which is applied in the field of concrete chemical admixtures, can solve the problems of unused, etc., and achieve the effects of enhancing machinability, high water-reducing capacity, and improving slump retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0107] In the preparation of the polymer, the amount of the polymerization initiator can be determined according to methods known in the art.

[0108] In addition, a reducing agent can further be used as a promoter (f). As reducing agents, sodium bisulfite, sodium sulfite, sodium formaldehyde sulfoxylate, potassium persulfate or ascorbic acid can be used in combination with amines such as ethylenediamine, sodium edetate and glycine. The amount of reducing agent can be appropriately controlled by methods known in the art.

[0109] Chain transfer agents may be used alone or in combination, if desired. Those skilled in the art can appropriately control the amount of the chain transfer agent.

[0110] In the layered double hydroxide of the nano-hybrid chemical admixture and the polyurethane copolymer, the polyurethane copolymer is present in an amount of 50 to 95 wt % based on the total weight of the concrete admixture. Within the above range, the anionic absorbent present in t...

Embodiment 1

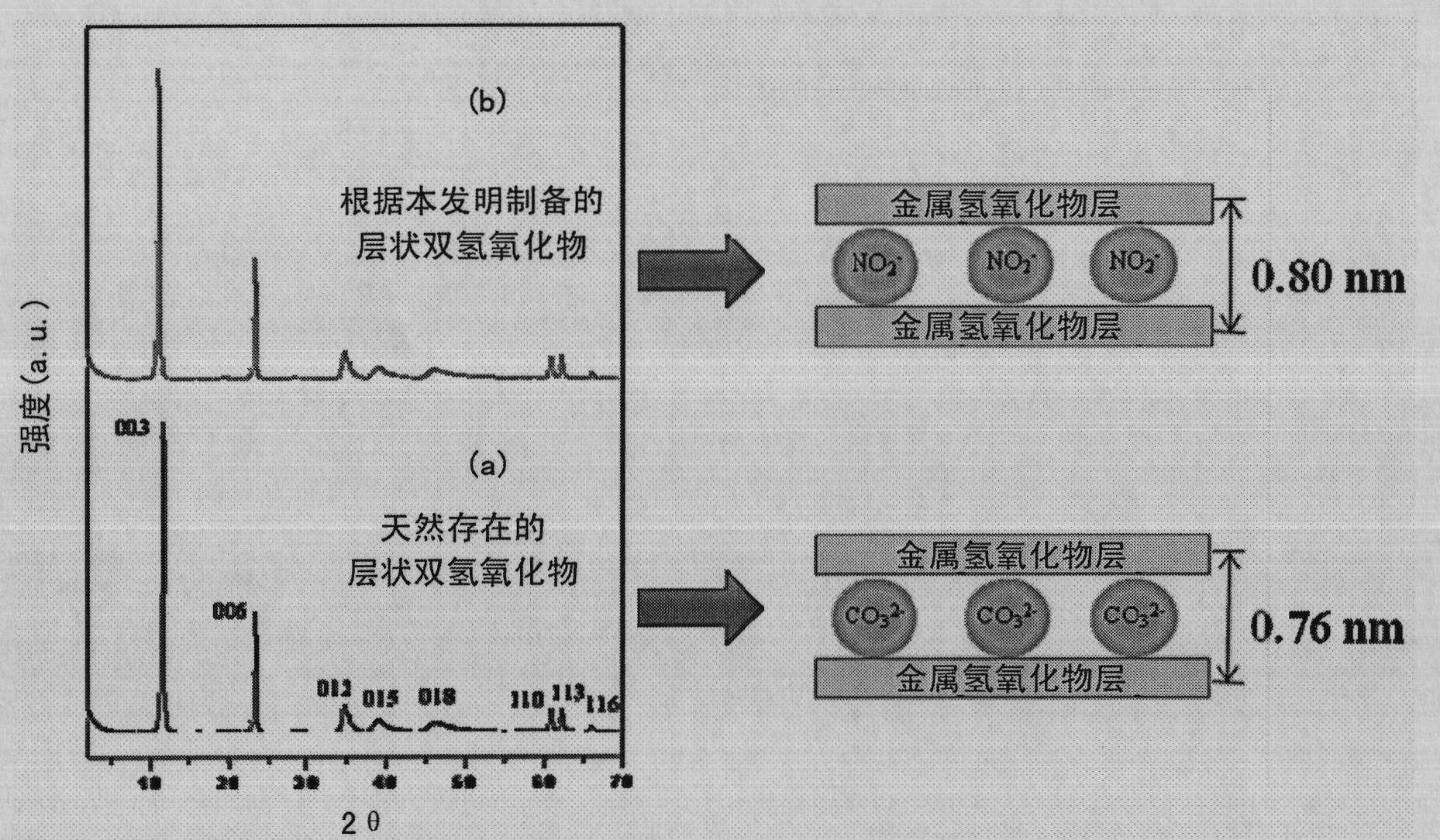

[0142] 1. Preparation of layered double hydroxide

[0143] Mg(NO 3 ) 2 ·6H 2 O (102 parts) and Al (NO 3 ) 3 9H 2 O (75 parts) was dissolved in standard water and the resulting solution was titrated to pH 9-10 with sodium nitrite in NaOH (14 parts). The resulting suspension was stirred at 100°C for 12 hours and unreacted salts were removed by washing. Finally the suspension was freezed and dried to obtain the layered double hydroxide.

[0144] 2. Preparation of polyurethane copolymer

[0145] In this method, 285 parts of distilled water are put into a 1L glass reactor equipped with a thermometer, a stirrer, a dropping funnel, a nitrogen inlet tube and a reflux condenser. The reactor was purged with nitrogen while stirring, and heated to 80°C under a nitrogen atmosphere. After stirring, a solution comprising 270 parts of unsaturated poly(meth)oxyalkylene urethane compound (adding 6 mol of urethane derivative-oxyalkylene), 55 parts of methacrylic acid and 50 parts of...

Embodiment 2 to Embodiment 5

[0150] A polyurethane copolymer was prepared in the same manner as in Example 1 except that the monomer components shown in Table 1 below were used instead of the monomer components shown in Example 1. Also combined with layered double hydroxide in the same manner as in Example 1 to obtain concrete chemical admixtures S-2 to S-5, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com