Non-autoclave primary health care (PHC) pipe pile concrete containing early strength composite mineral material and preparation method thereof

A technology of PHC pipe piles and composite minerals, applied in the field of building materials, can solve problems such as high production costs, heavy environmental pollution, and high energy consumption, and achieve the effect of improving work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Concrete Formulation

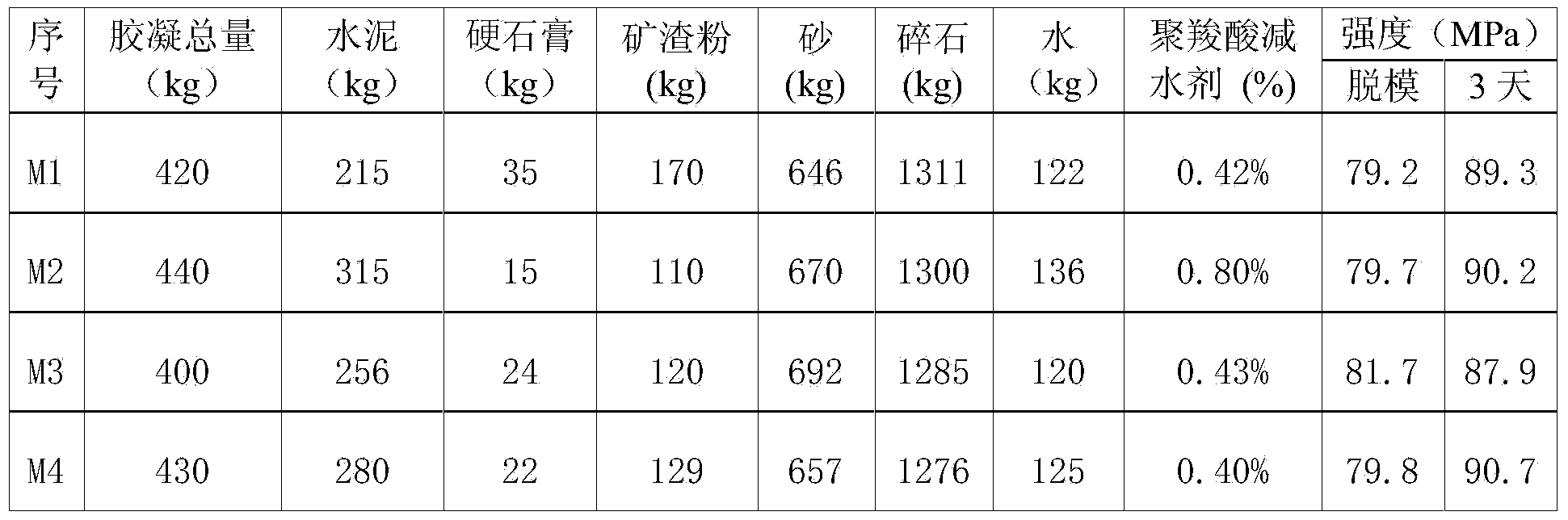

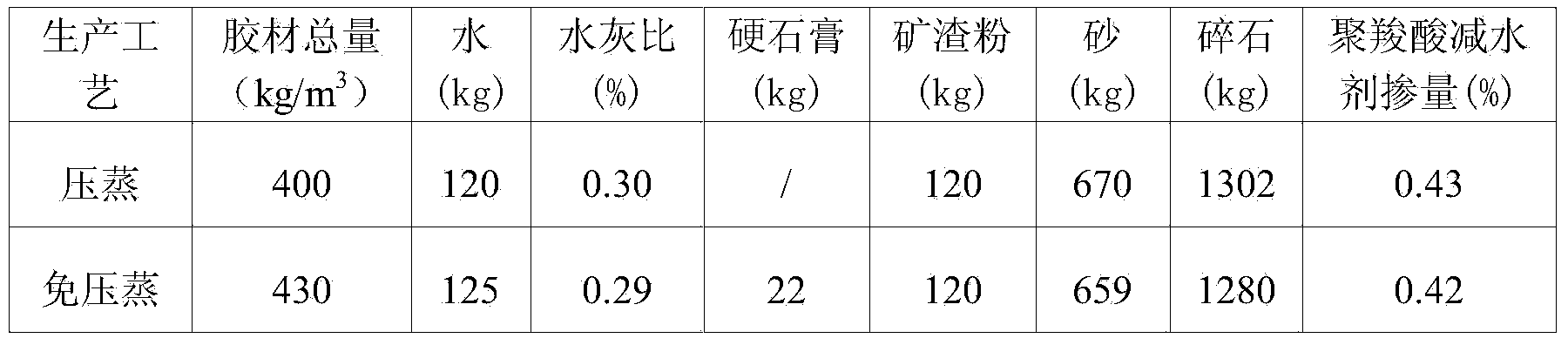

[0033] Concrete formula of the present invention is as shown in table 1:

[0034] Table 1 Autoclaved concrete formula

[0035]

[0036] The cement in the cementitious material in Table 1 is selected from commercially available P.O52.5 ordinary Portland cement.

[0037] The calcium-rich material is selected from anhydrite powder; anhydrite powder, fineness 200 mesh, specific surface area ≥ 400m 2 / kg, 0.045mm sieve is less than 1%; SO 3 The content is 48% to 52%.

[0038] The silicon-rich material is selected from one or more composite materials of blast furnace slag powder, fly ash, calcined kaolin, zeolite powder, and silica fume. The slag powder is S95 grade pure slag active powder, and the fly ash is selected from Class II F fly ash, with a fineness of 0.045mm and a sieve residue of 0.5% to 0.8%; the metakaolinite component in the calcined kaolin is 42% ~45%, the content of active aluminum material in the zeolite powder is 30...

Embodiment 2

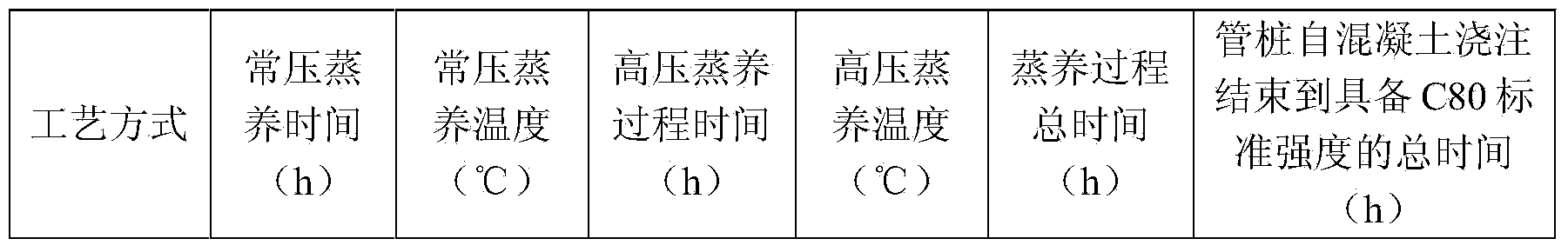

[0046] Embodiment 2 PHC autoclaved pipe pile processing technology

[0047] The specific process steps are as follows:

[0048] 1) According to the mix ratio of autoclaved concrete, first measure the total amount of cementitious material required for the corresponding volume, weigh the anhydrite powder and slag powder in the proportion of the total cementitious material, replace the cement in equal amounts, and then weigh The remaining amount of cement, then weigh the water reducer, water, coarse aggregate, and fine aggregate;

[0049] 2) Feed the weighed coarse aggregate and fine aggregate into the mixing pot first, then feed the weighed cement, slag powder and anhydrite powder into the stirring pot together, first stir the mixture at an even speed, Stop after 60 seconds;

[0050] 3) Then add water and water reducing agent together, and deduct the water content of water reducing agent from the total amount of water at the same time, carry out uniform speed stirring for 120 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com