Prestressed reinforced concrete pile foundation anticorrosive material for oceaneering and its construction method

A reinforced concrete and marine engineering technology, which is applied in infrastructure engineering, sheet pile walls, protection devices, etc., can solve the problems of high maintenance cost, complicated coating maintenance, and the coating cannot be dried and cured, and achieves high mechanical strength and construction. Simple, less stress-cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 3

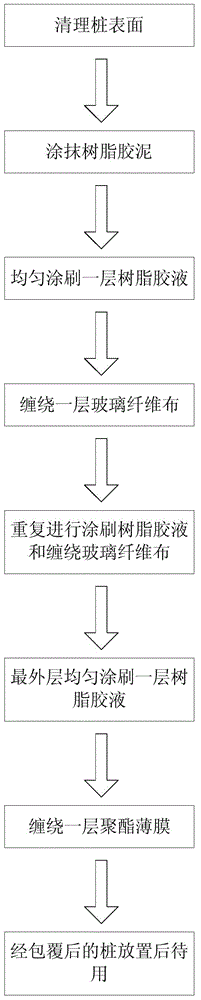

[0053] 1. Experimental method

[0054] Clean up the oil and other dirt, cement laitance and other loose matter in the area to be covered on the surface of the prestressed reinforced concrete pipe pile. Then, use resin cement to fill and smooth the surface defects of the pile to make the surface of the pile smooth. Among them, the components and parts by weight of the resin cement are: 100 parts of epoxy vinyl ester resin, 1.5 parts of methyl ethyl ketone peroxide, 0.5 parts of cobalt isooctanoate, and 100 parts of cement.

[0055] After the resin cement is solidified for 12-24 hours, preferably 24 hours, start to coat the glass fiber reinforced plastic. At the same time, take the pigment, thixotropic agent, ultraviolet absorber, and accelerator according to the proportion and add them to the resin in order to stir evenly, then add the initiator while stirring, wait for 3-5min, preferably 5min after stirring evenly, to obtain the resin glue. During the whole glue preparation ...

Embodiment 4~ Embodiment 6

[0119] The same experimental method as in the above-mentioned Examples 1 to 3 was adopted, wherein the composition and weight percentage of the raw material components of the anti-corrosion material forming the FRP anti-corrosion layer are shown in Table 4.

[0120] Formulation table of prestressed reinforced concrete pile foundation anticorrosion materials in marine engineering in Table 4 embodiment 4-6

[0121]

[0122] The marine engineering prestressed reinforced concrete pile foundation anticorrosion material prepared by the composition formula in Table 4 has performance results similar to those in Table 3 in Examples 1 to 3, and also has high mechanical strength, high interfacial bond strength, and anticorrosion performance Good advantages, anti-corrosion materials have an anti-chloride ion penetration life of more than 50 years, have high durability, and can meet the performance requirements of marine engineering structures for anti-corrosion materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com