Composite modified concrete and testing method of interfacial transition zone of composite modified concrete

A composite modification, concrete technology, used in the application of stable tension/pressure to test material strength, measurement devices, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

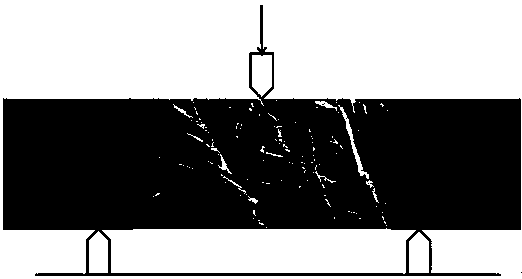

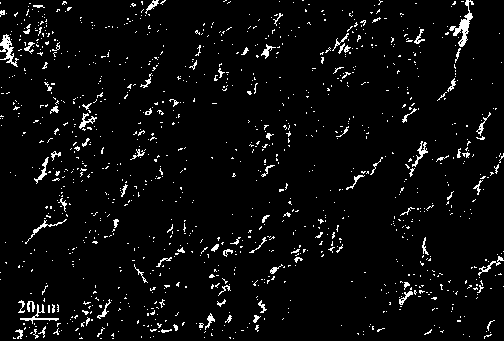

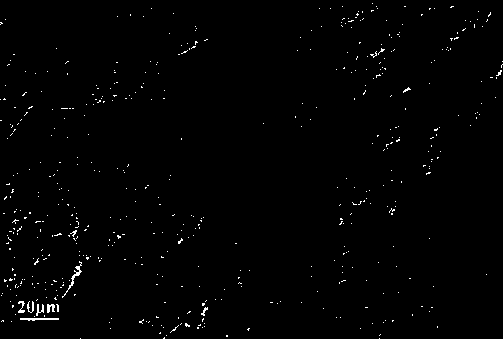

Method used

Image

Examples

Embodiment example 1

[0040] The raw materials were weighed according to the following proportions: 100 parts of cement, 250 parts of gravel, 160 parts of sand, 39 parts of water, 30 parts of fly ash, 1.2 parts of nano-silica, and 0.5 parts of superplasticizer.

[0041] The preparation process of the above-mentioned modified concrete is as follows:

[0042] (1) First, put the nano-silica and all the water into the ultrasonic system, the operating frequency of the ultrasonic system is 40khz, and the ultrasonic power supply is 50w, to prepare the nano-modifier dispersion;

[0043] (2) Then put cement, fly ash, silica fume, gravel, sand, and high-efficiency water reducer into the concrete mixer and stir for 4 minutes, so that all raw materials can be evenly mixed;

[0044] (3) Then pour the nano-dispersion into the mixer and stir for 6 minutes until a uniform concrete mixture is obtained;

[0045] (3) Put the concrete mixture into the mold for molding, remove the mold after one day, and maintain it u...

Embodiment example 2

[0051] The raw materials were weighed according to the following proportions: 100 parts of cement, 250 parts of gravel, 160 parts of sand, 39 parts of water, 30 parts of fly ash, 9 parts of silica fume, 1.2 parts of nano-silica, and 1.5 parts of superplasticizer.

[0052] The preparation process of the above-mentioned modified concrete is as follows:

[0053](1) First, put the nano-silica and all the water into the ultrasonic system, the operating frequency of the ultrasonic system is 40khz, and the ultrasonic power supply is 50w, to prepare the nano-modifier dispersion;

[0054] (2) Then cement, fly ash, silica fume, gravel, sand, and high-efficiency water reducer are put into the concrete mixer and stirred for 4 minutes, so that all raw materials can be evenly mixed;

[0055] (3) Then pour the nano-modifier dispersion into the mixer and stir for 6 minutes until a uniform concrete mixture is obtained;

[0056] (4) Put the concrete mixture into the mold for molding, remove th...

Embodiment example 3

[0059] The raw materials were weighed according to the following proportions: 100 parts of cement, 250 parts of gravel, 160 parts of sand, 39 parts of water, 30 parts of fly ash, 9 parts of silica fume, 1.8 parts of nano-titanium dioxide, and 1 part of superplasticizer.

[0060] The preparation process of the above-mentioned modified concrete is as follows:

[0061] (1) First, put nano-titanium dioxide and all water into the ultrasonic system, the operating frequency of the ultrasonic system is 40khz, and the ultrasonic power supply is 50w, to prepare the nano-modifier dispersion;

[0062] (2) Then cement, fly ash, silica fume, gravel, sand, and high-efficiency water reducer are put into the concrete mixer and stirred for 4 minutes, so that all raw materials can be evenly mixed;

[0063] (3) Then pour the nano-modifier dispersion into the mixer and stir for 6 minutes until a uniform concrete mixture is obtained;

[0064] (4) Put the concrete mixture into the mold for molding,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com