Expressway bridge concrete structure crash barrier nanometer coating method

A concrete structure and anti-collision guardrail technology, which is applied in the surface treatment of expressway concrete structure anti-collision guardrail and the nano-coating field of expressway concrete structure anti-collision guardrail, can solve the problem of neglecting protection and can not fully meet the requirements of anti-chloride ion penetration and anti-snow melting salt. Corrosion etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

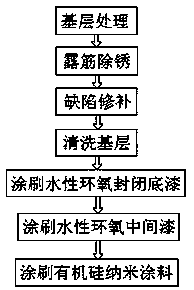

Embodiment 1

[0058] Remove the original putty, coating, grease and other foreign matter on the concrete anti-collision guardrail; use tools such as electric grinder (dust-free wall grinder) and high-pressure water gun to polish and remove the aging layer and damaged layer on the concrete anti-collision barrier until it is exposed Rough and fresh concrete base, the concrete base should be brushed; the exposed corroded steel bar should be wiped and derusted; when derusting, use a brush to apply the derusting agent on the surface of the corroded steel bar to be derusted, Apply once every 5 to 10 minutes, and rinse with clean water after the rust is removed; according to the mass ratio of 1:1.5:5, take liquid E-51 bisphenol A epoxy resin and non-ionic modified polyamine respectively. Stir the curing agent and water evenly with a stirring electric drill in the batching tank to prepare the first water-based epoxy sealing primer; according to the mass ratio 1: 1.5: 3.5, take liquid E-51 bisphenol ...

Embodiment 2

[0061] The anti-collision guardrail is painted according to the method of embodiment 1, when just preparing water-based epoxy intermediate paint, the mass ratio of water-based epoxy intermediate paint A and water-based epoxy intermediate paint B is 1: 4.

Embodiment 3

[0063] The anti-collision guardrail is painted according to the method of embodiment 1, when just preparing water-based epoxy intermediate paint, the mass ratio of water-based epoxy intermediate paint A and water-based epoxy intermediate paint B is 1: 3.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shock | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com