R744 high-temperature air conditioner hose and preparation method thereof

A hose and air-conditioning technology, applied in hoses, pipes, mechanical equipment, etc., can solve problems such as leakage, carbon dioxide medium penetration, and failure to meet the low permeability requirements of carbon dioxide refrigerant R744, and achieve good high temperature resistance and high pressure resistance , the effect of meeting the performance requirements of low permeability and high temperature and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] According to one aspect of the present invention, a preparation method of R744 high-temperature air-conditioning hose, the preparation method comprises the following steps:

[0044] (a), first refine the compound rubber of the inner and outer rubber layers, and then use the compound rubber to extrude the outer surface of the metal bellows to obtain the inner rubber layer;

[0045] (b), carrying out fiber weaving on the outer surface of the inner rubber layer to obtain a fiber reinforced layer;

[0046] (c), using the compounded rubber refined in step (a) to extrude the outer rubber layer on the outer surface of the fiber reinforced layer to obtain a semi-finished hose;

[0047] (d), wrapping water cloth on the outer layer of the semi-finished hose to carry out vulcanization treatment, untie the cloth after vulcanization, and obtain the R744 high-temperature air-conditioning hose.

[0048] The preparation method of the R744 high-temperature air-conditioning hose provide...

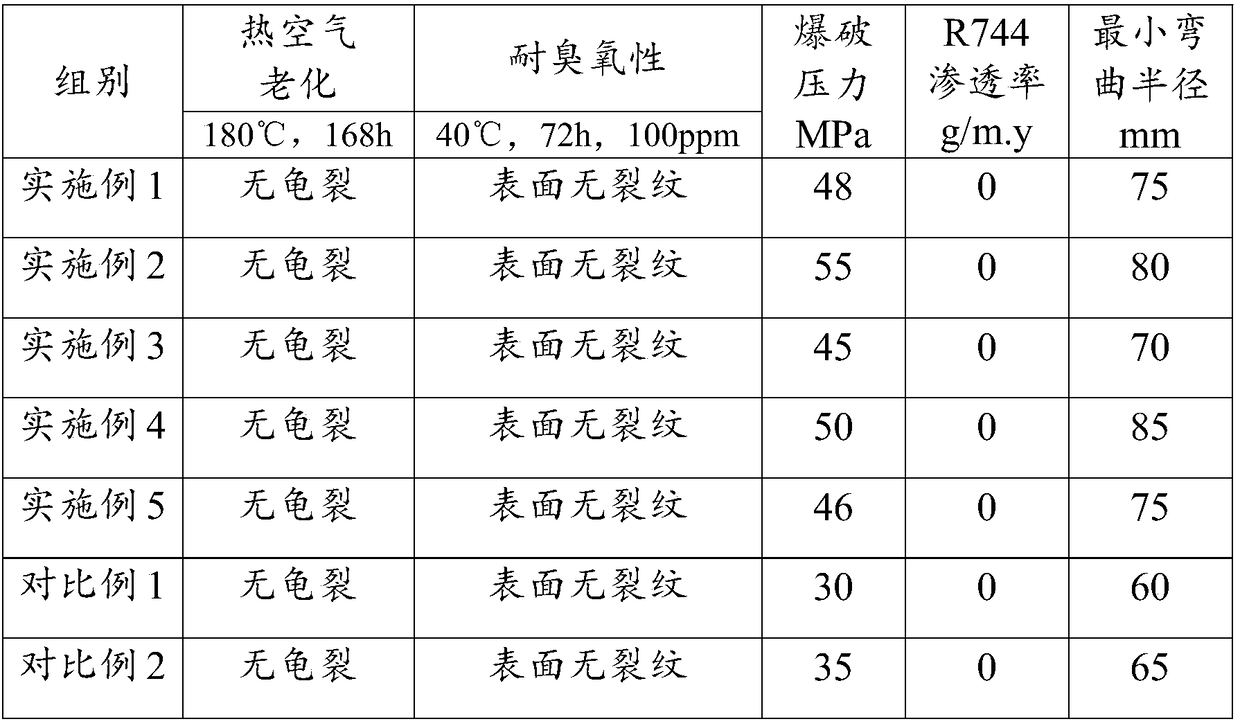

Embodiment 1

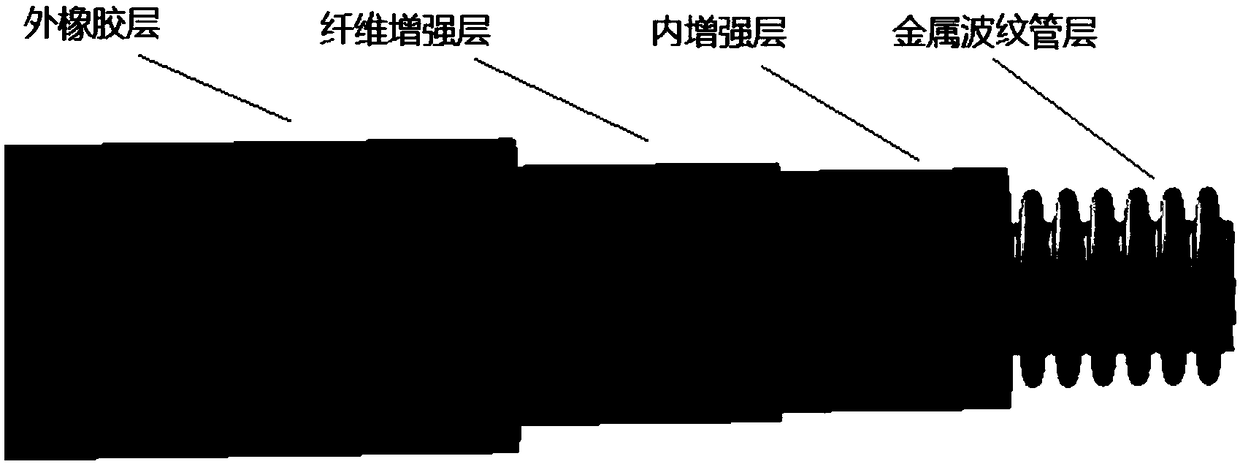

[0054] like figure 1 As shown, a R744 high-temperature air-conditioning hose, along the diameter direction of the air-conditioning hose, sequentially includes a metal bellows layer, an inner rubber layer, a fiber-reinforced layer and an outer rubber layer from the inside to the outside;

[0055] The preparation method of the above-mentioned R744 high-temperature air-conditioning hose comprises the following steps:

[0056] (a), first refine the inner and outer rubber layer AEM compound rubber, then pass a metal bellows with an inner diameter of 6.3mm, an outer diameter of 9.8mm, and a wall thickness of 0.15mm through a single-screw T-type extruder; use mixing The glue extrudes the inner rubber layer AEM on the outer surface of the metal bellows, with a thickness of 2.2mm;

[0057] (b), adopt Dupont's 2500dtex dipped aramid thread to carry out fiber weaving on the outer surface of the inner rubber layer, 24 spindles and 4 strands are braided, and the stroke is 30mm to obtain a...

Embodiment 2

[0061] A kind of R744 high-temperature air-conditioning hose, its preparation method comprises the following steps:

[0062] (a), first refine the inner and outer rubber layer AEM compound rubber, then pass a metal bellows with an inner diameter of 6.3mm, an outer diameter of 9.8mm, and a wall thickness of 1.0mm through a single-screw T-type extruder; use mixing The glue extrudes the inner rubber layer AEM on the outer surface of the metal bellows, with a thickness of 2.5mm;

[0063] (b), adopt Dupont's 2500dtex dipped aramid thread to carry out fiber weaving on the outer surface of the inner rubber layer, 24 spindles and 4 strands are braided, and the stroke is 30mm to obtain a fiber reinforced layer;

[0064] (c), using the compounded rubber refined in step (a) to extrude the outer rubber layer AEM on the outer surface of the fiber reinforced layer, with a thickness of 1.8mm, to obtain a semi-finished hose;

[0065] (d) After wrapping the outer layer of the semi-finished ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com