Oil casing head under-pressure leaking stoppage system and method

A technology of oil casing and headband, which is applied in the direction of pipeline system, pipe/pipe joint/pipe fitting, pipe element, etc., can solve the problem of grease filling and plugging of the main and auxiliary seals of casing, and the inability to inject grease under pressure in the main and auxiliary seals of casing. , There are no problems such as poor grease injection effect, to achieve the effect of flexible use, work efficiency, and good cementation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment discloses a plugging system with pressure on the casing head, which includes a liquid plugging device and a solid leak plugging device.

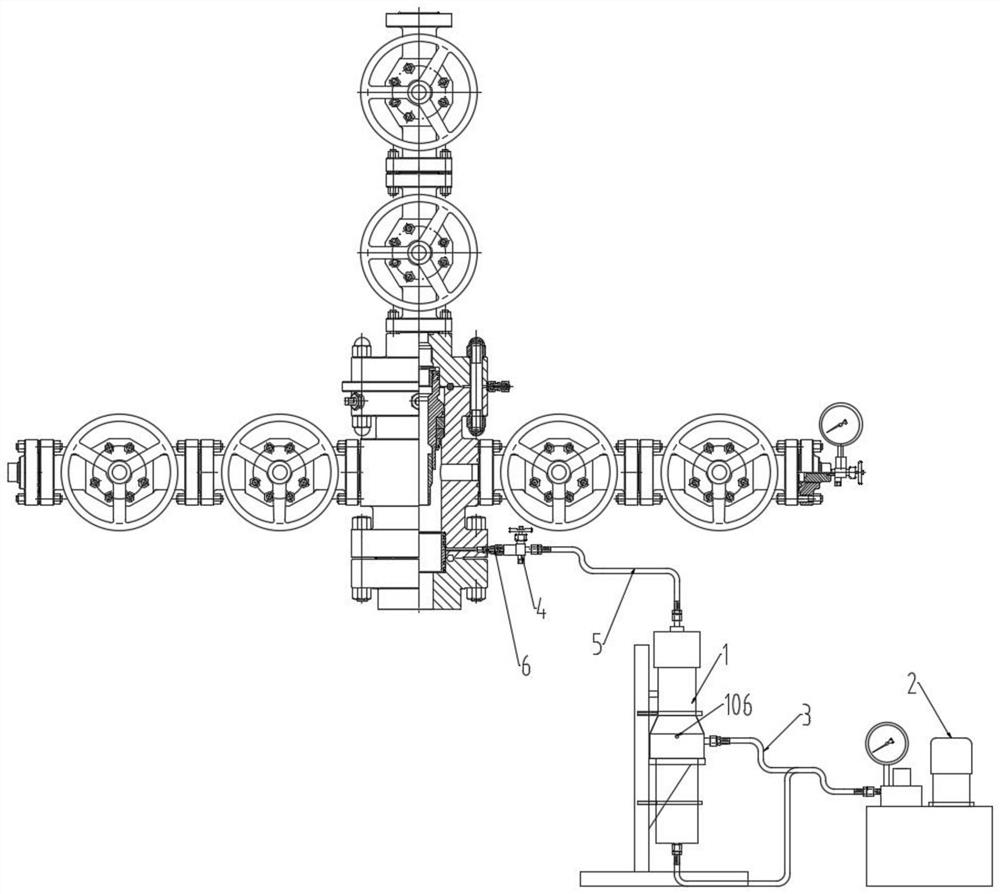

[0035] see Figure 1-2 , The liquid plugging device includes a high-pressure grease injector 1, an explosion-proof hydraulic pump station 2, a hydraulic pipeline 3, a first stop valve 4, and a first grease injection pipeline 5.

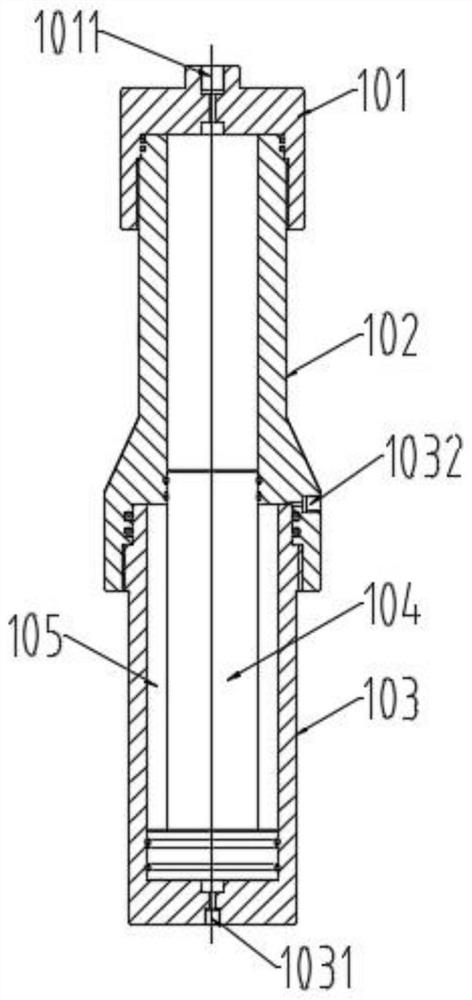

[0036] see figure 2 , the high-pressure grease injector 1 includes a first piston rod 104 and a first cylinder head 101 , an upper cylinder body 102 , and a lower cylinder body 103 which are sequentially threaded on the coaxial line.

[0037] The hollow upper cylinder body 102 and the lower cylinder body 103 form a stroke channel of the first piston rod 104 . Both ends of the first piston rod 104 are respectively sealed and connected to the upper cylinder body 102 and the lower cylinder body 103. Preferably, between the side wall at the top of the first piston rod 104 and the inner wall of ...

Embodiment 2

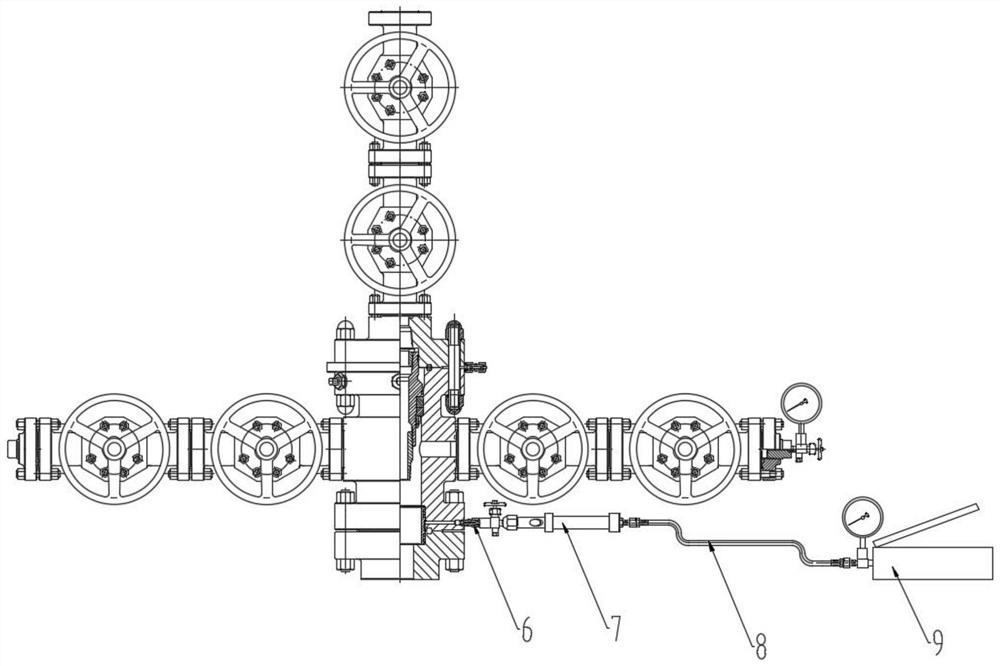

[0046] This embodiment discloses a plugging system with pressure on the casing head. The difference between this embodiment and Embodiment 1 lies in the reciprocating injection molding gun 7 .

[0047] For details, see Figure 6 , the reciprocating injection molding gun 7 in this embodiment includes a second piston rod 703, a rear cylinder cover 705, an oil return joint 712, and a front cylinder cover 701, a first cylinder body 702, a plastic filling cylinder 706, Threaded joint 707, second cut-off valve 708, injection joint 709, grease injection valve nut 710.

[0048] The front cylinder cover 701 is threadedly connected to the first cylinder body 702, and an oil inlet 7011 is opened on the front cylinder cover 701; Plastic tube 706, threaded joint 707, second cut-off valve 708, injection molding joint 709, grease injection valve nut 710 are threaded from head to tail.

[0049] The sidewalls at both ends of the second piston rod 703 are sealed and connected to the inner wal...

Embodiment 3

[0052] This embodiment discloses a leak plugging method with pressure on the oil casing head. The method includes:

[0053] Connect the grease injection valve 6 on the wellhead gate valve with the first shut-off valve 4 .

[0054] Fill the high-pressure grease injector 1 with a liquid leak-stopping agent.

[0055] Open the first cut-off valve 4, start the explosion-proof hydraulic pump station 2, and inject the liquid plugging agent in the high-pressure grease injector 1 into the grease injection valve 6 on the wellhead gate valve; close the first stop valve 4.

[0056] Connect the grease injection valve 6 on the wellhead gate valve with the second cut-off valve 708 .

[0057] Fill the solid plugging agent in the filling cylinder 706 of the reciprocating injection molding gun 7 .

[0058] Open the second shut-off valve 708, pressurize the manual pump 9, inject the solid leakage plugging agent in the reciprocating injection molding gun 7 into the grease injection valve 6 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com