Preparation of heat stabilizer for PVC plastics

A technology of heat stabilizer and polyvinyl chloride, which is applied in the field of preparation technology of high-efficiency heat stabilizer, can solve the problems of energy waste, material loss, production and use pollution of butyl tin oxide, etc., and achieves favorable environmental protection, reduction of material loss and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

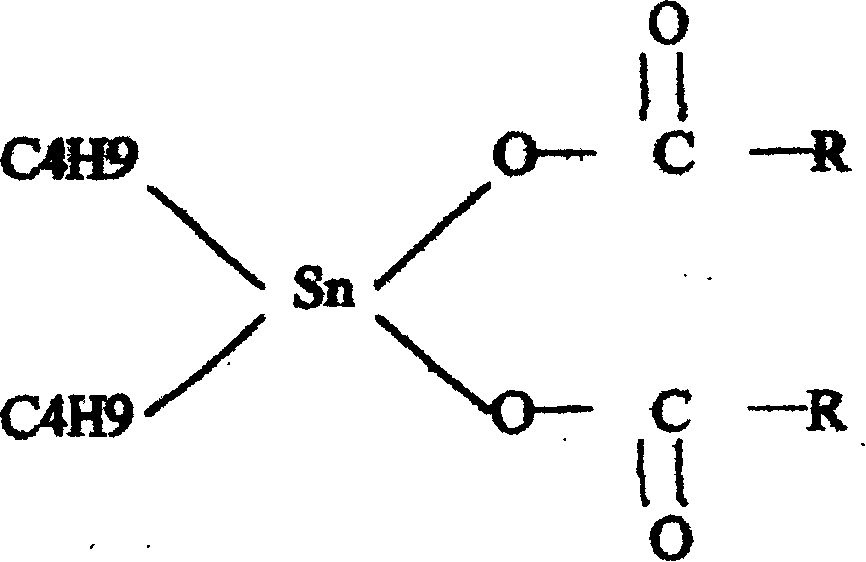

Image

Examples

Embodiment 1

[0058] In a 500ml flask equipped with a vacuum system and a stirrer, add 100 grams of tetrabutyltin, 60 grams of tin tetrachloride, plus some aluminum trichloride, tightly cover the bottle mouth, stir, open the vacuum system, and keep the pressure at Below 0.05Mpa, heat up to 130°C, keep warm, and carry out disproportionation reaction. After sufficient reaction, dibutyltin dichloride is obtained as a result of the reaction. Then add 2 times the molar ratio of coconut oleic acid and 2 times the molar ratio of sodium hydroxide to dibutyltin dichloride, tightly cover the mouth of the bottle, stir, and lower the temperature to 40°C, keep warm, and carry out the synthesis reaction. The pH value of the product is 4, after fully reacting, the reaction ends to obtain dibutyltin dicocotooleate, and through phase separation, the crude product of dibutyltin dicococoate is obtained. Then turn on the vacuum system, keep the vacuum degree below 0.09Mpa, gradually raise the liquid temperatur...

Embodiment 2

[0061]In a 500ml flask equipped with a vacuum system and a stirrer, add 100 grams of tetrabutyltin, 70 grams of tin tetrachloride, plus some aluminum trichloride, tightly cover the bottle mouth, stir, open the vacuum system, and keep the pressure at Below 0.05Mpa, heat up to 140°C, keep warm, and carry out disproportionation reaction. After sufficient reaction, dibutyltin dichloride is obtained as a result of the reaction. Then add 2 times the molar ratio of coconut oleic acid and 2 times the molar ratio of sodium hydroxide to dibutyltin dichloride, tightly cover the mouth of the bottle, stir, and reduce the temperature to 50°C, keep warm, and carry out the synthesis reaction. The pH value of the product is 6. After fully reacting, the reaction ends to obtain dibutyltin dicocotooleate, and through phase separation, the crude product of dibutyltin dicococoate is obtained. Then turn on the vacuum system again, keep the vacuum degree below 0.09Mpa, gradually raise the liquid temp...

Embodiment 3

[0064] In a 500ml flask equipped with a vacuum system and a stirrer, add 100 grams of tetrabutyltin, 75 grams of tin tetrachloride, plus some aluminum trichloride, tightly cover the bottle mouth, stir, open the vacuum system, and keep the pressure at Below 0.05Mpa, heat up to 145°C, keep warm, and carry out disproportionation reaction. After sufficient reaction, dibutyltin dichloride is obtained as a result of the reaction. Then add 2 times the molar ratio of coconut oleic acid and 2 times the molar ratio of sodium hydroxide to dibutyltin dichloride, tightly cover the mouth of the bottle, stir, and lower the temperature to 55°C, keep warm, and carry out the synthesis reaction. The pH value of the product is 5, after fully reacting, the reaction ends to obtain dibutyltin dicocotooleate, and through phase separation, the crude product of dibutyltin dicococoate is obtained. Then turn on the vacuum system again, keep the vacuum degree below 0.09Mpa, gradually raise the liquid temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com