Noctilucent PVC insulating material and BV wire

A technology of insulating materials and long-lasting luminous powder, applied in the direction of insulators, insulated conductors, insulated cables, etc., can solve problems such as waste of time and property, inconvenient use, and difficulty in finding fault points, so as to save costs, save additives, and overcome The effect of the oil problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

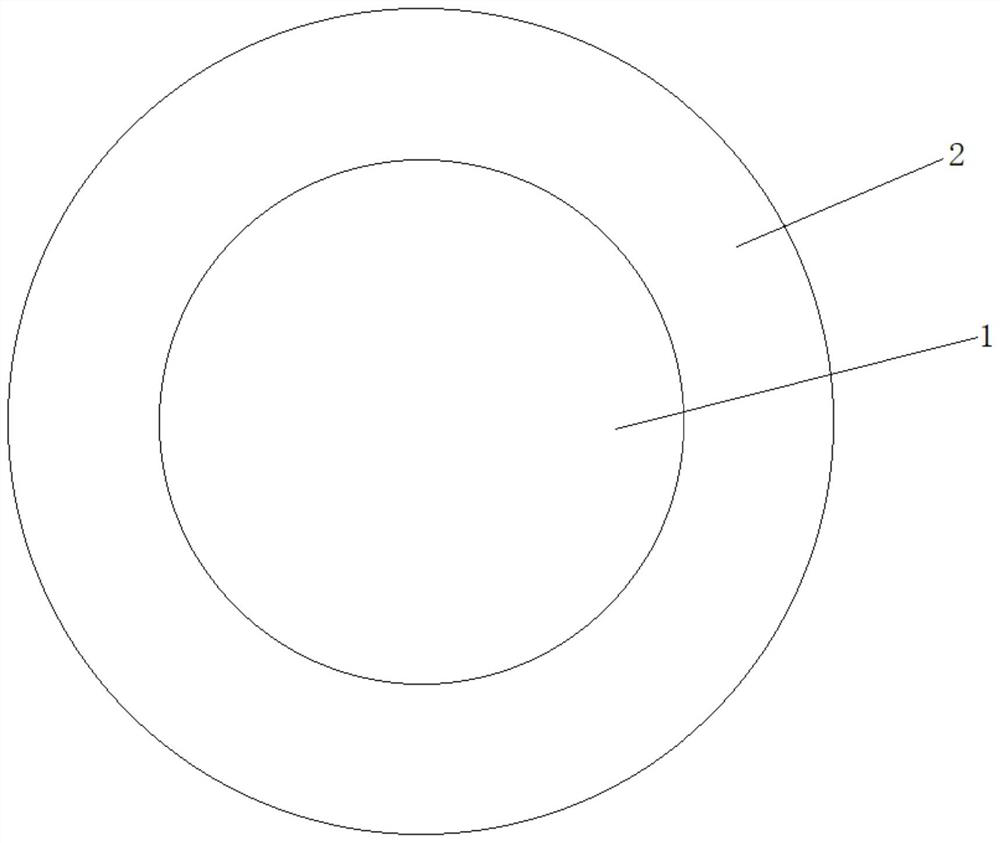

[0032] Such as figure 1 The BV line shown includes conductor 1 and insulation 2 wrapped outside conductor 1. Insulation 2 is made of transparent luminous PVC insulation material, so that it glows in a dark environment, and can be quickly detected by naked eyes when a fault occurs during use. It can be seen that it is easy to find the breakpoint of the conductor, and at the same time, it makes it possible to install it under special circumstances (such as dark and no electricity around), which expands the usage scenarios of the BV line. It can also be used as a home decoration. Users can lay out a beautiful picture when fixing it with a cable card according to their favorite shape. In this way, after absorbing enough light during the day, it can be beautiful and elegant without decoration at night and without power on. It also saves the procedure and cost of decorating the room with colorful lights to create an atmosphere, and at the same time, it also shows the user's sense of...

Embodiment 2

[0041] This example is similar to Example 1, the difference is that the ratio of raw materials of luminous PVC insulating material is different, specifically, 45 parts of base material, 22 parts of plasticizer, 6 parts of stabilizer, 12 parts of lubricant, and 4 parts of light stabilizer , 2 parts of decolorizer, 10 parts of long-lasting luminous powder. The stabilizer is composed of the following raw materials in parts by mass: 1 part of tin methyl mercaptide, 2 parts of hydrotalcite, 2 parts of metal soap Hst, and 2 parts of rare earth calcium zinc stabilizer. The lubricant consists of the following raw materials in parts by mass: 3 parts of CaSt calcium stearate, 8 parts of PE paraffin, and 3 parts of epoxidized soybean oil. The luminous PVC insulating material made of the proportioned raw materials of this embodiment has high transparency, and can shine brightly in a dark environment after absorbing light for a long time.

Embodiment 3

[0043] This example is similar to Example 1, the difference is that the raw material ratio of the luminous PVC insulating material is different, specifically, 55 parts of the base material, 26 parts of the plasticizer, 10 parts of the stabilizer, 16 parts of the lubricant, and 6 parts of the light stabilizer , 3 parts of decolorizer, 18 parts of long-lasting luminous powder. The stabilizer is composed of the following raw materials in parts by mass: 4 parts of tin methyl mercaptide, 3 parts of hydrotalcite, 5 parts of metal soap Hst, and 3 parts of rare earth calcium zinc stabilizer. The lubricant is composed of the following raw materials in parts by mass: 4 parts of CaSt calcium stearate, 13 parts of PE paraffin, and 4 parts of epoxidized soybean oil. The luminous PVC insulating material made of the proportioned raw materials of this embodiment also has high transparency, and can shine brightly in a dark environment after absorbing light for a long time.

[0044] The insula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com