Polypropylene solid wall permeation pipe for sponge city and preparation method thereof

A sponge city, polypropylene technology, applied in chemical instruments and methods, applications, household appliances, etc., can solve problems such as inability to meet infiltration drainage pipe network and green space construction, low ring stiffness, and only 5% large. Achieve the effect of light weight, material saving and high water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

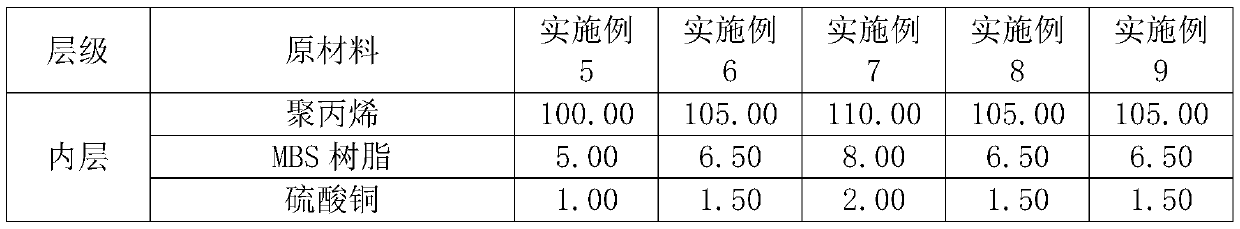

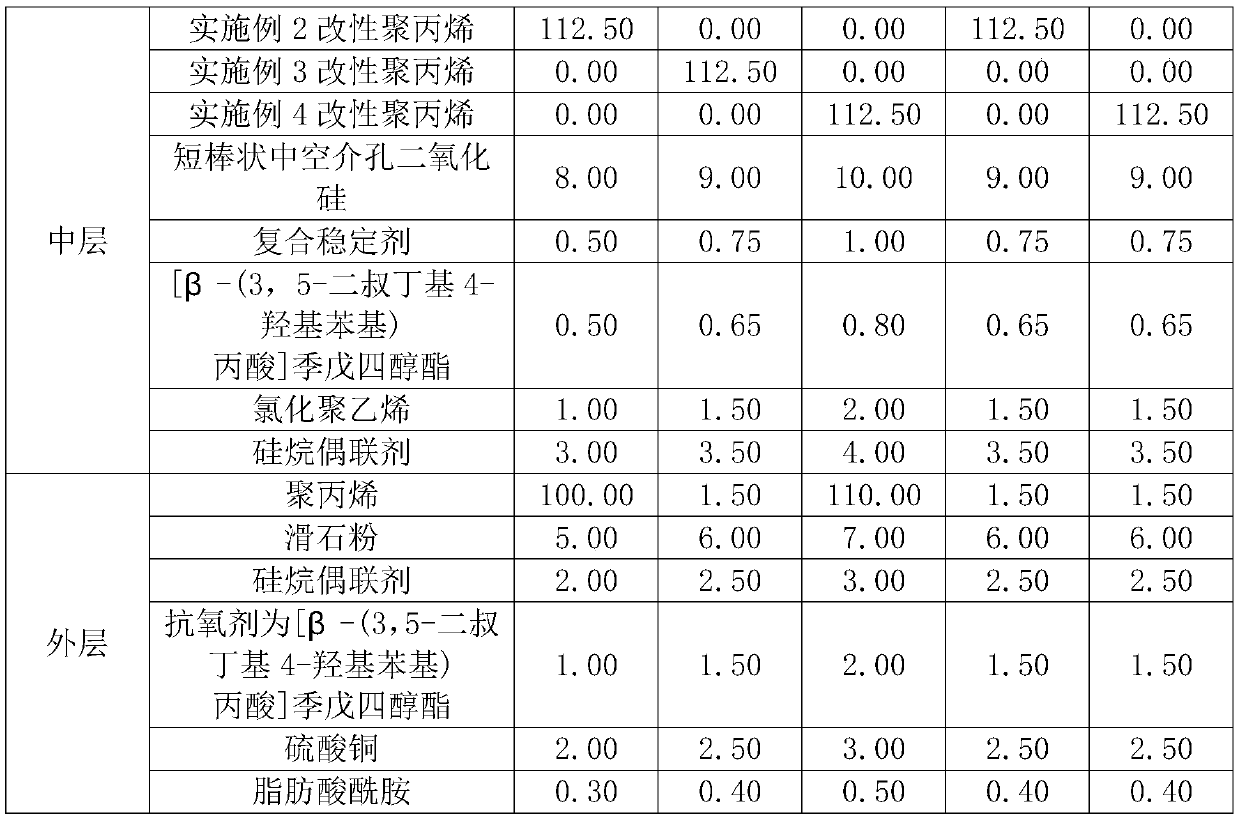

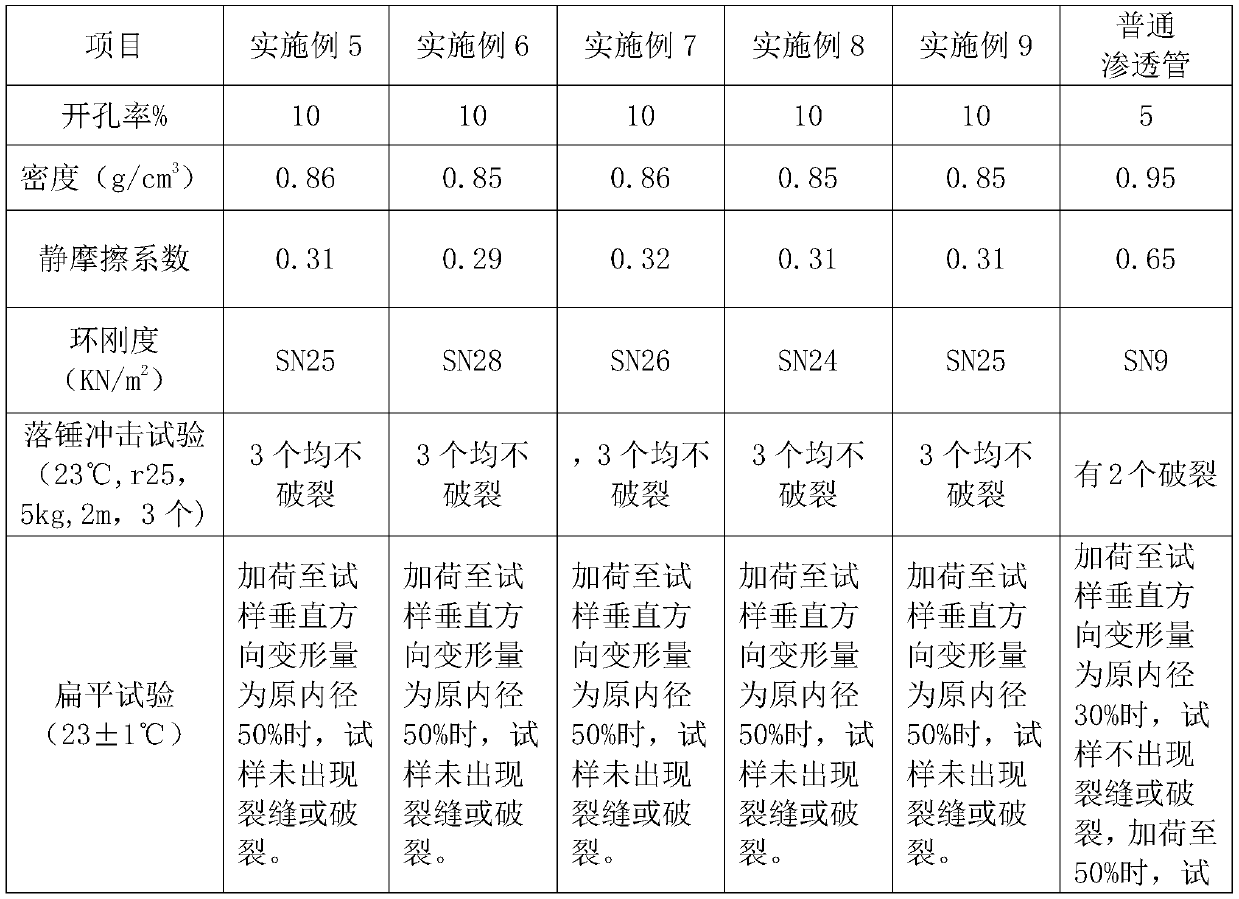

Examples

Embodiment 1

[0031] The preparation of short rod-shaped hollow mesoporous silica is carried out as follows:

[0032] Take 17.5 kg of tetraethyl orthosilicate, dissolve it in 25 kg of anhydrous ether, add 6 kg of polyethylene glycol and 4 kg of polyoxyethylene-polyoxypropylene-polyoxyethylene, stir evenly, let stand for 16 hours, and heat to After reacting at 100-120°C for 9 hours, the product was dried by suction filtration, and calcined at 650°C for 2.5 hours to prepare short rod-shaped hollow mesoporous SiO 2 .

Embodiment 2

[0034] The preparation method 1 of modified polypropylene comprises the following steps:

[0035] Take 20kg of graphite with a particle size of 100-200nm, add 20kg of concentrated sulfuric acid with a mass fraction of 98% and 3kg of sodium nitrate, stir evenly, then add 8kg of potassium permanganate, and react for 1h under stirring at 20r / min;

[0036] Add 80kg of deionized water to the above mixed solution, heat to 85°C, continue to stir and react for 0.5h, then add 10kg of 35% mass concentration of hydrogen peroxide, and continue to react for 10min to obtain a graphene oxide solution;

[0037]Add 100kg of polypropylene, 15kg of propylene glycol and 2kg of styrene to the graphene oxide solution for mixing, stir and react at 50r / min and 190°C for 20min, and use ultraviolet radiation with a wavelength of 100nm-150nm during the stirring process. During the process, irradiate for 5 minutes, stop irradiating for 3 minutes, filter, dry and pulverize to obtain the esterification rea...

Embodiment 3

[0041] The preparation method 2 of modified polypropylene comprises the following steps:

[0042] Take 25kg of graphite with a particle size of 100-200nm, add 25kg of concentrated sulfuric acid with a mass fraction of 98% and 4kg of sodium nitrate, stir evenly, then add 9kg of potassium permanganate, and react for 1.5h under stirring at 25r / min;

[0043] Add 85kg of deionized water to the above mixed solution, heat to 85-95°C, continue to stir and react for 0.75h, then add 12.5kg of 35% mass concentration of hydrogen peroxide, and continue to react for 13min to obtain a graphene oxide solution;

[0044] Add 110kg of polypropylene, 20kg of propylene glycol, and 3.5kg of styrene to the graphene oxide solution for mixing, stir and react at 55r / min and 200°C for 25min, and use ultraviolet radiation with a wavelength of 100nm-150nm during the stirring process. Finally, the reactants were cooled and granulated to obtain modified polypropylene particles; during the irradiation proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com