Cushion material gradation design optimization method based on pore distribution index in cold regions

A technology of pore distribution and cold regions, applied in the direction of dams, barrages, weirs, etc., can solve the problems affecting the stability of the dam body, uneven deformation and cracking of face dams, etc., to reduce the test workload, narrow the range of gradation selection, The effect of frost heave deformation is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Such as Figure 1-7 As shown, the cushion material gradation design optimization method based on the pore distribution index in the cold region is characterized in that it includes the following steps:

[0053] S01, determination of rolling density:

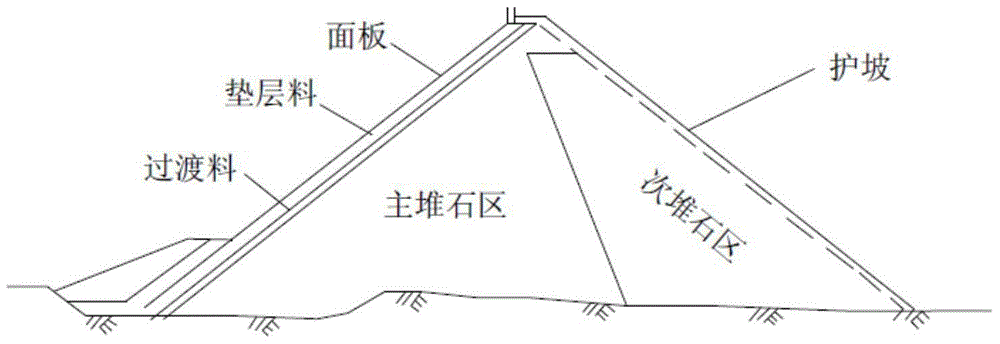

[0054] Such as figure 1 Shown is the position of the cushion material in the face dam, and its relative density requirements, the design code for concrete face rockfill dams require more than 0.75.

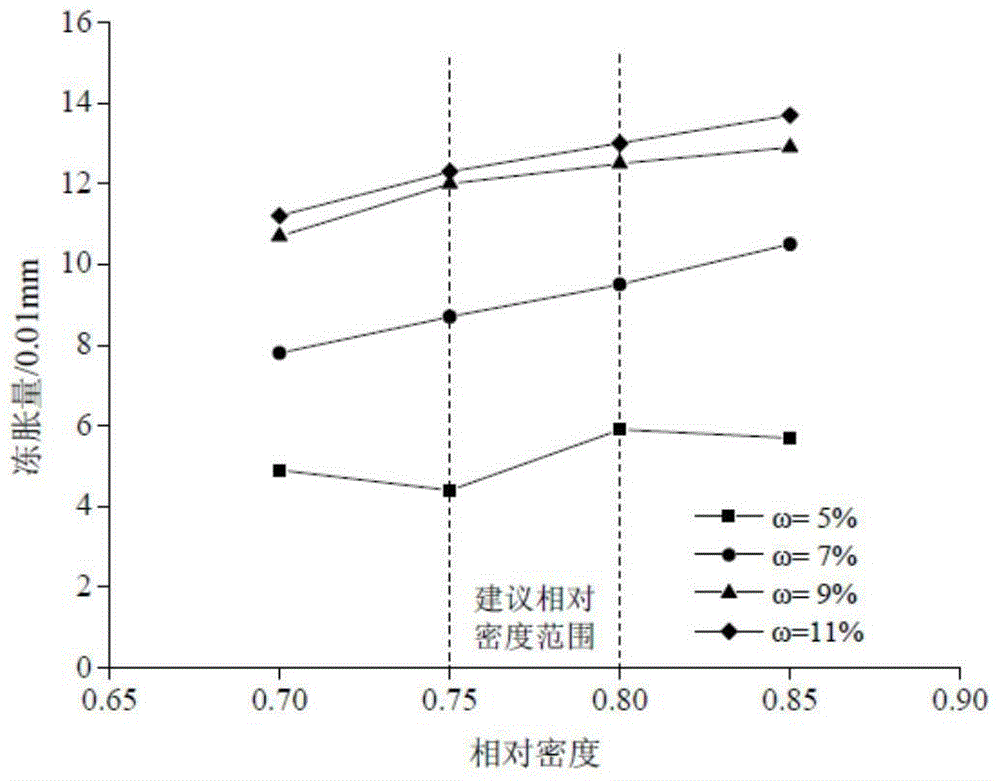

[0055] Such as figure 2 As shown, the law obtained from the frost heave test under the condition of freeze-thaw cycle is: the greater the relative density of the cushion material, the greater the frost heave deformation. In order to make the cushion material have a high relative density without causing large frost heave deformation, it is recommended that the relative density range of the cushion material be designed as 0.75-0.80.

[0056] S02, cosmid replacement method:

[0057] Such as image 3As shown, for the requir...

Embodiment 2

[0070] Such as Figure 1-7 As shown, the cushion material gradation design optimization method based on the pore distribution index in cold regions, preferably, the rolling density of the cushion material is designed to be 0.80; , the content of the fine sand group is 8.75%, and other gradations are the same as Sherard gradation; the pore distribution index of each group of gradations in the cushion material is -6.2; the face dam made according to the above parameters can be formed at one time. There is no need for repeated debugging, which reduces the number of experiments. Under the condition of not affecting the permeability, the deformation of the dam body is small during frost heaving. The internal seepage stability of the dam body is good, low compressibility, high shear strength, and the service life of the face dam is long.

Embodiment 3

[0072] Such as Figure 1-7 As shown, the cushion material gradation design optimization method based on the pore distribution index in cold regions, preferably, the rolling density of the cushion material is designed to be 0.78; , the content of the fine sand group is 4%, and other gradations are the same as Sherard gradation; the pore distribution index of each group of gradations in the cushion material is -6.25; the face dam made according to the above parameters is formed at one time. There is no need for repeated debugging, which reduces the number of experiments. Under the condition of not affecting the permeability, the deformation of the dam body is small during frost heaving. The internal seepage stability of the dam body is good, low compressibility, high shear strength, and the service life of the face dam is long.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com