Preparation method of light-weight aggregate concrete

A lightweight aggregate concrete, a single technology, applied in the field of building materials, can solve problems such as corrosion resistance can not meet the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

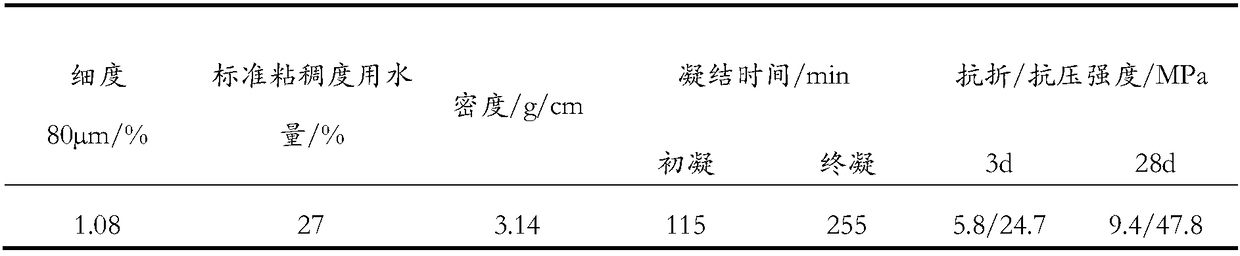

[0024] The preparation method of lightweight aggregate concrete according to the embodiment of the present invention includes: mixing water, cement, sand, plastic steel fiber, lightweight aggregate and water reducing agent according to the mixing ratio specified by the design strength level, and mixing the preset A single mineral admixture in a specific ratio or a multi-mineral admixture in a preset ratio can be used to obtain lightweight aggregate concrete.

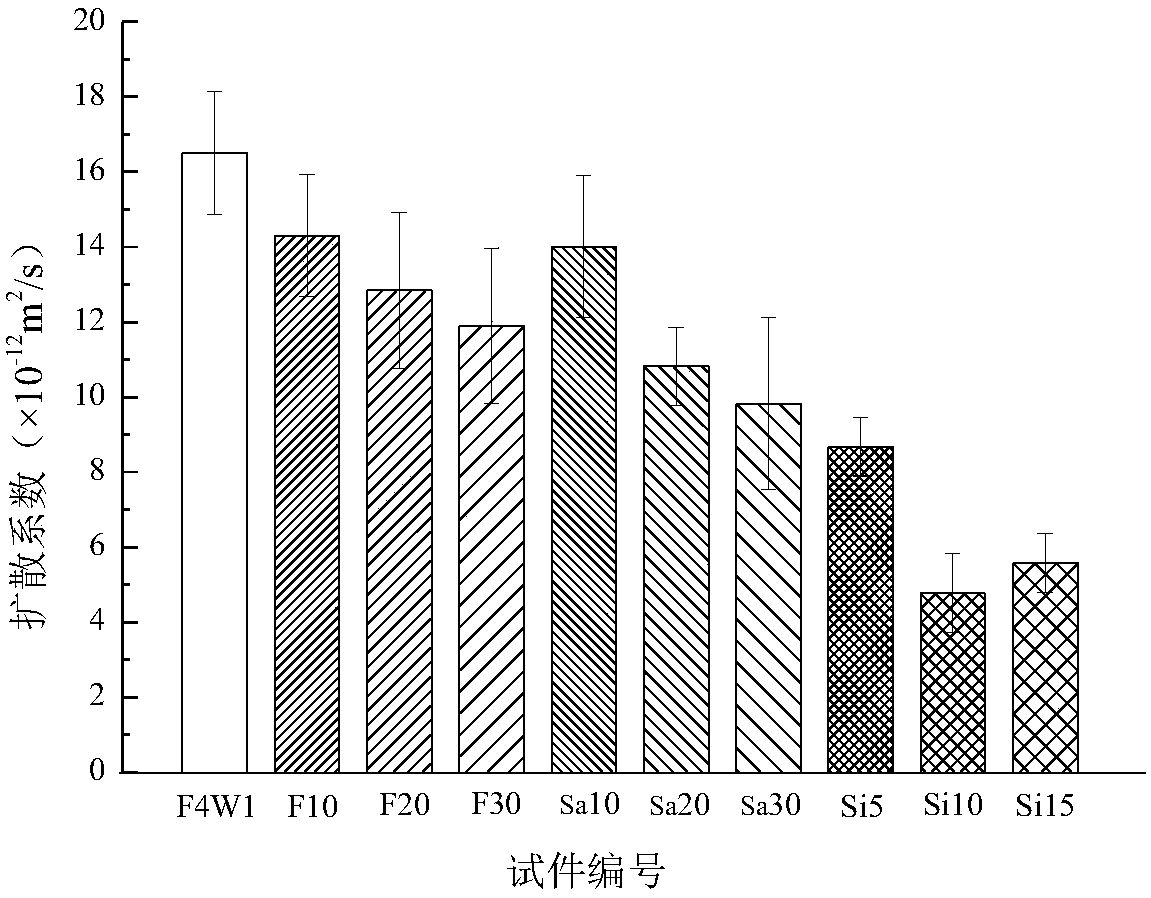

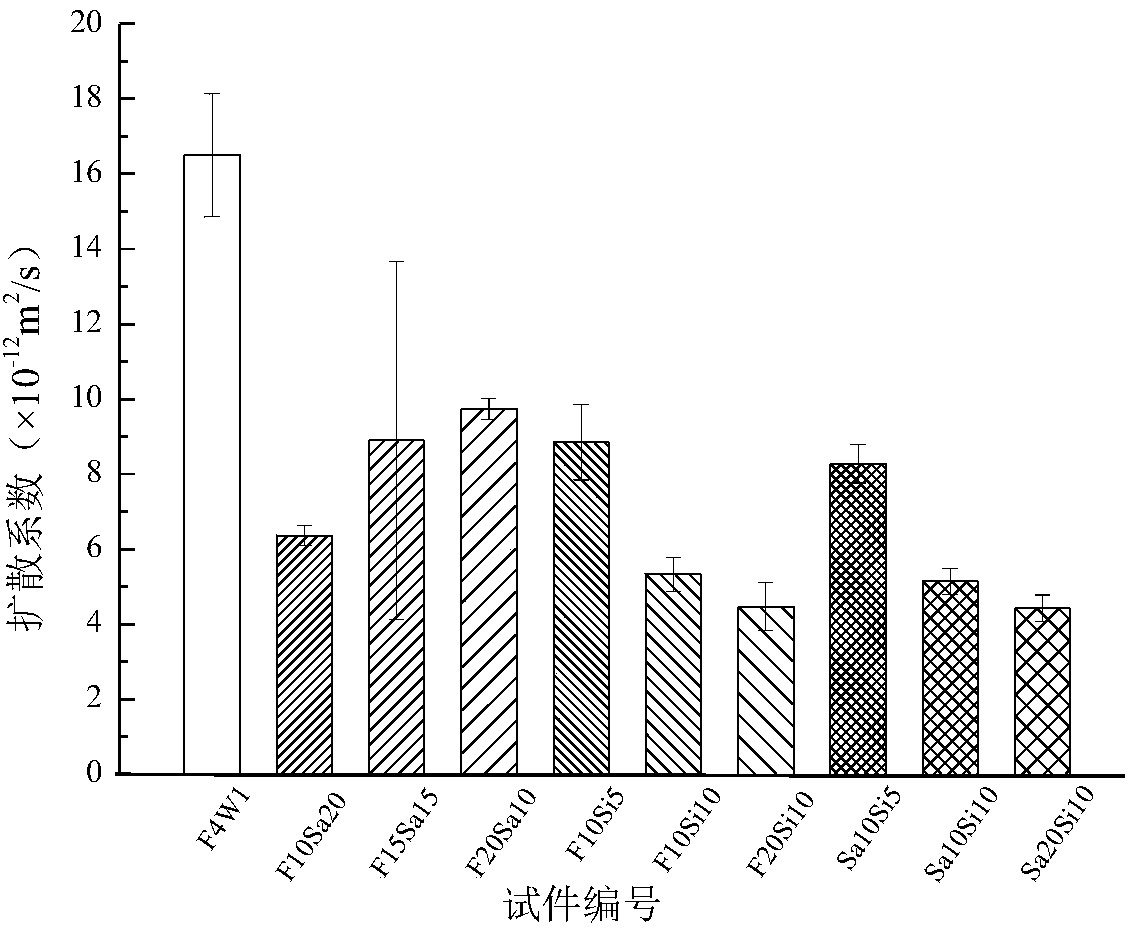

[0025] In reinforced concrete, chloride ions are the main cause of corrosion of steel bars. Lightweight aggregate itself is a porous material, and there are many connected pores inside. During the process of chloride ion penetration, these connected pores can be used as chloride ion penetration way. From the perspective of the microstructure of plastic-steel fiber lightweight aggregate concrete, the strength of the chloride ion permeability resistance of concrete is mainly related to the quality of the aggregate, cement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com