Unidirectional keel embedded assembled anti-cracking impermeable permanent formwork

An embedded and permanent technology, which is applied in the field of high-durability permanent formwork, protective panels and outer protective layers, can solve problems affecting the safe operation of structures, affecting durability and service life, and ordinary concrete is easy to crack. High crack control ability, improved durability and service life, and shortened construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is a further description of the specific implementation of the one-way keel-embedded, crack-proof and seepage-proof permanent formwork provided by the present invention with reference to the accompanying drawings.

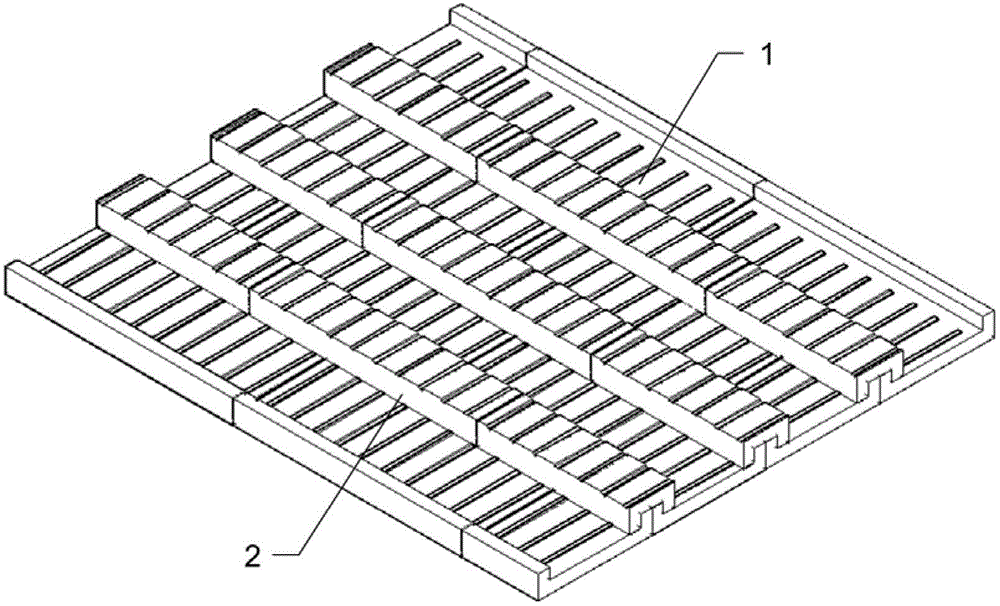

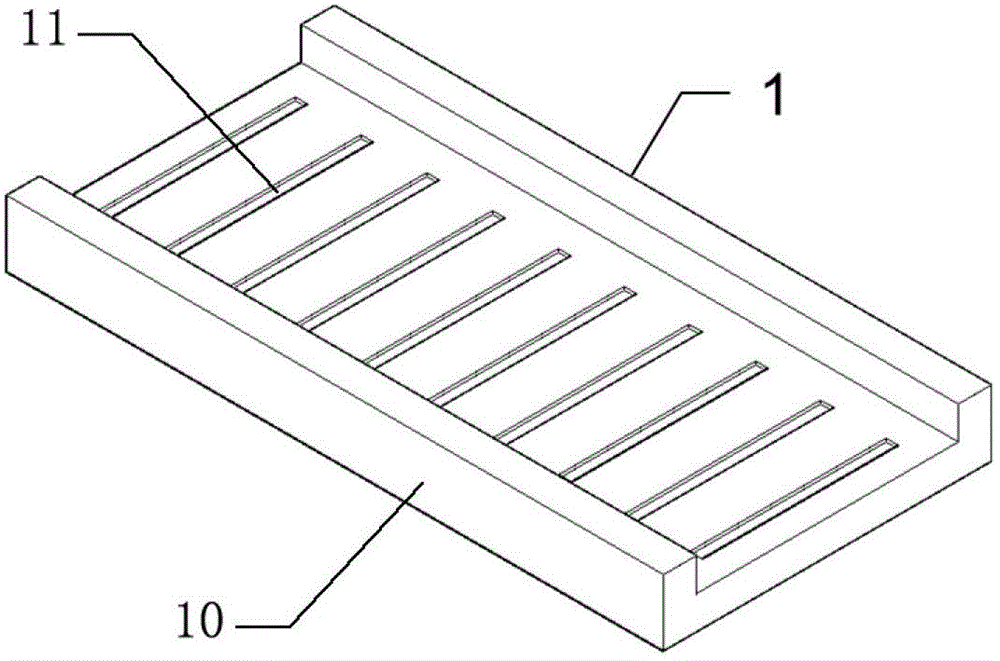

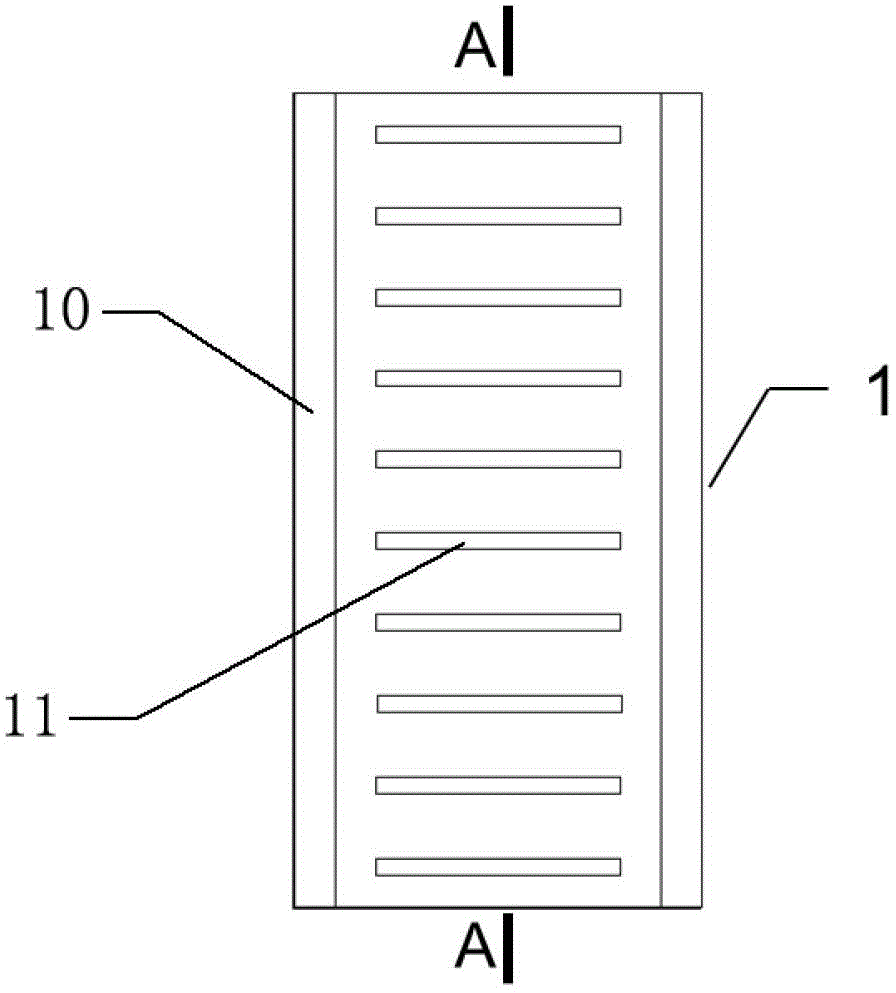

[0022] The one-way keel embedded permanent formwork of this embodiment includes six panels 1 and three connectors 2 . Such as Figure 4 As shown, the following describes the implementation method in the above situation.

[0023] 1. Use ultra-high toughness cement-based composite materials to make panels and connectors, including six panels 1 and three connectors 2. The ultra-high toughness cement-based composite material UHTCC material used to make the formwork has a tensile strain capacity of more than 1%, and the crack width under the ultimate tensile strain is less than 100 μm, and has excellent carbonation resistance, freeze-thaw resistance, and impermeability. The characteristics of impact toughness. The weight ratio of the components o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com