Underwater non-dispersible high-performance concrete

A high-performance concrete and high-performance technology, applied in the field of concrete, to achieve superior durability, good durability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions in the embodiments of the present invention will be clearly and completely described below. One aspect of the embodiments of the present invention provides a kind of underwater non-dispersible high-performance concrete, and the composition ratio is as follows:

[0019]

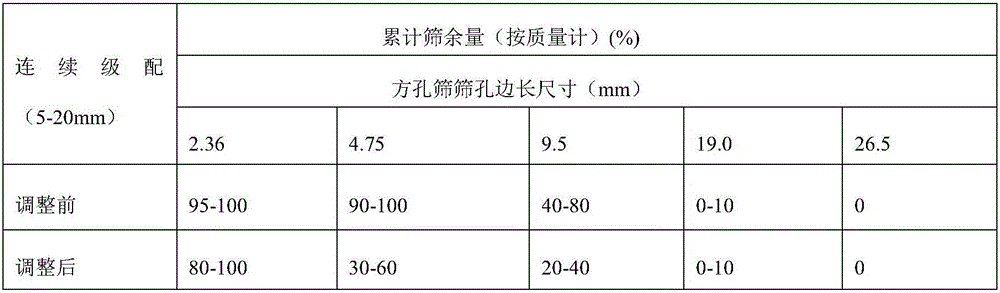

[0020] In the above-mentioned embodiments provided by the present invention, the ordinary Portland cement with a strength grade of 52.5 is selected for concrete; -20mm (2 grades) continuously graded gravel, the aggregate gradation is adjusted according to the bulk density to ensure good compactness of the concrete; the traditional flocculant is used, and the dosage is 2.5% of the cementitious material; Water agent, the dosage is 1.0% of the amount of gelling material, and the water reducing rate is greater than 25%.

[0021] According to the JTS202-2-2011 "Quality Control Standard for Water Transport Engineering Concrete" and "Quality Control Standard for High Performance Conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Electric flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com