Waterproof and corrosion-resistant coating for coastal region

A waterproof and anti-corrosion coating, regional technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of salt, alkali corrosion resistance and chloride ion penetration resistance, etc., to improve corrosion resistance and anti-corrosion Chloride ion permeability, improved compactness, improved water resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

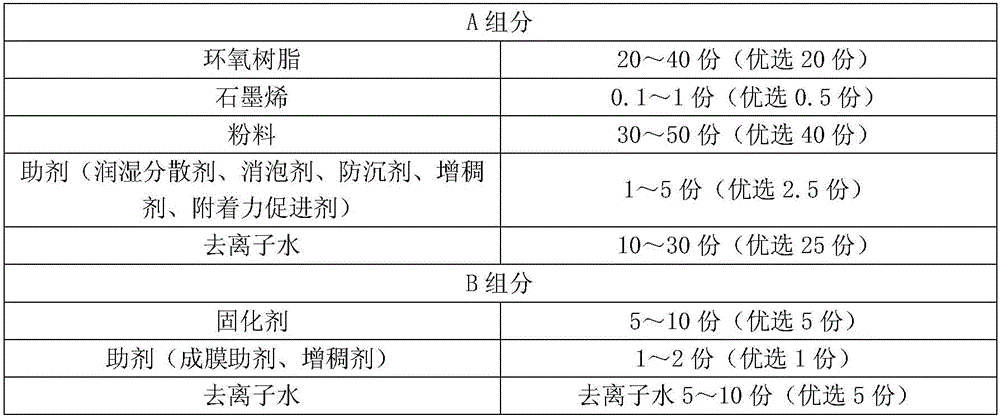

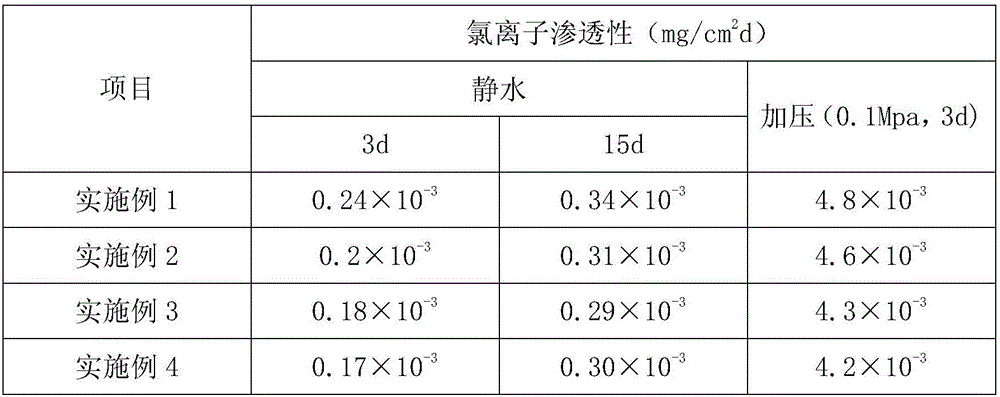

[0021] 20 parts of acrylic modified water-based epoxy resin emulsion, 0.1 part of graphene, 40 parts of powder (4 parts of titanium dioxide, 13 parts of mica powder 800 mesh, 13 parts of barium sulfate 400 mesh, 5 parts of zinc phosphate, aluminum tripolyphosphate 5 parts), 0.8 parts of wetting and dispersing agent (non-ionic polymer), 0.5 parts of defoamer (organic silicon defoamer), 0.4 parts of thickener (acrylic), 0.2 parts of anti-settling agent (gas phase Silicon dioxide), 0.2 part of anti-settling agent (organic modified bentonite), 0.4 part of adhesion promoter (silane), and 25 parts of deionized water were mixed uniformly to obtain component A.

[0022] Mix 5 parts of water-based epoxy curing agent (polyamine-epoxy adduct), 0.8 part of film-forming aid (Texanol), 0.2 part of thickener (acrylic), and 5 parts of deionized water to obtain group B point.

[0023] Mix components A and B uniformly at a ratio of 11:1 to obtain a waterproof and anti-corrosion coating for coa...

Embodiment 2

[0025] 20 parts of acrylic modified water-based epoxy resin emulsion, 0.3 part of graphene, 40 parts of powder (4 parts of titanium dioxide, 13 parts of mica powder 800 mesh, 13 parts of barium sulfate 400 mesh, 5 parts of zinc phosphate, aluminum tripolyphosphate 5 parts), 0.8 parts of wetting and dispersing agent (non-ionic polymer), 0.5 parts of defoamer (organic silicon defoamer), 0.4 parts of thickener (acrylic), 0.2 parts of anti-settling agent (gas phase Silicon dioxide), 0.2 part of anti-settling agent (organic modified bentonite), 0.4 part of adhesion promoter (silane), and 25 parts of deionized water were mixed uniformly to obtain component A.

[0026] Mix 5 parts of water-based epoxy curing agent (polyamine-epoxy adduct), 0.8 part of film-forming aid (Texanol), 0.2 part of thickener (acrylic), and 5 parts of deionized water to obtain group B point.

[0027] Mix components A and B uniformly at a ratio of 11:1 to obtain a waterproof and anti-corrosion coating for coa...

Embodiment 3

[0029] 20 parts of acrylic modified water-based epoxy resin emulsion, 0.5 part of graphene, 40 parts of powder (4 parts of titanium dioxide, 13 parts of mica powder 800 mesh, 13 parts of barium sulfate 400 mesh, 5 parts of zinc phosphate, 5 parts of aluminum tripolyphosphate part), 0.8 part of wetting and dispersing agent (non-ionic polymer), 0.5 part of defoamer (silicone defoamer), 0.4 part of thickener (acrylic), 0.2 part of anti-settling agent (gas phase two Silicon oxide), 0.2 parts of anti-settling agent (organic modified bentonite), 0.4 parts of adhesion promoter (silanes), and 25 parts of deionized water were mixed uniformly to obtain component A.

[0030] Mix 5 parts of water-based epoxy curing agent (polyamine-epoxy adduct), 0.8 part of film-forming aid (Texanol), 0.2 part of thickener (acrylic), and 5 parts of deionized water to obtain group B point.

[0031] Mix components A and B uniformly at a ratio of 11:1 to obtain a waterproof and anti-corrosion coating for c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com