An anti-erosion aluminophosphate cement-based gel material suitable for marine engineering

An aluminophosphate cement and iron-rich aluminophosphate technology, applied in the field of building materials, can solve the problems of unsolved dispersibility, poor ion erosion resistance of anti-abrasion concrete and high alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

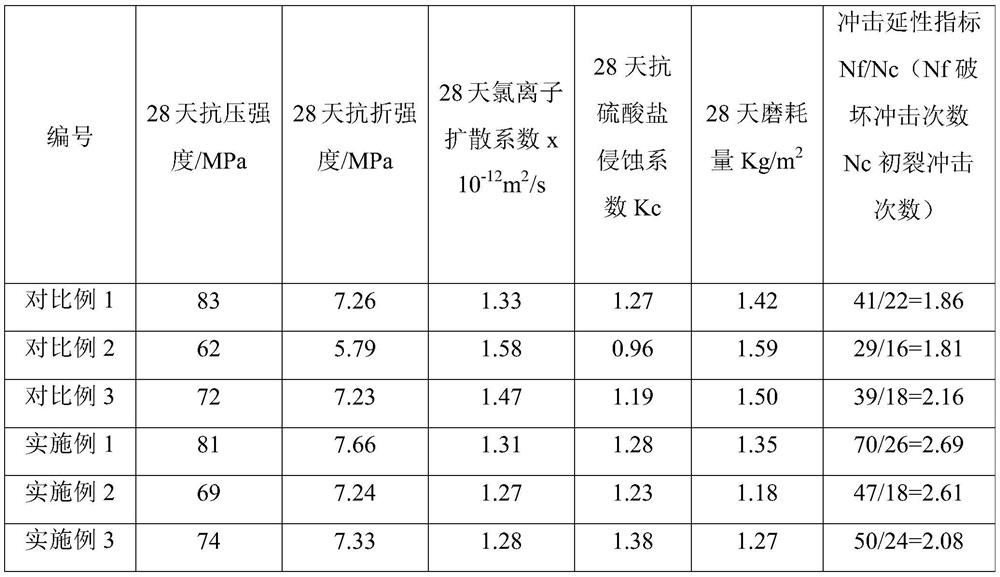

Examples

Embodiment 1

[0016] An anti-erosion aluminophosphate cement-based gel material suitable for marine engineering is prepared according to the following weight percentages:

[0017] Iron-rich aluminophosphate cement clinker 75%

[0018] Fly Ash 10%

[0019] Silicon carbide powder 8%

[0020] Rubber powder 3%

[0021] Alkali-resistant glass fiber 3%

[0022] Aluminum zirconium coupling agent 1%

[0023] Among them, the bulk density of iron-rich aluminophosphate cement clinker is 2.98g / cm 3 , the specific surface area is 319m 2 / kg, the cement fineness is 200 mesh, the sieve residue is 3.1%, the setting time is 220min for the initial setting, 260min for the final setting, and the iron phase content is 11%.

Embodiment 2

[0025] An anti-erosion aluminophosphate cement-based gel material suitable for marine engineering is prepared according to the following weight percentages:

[0026] Iron-rich aluminophosphate cement clinker 67%

[0027] Fly Ash 15%

[0028] Silicon carbide powder 4.5%

[0029] Rubber powder 6%

[0030] Alkali-resistant glass fiber 6%

[0031] Aluminum zirconium coupling agent 1.5%

[0032] Among them, the bulk density of iron-rich aluminophosphate cement clinker is 2.98g / cm 3 , the specific surface area is 319m 2 / kg, the cement fineness is 200 mesh, the sieve residue is 3.1%, the setting time is 220min for the initial setting, 260min for the final setting, and the iron phase content is 11%.

Embodiment 3

[0034] An anti-erosion aluminophosphate cement-based gel material suitable for marine engineering is prepared according to the following weight percentages:

[0035] Iron-rich aluminophosphate cement clinker 71%

[0036] Fly Ash 11%

[0037] Silicon carbide powder 7%

[0038] Rubber powder 4.5%

[0039] Alkali-resistant glass fiber 5%

[0040] Aluminum zirconium coupling agent 1.5%

[0041] Among them, the bulk density of iron-rich aluminophosphate cement clinker is 2.98g / cm 3 , the specific surface area is 319m 2 / kg, the cement fineness is 200 mesh, the sieve residue is 3.1%, the setting time is 220min for the initial setting, 260min for the final setting, and the iron phase content is 11%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com