Phosphorus slag-doped active powder concrete and preparation method thereof

A technology of active powder and concrete, which is applied in the field of building materials, can solve the problems of insufficient resource distribution and total quantity, unsatisfactory concrete engineering, low content, etc., achieve excellent frost resistance and chloride ion permeability resistance, promote high-efficiency utilization, The effect of saving resources and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0013] Example 1 (there are two products in this example, and their numbers are recorded as 1-1 and 1-2 respectively):

[0014] Phosphorous slag powder reactive powder concrete is prepared from cement, phosphorus slag powder, silica fume, water reducing agent, quartz sand, mixing water and steel fiber by the following method:

[0015] 1) Weighing of raw materials: Weigh each component according to the ratio shown in Table 1. Among them, the cement is P.O42.5, and its 28d compressive strength is 51.0MPa; the specific surface area of phosphorus slag powder is 397m 2 / kg, the fluidity ratio is 96%; the specific surface area of silica fume is 20000m 2 / kg, SiO 2 The content is 91%; the water reducing agent is a non-retarding polycarboxylate high-performance water reducing agent, and the water reducing rate is 30%; the particle size range of quartz sand is 0.16-0.63mm; the steel fiber is copper-plated flat straight micro-steel fiber, The diameter is 0.2mm, the length is 13mm...

example 2

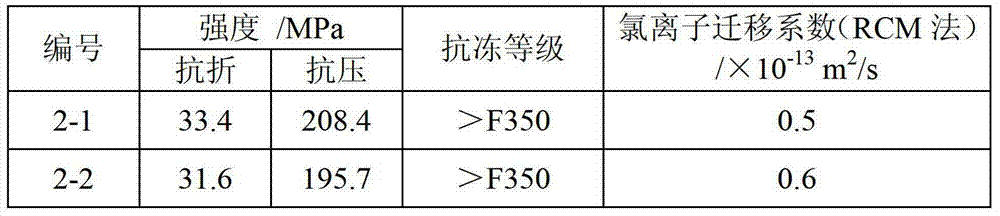

[0022] Example 2 (there are also two products in this example, whose serial numbers are respectively marked as 2-1 and 2-2):

[0023] Phosphorous slag-doped active powder concrete is prepared from cement, phosphorus slag powder, silica fume, water reducing agent, quartz sand, mixing water and steel fiber by the following method:

[0024] 1) Weighing of raw materials: Weigh each component according to the ratio shown in Table 3.

[0025] Table 3 Mixing ratio of phosphorus-doped slag active powder concrete (shown in the table is the parts by mass of each component)

[0026] Numbering

cement

Phosphorus slag powder

Quartz sand

steel fiber

water

2-1

50

35

15

100

15.6

14

2.5

2-2

50

35

15

100

15.6

16

2

[0027] Among them, the cement is P.O52.5 cement, the 28d compressive strength is 58.3MPa; the specific surface area of phosphorus slag ...

example 3

[0033] Example 3 (there are still two products in this example, whose serial numbers are recorded as 3-1 and 3-2 respectively):

[0034] Phosphorous slag-doped active powder concrete is prepared from cement, phosphorus slag powder, silica fume, water reducing agent, quartz sand, mixing water and steel fiber by the following method:

[0035] 1) Weighing of raw materials: Weigh each component according to the ratio shown in Table 5. Among them, the cement is PO52.5 cement, the 28d compressive strength is 58.3MPa; the specific surface area of phosphorus slag powder is 423m 2 / kg; fluidity ratio 98%; specific surface area of silica fume 20000m 2 / kg, SiO 2 The content is 96.9%; the water reducing agent is a non-retarding polycarboxylate high-performance water reducing agent, and the water reducing rate is 30%; the particle size range of quartz sand is 0.16-0.63mm; the steel fiber is copper-plated flat straight micro-steel fiber, The diameter is 0.2mm, the length is 13mm, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com