Underwater-curing long-acting anticorrosive coating for marine steel structures, and preparation method thereof

A long-term anti-corrosion, underwater curing technology, used in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problem of water being difficult to completely remove, affecting the performance of the paint film, etc., to ensure adhesion and curing shrinkage. , the effect of hard coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

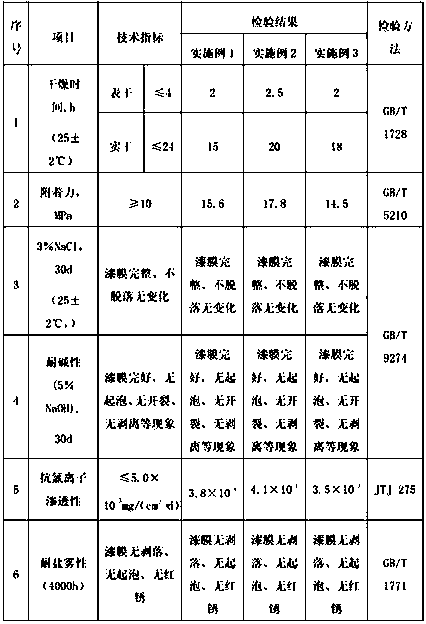

Examples

Embodiment 1

[0037] A preparation method for underwater solidified marine steel structure long-acting anti-corrosion coating, wherein, component A:

[0038] Phenolic modified epoxy resin: 45 parts

[0039] ZG8013 reactive diluent: 6 parts

[0040] Filling: 47 servings

[0041] Polyamide wax: 0.3 parts

[0042] BYK-2055: 0.8 parts

[0043] TEGO Foamex N: 0.5 parts

[0044] KH560: 0.6 parts

[0045] Component B:

[0046] Ancamide 2386: 50 servings

[0047] Modified amine curing agent: 50 parts

[0048] The preparation method comprises the following steps:

[0049] (1) Preparation of component A:

[0050] Step 1: Add phenolic modified epoxy resin, epoxy reactive diluent, wetting and dispersing agent, and coupling agent into the dispersion tank in proportion, and disperse at a speed of 1000r / min for 5 minutes to fully disperse evenly;

[0051] Step 2: Add thixotropic agent in proportion, first disperse at 800r / min for 5 minutes, then increase the dispersing speed to 1350r / min, and cont...

Embodiment 2

[0058] A preparation method for underwater solidified marine steel structure long-acting anti-corrosion coating, wherein, component A:

[0059] Phenolic modified epoxy resin: 50 parts

[0060] ZG8013 reactive diluent: 3 parts

[0061] Filling: 55 parts

[0062] Polyamide wax: 0.2 parts

[0063] BYK-2055: 1.0 copies

[0064] TEGO Foamex N: 0.3 parts

[0065] KH560: 0.3 parts

[0066] Component B:

[0067] Ancamide 2386: 60 servings

[0068] Modified amine curing agent: 40 parts

[0069] The preparation method comprises the following steps:

[0070] (1) Preparation of component A:

[0071] Step 1: Add phenolic modified epoxy resin, epoxy reactive diluent, wetting and dispersing agent, and coupling agent into the dispersion tank in proportion, and disperse at a speed of 900r / min for 5 minutes to fully disperse evenly;

[0072] Step 2: Add thixotropic agent in proportion, first disperse at 750r / min for 5 minutes, then increase the dispersing speed to 1000r / min, and conti...

Embodiment 3

[0079] A preparation method for underwater solidified marine steel structure long-acting anti-corrosion coating, wherein, component A:

[0080] Phenolic modified epoxy resin: 20 parts

[0081] ZG8013 reactive diluent: 8 parts

[0082] Filling: 25 servings

[0083] Polyamide wax: 1.0 parts

[0084] BYK-2055: 0.3 parts

[0085] TEGO Foamex N: 0.8 parts

[0086] KH560: 1.0 parts

[0087] Component B:

[0088] Ancamide 2386: 40 servings

[0089] Modified amine curing agent: 60 parts

[0090] The preparation method comprises the following steps:

[0091] (1) Preparation of component A:

[0092] Step 1: Add phenolic modified epoxy resin, epoxy active diluent, wetting and dispersing agent, and coupling agent into the dispersion tank in proportion, and disperse at a speed of 800r / min for 5 minutes to fully disperse evenly;

[0093] Step 2: Add thixotropic agent in proportion, first disperse at 500r / min for 5 minutes, then raise the dispersing speed to 1500r / min, and continue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com