Ultraviolet-curing light oil for plastic top-coat and preparation method thereof

A technology of ultraviolet light and varnish, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as the inability to further improve coating film performance, increase the content of inorganic components in coatings, and harm the environment and human body, and achieve Excellent wear resistance, improved mechanical properties and heat, good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

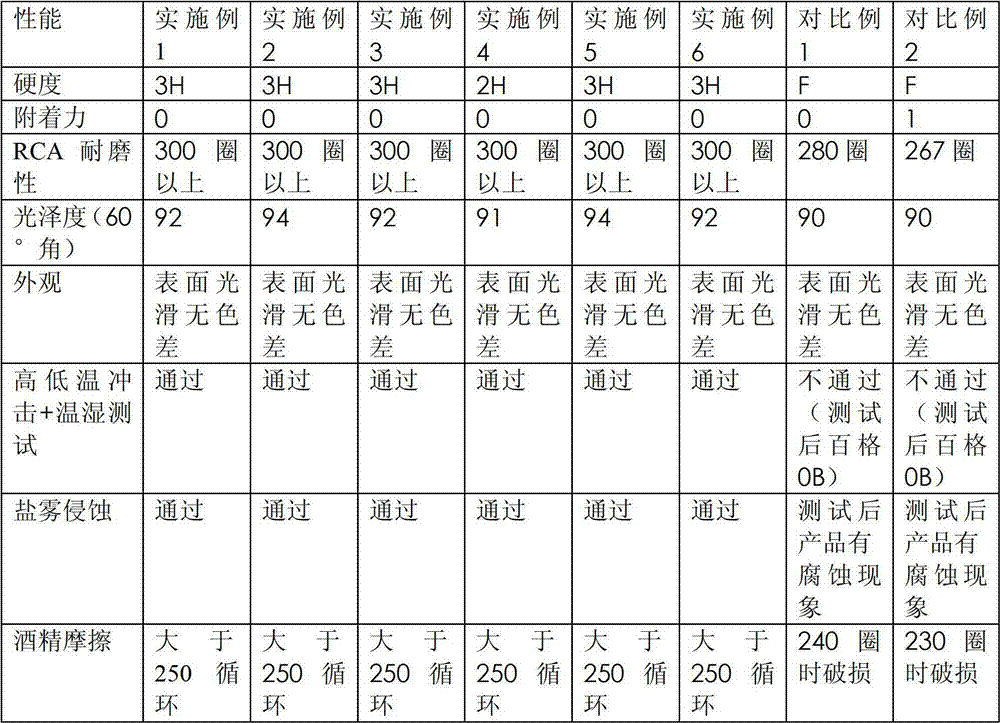

Examples

Embodiment 1

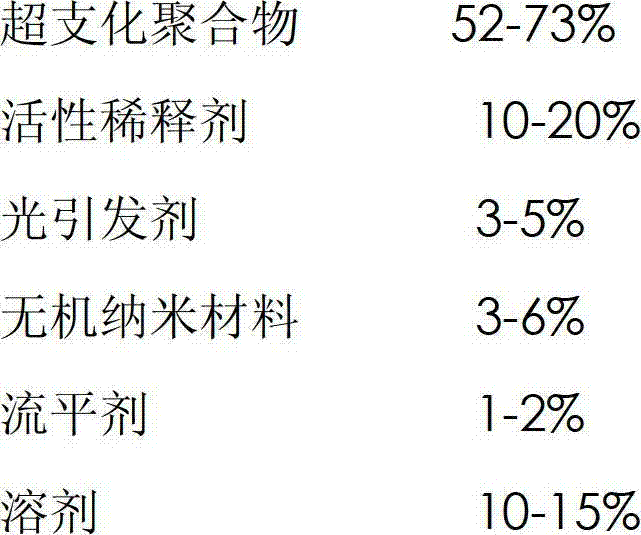

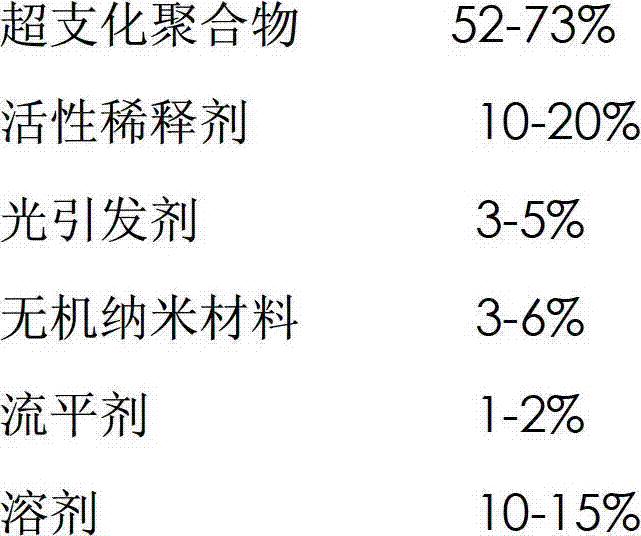

[0029] The weight percent composition of the UV-curable varnish for plastic topcoat is as follows:

[0030] Hyperbranched polyester acrylate (UVR-55, Japan Toi Chemical Co., Ltd.) 60%

[0031] Trimethylolpropane Triacrylate (TMPTA) 14%

[0032] Dipropylene glycol diacrylate (DPGDA) 6%

[0033] Hydroxycyclohexylbenzophenone (Irgacure184) 3%

[0034] Gas phase nano-SiO 2 (Degussa AEROSIL R972) 6%

[0035] Leveling agent (BYK306) 1%

[0036] Isopropanol 5%

[0037] Butyl acetate 5%

[0038] During the preparation, 6 g of Gas phase nano-SiO 2 (Degussa AEROSIL R972) was uniformly dispersed in 14g reactive diluent trimethylolpropane triacrylate (TMPTA) and 6g dipropylene glycol diacrylate (DPGDA), and then added 60g hyperbranched polyester acrylate ( Japan Toi Chemical Co., Ltd. UVR-55), 3g initiator hydroxycyclohexyl benzophenone (Irgacure184), 1g leveling agent BYK306, 5g isopropanol, 5g butyl acetate, mix well and stir well to obtain UV-curable coating.

[0039] Spray t...

Embodiment 2

[0041] The weight percent composition of the UV-curable varnish for plastic topcoat is as follows:

[0042] Hyperbranched polyester acrylate (UVR-55, Japan Toi Chemical Co., Ltd.) 15%

[0043] Hyperbranched polyurethane acrylate (UVR-52, Japan Toi Chemical Co., Ltd.) 46%

[0044] Trimethylolpropane Triacrylate (TMPTA) 10%

[0045] Tripropylene glycol diacrylate (TPGDA) 7%

[0046] Hydroxycyclohexylbenzophenone (Irgacure184) 2%

[0047] α,α-Dimethyl-α-hydroxyacetophenone (Irgacure1173) 1%

[0048] Gas phase nano-SiO 2(Degussa AEROSIL R972) 4%

[0049] Leveling agent (GLK383) 2%

[0050] Ethyl acetate 5%

[0051] Butyl acetate 8%

[0052] During the preparation, 4g of Gas phase nano-SiO 2 (Degussa AEROSIL R972) was uniformly dispersed in 10g reactive diluent TMPTA and 7gDPGDA in advance, and then added 15g hyperbranched polyester acrylate (UVR-55 from Japan Toi Chemical Co., Ltd.), 46g hyperbranched polyurethane acrylate ( Japan Toi Chemical Co., Ltd. UVR-52), 2g init...

Embodiment 3

[0055] The weight percent composition of the UV-curable varnish for plastic topcoat is as follows:

[0056] Hyperbranched polyester acrylate (UVR-55, Japan Toi Chemical Co., Ltd.) 27%

[0057] Hyperbranched urethane acrylate (UVR-52, Japan Toi Chemical Co., Ltd.) 38%

[0058] Trimethylolpropane Triacrylate (TMPTA) 7%

[0059] 1,6-Hexanediol diacrylate (HDDA) 6%

[0060] Hydroxycyclohexylbenzophenone (Irgacure184) 3%

[0061] Gas phase nano-SiO 2 (Degussa AEROSIL R972) 5%

[0062] Leveling agent (BYK361) 2%

[0063] Butyl acetate 6%

[0064] Methyl isobutyl ketone 6%

[0065] During the preparation, a high-speed shear disperser (GFJ-0.4 type, Shanghai Modern Environmental Engineering Technology Co., Ltd.) and ultrasonic oscillation (ultrasonic cell disruptor BRANSON Models450) were used to dissolve 5 g of nano-SiO 2 (Degussa AEROSIL R972) was uniformly dispersed in 7g of reactive diluent TMPTA and 6g of HDDA in advance, and then 27g of hyperbranched polyester acrylate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com