Ultra-high performance concrete with low water-binder ratio and preparation method thereof

A technology with ultra-high performance and water-binder ratio, applied in the field of concrete, can solve problems such as not being able to meet the requirements of use well, and achieve the effects of excellent resistance to chloride ion penetration, excellent mechanical properties, and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

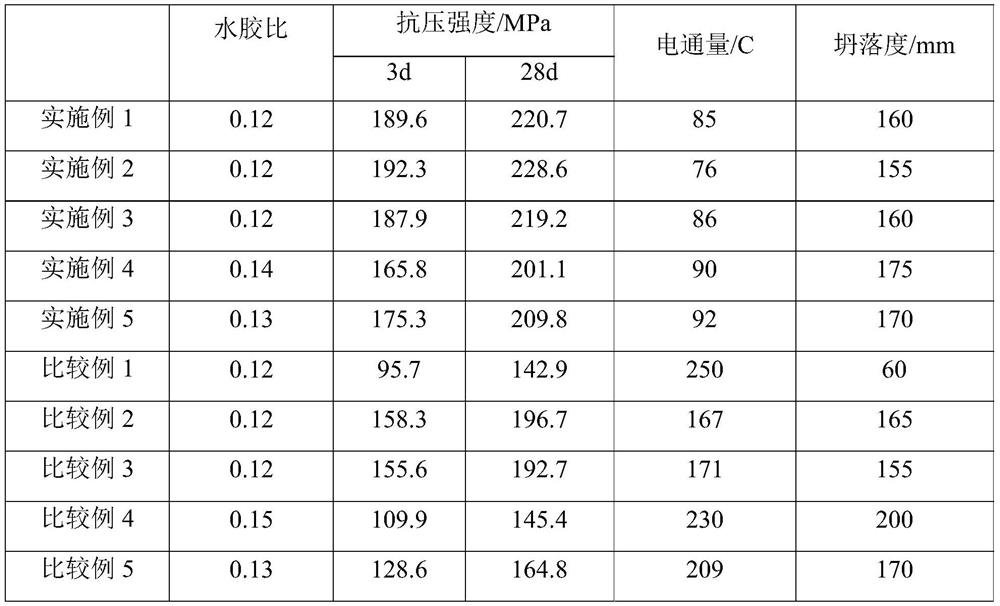

Examples

preparation example Construction

[0022] The present invention also provides a method for preparing ultra-high performance concrete with a low water-binder ratio as described above, including:

[0023] 1) The polycarboxylate water reducer, defoamer and water are first mixed to obtain the admixture;

[0024] 2) secondly mixing cement, silica fume, fly ash, mineral powder and sand to obtain a mixed powder, and then adding steel fibers under stirring to obtain a mixed material;

[0025] 3) The mixture, admixture and water are mixed for the third time to obtain ultra-high performance concrete with low water-binder ratio.

[0026] In the above-mentioned preparation method, the mode and time of the first mixing can be selected in a wide range, but in order to further improve the mechanical properties (crack resistance and compression resistance), fluidity and chloride ion penetration resistance of concrete, preferably , the first mixing is carried out by stirring, and the mixing time is 100-200s.

[0027] In the a...

Embodiment 1

[0039] 1) Weigh 152g of polycarboxylate superplasticizer-1, 0.3g of defoamer-1 and 152g of water, stir for 150s to obtain the admixture, and set aside;

[0040] 2) Weigh 4.52kg of PⅡ52.5 cement, 2.28kg of S140 mineral powder, 500g of silica fume-1, 298g of grade I fly ash, 7.6kg of natural quartz sand (average particle size is 1.0mm), 2.2kg of steel fiber (length 18mm, diameter 0.20mm), spare.

[0041] Add cement, mineral powder, silica fume, fly ash, and natural quartz sand into the mixing pot and stir for 120s, then add steel fibers while stirring. The feeding time of steel fibers is controlled at 60s. After the feeding is completed, continue stirring for 120s to obtain Mixture.

[0042] 3) Add 304.3g of admixture and 912g of water to the above mixture, and stir for 120s to prepare a concrete mixture.

[0043] 4) The concrete mixture prepared above was placed in a concrete mold by pouring, placed on a concrete vibrating table, vibrated for 120s, and finally placed in a sta...

Embodiment 2

[0045] According to the method of Example 1, the difference is that the polycarboxylate superplasticizer-1 is replaced by the polycarboxylate superplasticizer-2, the defoamer-1 is replaced by the defoamer-2, and the PⅡ52. 5 Replace cement with PO 52.5 cement, replace grade I fly ash with grade II fly ash, replace silica fume-1 with silica fume-2, replace natural quartz sand with artificial quartz sand, and replace S140 mineral powder with S120 slag powder, the average particle size of quartz sand is 0.08mm; the steel fiber meets the requirements: the length is 12mm, and the diameter is 0.22mm;

[0046] In steps 2) and 3), the weight ratio of cement, silica fume-2, fly ash, mineral powder, quartz sand, steel fiber, admixture and water is 500:50:20:250:900:250:30: 80, 1 part by weight corresponds to 8g; in step 1), the weight ratio of polycarboxylate superplasticizer-2, defoamer-2 and water is 30:0.07:40, 1 part by weight corresponds to 5g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com