A kind of granite stone powder concrete whose strength grade is not greater than C40 and its preparation method

A technology of granite rock powder and strength grade, applied in the field of concrete, can solve the problem of lack of research on the reaction mechanism of granite rock powder, and achieve the effect of saving cement and improving the interface structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The above-mentioned content of the present invention will be described in further detail below through the embodiment form, but this should not be interpreted as the scope of the above-mentioned theme of the present invention is limited to the following embodiments, all technologies realized based on the above-mentioned content of the present invention belong to this invention the scope of the invention.

[0033] 1. The materials used in the test are as follows:

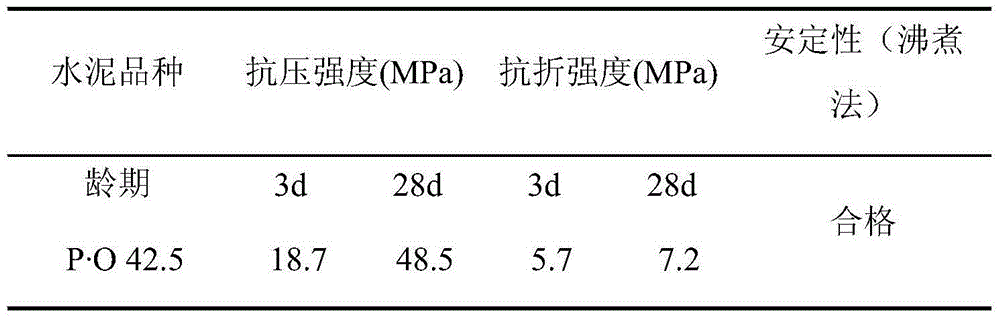

[0034] Cement: P·O42.5 Ordinary Portland Cement

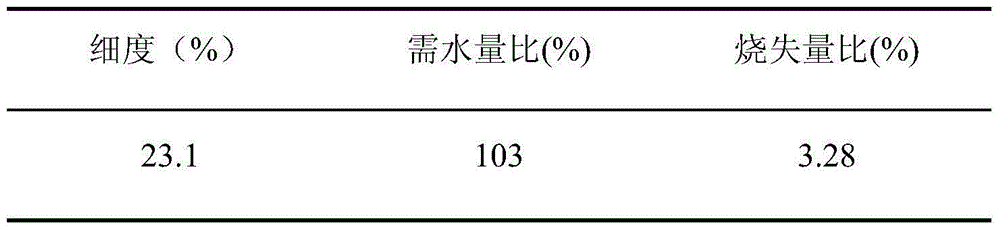

[0035] Mineral powder: S95 mineral powder

[0036] Fly ash: Class II fly ash

[0037] Stone powder: Granite stone powder (45μm sieve remaining 38.2%)

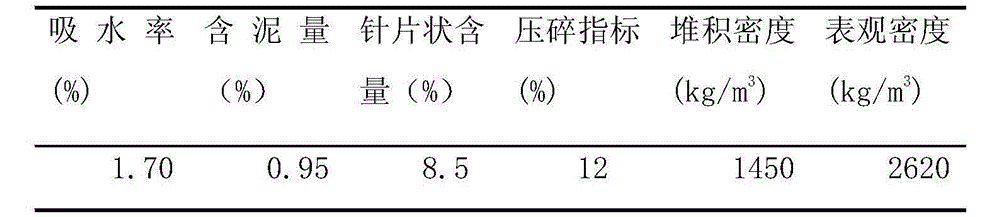

[0038] Coarse aggregate: 5-25mm continuous graded granite crushed stone, meeting the requirements of JGJ52-2006

[0039] Fine aggregate: machine-made sand, medium sand with a fineness modulus of 3.1 that meets the requirements of JGJ52-2006, and a mud content of 3%

[0040] Admixture: Self-compounded polyca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com