Hydrophilic dual-effect array coating capable of promoting aluminum melt spreading and preparation method thereof

A technology of aluminum melt and aluminum coating, which is applied in coating, metal material coating process, melt spraying and other directions to achieve the effects of improving film formation and interface heat exchange, improving film formation rate, and expanding the scope of spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

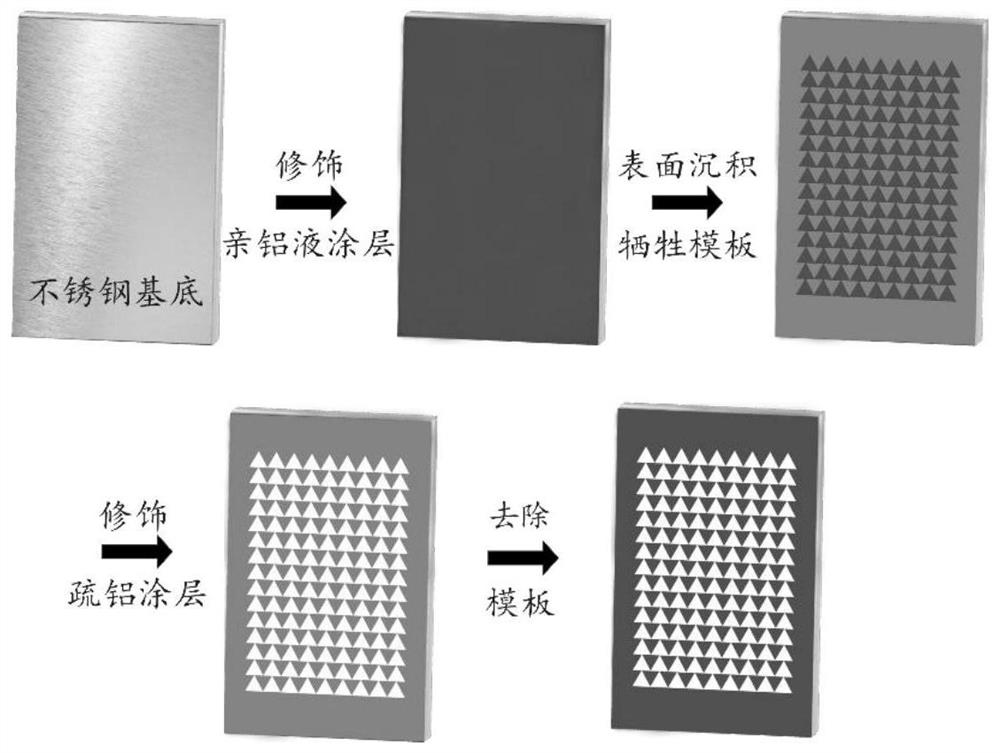

[0026] The preparation method of the hydrophilic-phobic dual-effect array coating that can promote the spreading of aluminum melt provided by the present invention, see figure 1 shown, including the following steps:

[0027] choose a base;

[0028] modifying a 2mm thick aluminophilic liquid coating on the substrate;

[0029] A 2mm thick aluminum layer is deposited on the aluminophilic liquid coating as a sacrificial template;

[0030] A 2mm thick aluminum-repellent liquid coating is decorated on the sacrificial template; in order to ensure the regular distribution of the aluminum-repellent coating, the aluminum-repellent liquid coating is composed of an array of aluminum-repellent coating units;

[0031] Then, the sacrificial template is etched to expose a part of the aluminum-philic liquid coating on the upper layer of the substrate, that is, the dual-effect array coating of hydrophilic and phobic effect is obtained on the substrate.

Embodiment 1

[0033] A preparation method of a hydrophilic-phobic dual-effect array coating that can promote the spreading of aluminum melt, comprising the following steps:

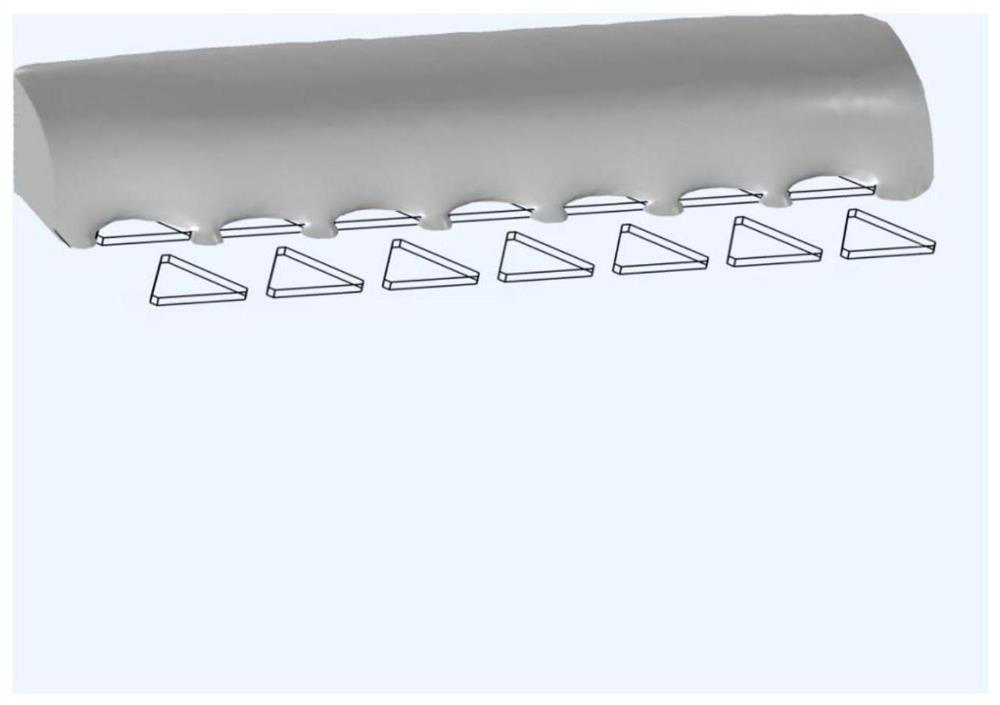

[0034] Firstly, 304 stainless steel plate is selected as the substrate, and the chrome-plated coating on the surface of the substrate is modified by plasma spraying as the aluminum-philic liquid coating. Coating method to modify 2mm thick TiO 2 The coating is used as aluminophobic liquid coating, and the modified aluminophobic liquid coating is composed of aluminophobic coating units arranged in an array; the shape of each aluminophobic coating unit is an isosceles triangle with an apex angle of 60°, The distribution spacing of each triangle is 6mm, and finally the etching template exposes part of the chrome coating on the upper layer of the substrate to obtain chrome-TiO 2 Philophilic aluminum dual-effect array coating.

Embodiment 2

[0036] A preparation method of a hydrophilic-phobic dual-effect array coating that can promote the spreading of aluminum melt, comprising the following steps: firstly, a 304 stainless steel plate is selected as a substrate, and a chrome-plated coating is modified on the surface of the substrate by a plasma spraying method as an aluminum-philic liquid coating, After completion, a 2mm-thick aluminum layer was deposited on the aluminophilic liquid coating as a sacrificial template, and then the 2mm-thick TiO was modified by direct coating. 2 The coating is used as aluminophobic liquid coating, and the modified aluminophobic liquid coating is composed of aluminophobic coating units arranged in an array; the shape of each aluminophobic coating unit is an isosceles triangle with an apex angle of 30°, The distribution spacing of each triangle is 5mm, and finally, the template is etched to expose part of the chrome coating on the upper layer of the substrate to obtain chrome-TiO 2 Phi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com