Heat sink zinc-based microalloy

A micro-alloy, zinc-based technology, applied in stacked capacitors, parts of fixed capacitors, electrodes of fixed capacitors, etc., can solve the problems of inconvenient storage, transportation and production management, low density, splashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

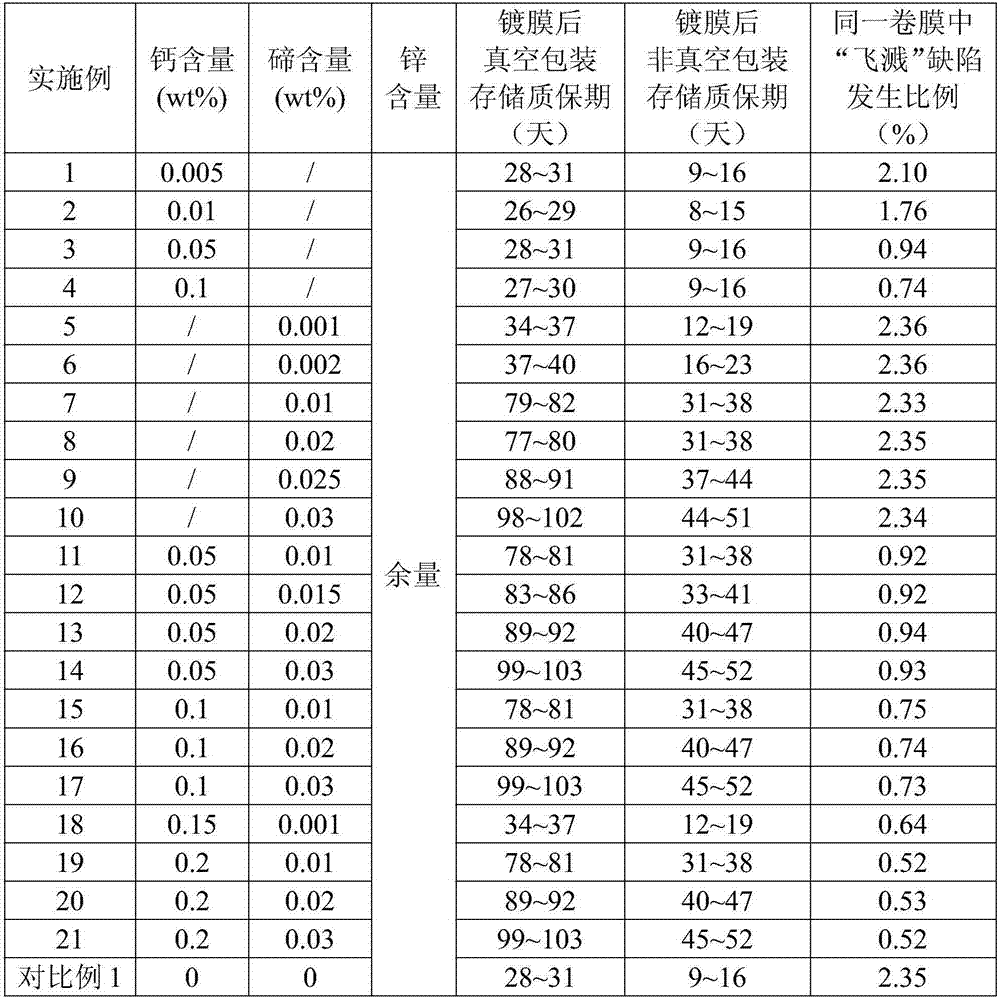

Examples

Embodiment 1

[0015] Embodiment 1: A heat sinking zinc-based microalloy, with zinc as the matrix, adding a trace amount of calcium, the components are composed of 0.005% calcium by weight percentage, and the total amount of impurities is not more than 0.02%. The amount is zinc, and the weight percentage sum of each component is 100%.

[0016] Embodiment: 2: a kind of heat-sinking zinc-based microalloy, with zinc as matrix, add trace calcium, described each component composition is respectively calcium 0.01% by weight percentage, and the impurity that total amount is not more than 0.02%, The balance is zinc, and the weight percentage sum of each component is 100%

Embodiment 3

[0017] Embodiment 3: A heat sinking zinc-based microalloy, with zinc as the matrix, adding a trace amount of calcium, the components are composed of 0.05% calcium by weight percentage, and the total amount of impurities is not more than 0.02%. The amount is zinc, and the weight percentage sum of each component is 100%

Embodiment 4

[0018] Embodiment 4: A heat-sinking zinc-based microalloy, with zinc as the matrix, adding a small amount of calcium, the components are composed of 0.1% calcium by weight percentage, and the total amount of impurities is not more than 0.02%. The amount is zinc, and the weight percentage sum of each component is 100%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com