Soldering lug for CAB soldering without soldering flux

A flux-free, brazing technology, applied in welding equipment, welding media, welding/cutting media/materials, etc., can solve the problems that cannot be applied, and the brazing sheet cannot be brazed with CAB flux-free, so as to save materials. The effect of dosage, simple structure and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

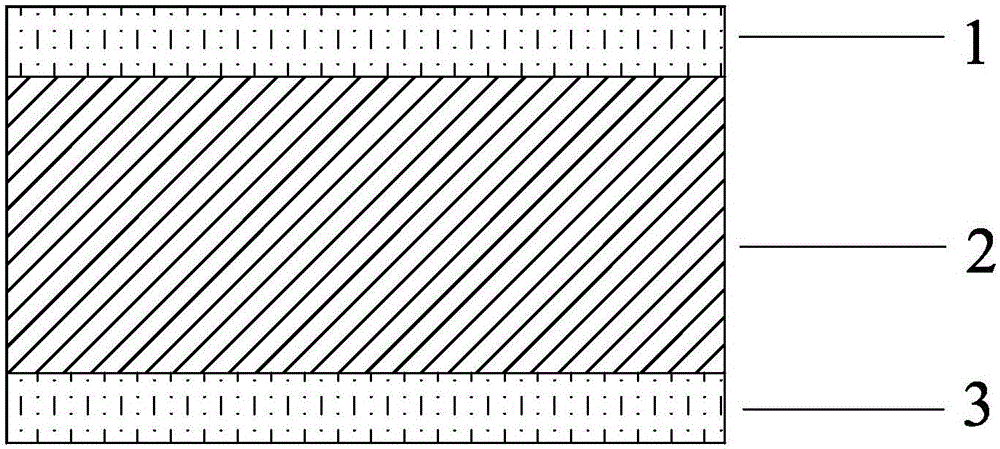

[0024] refer to figure 1 , a solder sheet for CAB flux-free brazing of the present invention, comprising a solder layer 2 and skin layers 1 and 3 coated on both sides of the solder layer, and the solder layer 2 contains 5% to 15% of Silicon, 0.01%-1% magnesium and 0.05%-0.15% bismuth, the skin layers 1 and 3 contain 3%-12% Si and less than 0.10% magnesium.

[0025] The beneficial effects of the present invention are further illustrated below through a group of comparative tests.

[0026] Using casting equipment medium frequency induction furnace and mould, cast an ingot block with a length of 300mm, a width of 200mm, and a thickness of 30mm, and use a spectrum analyzer to test the chemical composition of the alloy as shown in Table 1, where A represents the cortical alloy and B represents the solder layer alloy.

[0027] The chemical composition of each layer tested in Table 1

[0028] layers layer type Si Fe mn Mg Bi Cu Al A1 cortex 8.25 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com