Multi-size surface microstructure composite regulation aluminum stainless steel laser connection method

A connection method and stainless steel technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as brittle compounds and thermal stress cracking, and achieve the effects of optimizing stress distribution, improving joint strength, and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

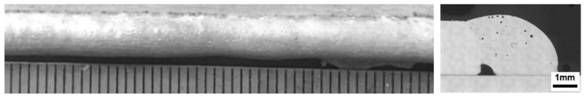

[0053] The invention provides a method for laser joining of aluminum and stainless steel with multi-scale surface microstructure compound control, which is prepared according to the following steps:

[0054] Specifically include the following steps:

[0055] Clean the stainless steel and aluminum plates to be welded before welding.

[0056] The material to be welded is 2mm thick 304 stainless steel and 2mm thick 6063 aluminum alloy, and the stainless steel plate and aluminum plate to be welded are cleaned before welding. The aluminum plate is polished with sandpaper and then wiped with acetone.

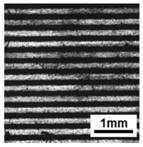

[0057] Laser etching was carried out on the surface of the cleaned stainless steel plate to prepare the surface microstructure.

[0058] A short-pulse nanosecond laser was used to perform laser etching on the stainless steel obtained after cleaning. The laser power was 90W, the scanning speed was 600mm / s, and the scanning times were 10 times. The scanning strategy is set to be line...

Embodiment 2

[0068] This embodiment provides a method for laser joining of aluminum and stainless steel with composite control of multi-scale surface microstructures, which specifically includes the following steps:

[0069] Clean the stainless steel and aluminum plates to be welded before welding.

[0070] The material to be welded is 2mm thick 304 stainless steel and 2mm thick 6063 aluminum alloy, and the stainless steel plate and aluminum plate to be welded are cleaned before welding. The aluminum plate is washed with sodium hydroxide solution, pickled with hydrochloric acid, and wiped with acetone after drying.

[0071] Laser etching was carried out on the surface of the cleaned stainless steel plate to prepare the surface microstructure.

[0072] A short-pulse nanosecond laser was used to perform laser etching on the cleaned stainless steel, the laser power was 150W, the scanning speed was 500mm / s, and the number of scanning was 15 times. The scanning strategy is set to be linear, m...

Embodiment 3

[0083] This embodiment provides a method for laser joining of aluminum and stainless steel with composite control of multi-scale surface microstructures, which specifically includes the following steps:

[0084] Clean the stainless steel and aluminum plates to be welded before welding.

[0085] The material to be welded is 2mm thick 304 stainless steel and 2mm thick 6063 aluminum alloy, and the stainless steel plate and aluminum plate to be welded are cleaned before welding. The aluminum plate is washed with sodium hydroxide solution, pickled with hydrochloric acid, and wiped with acetone after drying.

[0086]Laser etching was carried out on the surface of the cleaned stainless steel plate to prepare the surface microstructure.

[0087] A short-pulse nanosecond laser was used to perform laser etching on the stainless steel obtained after cleaning. The laser power was 100W, the scanning speed was 1500mm / s, and the number of scanning was 30 times. The scanning strategy is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com