Asphalt warm mixing agent, preparation method and application

A warm mix agent and asphalt technology, applied in climate change adaptation, building thermal insulation materials, building components, etc., can solve the problems of restricting the popularization and application of warm mix agents, less development and research, etc., and achieve great practical significance and economical, raw materials. Easy to get, low dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

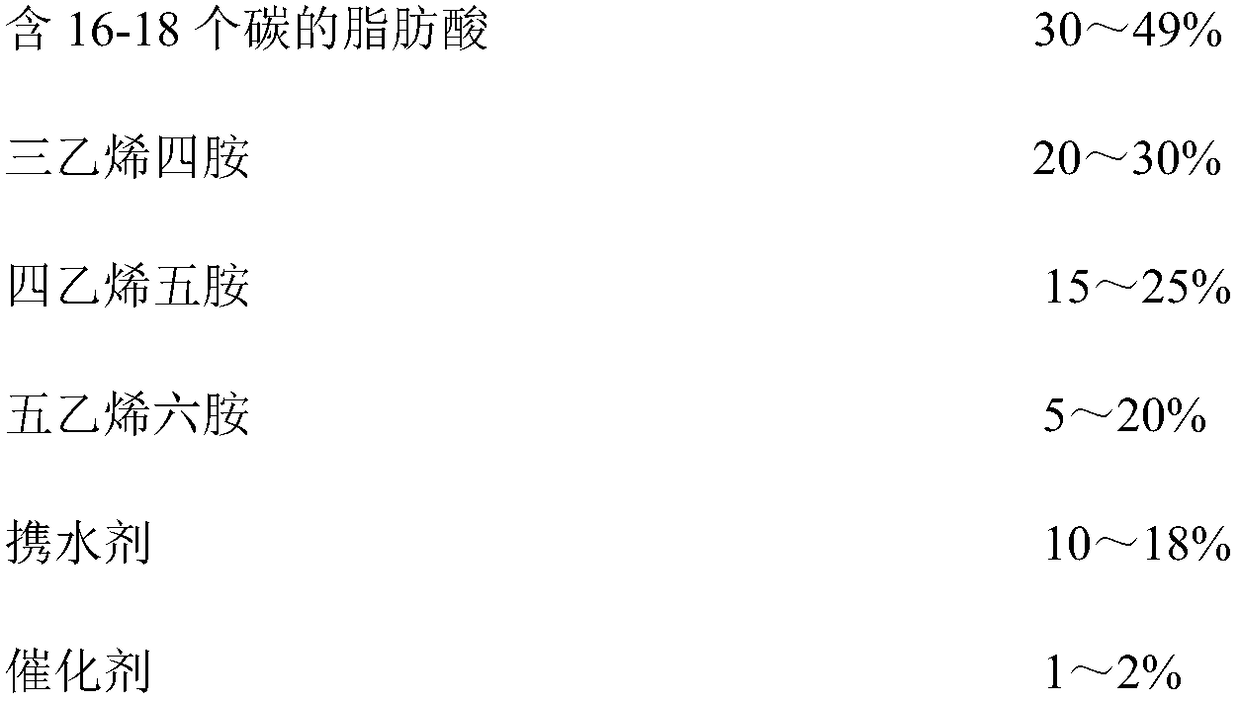

[0023] The components and quality of asphalt warm mix agent are:

[0024]

[0025] The preparation method of asphalt warm mix agent of the present embodiment is divided into three steps:

[0026] The first step is that in a 500mL there-necked flask equipped with a stirrer, reflux condenser, water separator, and tail gas absorption device, the mixed acid of palmitic acid and oleic acid (palmitic acid and oleic acid mass ratio is 1:1), Xylene was sequentially added to the three-neck flask reactor.

[0027] The second step is to fill the three-necked flask with nitrogen, and under the protection of nitrogen, heat up to 100°C. After the acid is completely melted, add triethylenetetramine, tetraethylenepentamine, pentaethylenehexamine and a catalyst, and slowly heat up to 155°C , Keep the temperature reaction for 4.5h.

[0028] The third step is to recover the xylene after the reaction is completely dehydrated to obtain a viscous liquid product, which is the product of the pre...

Embodiment 2

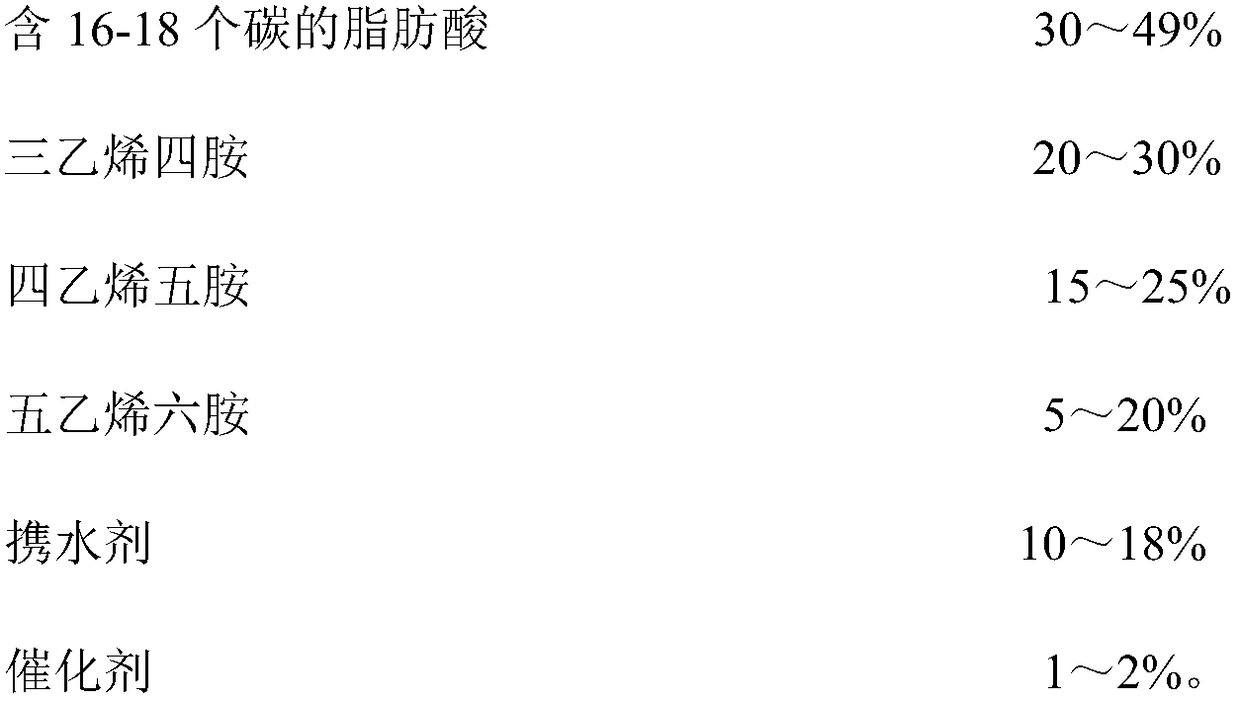

[0031] The components and quality of asphalt warm mix agent are:

[0032]

[0033] In this example, the fatty acid containing 16-18 carbons is palmitic acid. The catalyst is alumina.

[0034] Its preparation method is identical with embodiment 1.

Embodiment 3

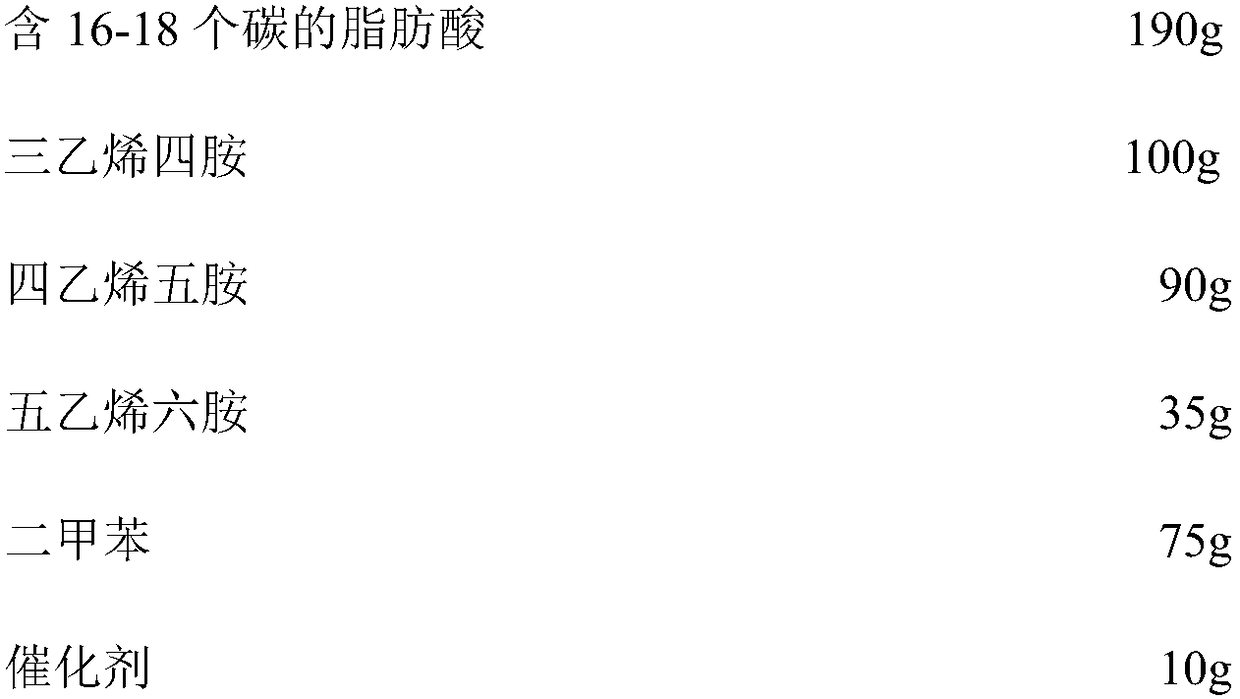

[0036] The components and quality of asphalt warm mix agent are:

[0037]

[0038]

[0039] In this example, the fatty acid containing 16-18 carbons is oleic acid. The catalyst is sodium fluoride.

[0040] Its preparation method is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com