Laser surfacing modification method for thermal barrier coating

A technology of laser surface modification and thermal barrier coating, applied in the direction of coating, metal material coating process, climate sustainability, etc., can solve the problems of large residual stress, interdiffusion and dilution between bonding layer and ceramic layer, etc. , to improve the structure of the coating, reduce the stress of laser modification, and improve the surface roughness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

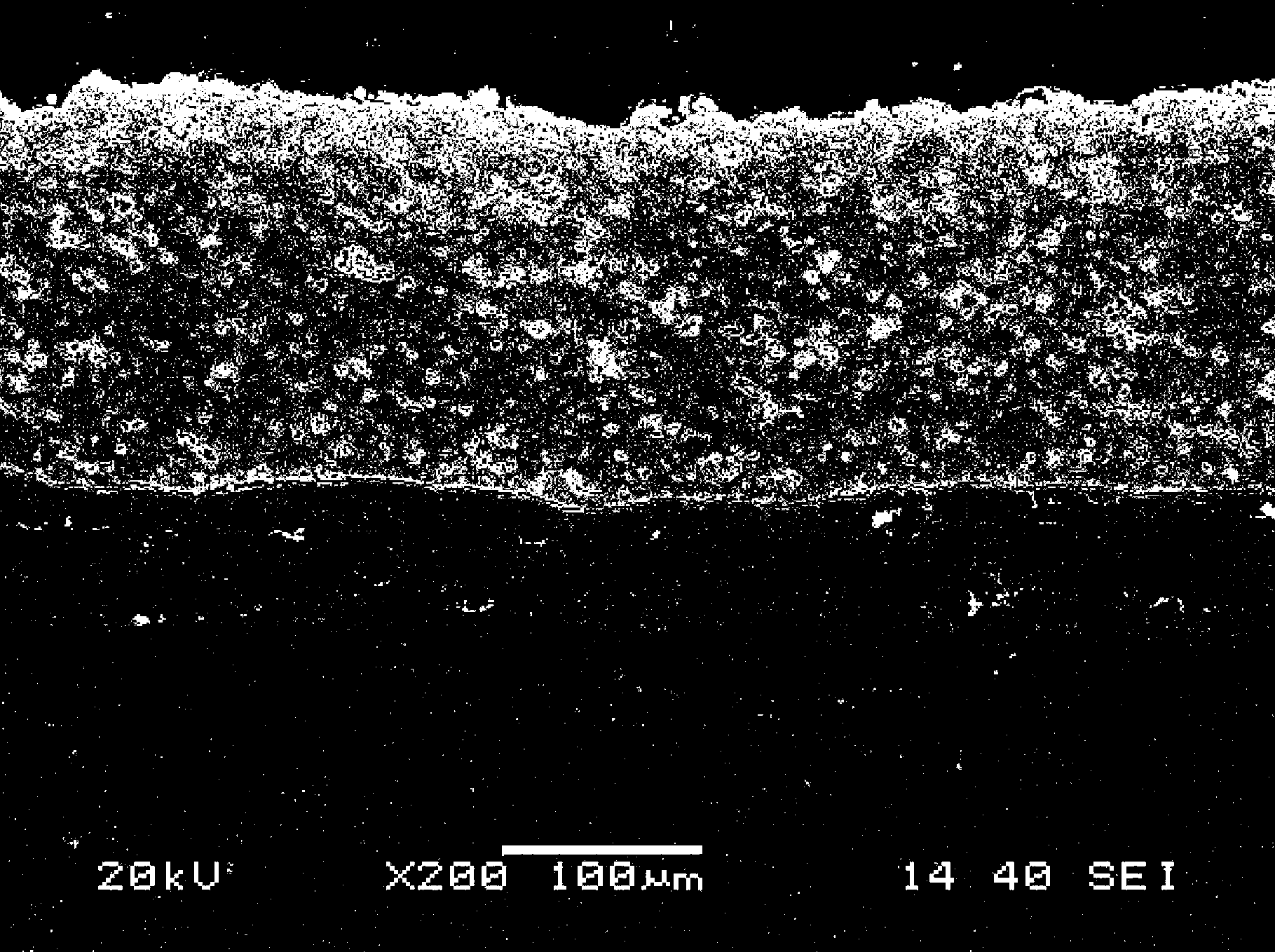

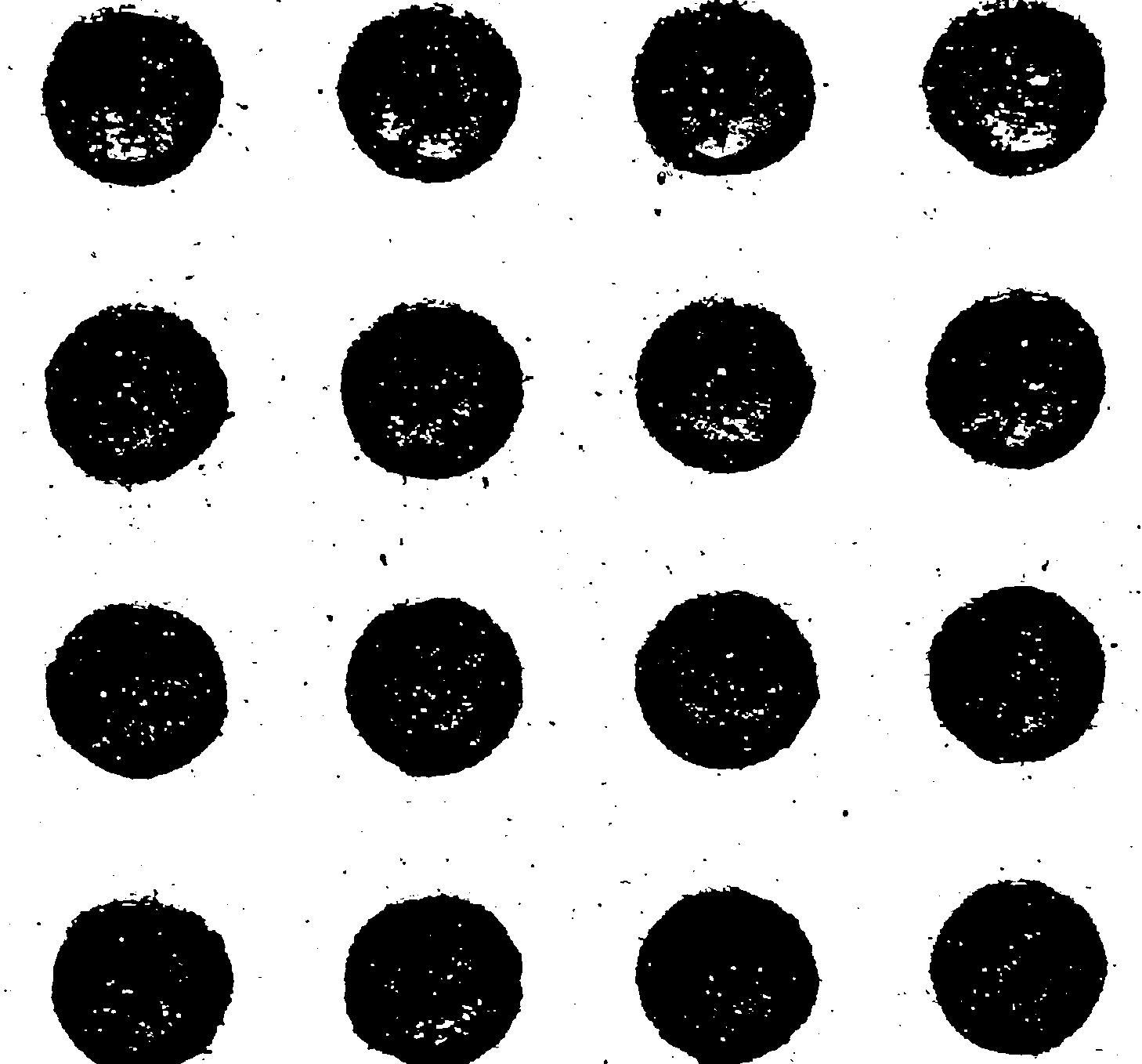

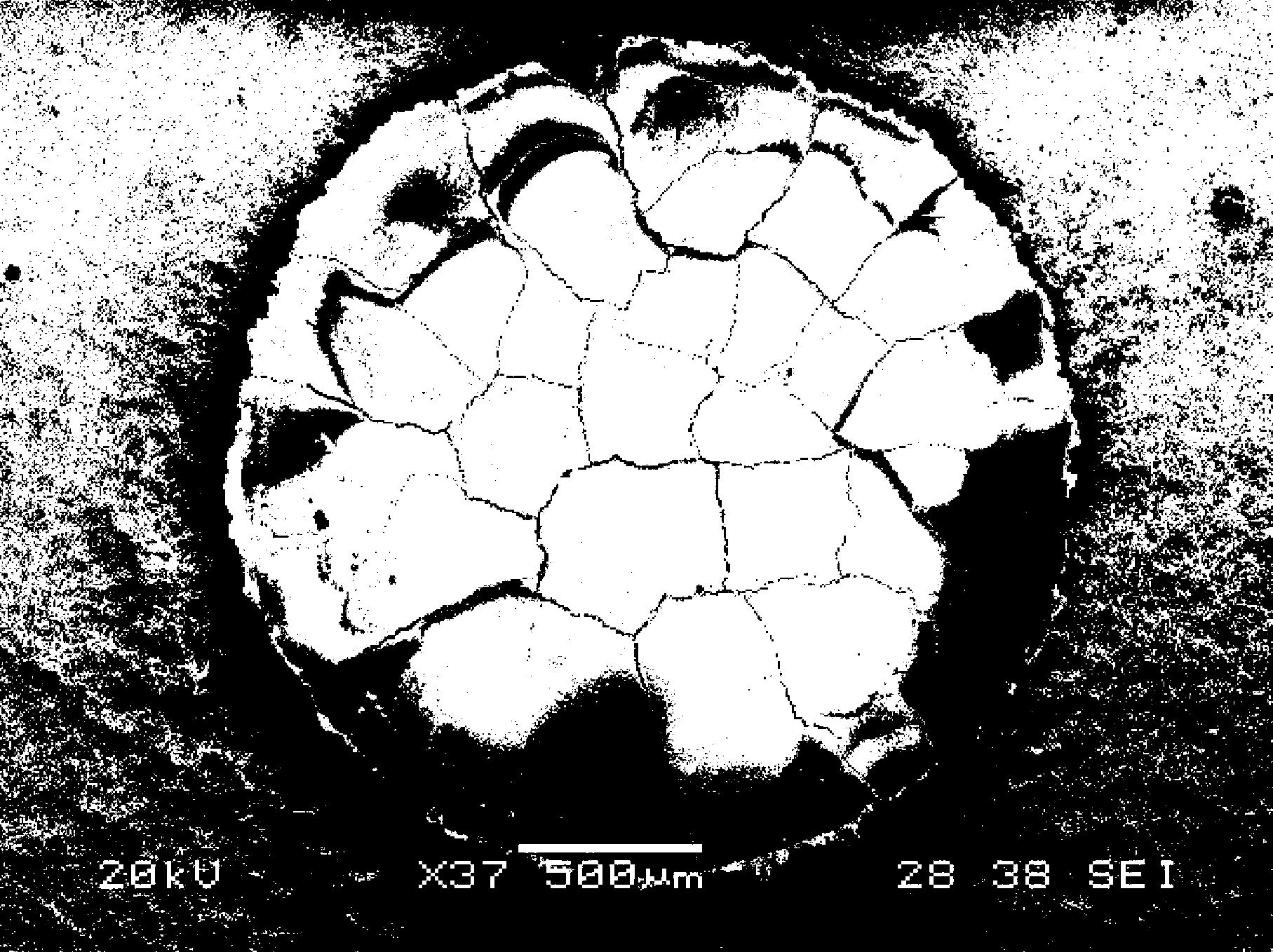

[0028] First, the GH4169 superalloy substrate is cleaned and sandblasted according to the conventional process; then, a thermal sprayed thermal barrier coating is prepared on the surface of the substrate. Since the thermal barrier coating is composed of a ceramic layer and a bonding layer, the fabrication In this case, a NiCoCrAlYTa bonding layer with a thickness of about 60 μm was first prepared by supersonic spraying, and then a 7% yttrium oxide partially stabilized zirconia ceramic layer with a thickness of about 200 μm was prepared by atmospheric plasma spraying. The cross-sectional shape is as figure 1 As shown; then, the peg structure laser modified unit body is designed by computer and design software, the peg structure laser modified unit body is an inverted spherical crown unit body, and the exposed surface of the inverted spherical crown unit body is a circle shape, the diameter of the circular surface of the inverted spherical crown unit is 2 mm, the height of the i...

Embodiment 2

[0030]First, the GH4169 superalloy substrate is cleaned and sandblasted according to the conventional process; a thermally sprayed thermal barrier coating is prepared on the surface of the substrate. Since the thermal barrier coating is composed of a ceramic layer and a bonding layer, when making it, First, a NiCoCrAlYTa bonding layer with a thickness of about 100 μm was prepared by low-pressure plasma spraying, and then a 7% yttrium oxide partially stabilized zirconia ceramic layer with a thickness of about 300 μm was prepared by atmospheric plasma spraying; then, the pile nail structure was designed by computer and design software. Modified unit body, the design of the peg structure laser modified unit body is completed by computer and design software, the peg structure laser modified unit body is an inverted spherical crown unit body, and the exposed spherical crown unit body The surface is circular, the diameter of the circular surface of the inverted spherical crown unit i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com