Patents

Literature

40results about How to "Quenching stress relief" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

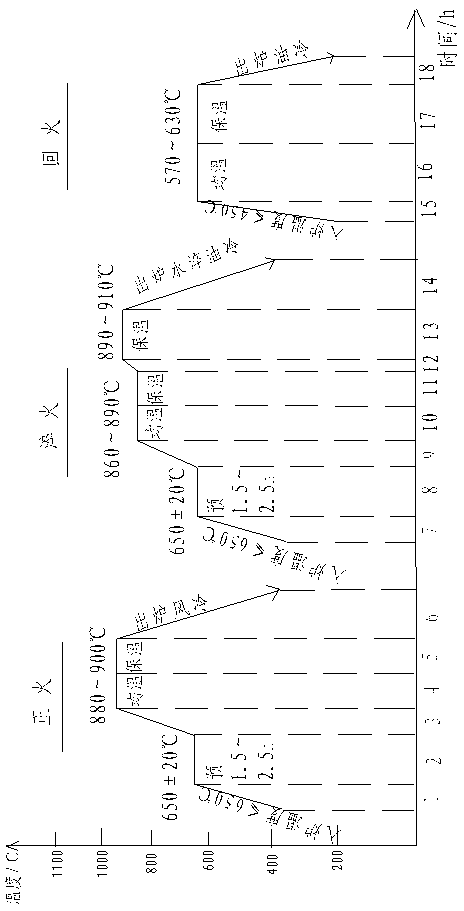

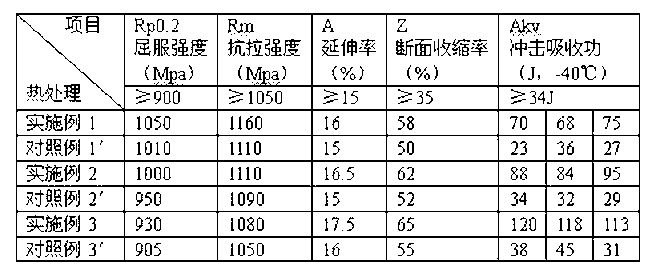

Thermal treatment technology for improving low-temperature impact toughness of 25Cr2Ni4MoV steel forging

The invention belongs to the technical field of production of steel forging products used at low temperature, relating to a thermal treatment technology requiring higher low-temperature impact toughness, and particularly relating to a thermal treatment technology for improving the low-temperature impact toughness of a 25Cr2Ni4MoV steel forging. The thermal treatment technology comprises the following steps of: (1) normalizing heating; (2) normalizing cooling; (3) quenching heating; and (4) quenching cooling. The thermal treatment technology provided by the invention effectively improves the low-temperature impact toughness and prolongs the service life of a product while guaranteeing the material strength.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

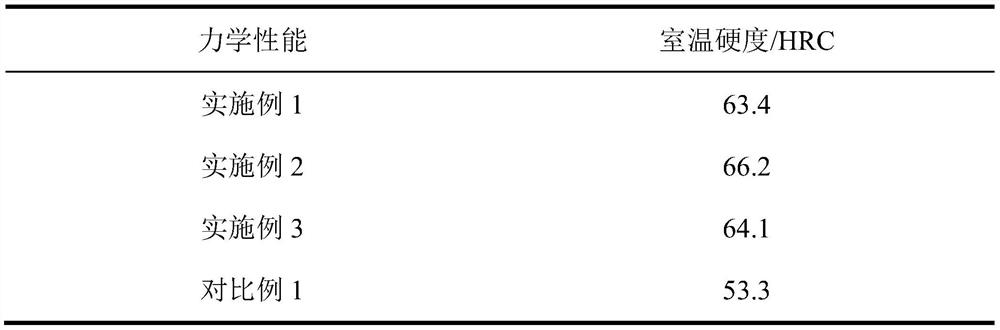

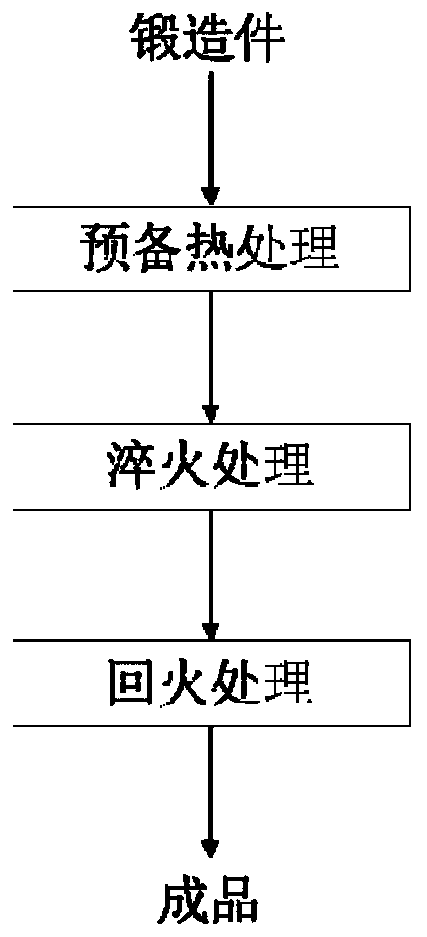

Heat treatment process for die steel

The invention discloses a heat treatment process for die steel. The heat treatment process for the die steel is characterized in that the heat treatment process comprises the following steps that 1, preheating treatment is conducted, specifically, isothermal spheroidizing annealing needs to be conducted immediately after the die steel is forged, the heating temperature is 840 DEG C-860 DEG C, and heat preservation lasts for 2-4 h; then the die steel is cooled to 720 DEG C-740 DEG C, and the constant temperature lasts for 4-6 h; the die steel is subjected to furnace cooling till to be 500 DEG C or blow, taken out of a furnace and subjected to air cooling; and 2, quenching and tempering are conducted, specifically, the quenching temperature is 1100 DEG C-1150 DEG C, and oil cooling is conducted; the tempering temperature is 530 DEG C-540 DEG C, tempering is conducted for two to three times, heat preservation lasts for 1.0-2.0 h each time, and the hardness of the die steel is 57-63 HRC. According to the heat treatment process for the die steel, the hardness and the abrasion resistance of the die steel can be improved.

Owner:重庆基石机械有限公司

Wear resistant cast iron

InactiveCN101440454AImprove hardness and wear resistanceImprove metallographic structureWear resistantCast iron

The invention discloses a cast iron material with higher hardness, corrosion resistance, high-temperature oxidation resistance and abrasion endurance of an abrasive material with larger impact load. The cast iron material consists of the following compositions by weight percentage: 2.8 percent of C, 0.2 to 1.0 percent of Si, 0.5 to 1.0 percent of Mn, less than or equal to 0.06 percent of S, less than or equal to 0.1 percent of P, 21 to 23 percent of Cr, 0 to 1.5 percent of Ni, 1.0 to 1.5 percent of Mo, and the balance being Fe and unavoidable impurities. The cast iron material has the advantages of improving hardness and other comprehensive performances of the material, and being helpful for prolonging the service life of a finished product manufactured by the cast iron material.

Owner:蔡柏林

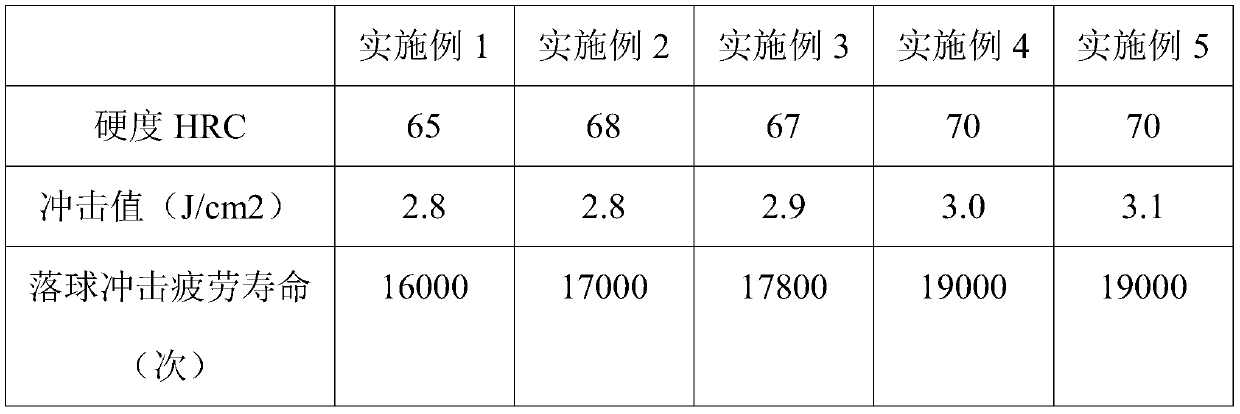

High-chromium cast iron for wear-resisting grinding ball and preparation method of high-chromium cast iron

InactiveCN110129664AHigh hardnessIncrease shock loadFurnace typesProcess efficiency improvementChemical compositionHardness

The invention discloses high-chromium cast iron for a wear-resisting grinding ball and a preparation method of the high-chromium cast iron, and relates to the technical field of wear-resisting grinding balls. The high-chromium cast iron comprises the following components of, in percentage by weight, 2.3%-3.0% of C, 0.5%-1.0% of Si, 0.4%-1.0% of Mn, 16%-20% of Cr, 0.3%-0.6% of Mo, 0.4%-0.8% of Ni,0.02%-0.08% of V, 0.05%-0.1% of B, 0.1%-0.2% of Nb, 0.01%-0.1% of Re, less than or equal to 0.03% of S, less than or equal to 0.03% of P, and the balance of Fe. According to the high-chromium cast iron, the contents of the chemical components in the high-chromium cast iron are reasonably adjusted, and the quenching stress is effectively eliminated by controlling the chromium-carbon ratio and the heat treatment process; a prepared grinding ball is high in impact load, and the hardness, the impact toughness and the wear-resisting property of the cast ball can be well balanced, so that the phenomena that in early stage, the surface of the cast ball is easy to be peeled, the broken ball rate is high and the like are improved; and the prepared grinding ball is high in impact load, and can meetthe use requirements of large-scale ball grinders in the industry of cement, mines, electric power and the like.

Owner:NINGGUO HUAFENG WEAR RESISTANT MATERIAL

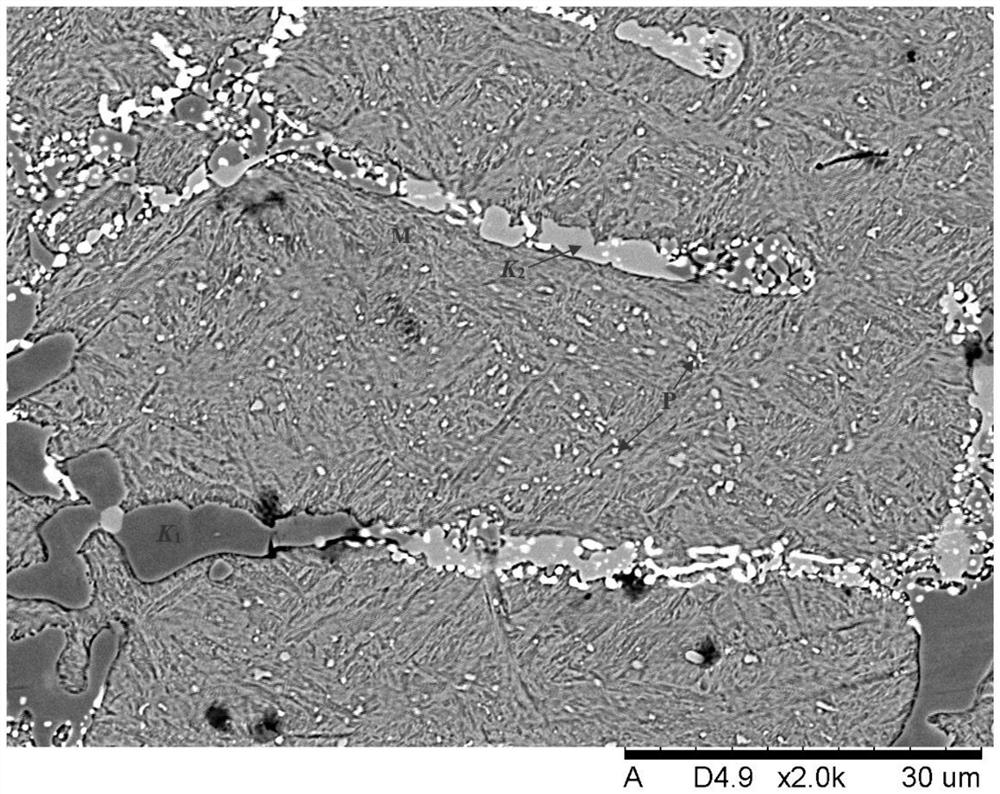

Heat treatment method of M2 high-speed steel work roller

InactiveCN109457102AImprove quenching stress stateGuarantee the quality of quenchingFurnace typesHeat treatment furnacesWater basedRoom temperature

The invention relates to a heat treatment method of an M2 high-speed steel work roller, and belongs to the technical field of roller heat treatment. The method comprises the following process steps of(1) primary preheating, wherein the roller is heated by a heat treatment furnace at the speed ranging from 50 DEG C / h to 200 DEG C / h till the temperature ranges from 500 DEG C to 600 DEG C, and heatpreservation is carried out; (2) secondary preheating, wherein the roller continues to be heated at the speed ranging from 50 DEG C / h to 200 DEG C / h till the temperature ranges from 800 DEG C to 900 DEG C, and heat preservation is carried out; (3) high-temperature heating, wherein the roller is heated at the speed ranging from 50 DEG C / h to 100 DEG C / h till the temperature ranges from 1140 DEG C to 1210 DEG C, and heat preservation is carried out; (4) cooling, wherein the roller subjected to high-temperature heating and heat preservation is cooled by a water-based quench bath, the roller is vertically placed into the water-based quench bath to be cooled till the temperature ranges from 300 DEG C to 400 DEG C; and (5) tempering treatment, wherein the cooled roller is heated till the temperature ranges from 540 DEG C to 560 DEG C, after heat preservation is carried out for 3 h to 10 h, air cooling is carried out to room temperature, and tempering treatment is carried out several times. By means of the heat treatment method, the quenching stress state can be improved, and the quenching quality can be guaranteed.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Heat treating method of high-hardness and wear-resistant cast-iron

The invention discloses a method for treating abrasion-resistant cast iron, which comprises the following heat treatment technological processes: firstly, annealing, namely a casting is directly heated to a temperature of between 920 and 960 DEG C, maintained for 1 to 8 hours at the temperature, slowly cooled until the temperature is between 700 and 750 DEG C, maintained for 4 to 10 hours at the temperature, slowly cooled until the temperature is less than 550 DEG C, and discharged for air cooling, so as to prevent segregation of compositions and eliminate the casting stress; secondly, quenching, namely the annealed casting is directly heated to the temperature of 1,100 DEG C, maintained for 2 to 6 hours at the temperature, and discharged for air cooling; and thirdly, tempering, namely the casting is maintained for 2 to 8 hours at a temperature of between 200 and 300 DEG C, and discharged for air cooling. The service life of the abrasion-resistant cast iron subjected to heat treatment is 1.3 to 1.6 times of that of abrasion-resistant cast iron prepared by the prior treatment method, and the hardness and the abrasion resistance of the material after heat treatment are further improved.

Owner:蔡柏林

Low carbon, low boron, and high chromium alloy steel and preparation method thereof

InactiveCN108929983AGuaranteed wear resistanceImprove hardenabilityProcess efficiency improvementTungstenAluminium

The invention discloses low carbon, low boron, and high chromium alloy steel and a preparation method thereof which relates to the technical field of alloy steel. The low carbon, low boron, and high chromium alloy steel includes, by weight, 0.05-0.30% of carbon, 1-3.0% of silicon, 0.8-1.3% of manganese, <0.04% of phosphorus, <0.04% of sulfur, 8-13% of chromium, 0.5-2.5% of nickel, 0.1-0.8% of molybdenum, 0.03-0.25% of boron, 0.1-0.3% of aluminum, 0.05-0.2% of tin, 0.3-1.0% of vanadium, 0.1-1.5% of tungsten, 0.05-0.3% of copper, 0.005-0.015% of tantalum, 0.05-0.15% of cobalt, 0.05-0.25% of niobium, 0.8-2.0% of cerium, 0-0.08% of titanium, with the balance being iron and unavoidable impurities. The alloy steel of the invention enables high toughness and impact resistance performance to be ensured, enables wear resistance and hardness to be improved, is easy to control in process, and is suitable for civilian use and promotion.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

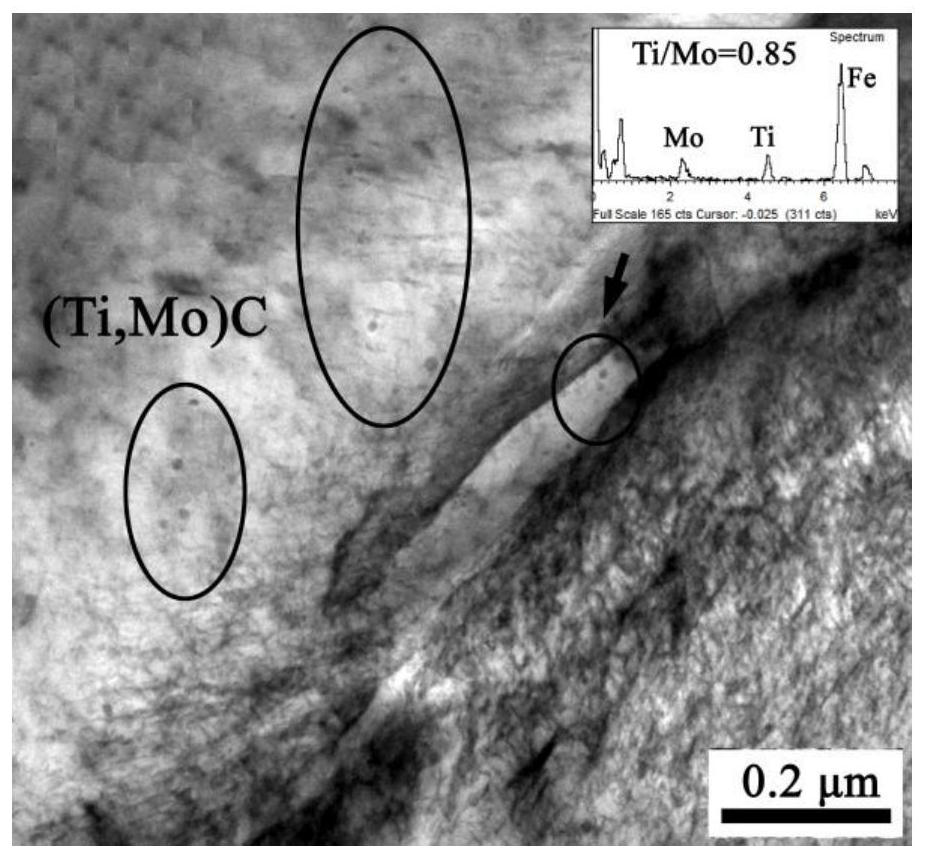

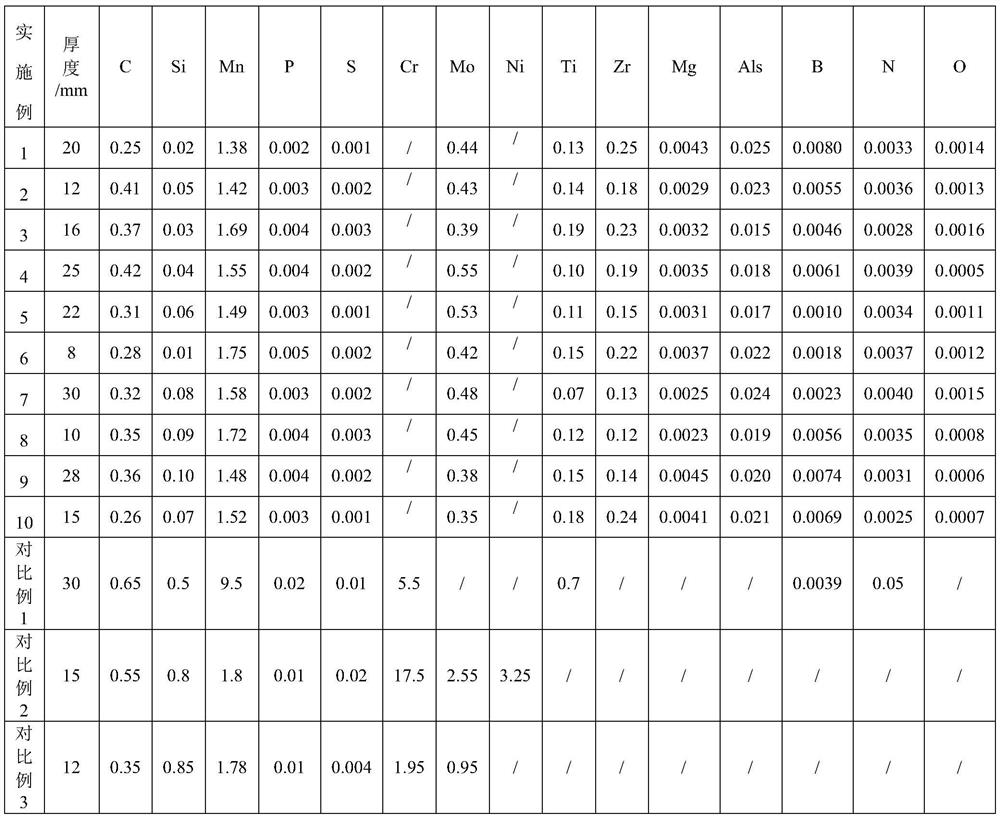

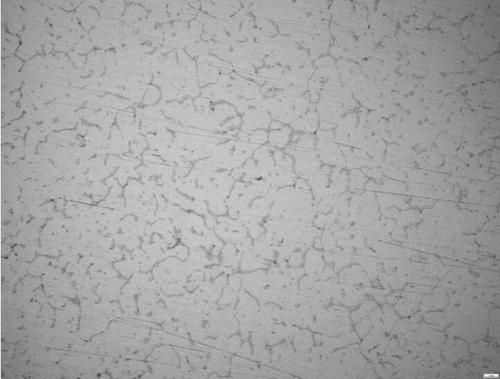

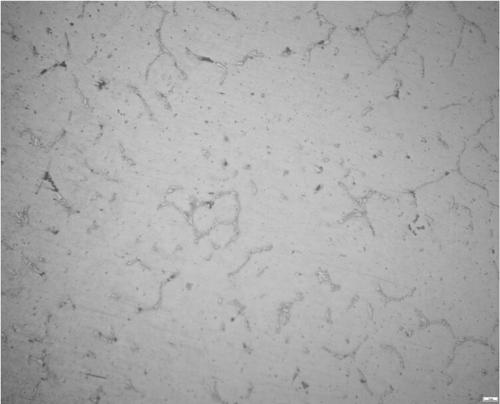

High-strength and high-toughness weldable corrosion-resistant and abrasion-resistant steel plate and preparation method thereof

The invention discloses a high-strength and high-toughness weldable corrosion-resistant and abrasion-resistant steel plate and a preparation method thereof. According to the technical scheme, the steel plate comprises, by mass, 0.25-0.42% of C, 0.01-0.10% of Si, 1.35-1.75% of Mn, not greater than 0.005% of P, not greater than 0.002% of S, 0.35-0.55% of Mo, 0.07-0.19% of Ti, 0.12-0.25% of Zr, 0.0023-0.0045% of Mg, 0.015-0.025% of Als, 0.001-0.008% of B, 0.0025-0.0040% of N, 0.0005-0.0015% of O, and the balance Fe and trace impurity elements, wherein the ratio of Mo to Ti is 1.8-7.0, and the ratio of Ti to Als is 3-13. According to the high-strength and high-toughness weldable corrosion-resistant and abrasion-resistant steel plate and the preparation method thereof, the alloy adding amount is small, the welding performance is improved, and the production cost is reduced; and through whole-process technological control of rolling, online quenching, offline quenching and low-temperature tempering, the grain size is refined, precipitation and dispersion distribution of nanoscale Ti-containing second-phase particles are promoted, and the toughness and corrosion-resistant and abrasion-resistant performance of the product are improved.

Owner:WUHAN UNIV OF SCI & TECH

Low-carbon low-boron medium-chromium alloy steel, and preparation method thereof

The invention discloses a low-carbon low-boron medium-chromium alloy steel, and a preparation method thereof, and belongs to the technical field of alloy steel manufacturing. The low-carbon low-boronmedium-chromium alloy steel comprises 0.05 to 0.30% of carbon, 1.0 to 3.0% of silicon, 0.8 to 1.3% of manganese, phosphor of 0.04% or lower, sulfur of 0.04% or lower, 3.5 to 7.9% of chromium, 0 to 0.08% of titanium, 0.3 to 2.0% of nickel, 0.1 to 0.5% of molybdenum, 0.03 to 0.25% of boron, 0.1 to 0.3% of aluminium, 0.5 to 1.5% of cerium, 0.02 to 0.1% of tin, 0.3 to 1.0% of vanadium, 0.1 to 1% of tungsten, 0.05 to 0.3% of copper, 0.005 to 0.015% of tantalum, 0.05 to 0.15% of cobalt, 0.05 to 0.25% of niobium, and the balance iron and unavoidable impurities. The hardness of the low-carbon low-boron medium-chromium alloy steel is HRC45-55, the impact energy is 8 to 15J / mm<2>. The preparation method is capable of guaranteeing the high toughness and impact resistance, and improving the wear resistance and hardness, is convenient to control, and is suitable for civil applications and popularization.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

Method for remanufacturing scrapped rollers to be qualified rollers

InactiveCN103484791AReduce tensile stressQuenching stress reliefFurnace typesHeat treatment furnacesResource consumptionEngineering

The invention relates to a method for remanufacturing crapped rollers to be qualified rollers. The method particularly comprises the followings: (1), carrying out annealing process; (2), machining the scrapped rollers to be roller blank after annealing; (3), carrying out quenching and tempering treatment; (4), carrying out final heat treatment. Compared with the prior art, the method provided by the invention has the positive effects as follows: the scrapped rollers are remanufactured to be the qualified rollers, the roller manufacturing period is shortened, the procurement cost of enterprises can be reduced, the resource consumption is lowered, the environment pollution is reduced, and the purpose of recycling economy is achieved.

Owner:湖州市银鑫轧辊有限公司

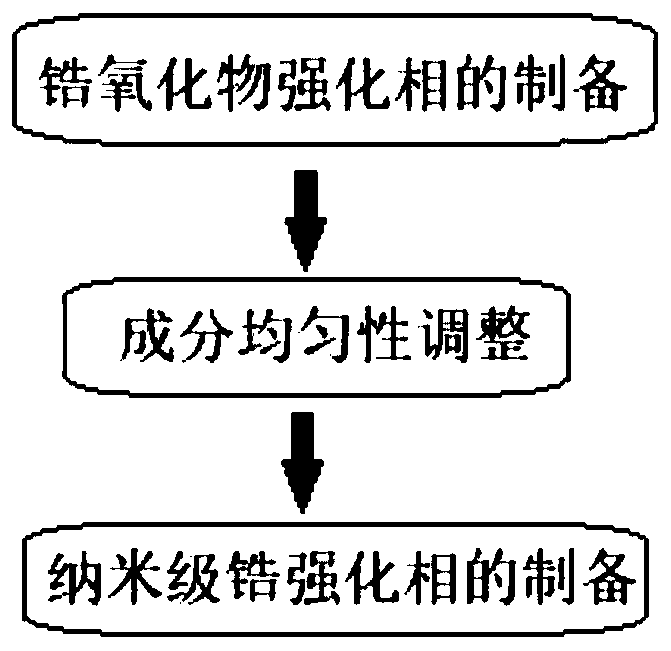

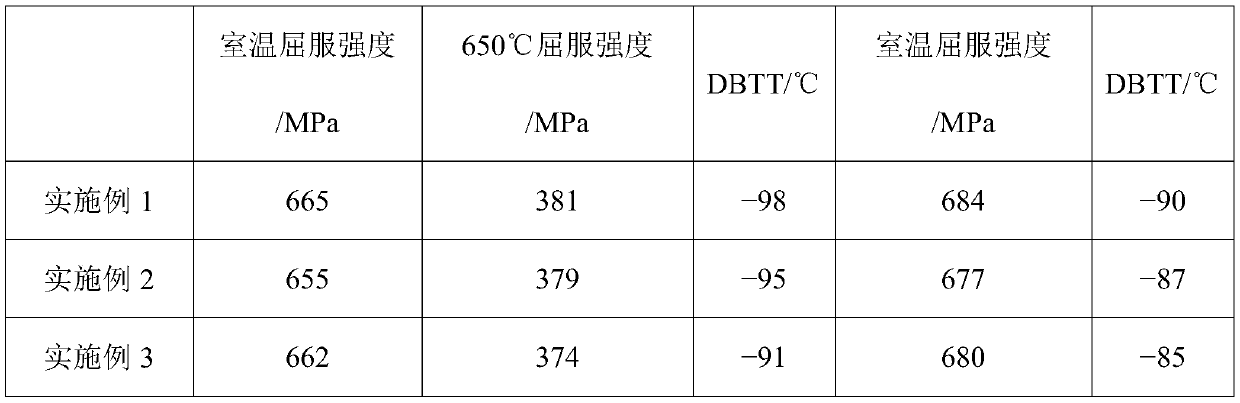

Zirconium-reinforced low-activation martensitic steel and preparation method thereof

ActiveCN111519108AImprove mechanical propertiesEasy to useIncreasing energy efficiencyTemperingIngot

The invention discloses zirconium-reinforced low-activation martensitic steel and a preparation method thereof. The zirconium-reinforced low-activation martensitic steel comprises, by mass, 0.01%-0.02% of C, 0.01%-0.05% of Si, 0.3%-0.5% of Mn, 8.0%-9.0% of Cr, 1.0%-1.5% of W, 0.2%-0.3% of V, 0.01%-0.03% of Zr, 0.01%-0.02% of N, 0.01%-0.02% of O, and the balance Fe. During preparation, Fe, Cr and Ware melted in a vacuum induction furnace; then, C is added for deoxidization; then, Zr, Mn, Si, V and C are added in sequence, and after all alloys are melted down, casting is performed under nitrogen protection to obtain a cast ingot; the cast ingot is subjected to component uniformity adjustment and then machined into a rolling billet; and the rolling billet is rolled, slow cooling is performedafter rolling is completed, and then quenching and tempering are performed to obtain the zirconium-reinforced low-activation martensitic steel. According to the method, by adding zirconium instead ofTa for reinforcement, an oxide zirconium reinforcing phase and nano-scale zirconium carbide can be formed, and the use performance of the steel is improved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

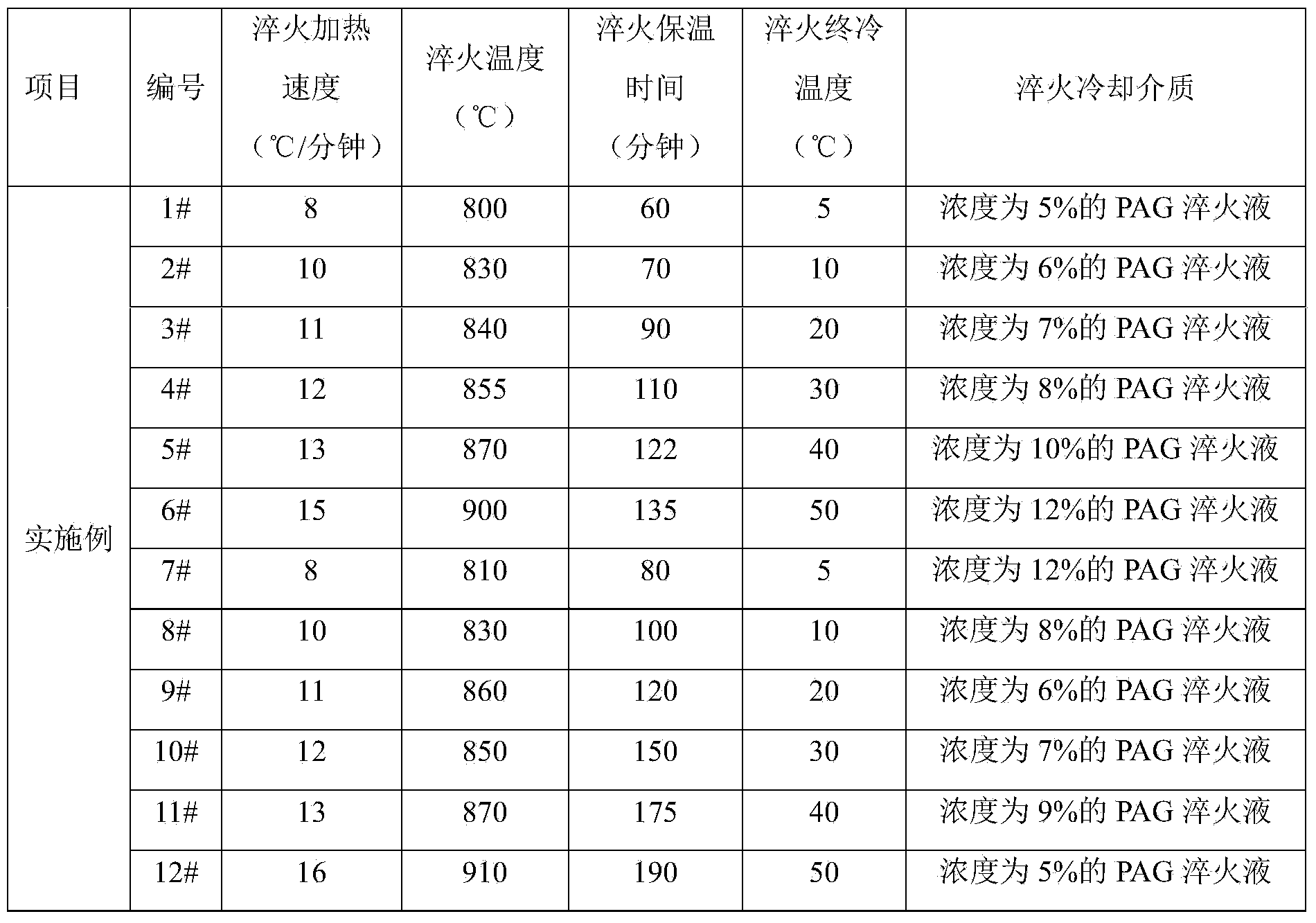

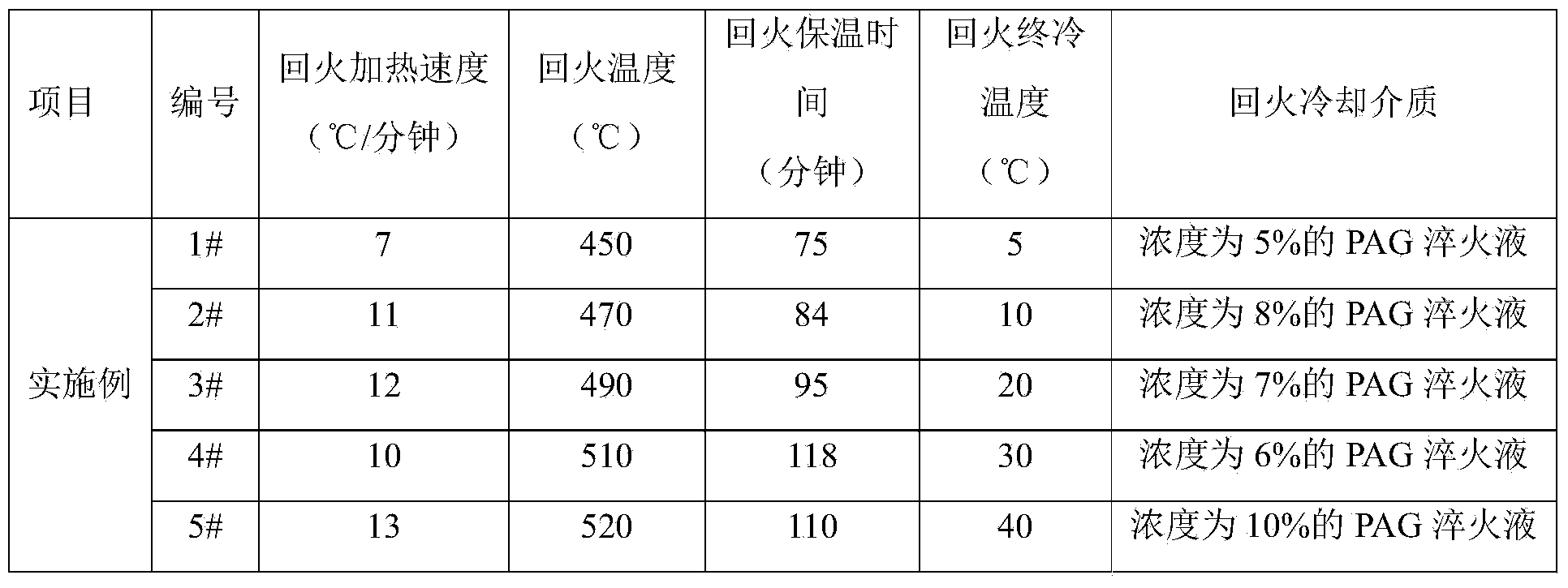

Thermal treatment method of 42CrMo workpiece

The invention discloses a thermal treatment method of a 42CrMo workpiece. The effective size of the workpiece is D millimeters. The thermal treatment method comprises the steps of sequentially carrying out quenching treatment and tempering treatment on the workpiece. The method is characterized in that the quenching treatment comprises the steps of heating the workpiece to 830-870 DEG C, preserving the heat for 2.0*D-3.5*D minutes and cooling the workpiece in a quenching cooling medium; the tempering treatment comprises the steps of heating the workpiece to 470-520 DEG C, preserving the heat for 2.4*D-3.4*D minutes and cooling the workpiece in the quenching cooling medium, wherein the D is a number greater than zero. The thermal treatment method is few in process and the 42CrMo workpiece obtained by using the method is good in mechanical property.

Owner:ZOOMLION HEAVY IND CO LTD

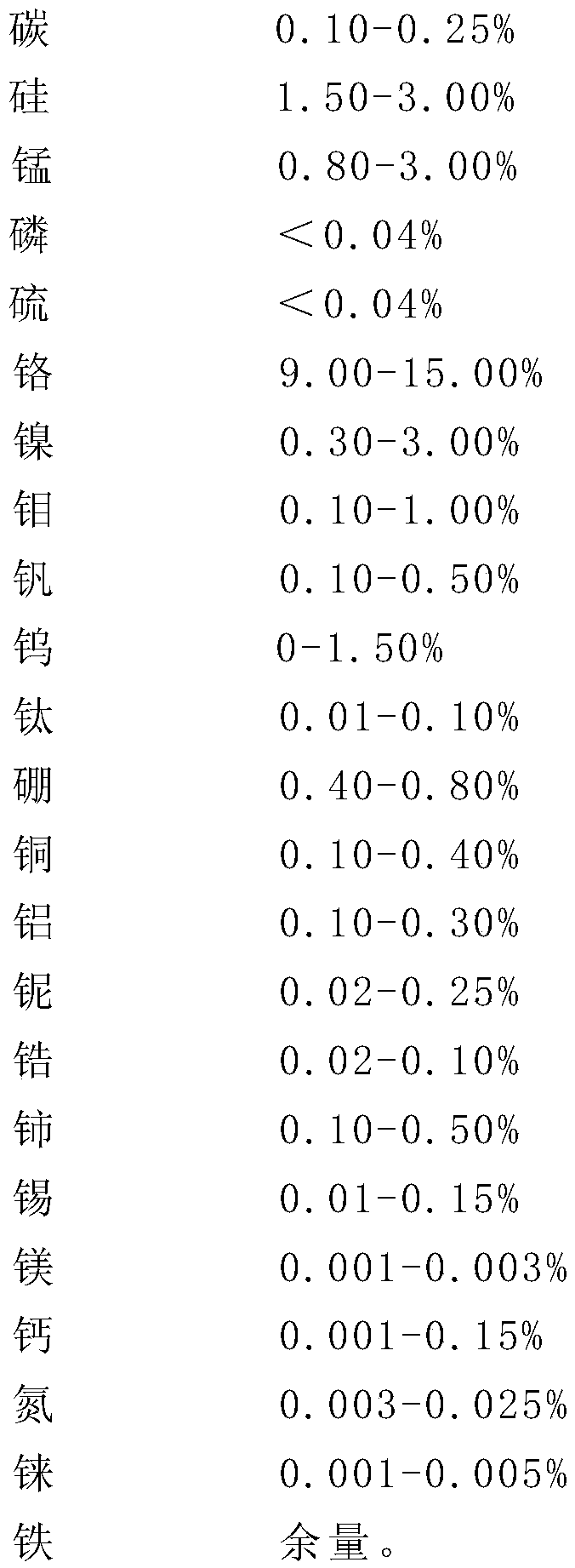

Micro-carbon high-chromium high-boron wear-resistant steel and preparation method thereof

InactiveCN109825778AHinder segregationAvoid hydrogen embrittlementProcess efficiency improvementWear resistantCerium

The invention discloses micro-carbon high-chromium high-boron wear-resistant steel and a preparation method thereof. The prepared wear-resistant steel comprises the following components of, in percentage by weight, 0.10-0.25% of carbon, 1.50-3.00% of silicon, 0.80-3.00% of manganese, less than 0.04% of phosphorus, less than 0.04% of sulfur, 9.00-15.00% of chromium, 0.30-3.00% of nickel, 0.10-1.00%of molybdenum, 0.10-0.50% of vanadium, 0-1.50% of tungsten, 0.01-0.10% of titanium, 0.40-0.80% of boron, 0.10-0.40% of copper, 0.10-0.30% of aluminum, 0.02-0.25% of niobium, 0.02-0.10% of zirconium,0.10-0.50% of cerium, 0.01-0.15% of tin, 0.001-0.003% of magnesium, 0.001-0.15% of calcium, 0.003-0.025% of nitrogen, 0.001-0.005% of rhenium, and the balance iron. The steel not only has the high hardness, also has the characteristics of certain toughness and high wear resistance at the same time.

Owner:陈章华

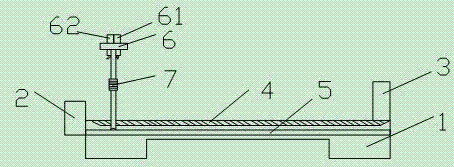

Continuous flame quenching heat treatment method and device for roll necks

InactiveCN107058713AMeet the working conditionsImprove quenching uniformityFurnace typesHeat treatment furnacesHardnessService condition

The invention discloses a continuous flame quenching heat treatment method for roll necks. The method comprises the following steps: carrying out displacement type quenching on a roll neck when a roll rotates; and after quenching on one side of the roll neck is finished, turning the roll and quenching the roll in the same mode. Meanwhile, the invention further discloses a continuous flame quenching heat treatment device for roll necks. The roll neck with the surface hardness of 40-55 HSc can be obtained, service conditions of a roll bearing are met, the roll rotates in a quenching process, a quenching device continuously moves from one side to the other side at constant speed, quenching uniformity is good, quenching operation is simple, and a process is controlled stably.

Owner:安徽宝昌联合轧辊有限公司

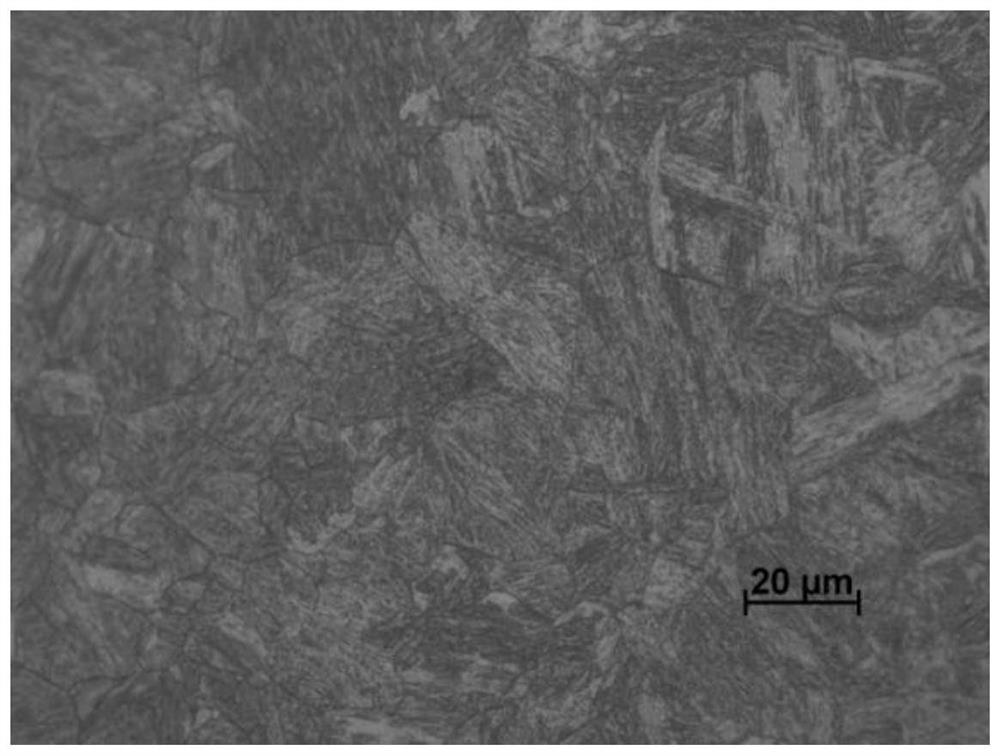

Carburizing and quenching heat treatment method

InactiveCN112593183AGuaranteed technical requirementsEnsure carburizing efficiencySolid state diffusion coatingHeat treatment process controlTemperingCarbon potential

The invention discloses a carburizing and quenching heat treatment method which is applied to gas carburizing and quenching production normally required by common low-carbon steel and low-carbon alloysteel workpieces. The carburizing and quenching heat treatment method specifically comprises the following steps of S1, firstly, putting the workpieces into a carburizing furnace, and strong carburizing section treatment and diffusion section treatment are performed on the workpieces in the carburizing furnace, wherein the carburizing temperature of the strong carburizing section treatment is 915DEG C-925 DEG C, the carbon potential of the strong carburizing section treatment is 1.1%-1.2%, the carburization temperature of the diffusion section treatment is 905 DEG C-915 DEG C, the carbon potential of the diffusion section treatment is 0.8%-0.9%, and the carburizing heat preservation time ratio of the strong carburizing section treatment to the diffusion section treatment is 11: 9; S2, performing cooling and quenching along with the carburizing furnace; S3, performing quenching oil cooling; and S4, performing tempering. By means of the method, the hardness and the hardened layer depthof the low-carbon alloy steel workpieces are guaranteed, meanwhile, it is guaranteed that the refined metallographic structure meets the national standard, and the carburizing and quenching quality is stably improved.

Owner:JIANGSU JUYUAN ELECTRICAL

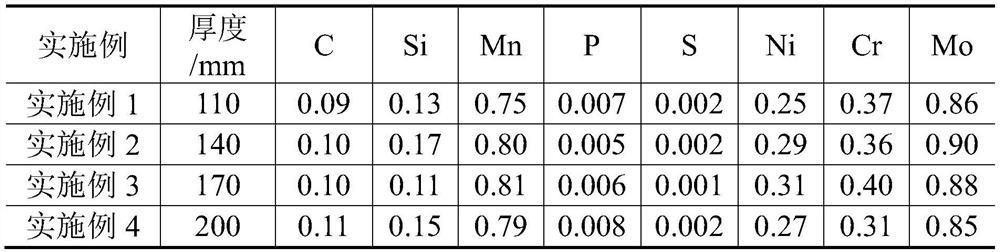

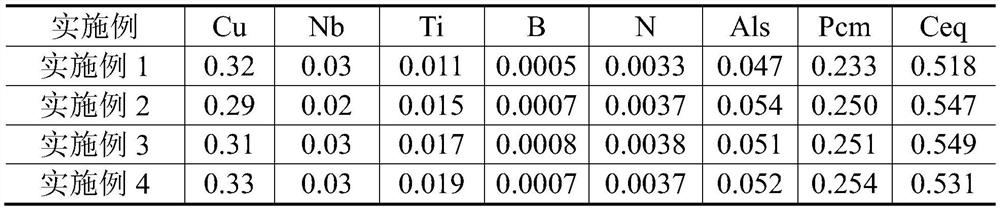

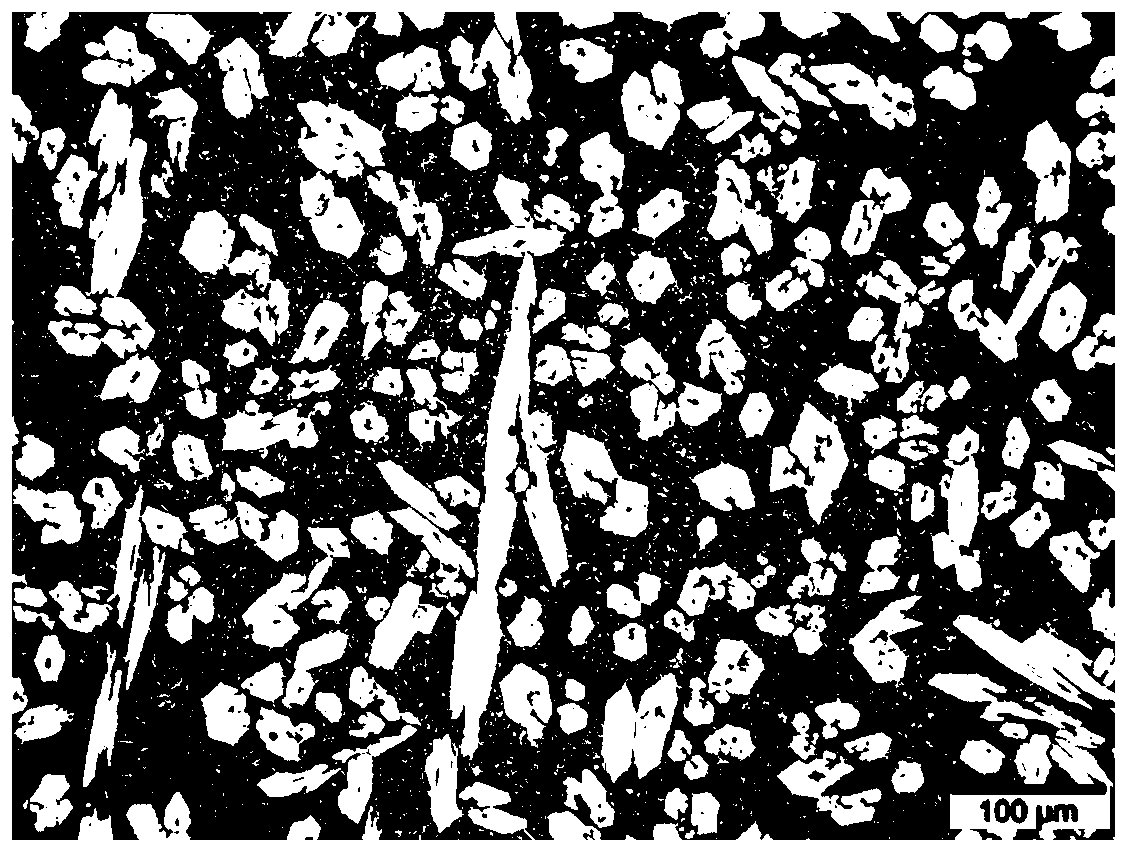

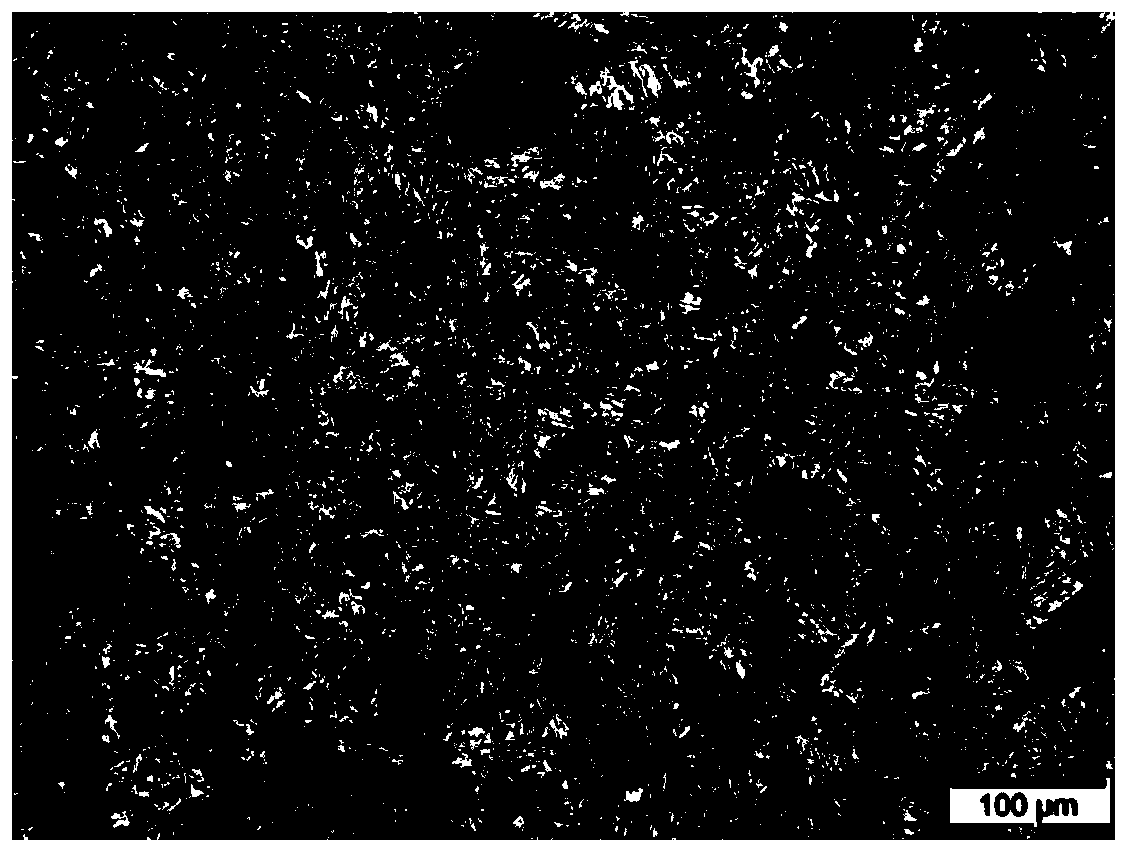

High-strength and high-toughness super-thick quenched and tempered hydroelectric steel plate and preparation method thereof

The invention discloses a high-strength and high-toughness super-thick quenched and tempered hydroelectric steel plate and a preparation method thereof. The steel plate comprises the following chemical components: 0.09-0.11% of C; 0.10-0.20% of Si; 0.70-0.90% of Mn; less than or equal to 0.010% of P; less than or equal to 0.003% of S; 0.20-0.40% of Ni; 0.30-0.40% of Cr; 0.85-0.95% of Mo; 0.25-0.35% of Cu; 0.02-0.04% of Nb; 0.010-0.020% of Ti; 0.035-0.055% of Als; 0.0004-0.0010% of B; less than 50 ppm of N; and the balance of Fe and inevitable impurities. Meanwhile, it is guaranteed that Pcm=C+Si / 30+(Mn+Cu+Cr) / 20+Ni / 60+Mo / 15+V / 10+5B is less than 0.26%; Ceq(%)=C+Mn / 6+Si / 24+Ni / 40+Cr / 5+Mo / 4 V / 14 is less than 0.56%. The thickness of the high-strength and high-toughness super-thick quenched and tempered hydroelectric steel plate is larger than 100 mm, the tensile strength is larger than or equal to 780 MPa, the yield strength is larger than or equal to 690 MPa, and the transverse Kv-70 DEG C is larger than or equal to 100 J.

Owner:NORTHEASTERN UNIV

Heat treatment method of iron-based wear-resistant coating plough shovel tip

ActiveCN110592357AImprove quality stabilityShort holding timeMolten spray coatingFurnace typesWear resistantHardness

The invention relates to the field of production and processing of agricultural implements, in particular to a heat treatment method of an iron-based wear-resistant coating plough shovel tip. According to the method, a boron steel material plough shovel tip is taken as a substrate, and the plough shovel tip substrate is coated with an iron-based wear-resistant layer by adopting a plasma spray welding technology; the plough shovel tip coated with the wear-resistant layer by plasma spray welding is heated to the temperature higher than austenitizing temperature in an induction heating mode, subjected to heat preservation for a certain time, quickly transferred into a salt bath for quenching, and placed in air for cooling after being quenched, and self tempering is achieved by utilizing material characteristics. By adopting the plough shovel tip produced by the method, quenching secondary cracking of the wear-resistant layer can be basically avoided, the production cost is low, and the batch stability is good. After the heat treatment, the hardness of the wear-resistant layer is more than 63HRC, the hardness of the matrix is more than 45HRC, the impact toughness (akv) of the matrix reaches 30J / cm<2>, and the product performance and service life are greatly higher than those of similar products in China.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

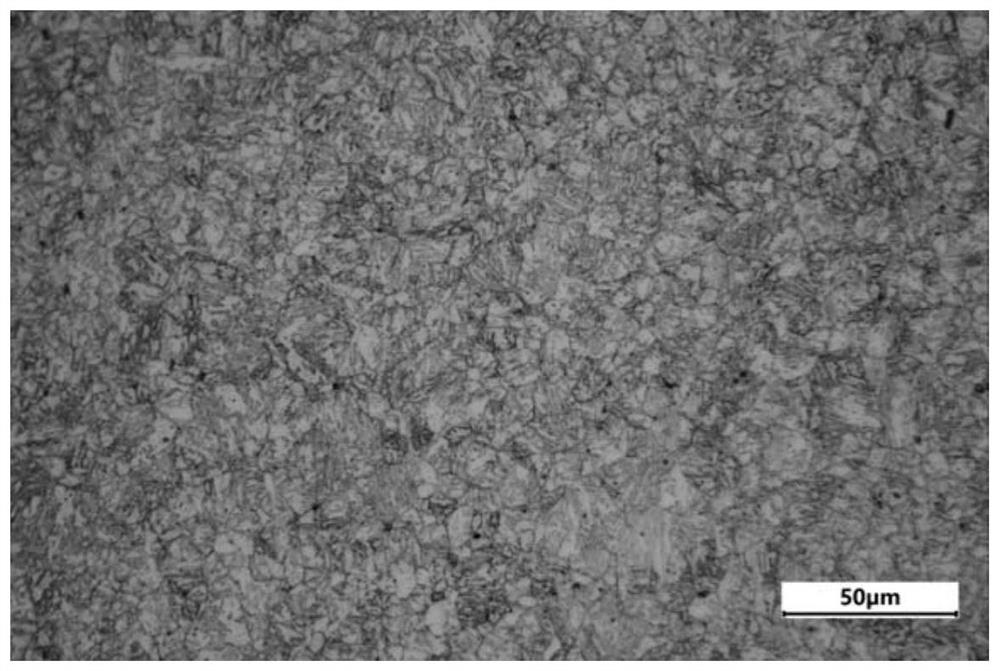

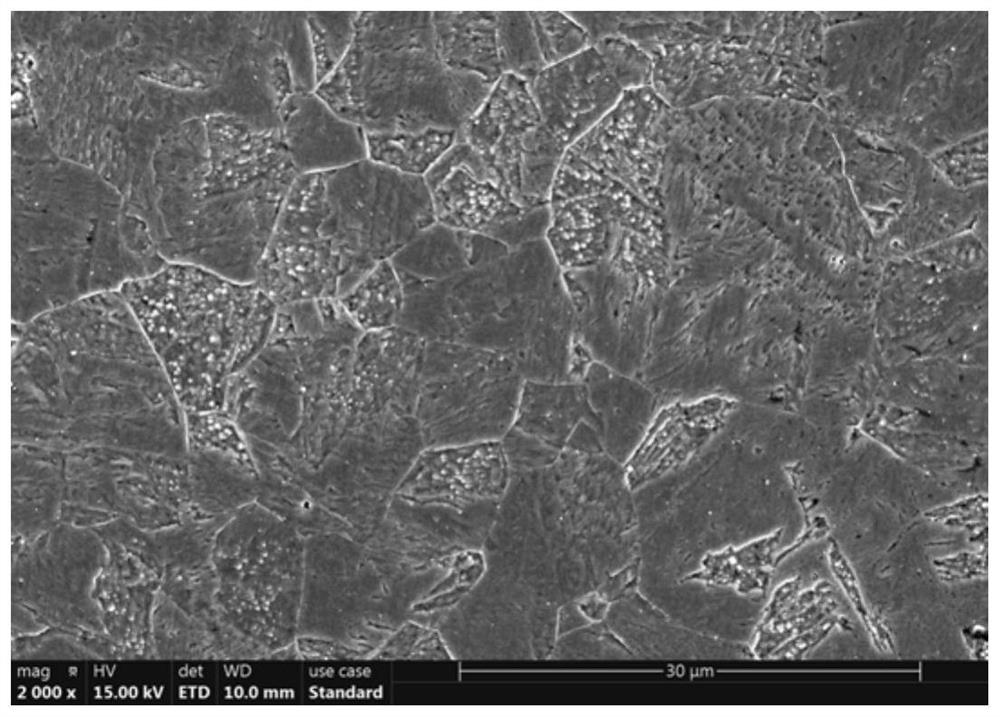

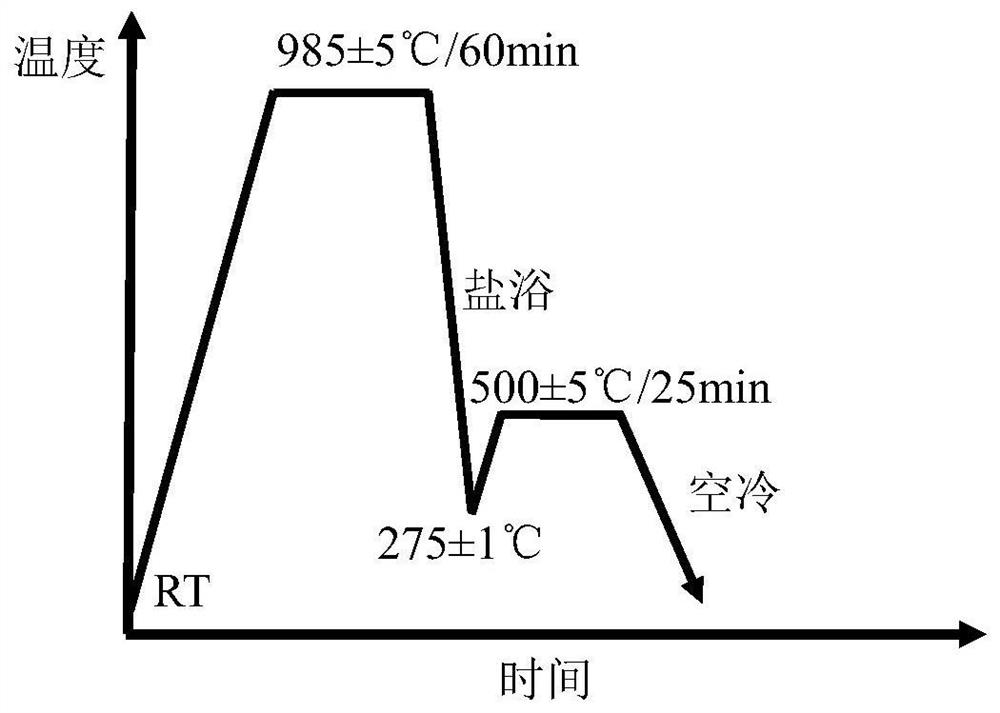

High-strength RAFM steel and novel heat treatment process thereof

The invention provides novel RAFM steel and a heat treatment process thereof. The RAFM steel comprises, by mass percent, 0.10% < = C < = 0.13%, 8.50% < = Cr < = 9.00%, 1.80% < = W < = 2.00%, 0.20% < = V < = 0.25%, 0.15% < = Ta < = 0.20%, 0.01% < = Zr < = 0.02%, 0.45% < = Mn < = 0.50%, 0.2% < = Si < = 0.4%, 0.02% < = N < = 0.04%, RE (rare earth element) < = 0.03%, O < 0.004%, P < 0.004%, S < 0.004% and the balance Fe. The heat treatment process of the RAFM steel comprises the steps that heat preservation is conducted for 60 min in a 985 + / -5 DEG C high-temperature furnace, then the RAFM steel is rapidly put into a 275 + / -1 DEG C salt bath pan to be subjected to heat preservation for 60 s, then the RAFM steel is rapidly put into a 500 + / -5 DEG C high-temperature furnace to be subjected to heat preservation for 25 min, and then the RAFM steel is air-cooled to the room temperature after being discharged out of the furnace. The novel RAFM steel is combined with the heat treatment process of the novel RAFM steel so that higher strength can be obtained while plasticity is not obviously reduced.

Owner:SICHUAN UNIV

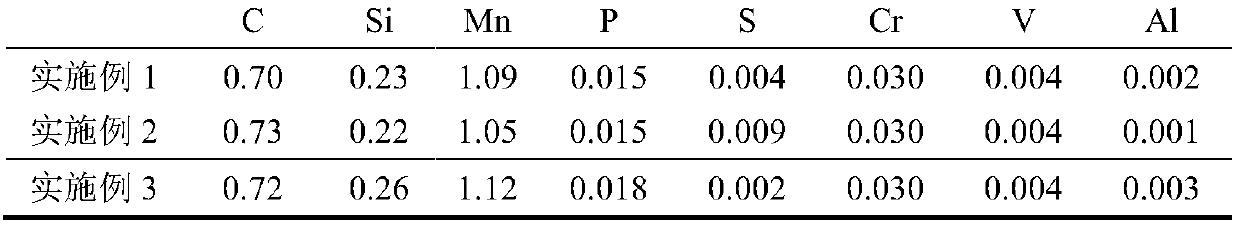

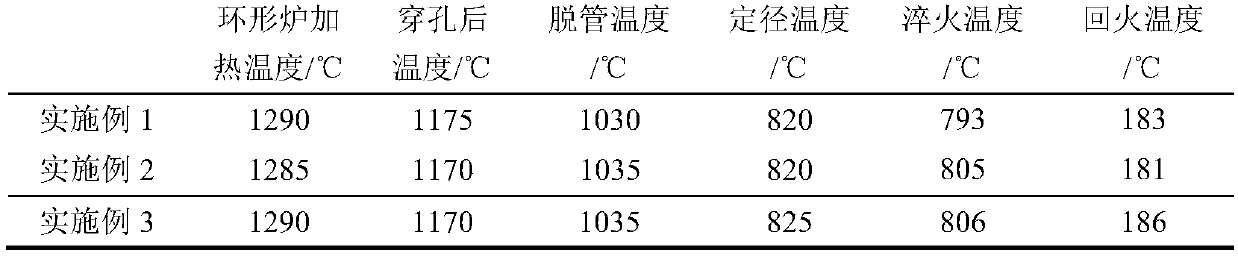

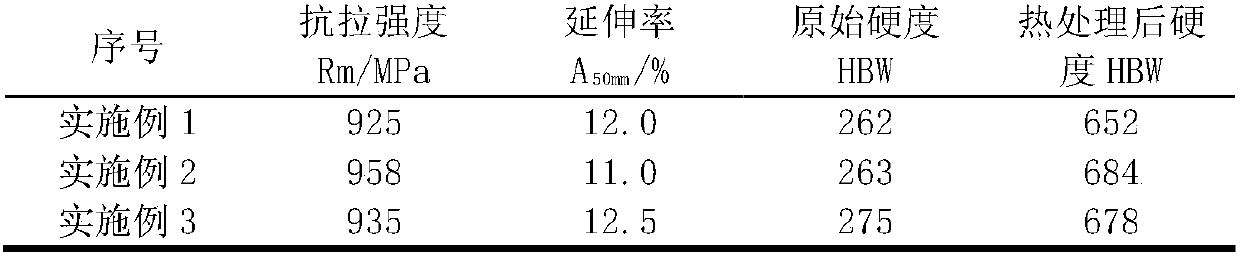

A kind of nm600 high-strength wear-resistant pipe and its manufacturing process

ActiveCN107630165BReach a steady stateMeet the mechanical performance requirements of high-strength wear-resistant pipesStable stateChemical composition

The invention provides an NM600 high-strength wear-resistant pipe and a production process thereof. The NM600 high-strength wear-resistant pipe is characterized by comprising the following chemical components by weight: 0.69 to 0.75% of C, 0.20 to 0.40% of Si, 1.00 to 1.15% of Mn, no more than 0.025% of P, no more than 0.020% of S, 0.12 to 0.20% of Cr, 0.030 to 0.050% of V and no more than 0.010%of Al, with the balance being Fe and unavoidable impurities. According to the invention, the content of C is increased; proper V and Cr are added; the contents of sulfur and phosphorus are controlled;a high-temperature high-speed rolling method is employed; quenching treatment is carried out after rolling so as to obtain a martensite matrix structure; quenching stress is eliminated through low-temperature tempering treatment, so brittleness is reduced, and the structure reaches a stable state and can ultimately meet requirements on the mechanical properties of the NM600 high-strength wear-resistant pipe.

Owner:ANGANG STEEL CO LTD

Low-carbon low-boron low-chromium alloy steel, and preparation method thereof

The invention discloses a low-carbon low-boron low-chromium alloy steel, and a preparation method thereof, and belongs to the technical field of alloy steel manufacturing. According to the preparationmethod, low-carbon low-boron low-chromium materials are combined with cerium rare earth, vanadium, tungsten, copper, tantalum, cobalt, niobium, and the like, technical target value determination, material preparation, melting, sampling adjusting, casting moulding, and heat treatment are carried out so as to obtain the low-carbon low-boron low-chromium alloy steel at last; the hardness is HRC42-52, the impact energy is as high as 11 to 20 joules. The preparation method is capable of guaranteeing the certain hardness of the alloy steel, and at the same time, improving the impact resistance, thetoughness, and the wear resistance greatly.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

Cold treatment process for carburized gear part

InactiveCN111235358AQuenching stress reliefReduced risk of crackingFurnace typesHeat treatment furnacesCold treatmentTempering

The invention discloses a cold treatment process for a carburized gear part. The process comprises the following steps that firstly, a gear part is carburized to obtain the carburized gear part; secondly, the carburized gear part is subjected to high-temperature tempering and then subjected to quenching; thirdly, the quenched carburized gear part is subjected to low-temperature tempering; fourthly, the carburized gear part obtained after low-temperature tempering is subjected to cold treatment; fifthly, the carburized gear part obtained after cold treatment is warmed up; and sixthly, the warmed-up carburized gear part is subjected to low-temperature tempering. According to the process, before cold treatment, quenching stress of the carburized gear part is eliminated through low-temperaturetempering, the cracking risk during cold treatment is reduced, cold treatment cracks are avoided, the carburized gear part is subjected to cold treatment, the hardness and wear resistance of the carburized gear part are obviously improved, the cracking risk is avoided, and the risk of grinding cracks is suppressed; and the carburized gear part obtained after cold treatment is warmed up, cold treatment stress is reduced, and the risk that the carburized gear part cracks is reduced.

Owner:XIAN COAL MINING MACHINERY

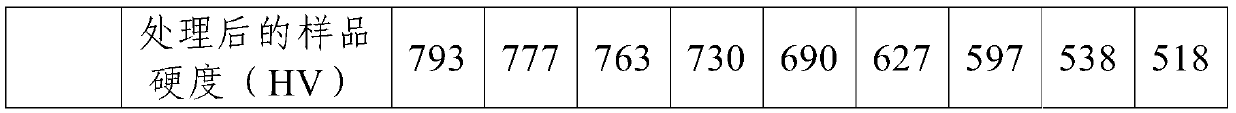

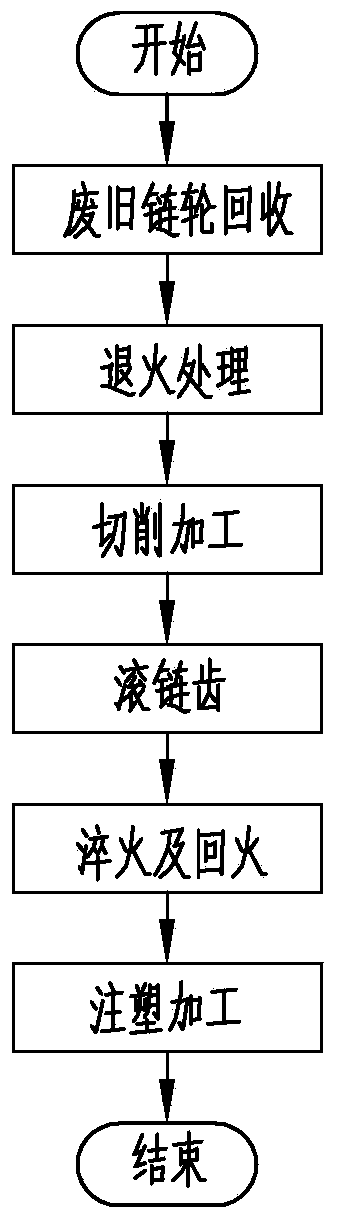

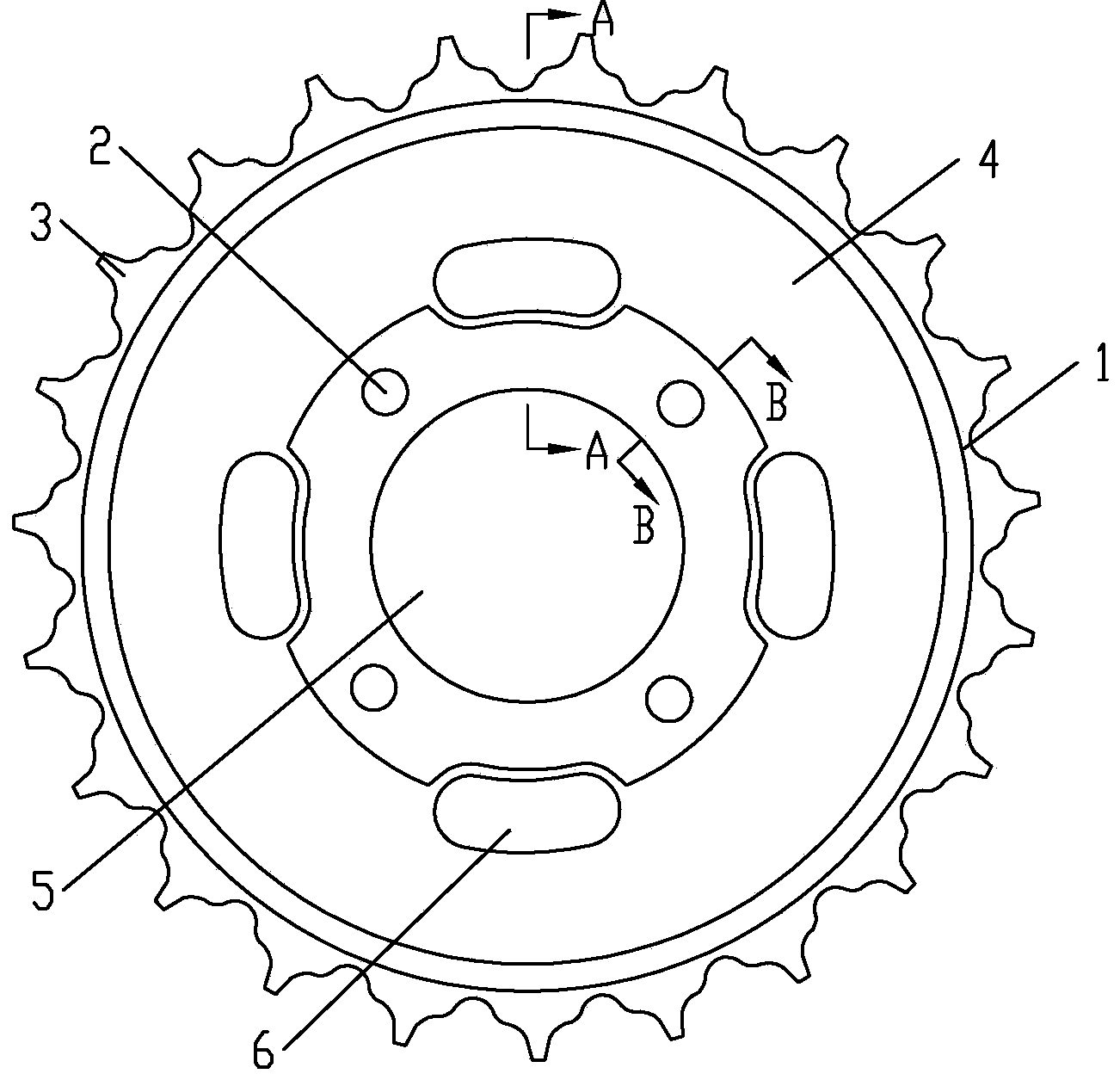

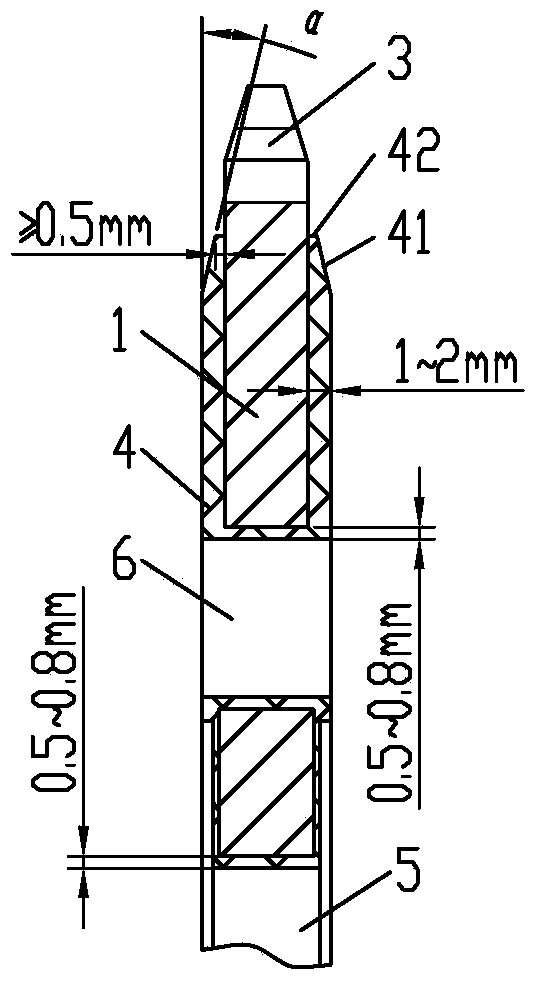

Motorcycle sprocket regeneration method

InactiveCN103639659AReduce recycling costsReduce processing quality requirementsSocial benefitsEconomic benefits

The invention discloses a motorcycle sprocket regeneration method. The method comprises waste sprocket recovery: motorcycle waste sprockets flawless in sprocket bodies are recovered selectively, and lightening holes and screw connection holes are formed in the sprocket bodies; annealing treatment: the waste sprockets are subjected to annealing treatment; cutting machining: teeth of the waste sprockets are removed through a turning mode to form addendum circles of regenerated sprockets; rolling the teeth: the regenerated teeth are subjected to roll cutting, and the number of the teeth of the regenerated sprockets are 2 to 4 smaller than that of the teeth of the waste sprockets; quenching and tempering: local quenching and tempering is performed on the teeth of the regenerated sprockets; injection molding: injection molding layers are formed on the sprocket bodies of the regenerated sprockets by using modified polypropylene for vehicles through an injection molding mode to form regenerated sprocket finished products, and the injection portions on the two sides of the sprocket bodies are integrated through portions covering the lightening holes and the screw connection holes. The method has the advantages that waste sprocket resources are fully used, the regeneration efficiency is high, regeneration costs are low, and economic benefits and social benefits are apparent.

Owner:CHONGQING QIUSHOU MACHINERY

Heat treatment process for high-carbon-chromium bearing steel pipe

InactiveCN108504839ADecompose fullyImprove conversion rateFurnace typesQuenching agentsHigh carbonRoom temperature

The invention relates to a heat treatment process for a high-carbon-chromium bearing steel pipe. The heat treatment process comprises the following steps that the high-carbon-chromium bearing steel pipe is heated in a quenching furnace to 850-890 DEG C, and heat preservation is conducted; after being washed and dried, the high-carbon-chromium bearing steel pipe is placed into a vacuum cooling oilfurnace to be cooled to 76-82 DEG C, and heat preservation is conducted for 2-5 min; the high-carbon-chromium bearing steel pipe is placed into a tempering furnace to be heated to 165-190 DEG C, heatpreservation is conducted for 1.5-2.5 h, and then the high-carbon-chromium bearing steel pipe is placed into the vacuum cooling oil furnace to be cooled to 80-95 DEG C, taken out to be washed and dried, and cooled in air to be the room temperature; and tempering treatment operation is repeated, and the high-carbon-chromium bearing steel pipe is subjected to secondary tempering treatment. The high-carbon-chromium bearing steel pipe produced by the heat treatment process is high in hardness, uniform in structure, good in abrasion resistance and high in toughness.

Owner:ZHEJIANG JIANLI CO LTD

Low-chrome wear-resistant alloy steel, and preparation method thereof

The invention discloses a low-chrome wear-resistant alloy steel, and a preparation method thereof. The preparation method comprises following steps: technology target value determination, material preparation, melting, sampling and adjusting, casting and moulding, and hot treatment. The low-chrome wear-resistant alloy steel comprises, by weight, 0.25 to 0.35% of carbon, 0.6 to 1.5% of silicon, 0.8to 1.3% of manganese, phosphor<0.04%, sulfur<0.04%, 1 to 3.5% of chromium, 0.1 to 0.5% of nickel, 0.1 to 0.3% of molybdenum, 0.03 to 0.25% of boron, 0.1 to 0.3% of aluminium, 0.1 to 1.2% of cerium, 0.02 to 0.1% of tin, and the balance iron. According to the preparation method, both wear resistance and hardness requirements are satisfied, the toughness is increased greatly, impact resistance is excellent, impact energy is as high as 5 to 8 joules, and cobblestones can be crushed using the low-chrome wear-resistant alloy steel easily.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

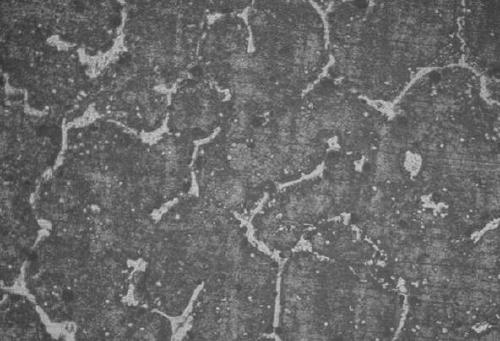

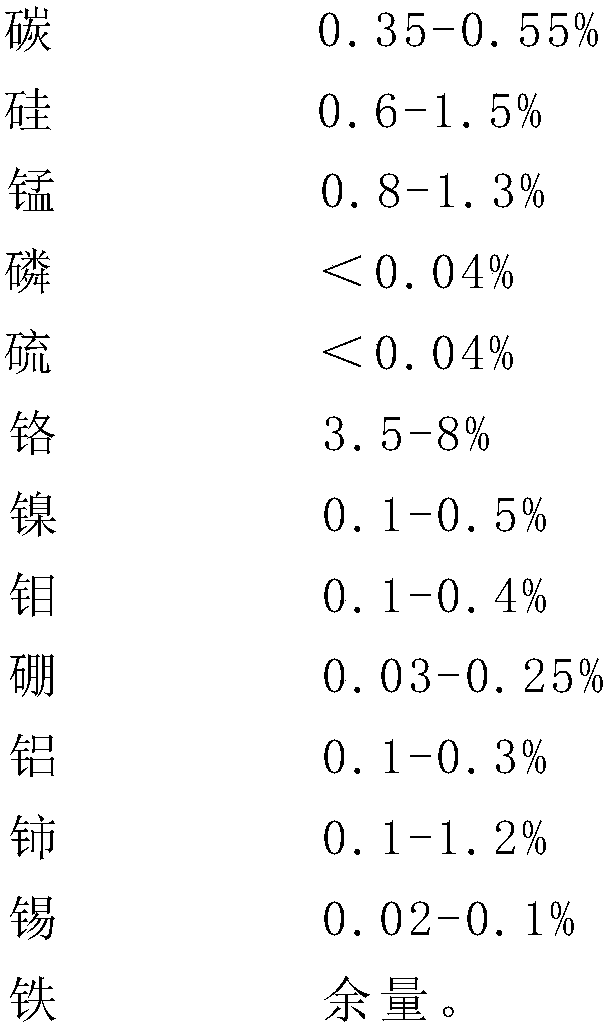

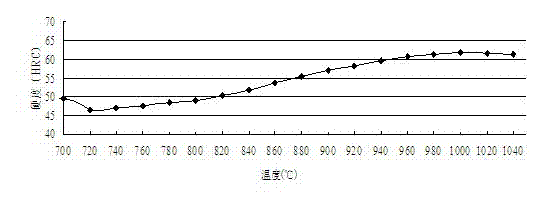

Medium-chromium wear-resistant alloy steel, and preparation method thereof

The invention discloses a medium-chromium wear-resistant alloy steel, and a preparation method thereof. The preparation method comprises steps of technology target value determination, material preparation, melting, sampling and adjusting, casting moulding, and thermal treatment. The medium-chromium wear-resistant alloy steel comprises, by weight, 0.35 to 0.55% of carbon, 0.6 to 1.5% of silicon, 0.8 to 1.3% of manganese, phosphor <0.04%, sulfur <0.04%, 3.5 to 8% of chromium, 0.1 to 0.5% of nickel, 0.1 to 0.4% of molybdenum, 0.03 to 0.25% of boron, 0.1 to 0.3% of aluminium, 0.1 to 1.2% of cerium, 0.02 to 0.1% of tin, and the balance iron. The relatively toughness and the impact resistance performance are ensured; the wear resistance and the hardness are improved; the technology is easy to control; and the medium-chromium wear-resistant alloy steel is suitable for civil applications and popularization.

Owner:LESHAN TAIGANG SUNKOS MACHINERY MFG

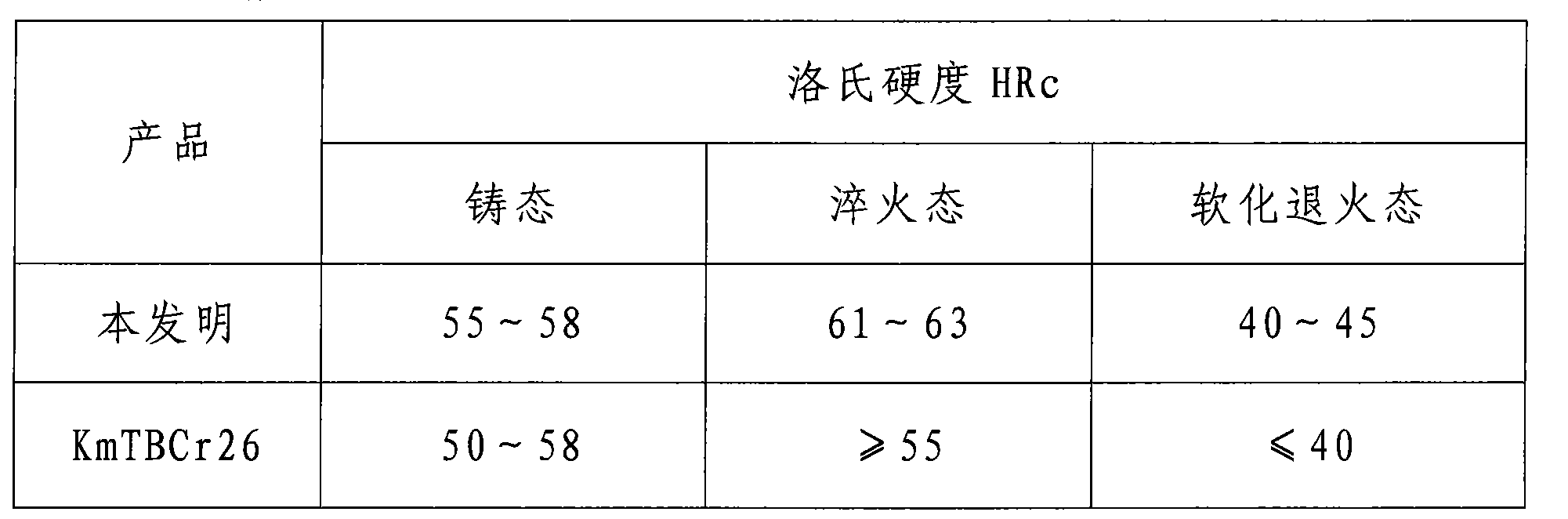

Heat-treatment method of high-chromium wear-resistant white cast iron Cr28

The invention discloses a heat-treatment method of high-chromium wear-resistant white cast iron Cr28. According to the invention, high-chromium wear-resistant white cast iron Cr28 is heated to 1000-1050 DEG C; the white cast iron Cr28 is heated and the temperature is maintained for 1.5-3h; the white cast iron Cr28 is air-cooled to room temperature; the white cast iron Cr28 is heated to 710-730 DEG C; the white cast iron Cr28 is tempered at the temperature for 1.5-2h; and the white cast iron Cr28 is air-cooled to room temperature, such that the high-chromium wear-resistant white cast iron Cr28 with improved machining performance is obtained. According to the invention, the improved cast iron Cr28 has relatively low hardness, such that machining is convenient. Also, processed workpiece is subjected to quenching and low-temperature tempering, such that workpiece impact toughness can be improved, and wear-resistance can be improved.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Chromium manganese tungsten molybdenum high alloy steel and manufacturing method

The invention discloses chromium manganese tungsten molybdenum high alloy steel and a manufacturing method thereof. The chromium manganese tungsten molybdenum high alloy steel comprises the followingcomponents in percentage by weight: 2-4% of carbon, 24-28% of chromium, 1-3% of silicon, 0.01-0.03% of phosphorus, 1.0-1.2% of manganese, 0.2-0.4% of nickel, 0.2-0.3% of tungsten, 0.1-0.3% of molybdenum, 0.1-0.3% of aluminum, 0.05-0.1% of tin, 0.05-0.06% of titanium, 0.1-0.15% of vanadium, 0.0005-0.0008% of antimony, and the balance of iron and impurities. The chromium manganese tungsten molybdenum high alloy steel has strict demands on the matching precision of all elements, so that the out-of-round rate and the breakage rate in the operation process are low; the preparation method is simplein process; a chilling process for aerospace science and technology is adopted in casting, so that grains of cast balls are finer, the structure is more compact, the wear resistance is improved, the electric energy loss is effectively reduced, and the effects of energy conservation and consumption reduction are achieved; after annealing, the alloy steel can eliminate the quenching stress; and remained austenite is converted to bainite to increase the hardness, so that the wear resistance, the hardness and the toughness of the alloy steel are guaranteed.

Owner:HUNAN CHANGJIANG WEARPROOF NEW MATERIAL CO LTD

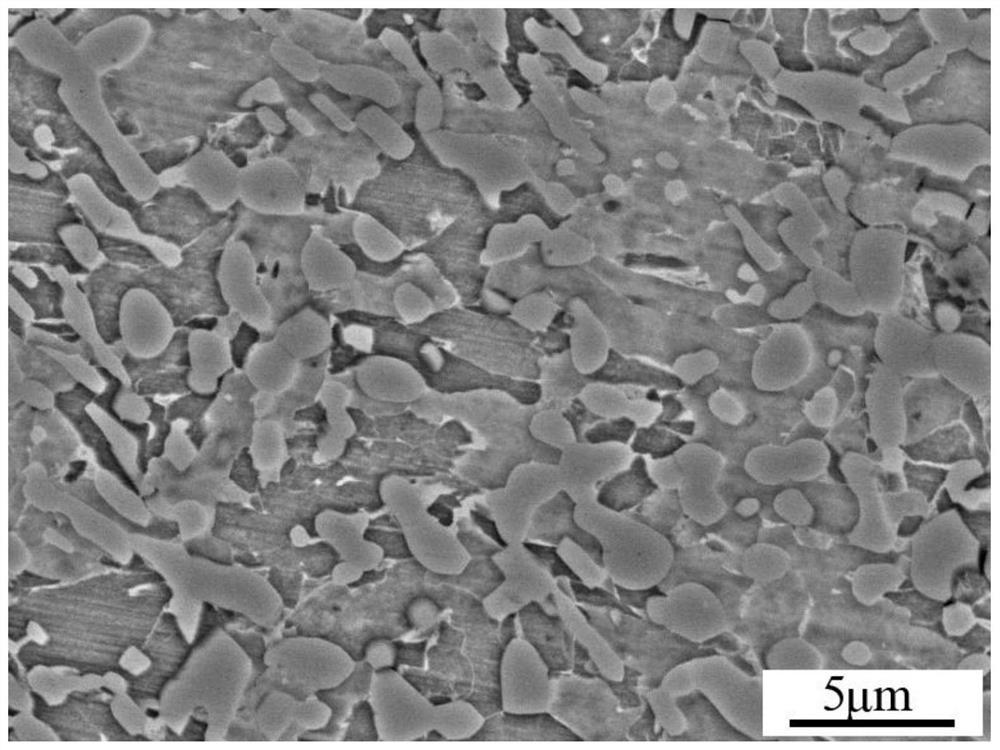

Heat-treated vanadium-containing high-boron high-speed steel and heat treatment method thereof

The invention discloses a heat-treated vanadium-containing high-boron high-speed steel and a heat treatment method thereof. According to the heat treatment method, quenching treatment is conducted on the vanadium-containing high-boron high-speed steel at the temperature of 1010-1060 DEG C to obtain a quenched part; and the quenched part is subjected to tempering treatment twice, and after the part is subjected to air cooling to the room temperature, the heat-treated vanadium-containing high-boron high-speed steel is obtained. According to the vanadium-containing high-boron high-speed steel and the preparation method thereof, the form of boron carbide is improved through vanadium addition and a heat treatment process, matrix strengthening is promoted, the vanadium-containing high-boron high-speed steel with excellent strength and toughness is obtained, and the vanadium-containing high-boron high-speed steel subjected to heat treatment can be better adapted to severe working conditions when being applied to actual production.

Owner:XI AN JIAOTONG UNIV

High-wear-resistant-edge mold material and heat treatment process thereof

InactiveCN110527919AHigh strengthImprove wear resistanceQuenching agentsWear resistantRoom temperature

The invention discloses a high-wear-resistant edge mold material and a heat treatment process thereof, and belongs to the technical field of mold materials. The high-wear-resistant edge mold materialcomprises the following components in percentage by mass: 0.45%-0.55% of C, 0.9%-1.2% of Si, 0.3%-0.6% of Mn, 4.9%-5.5% of Cr, 1.3%-1.6% of V, 1.3%-1.6% of Mo, P <= 0.03%, S<= 0.03% and the balance Feand inevitable impurities. The heat treatment process comprises the following steps: 1, pre-heat treatment: heating an edge mold material to 830-870 DEG C, keeping the temperature for 2-3 hours, andair-cooling to room temperature; 2, quenching treatment, specifically, the edge mold material treated in the step 1 is heated to 820-840 DEG C, and after heat preservation is conducted for 5-7 hours,the edge mold material is put into a quenching medium to be cooled to the room temperature; and thirdly, tempering treatment, specifically, tempering treatment is conducted on the blade mold materialtreated in the second step. By improving the components of the edge mold material and the heat treatment process, the wear resistance and comprehensive mechanical properties of the blade mold materialare greatly improved.

Owner:ANHUI LINGFENG METALLURGICAL MACHINERY

Nanometer M2B reinforced iron-based wear-resistant coating and preparation method thereof

ActiveCN112981052AImprove wear resistanceApplicable to wear conditionsIncreasing energy efficiencyTemperingHigh energy laser

The invention discloses a nanometer M2B reinforced iron-based wear-resistant coating and a preparation method thereof. The method comprises the following steps of selecting cast Fe-B alloy as an original matrix, and polishing and derusting the surface of the original matrix; placing the treated original matrix in argon for preheating treatment; conducting surface melting treatment on the pretreated original matrix by utilizing high-energy laser; and conducting quenching and tempering heat treatment on the original matrix subjected to surface melting treatment, and preparing the surface wear-resistant coating of the nanometer M2B enhanced martensitic matrix on the surface of the original matrix. The prepared nanometer M2B reinforced iron-based wear-resistant coating has excellent wear resistance and can be used for the working condition of impact abrasive wear resistance, the wear resistance of the coating is improved by 3-7 times compared with the wear resistance of a cast Fe-B alloy, the traditional Fe-B wear-resistant alloy can be applied to the working condition of impact wear after being subjected to proper laser surface melting to prepare the coating, and the coating has important engineering application and popularization value.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com