High-wear-resistant-edge mold material and heat treatment process thereof

A mold material and high wear-resistant technology, applied in heat treatment equipment, manufacturing tools, quenching agents, etc., can solve the problems of low comprehensive performance such as steel hardness and wear resistance, and achieve improved wear resistance, mechanical properties, and improved The effect of strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The high wear-resistant blade mold material of this embodiment has the mass percentages of its components: C 0.45%, Si 0.9%, Mn0.3%, Cr 4.9%, V 1.3%, Mo 1.3%, P 0.01%, S 0.01 %, the rest is Fe and unavoidable impurities.

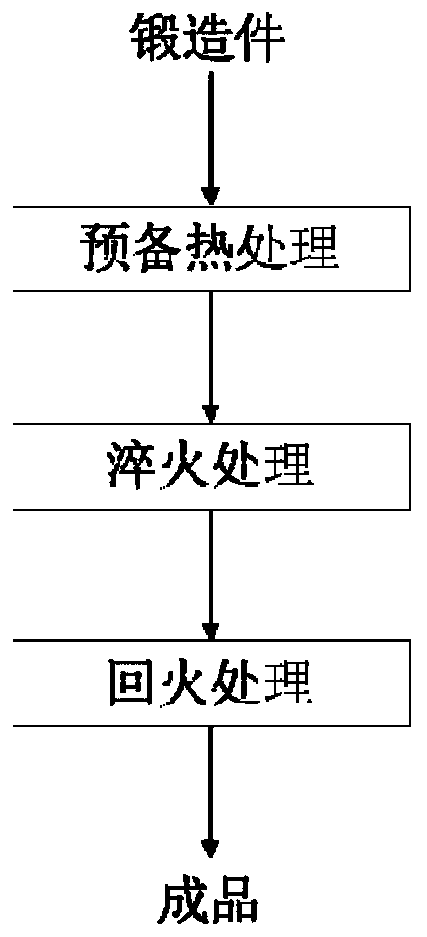

[0057] Such as figure 1 As shown, the heat treatment process is as follows:

[0058] 1. Preliminary heat treatment: heat the forged blade mold material to 830°C, keep it warm for 2 hours, and then air cool it to room temperature;

[0059] 2. Quenching treatment: heat the blade mold material treated in step 1 to 820°C, keep it warm for 5 hours, put it into an inorganic polymer water-soluble quenching medium and cool it to room temperature;

[0060] 3. Tempering treatment: Temper the blade mold material processed in step 2, heat it to 550° C., and keep it warm for 8 hours.

[0061] The finished product after the heat treatment process, after testing,

[0062] Central looseness (grade): 1.0;

[0063] Segregation (level): 2.0;

[0064] Grain size (a...

Embodiment 2

[0069] The high wear-resistant blade mold material of this embodiment has the mass percentage of each component: C 0.55%, Si 1.2%, Mn0.6%, Cr 5.5%, V 1.6%, Mo 1.6%, P 0.03%, S 0.03 %, the rest is Fe and unavoidable impurities.

[0070] Such as figure 1 As shown, the heat treatment process is as follows:

[0071] 1. Preliminary heat treatment: heat the forged blade mold material to 870°C, keep it warm for 3 hours, and then air cool it to room temperature;

[0072] 2. Quenching treatment: heat the blade mold material treated in step 1 to 840°C, keep it warm for 7 hours, put it into an inorganic polymer water-soluble quenching medium and cool it to room temperature;

[0073] 3. Tempering treatment: Temper the blade mold material processed in step 2, heat it to 600° C., and keep it warm for 10 hours.

[0074] The finished product after the heat treatment process, after testing,

[0075] Central looseness (level): 1.0;

[0076] Segregation (level): 2.0;

[0077] Grain size (a...

Embodiment 3

[0082] The high wear-resistant blade mold material of this embodiment, the mass percent of each component is: C 0.47%, Si 1.1%, Mn0.4%, Cr 5.3%, V 1.4%, Mo 1.4%, P 0.01%, S 0.01 %, the rest is Fe and unavoidable impurities.

[0083] Such as figure 1 As shown, the heat treatment process is as follows:

[0084] 1. Preliminary heat treatment: heat the forged blade mold material to 850°C, keep it warm for 2.5 hours, and then air cool it to room temperature;

[0085] 2. Quenching treatment: heat the blade mold material treated in step 1 to 830°C, keep it warm for 6 hours, put it into an inorganic polymer water-soluble quenching medium and cool it to room temperature;

[0086] 3. Tempering treatment: Temper the blade mold material processed in step 2, heat it to 600° C., and keep it warm for 9 hours.

[0087] The finished product after the heat treatment process, after testing,

[0088] Central looseness (level): 1.0;

[0089] Segregation (level): 2.0;

[0090] Grain size (accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com