Zirconium-reinforced low-activation martensitic steel and preparation method thereof

A martensitic steel, low activation technology, applied in the field of metal materials, can solve the problems of pollution, easy oxidation of powder, deterioration of mechanical properties of experimental steel, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

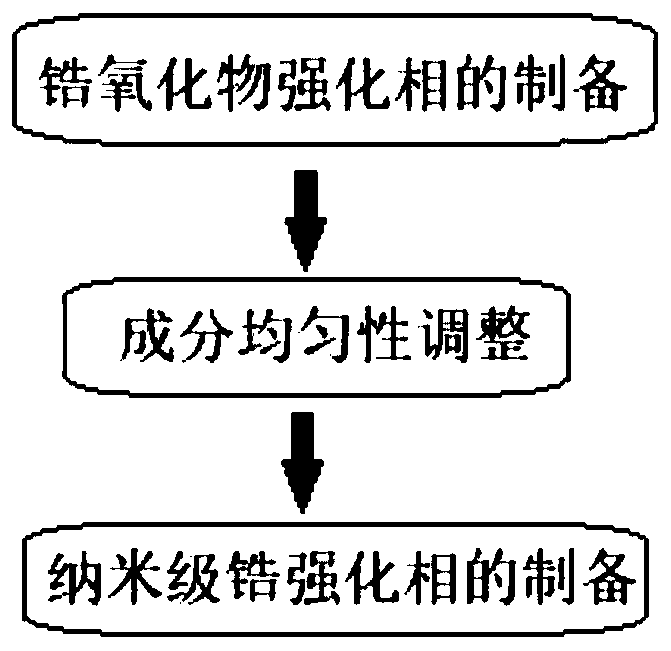

[0038] The preparation of zirconium reinforced low activation martensitic steel of the present invention comprises the following steps:

[0039] (1) Preparation of zirconium oxide strengthening phase

[0040] The raw materials Fe, Cr and W are loaded into a vacuum induction furnace, and the alloy material is melted under vacuum; the oxygen mass fraction (Xo 2 ) for measurement; according to the measurement results, add C to the steel for deoxidation, so that the oxygen in the alloy liquid can be removed to 100-180ppm; ; After all the alloys are melted, cast under nitrogen protection to obtain ingots containing zirconium oxide strengthening phase, and the nitrogen pressure in the furnace is controlled at 1000-2000Pa;

[0041] In this step, the purpose of measuring the oxygen mass fraction in molten steel is to estimate how much oxygen needs to be removed, and carbon deoxidation is used because C+O 2 =CO 2 generated CO 2 The gas can be released directly without polluting the...

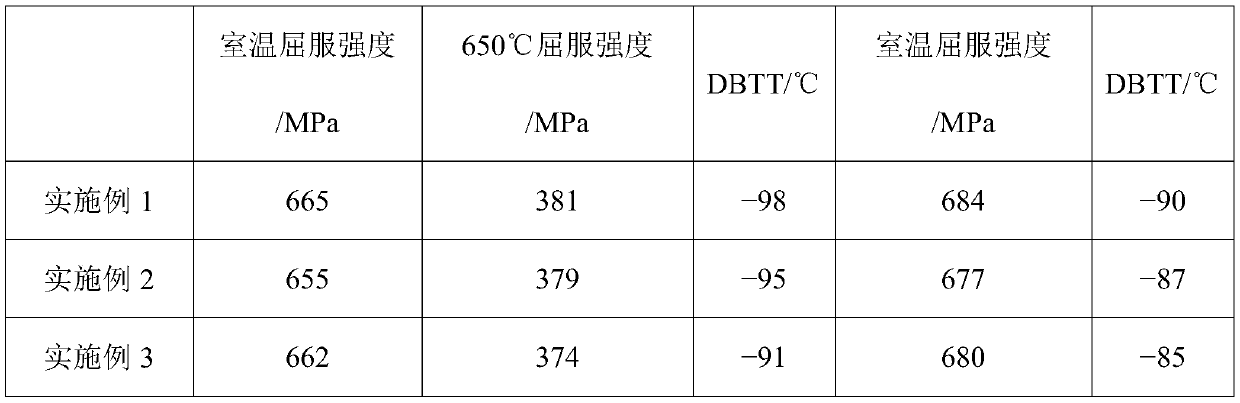

Embodiment 1

[0052] In this embodiment, the smelting of 100 kg of zirconium-strengthened low-activation martensitic steel is taken as an example for illustration. The chemical components and the mass percentages of each component in the zirconium-strengthened low-activation martensitic steel are as follows:

[0053] C: 0.01%, Si: 0.03%, Mn: 0.5%, Cr: 8.0%, W: 1.0%, V: 0.2%, Zr: 0.01%, N: 0.02%, O: 0.0125%, and the rest is Fe.

[0054] The preparation of zirconium reinforced low activation martensitic steel in this embodiment comprises the following steps:

[0055] (1) Preparation of zirconium oxide strengthening phase

[0056] The raw materials Fe, Cr and W are loaded into a vacuum induction furnace, and the alloy material is melted under vacuum; the oxygen mass fraction (Xo 2 ) for measurement, the oxygen mass fraction in the alloy liquid (Xo 2 ) is 400ppm; the vacuum degree is controlled at 5-10Pa, and 0.0102kg C is added to the steel for deoxidation, so that the oxygen in the alloy li...

Embodiment 2

[0063] In this embodiment, the smelting of 100 kg of zirconium-strengthened low-activation martensitic steel is taken as an example for illustration. The chemical components and the mass percentages of each component in the zirconium-strengthened low-activation martensitic steel are as follows:

[0064] C: 0.02%, Si: 0.05%, Mn: 0.4%, Cr: 9.0%, W: 1.2%, V: 0.25%, Zr: 0.02%, N: 0.01%, O: 0.0150%, and the rest is Fe.

[0065] The preparation of zirconium reinforced low activation martensitic steel in this embodiment comprises the following steps:

[0066] (1) Preparation of zirconium oxide strengthening phase

[0067] The raw materials Fe, Cr and W are loaded into a vacuum induction furnace, and the alloy material is melted under vacuum; the oxygen mass fraction (Xo 2 ) for measurement, the oxygen mass fraction in the alloy liquid (Xo 2 ) is 420ppm; the vacuum degree is controlled at 5-10Pa, and 0.010kgC is added to the steel for deoxidation, so that the oxygen in the alloy liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com