Nanometer M2B reinforced iron-based wear-resistant coating and preparation method thereof

A wear-resistant coating and nanotechnology, which is applied in the field of nano-M2B reinforced iron-based wear-resistant coating and its preparation, can solve the problems of affecting wear resistance, cracking and crushing, cracking failure on the surface of parts, etc., so as to improve wear resistance. , Excellent wear resistance, solve the effect of easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A kind of nano M of the present invention 2 B strengthens the preparation method of iron-based wear-resistant coating, comprises the following steps:

[0033] S1, material selection;

[0034] The cast Fe-B alloy is selected as the raw material, and the surface of the alloy is polished to remove rust.

[0035] The boride content in the Fe-B alloy ranges from 10% to 40%.

[0036] S2, preprocessing

[0037] Place the processed alloy block in an argon gas protection chamber for preheating.

[0038] The alloy test block is preheated, and the preheating temperature is 150-500°C.

[0039] S3, laser melting

[0040] Use laser to melt the surface of cast Fe-B alloy;

[0041] The laser power is 0.5-2kW, and the scanning speed is 0.1-1m / min.

[0042] S4, heat treatment

[0043] The sample after surface melting treatment is subjected to quenching + tempering heat treatment to obtain nanometer M 2 B enhanced martensite matrix wear-resistant coating.

[0044] The quenching ...

Embodiment 1

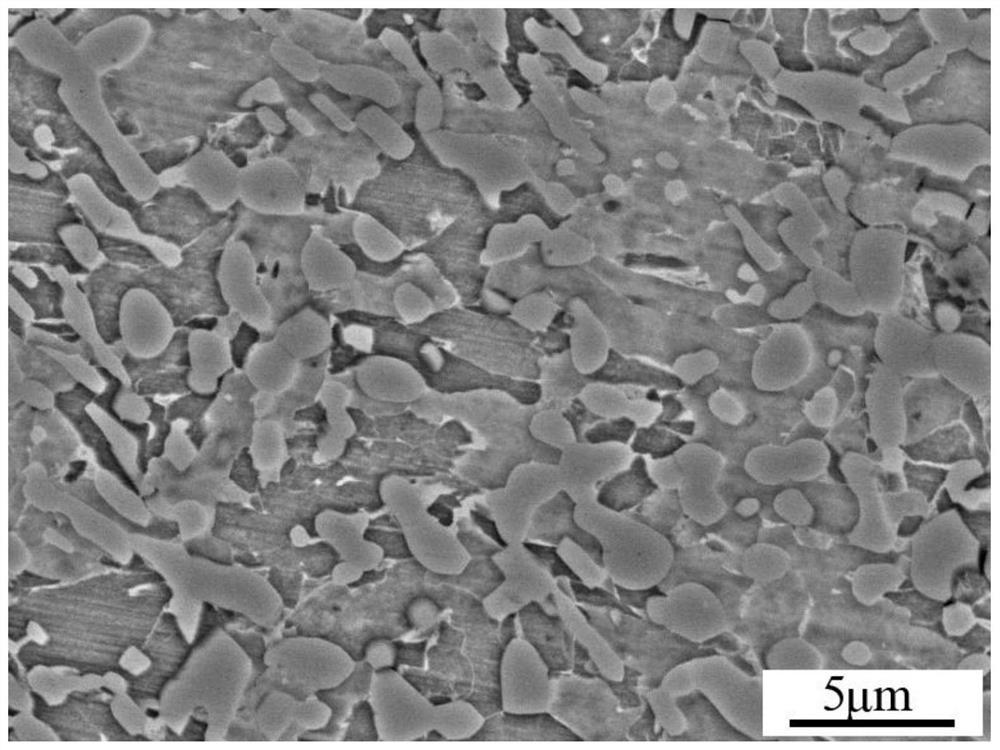

[0051] The cast Fe-B alloy is used as the raw material, and the volume fraction of boride is 10%. The surface of the alloy is polished and rust-removed. The treated alloy sample is placed in an argon gas protection chamber, and the alloy is heat-treated. The heat temperature is 150°C. The alloy is melted by a laser, the laser power is 0.5kw, and the scanning speed is 0.1m / min. The processed sample is subjected to quenching+tempering heat treatment: the quenching temperature is 1050°C, the heating rate is 20°C / min, after 2 hours of heat preservation, it is cooled in engine oil for 5 minutes; the tempering temperature is 350°C, and the heating rate is 5°C / min , keep warm for 4h, and cool down with the furnace.

[0052] Nano-M prepared in this experiment 2 B reinforced iron-based wear-resistant coating, hard phase M 2 The size of B is 40nm, the hardness is 59.0HRC, and the wear resistance against impact abrasive wear is 3.7 times that of Fe-B alloy.

Embodiment 2

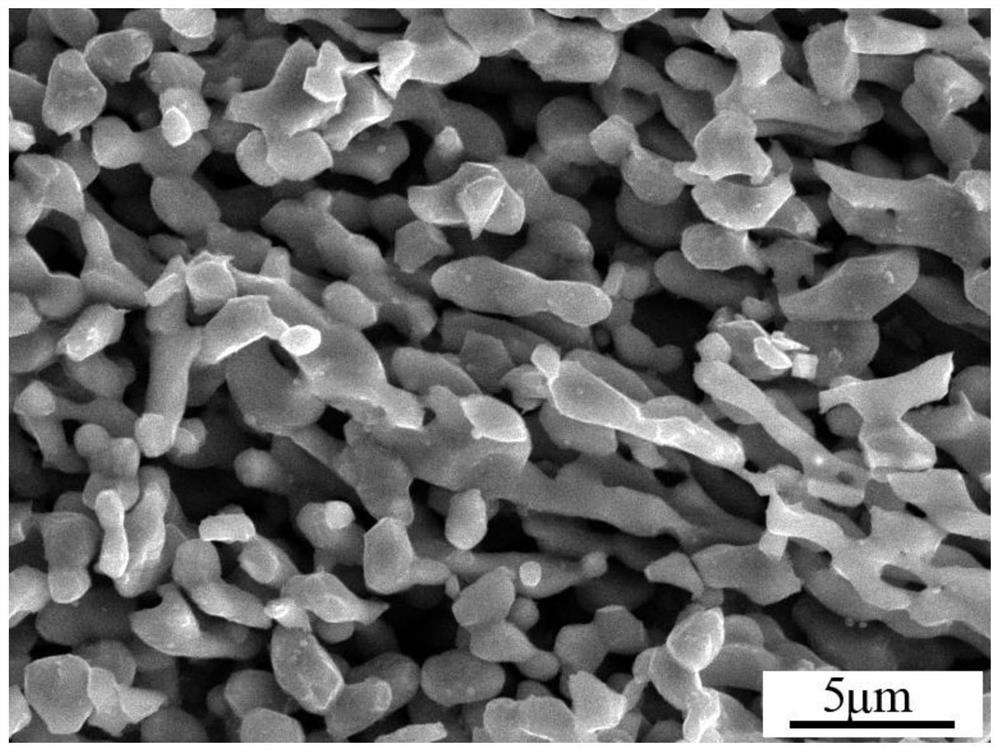

[0054] The cast Fe-B alloy is used as the raw material, and the boride volume fraction is 26%. The surface of the alloy is polished and rust-removed. The treated alloy sample is placed in an argon gas protection chamber, and the alloy is heat-treated. The heating temperature is 250°C. The alloy is melted with a laser, the laser power is 1.0kw, and the scanning speed is 0.5m / min. The treated sample is subjected to quenching + tempering heat treatment: the quenching temperature is 950°C, the heating rate is 15°C / min, after holding for 3 hours, it is cooled in engine oil for 5 minutes; the tempering temperature is 300°C, and the heating rate is 8°C / min , keep warm for 3.5h, and cool with the furnace.

[0055] Nano-M prepared in this experiment 2 B reinforced iron-based wear-resistant coating, hard phase M 2 The size of B is 356nm, the hardness is 61.5HRC, and the wear resistance against impact abrasive wear is 4.6 times that of Fe-B alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com