Patents

Literature

40results about How to "Improve service safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

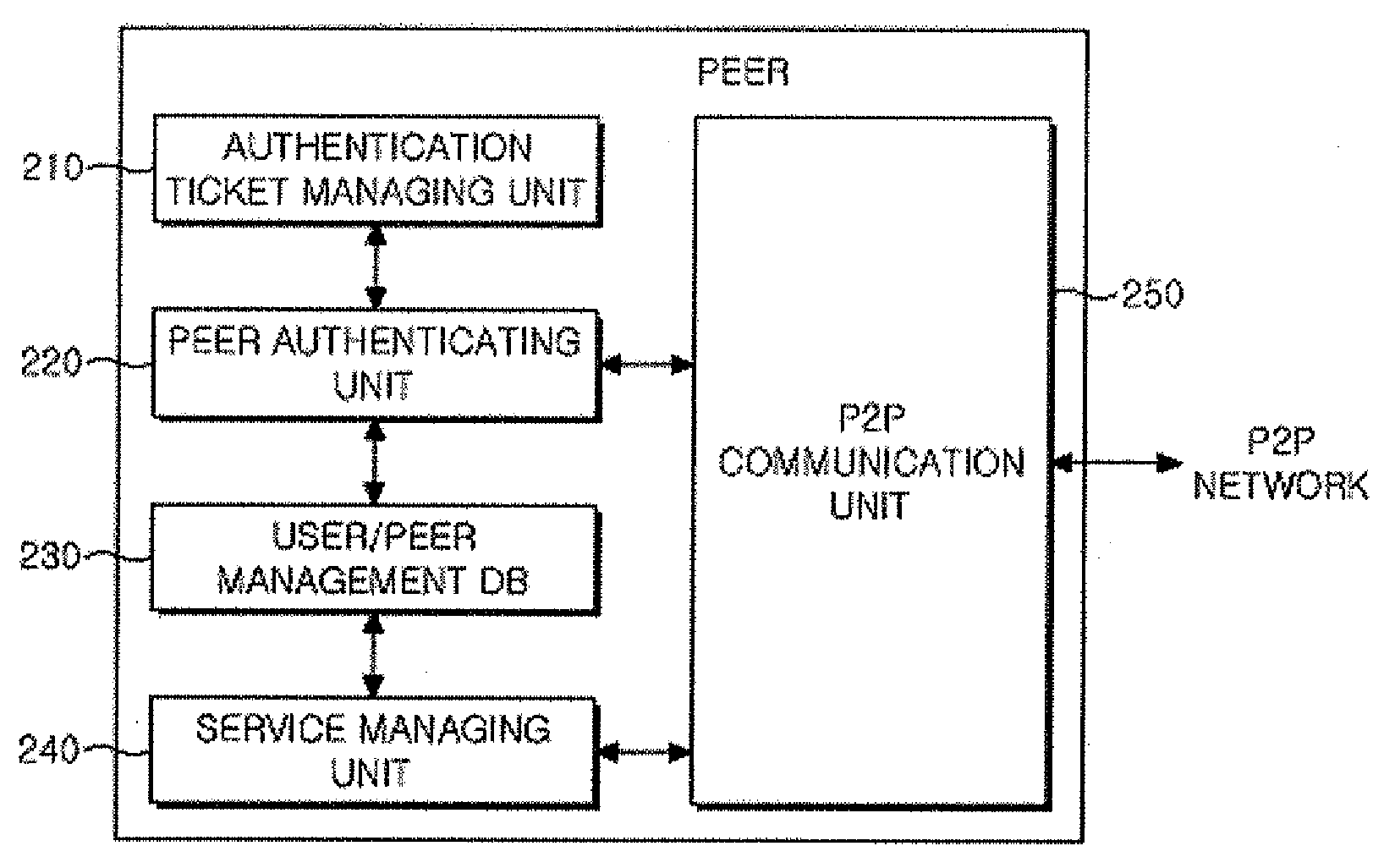

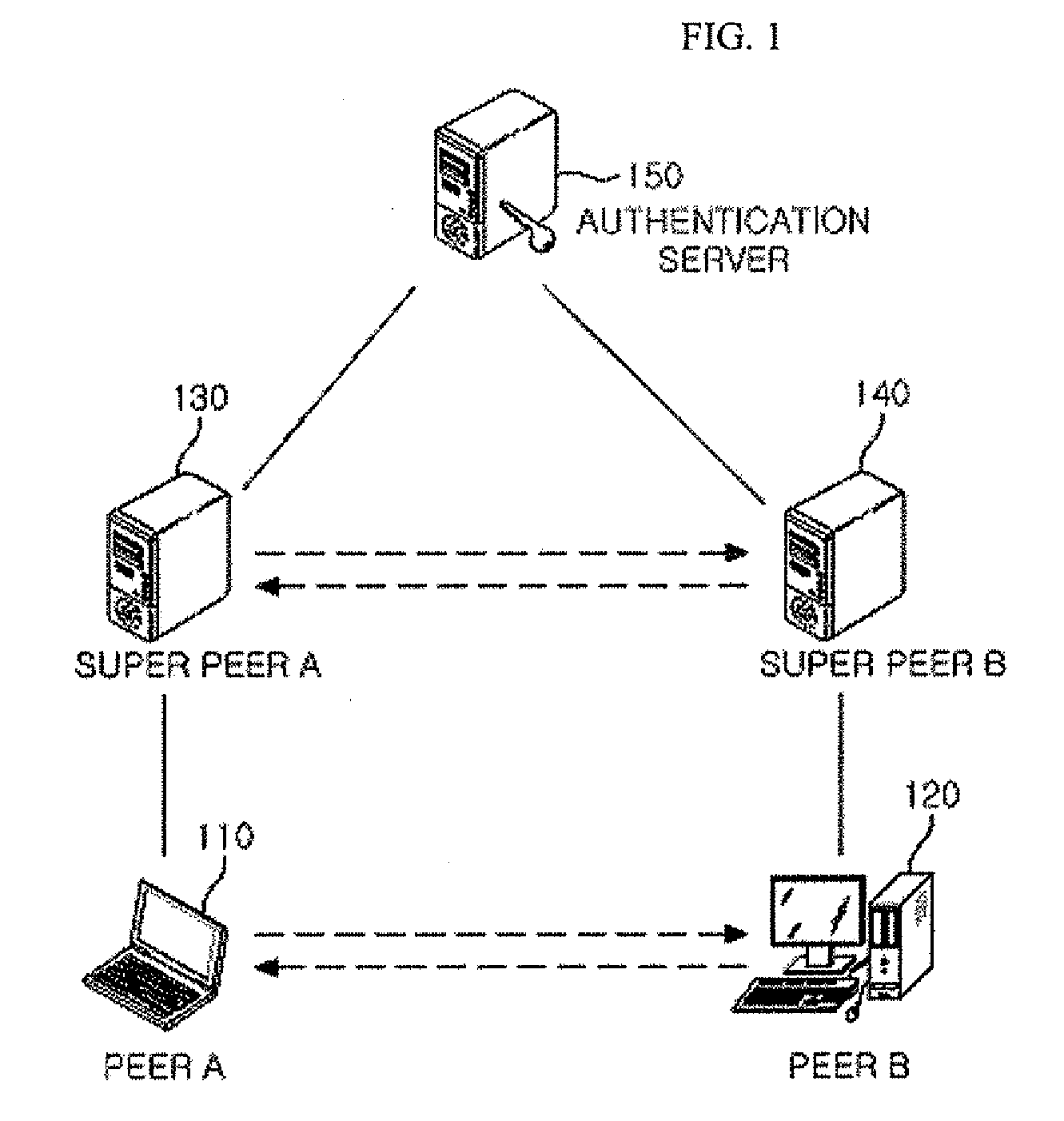

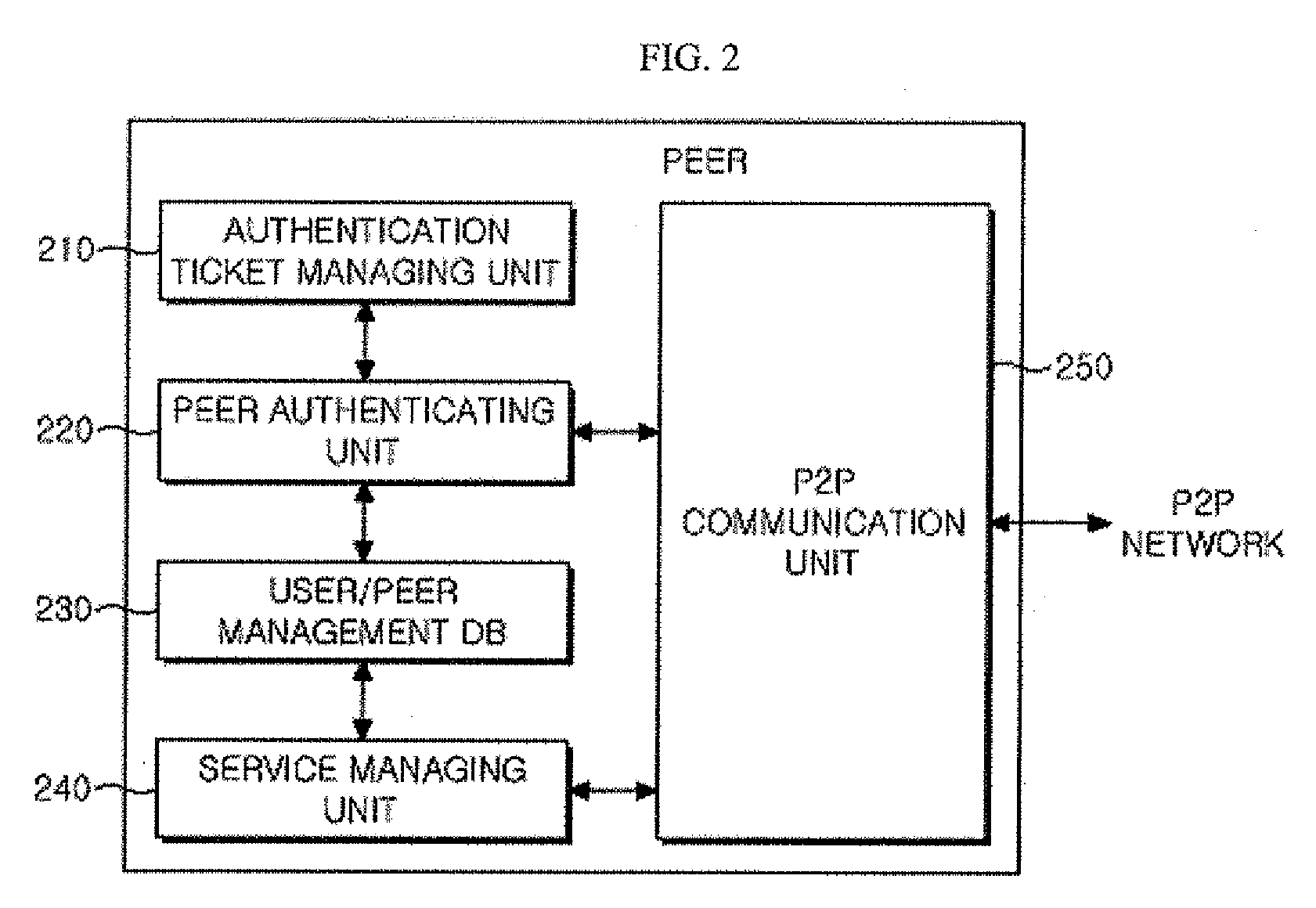

Super peer based peer-to-peer network system and peer authentication method thereof

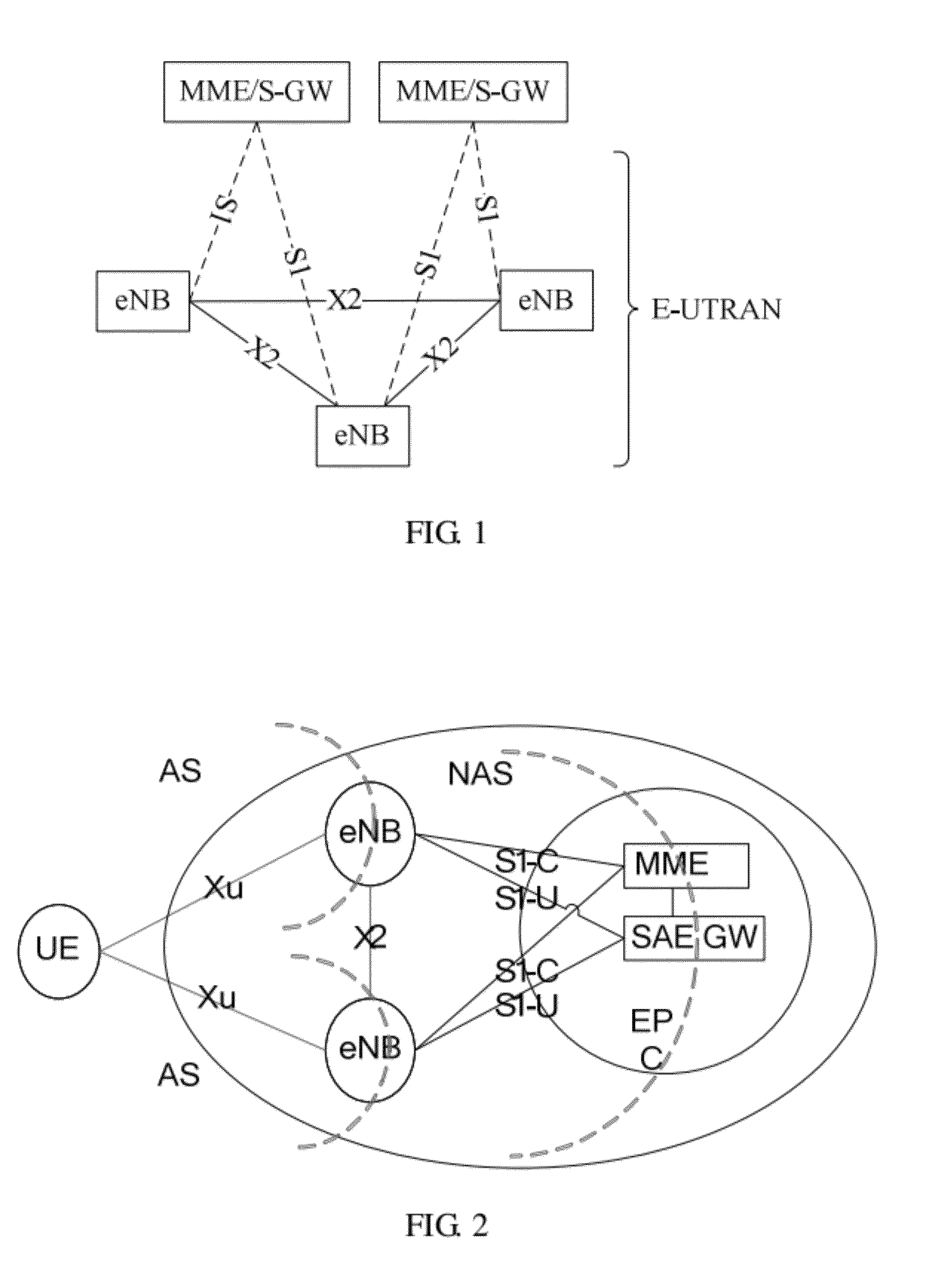

InactiveUS20090158394A1Improve service safetyDigital data processing detailsUser identity/authority verificationService provisionPeer-to-peer

Provided are a super peer based P2P network system and a peer authentication method thereof. The authentication method includes a first authentication process and a second authentication process. In the first authentication process, a user and a peer which want to use a P2P network are verified by submitting authentication information and a public key infrastructure (PKI) certificate, and receive the permission of connection. In the second authentication process, a user and a peer requesting the use of a specific service are authenticated by using an authentication ticket and a service access-permitted time is limited in order to reinforcing the security of the specific service, which is searched in the P2P network and provided by the peer. Accordingly, the service providers can verify users more securely and limit the service available time of each user with respect to a specific service provided by the peer by using the lifetime of the ticket.

Owner:ELECTRONICS & TELECOMM RES INST

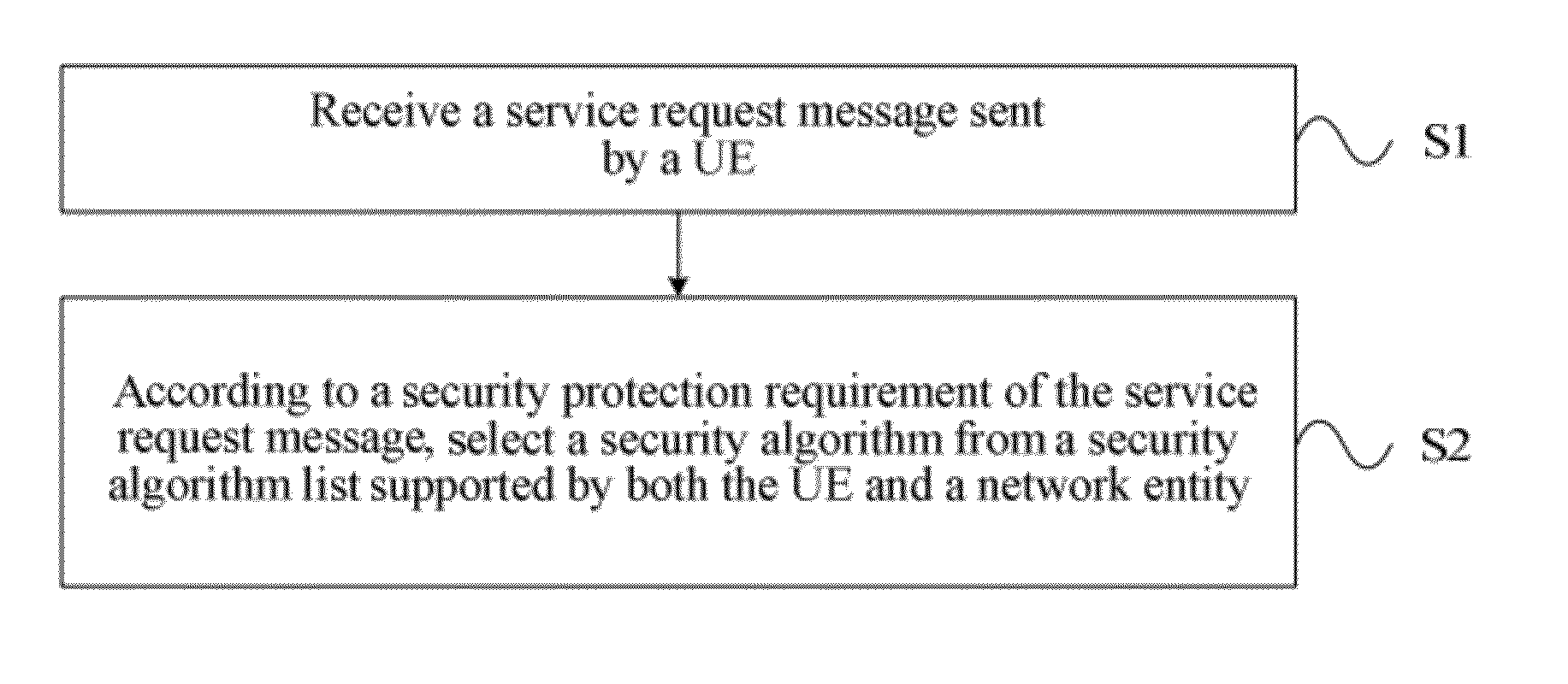

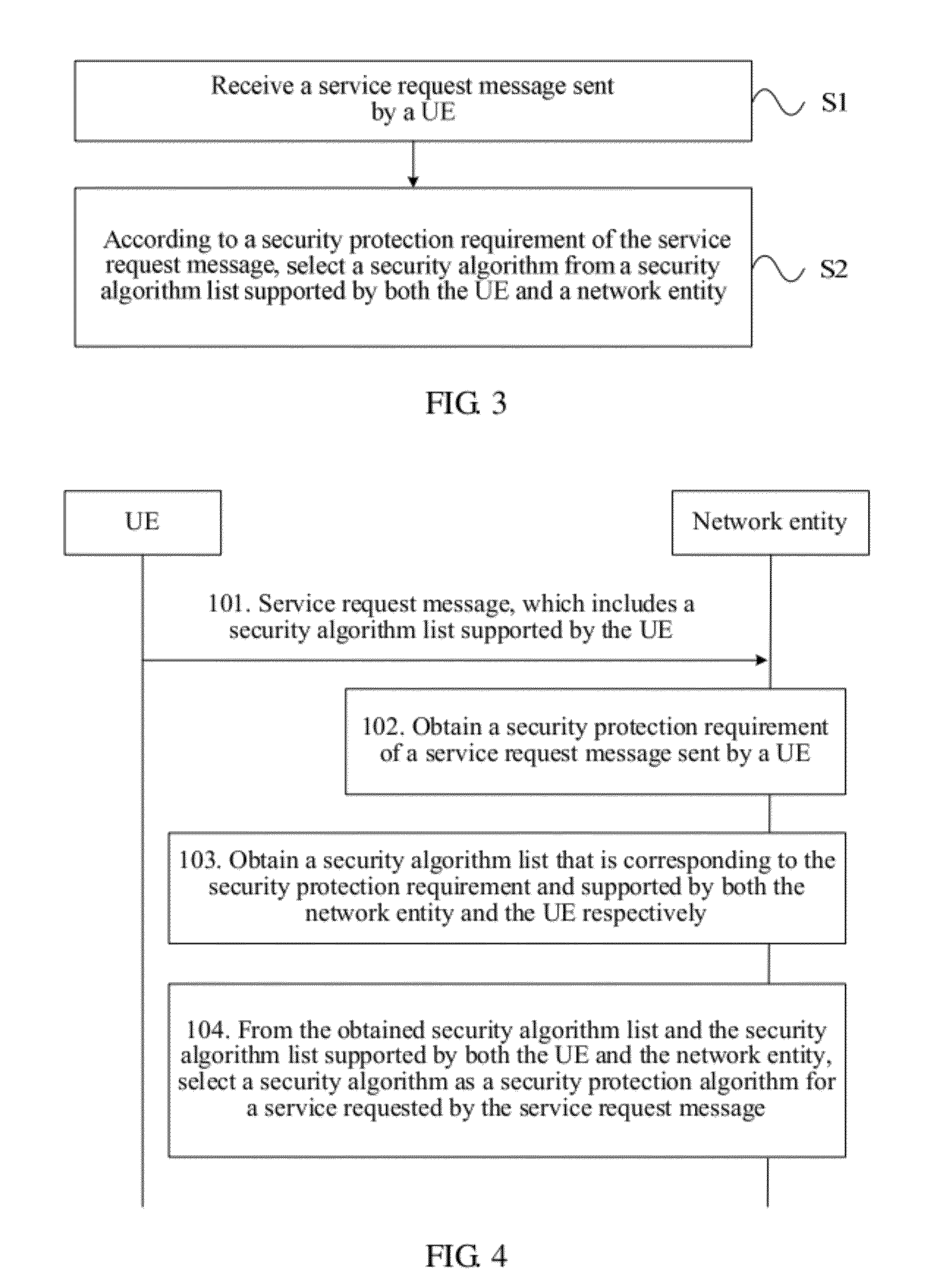

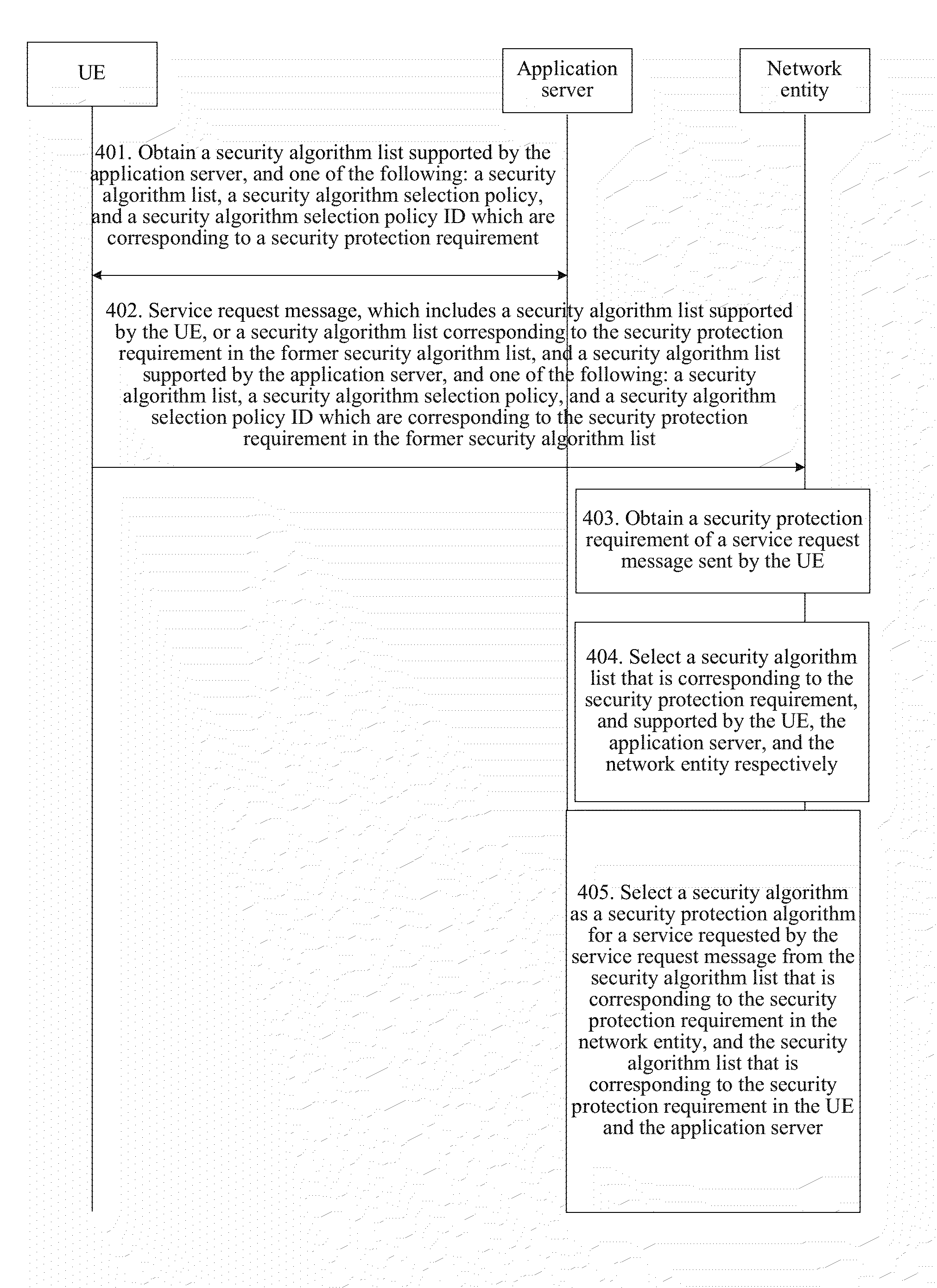

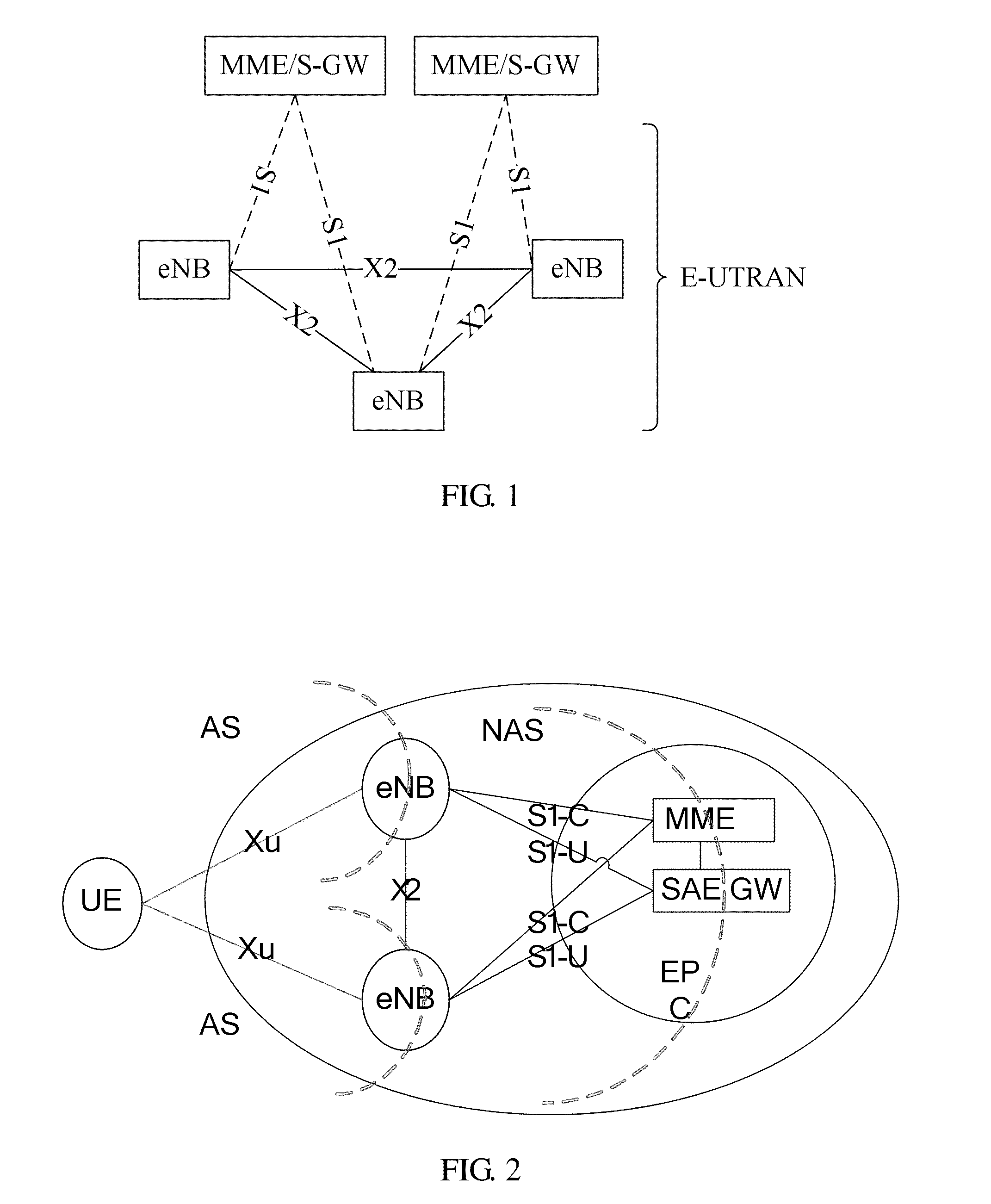

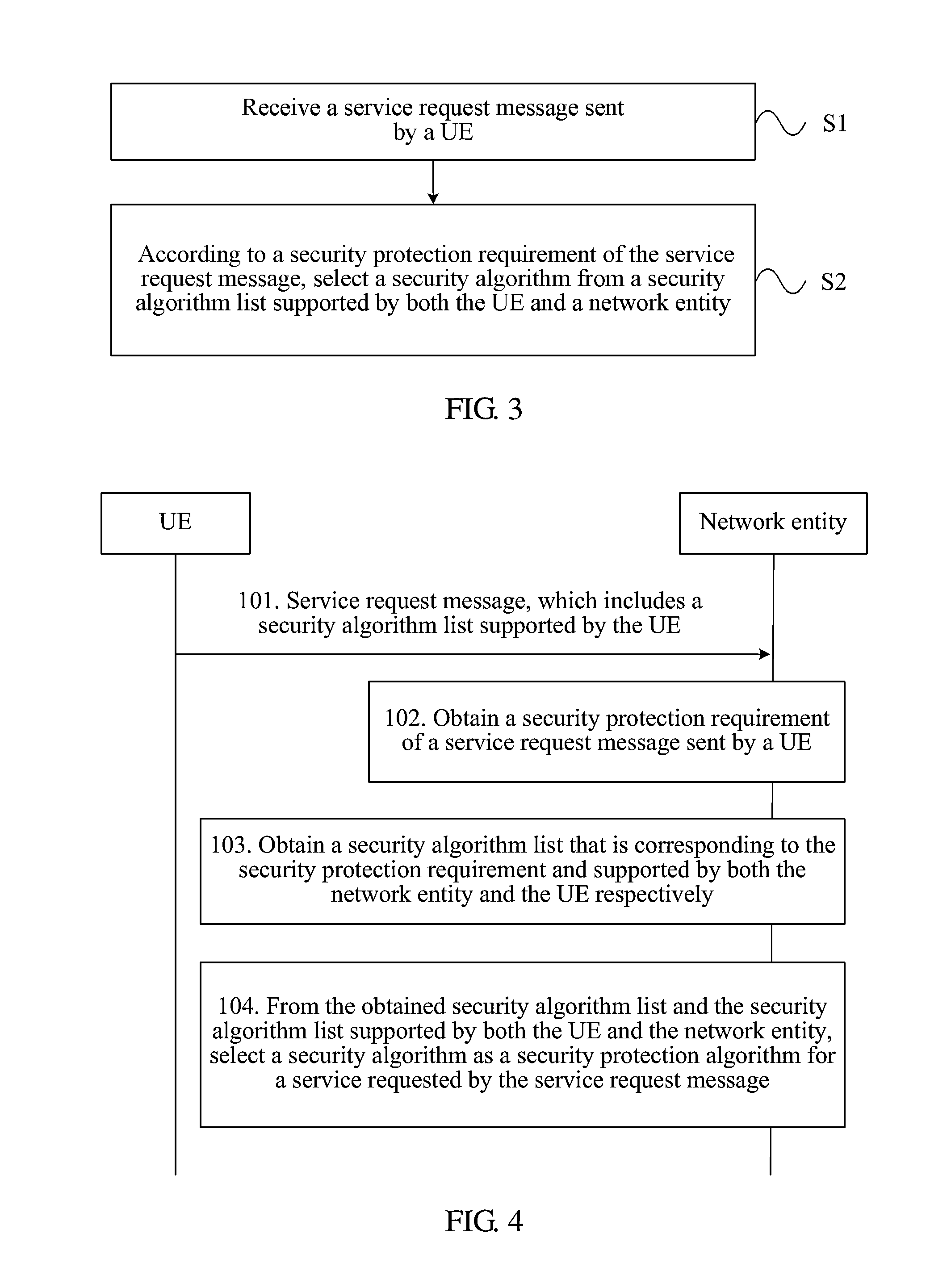

Method and apparatus for security algorithm selection processing, network entity, and communication system

ActiveUS20120066737A1Improve service safetyImprove communication system performanceComputer security arrangementsTransmissionCommunications systemUser equipment

Embodiments of the present invention disclose a method and an apparatus for security algorithm selection processing, a network entity, and a communication system. The method includes: receiving a service request message sent by user equipment; and according to a security protection requirement of the service request message, selecting a security algorithm from a security algorithm list supported by both the user equipment and a network entity, where security algorithm lists supported by the user equipment and / or the network entity are set separately based on different security protection requirements, or security algorithm lists supported by the user equipment and the network entity are used for indicating security capability of the user equipment and the network entity respectively.

Owner:HUAWEI TECH CO LTD

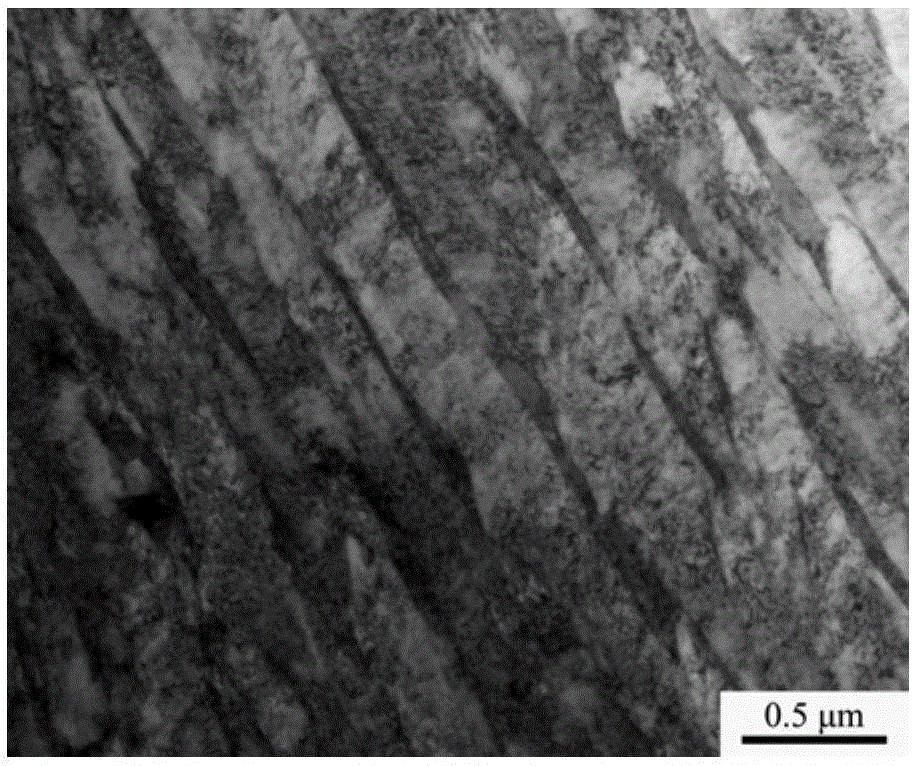

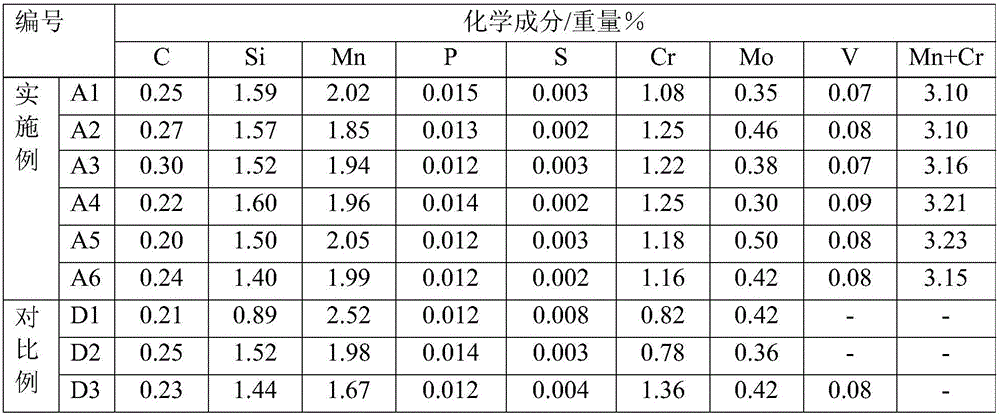

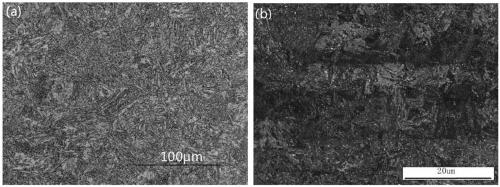

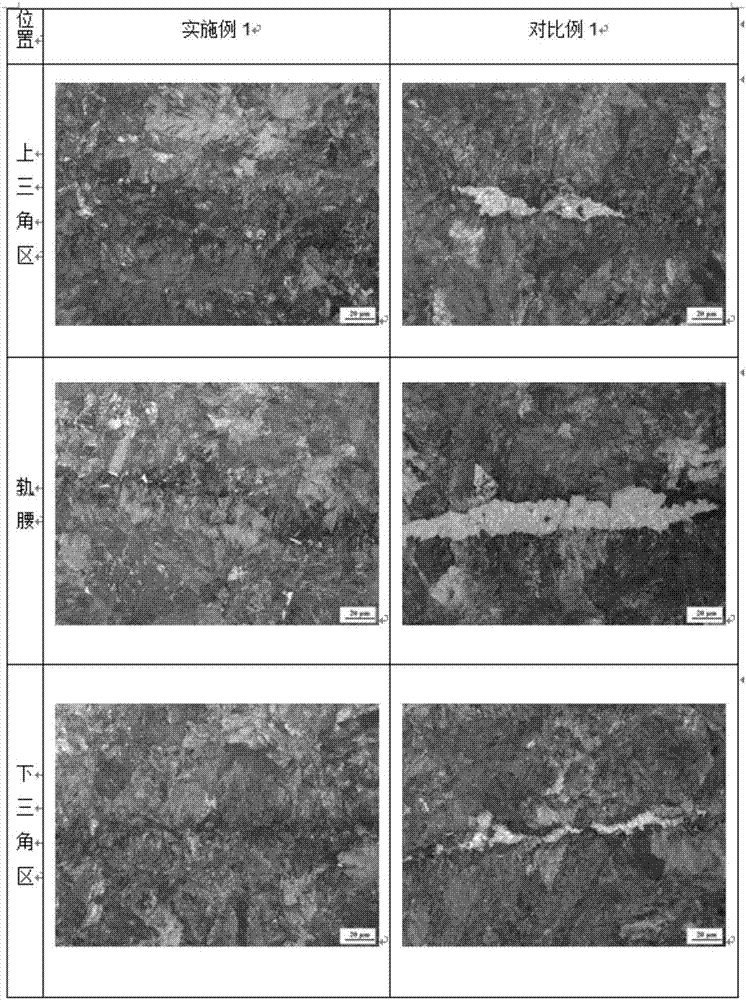

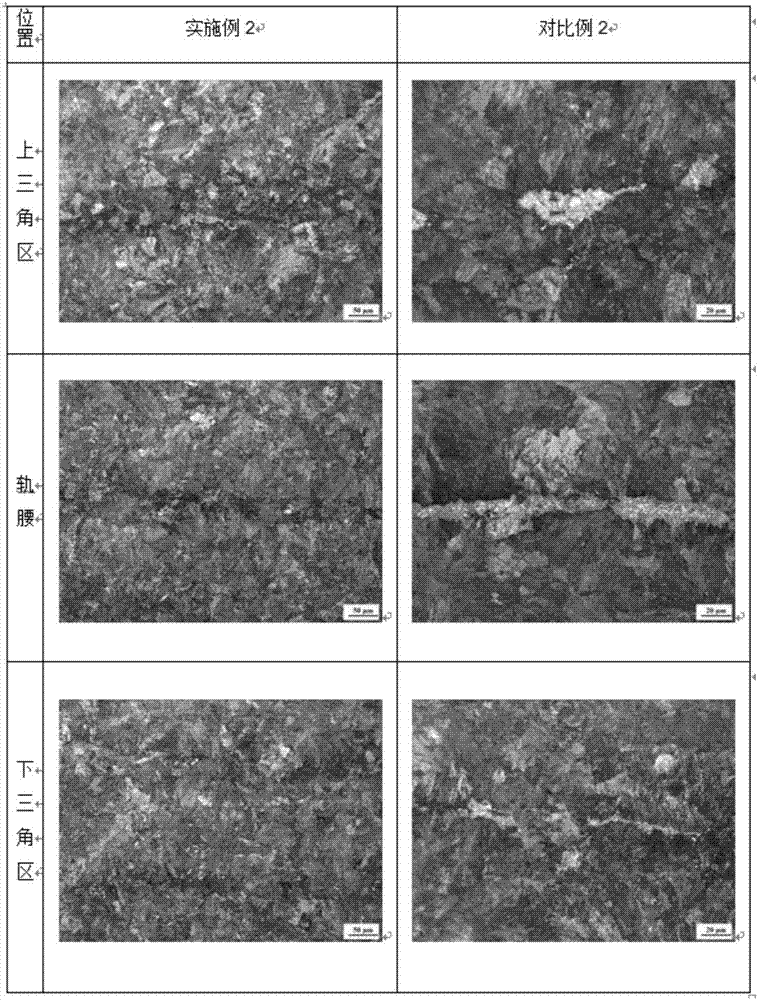

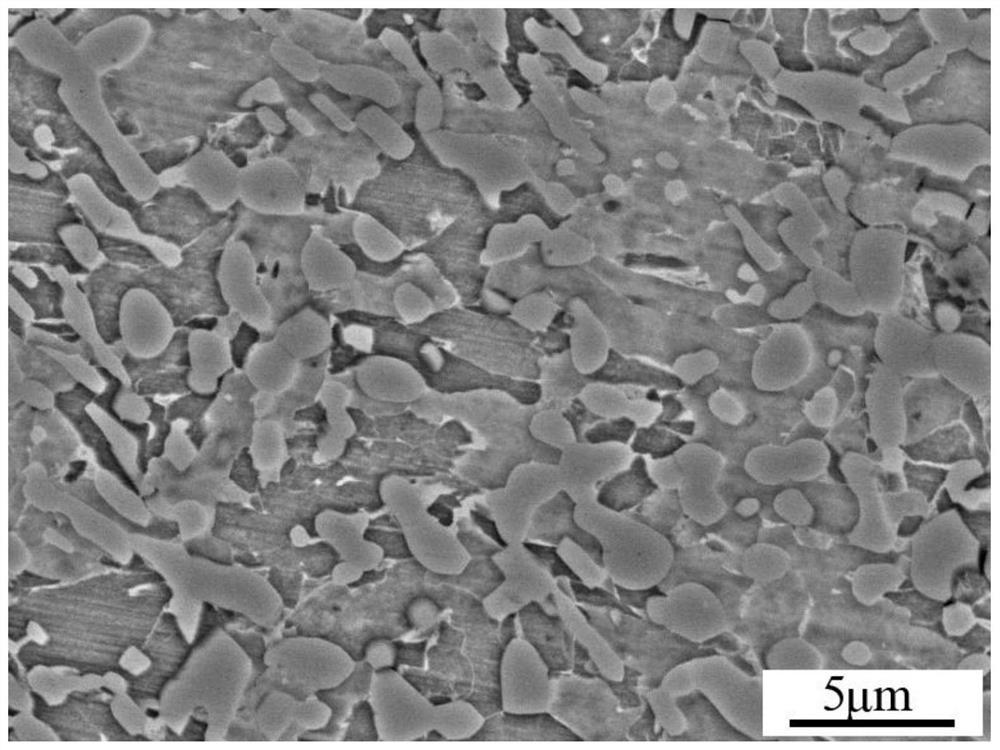

Bainite steel rail and preparation method thereof

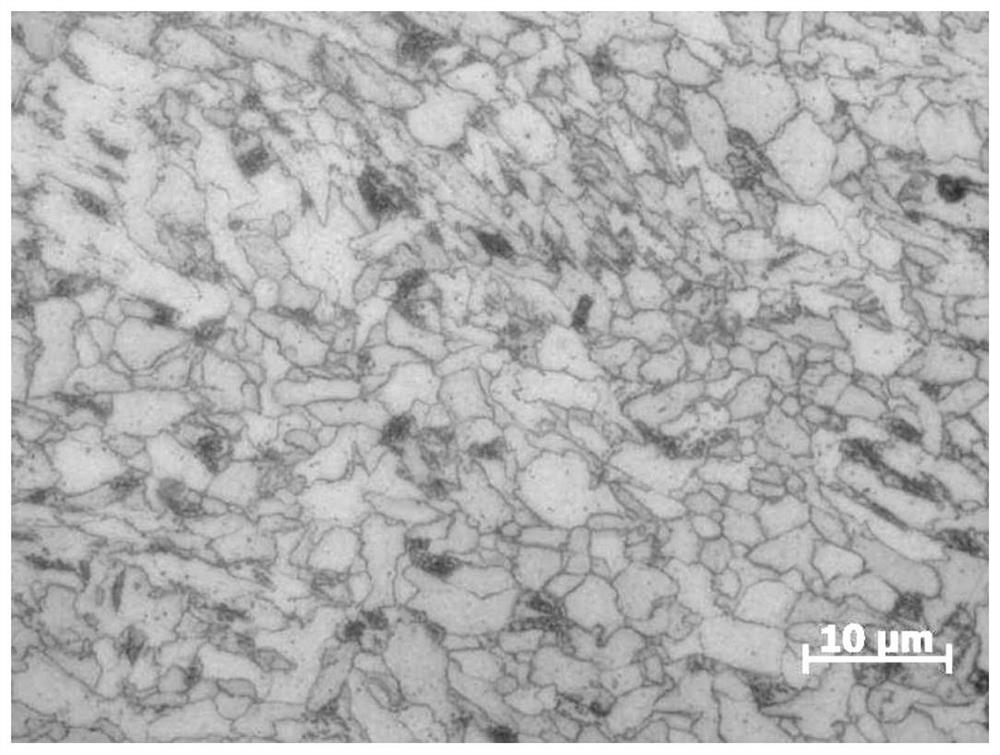

ActiveCN106435367AExcellent toughnessExcellent service safetyFurnace typesHeat treatment furnacesMetallurgyBainite

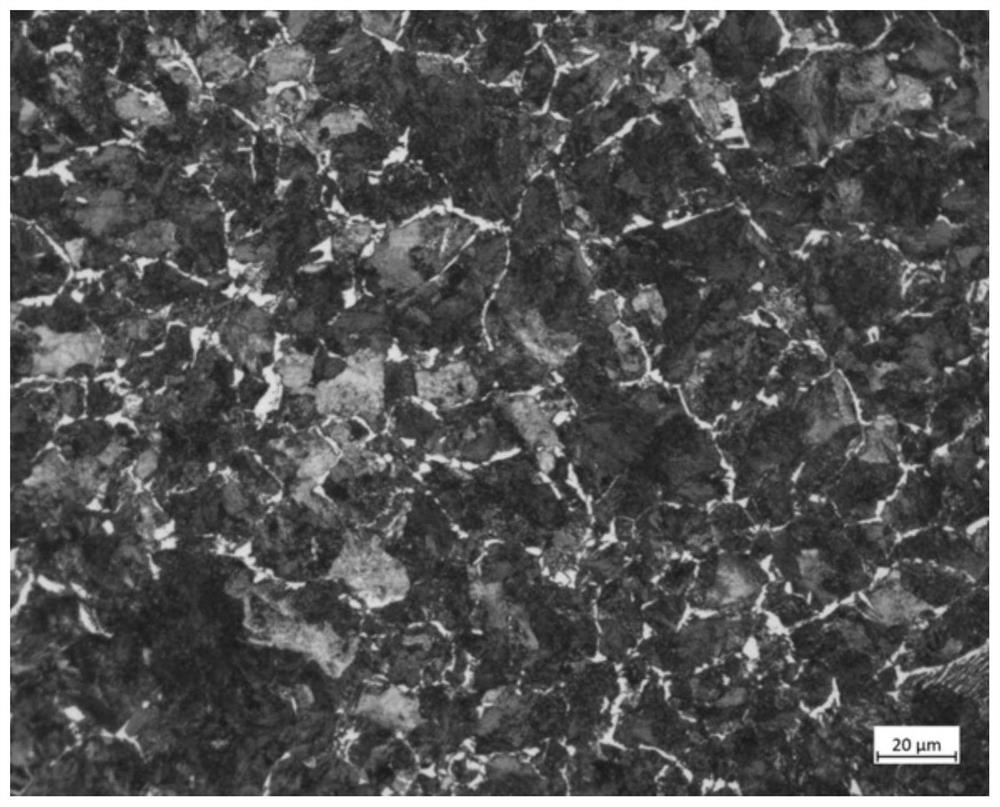

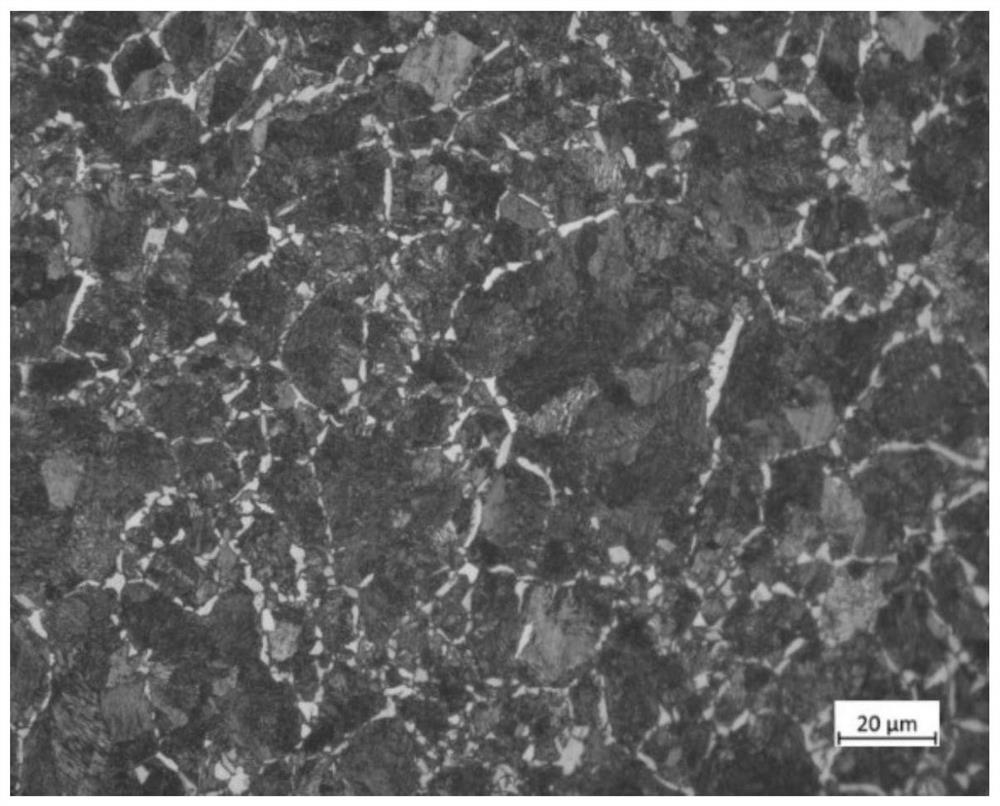

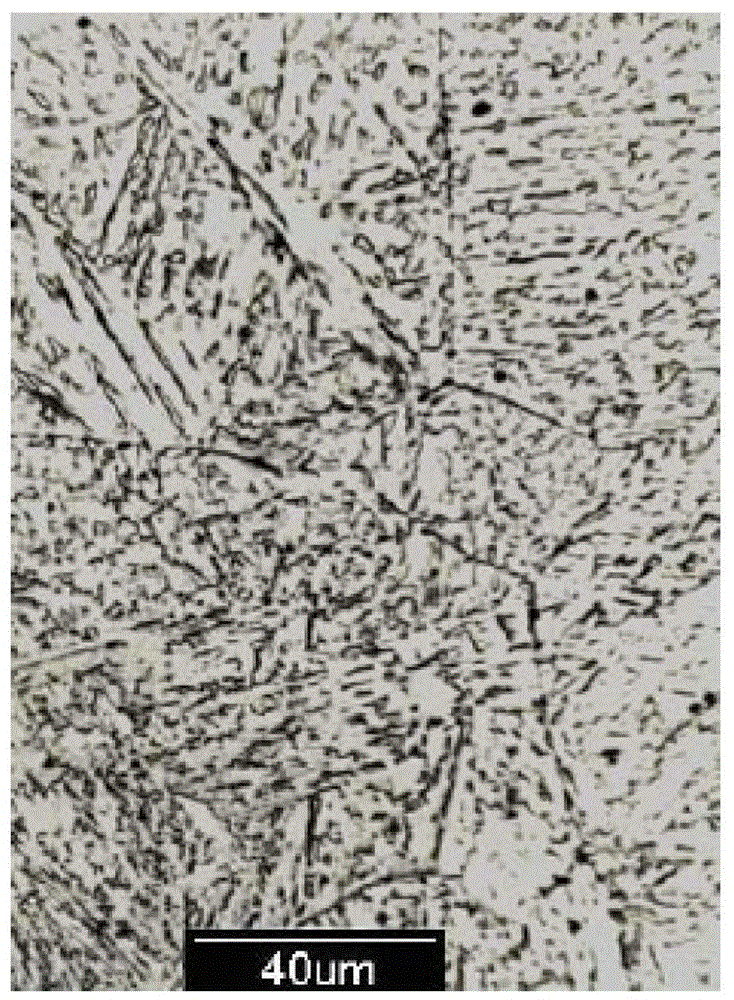

The invention relates to the field of steel rail materials and discloses a bainite steel rail and a preparation method thereof. On the basis of the weight of the bainite steel rail, the content of a bainite ferrite strip in a microscopic structure of a fillet part on a rail head of the bainite steel rail is more than or equal to 90wt% and the width of the bainite ferrite strip is 0.3-0.8 mu m; the content of a film-shaped retained austenite is less than or equal to 5wt% and the width of the film-shaped retained austenite is less than 0.1 mu m; the content of martensite is less than or equal to 5wt%; the chemical components of the billet steel of the acquired bainite steel rail meet the following conditions: on the basis of the weight of the bainite steel rail, the billet steel contains 0.20-0.30wt% of C, 1.40-1.60wt% of Si, 1.85-2.05wt% of Mn, 1.00-1.25wt% of Cr, 0.30-0.50wt% of Mo and 0.07-0.09wt% of V, wherein Mn+Cr is more than or equal to 3.1wt% but less than or equal to 3.3wt%. The bainite steel rail has excellent toughness performance and service safety.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

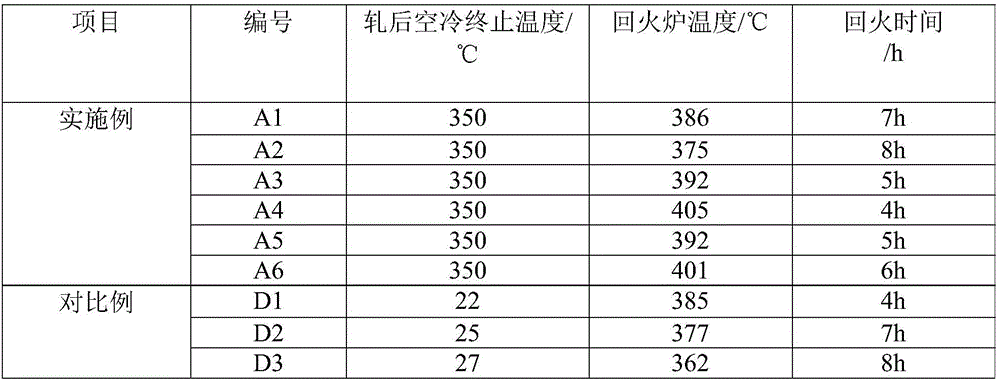

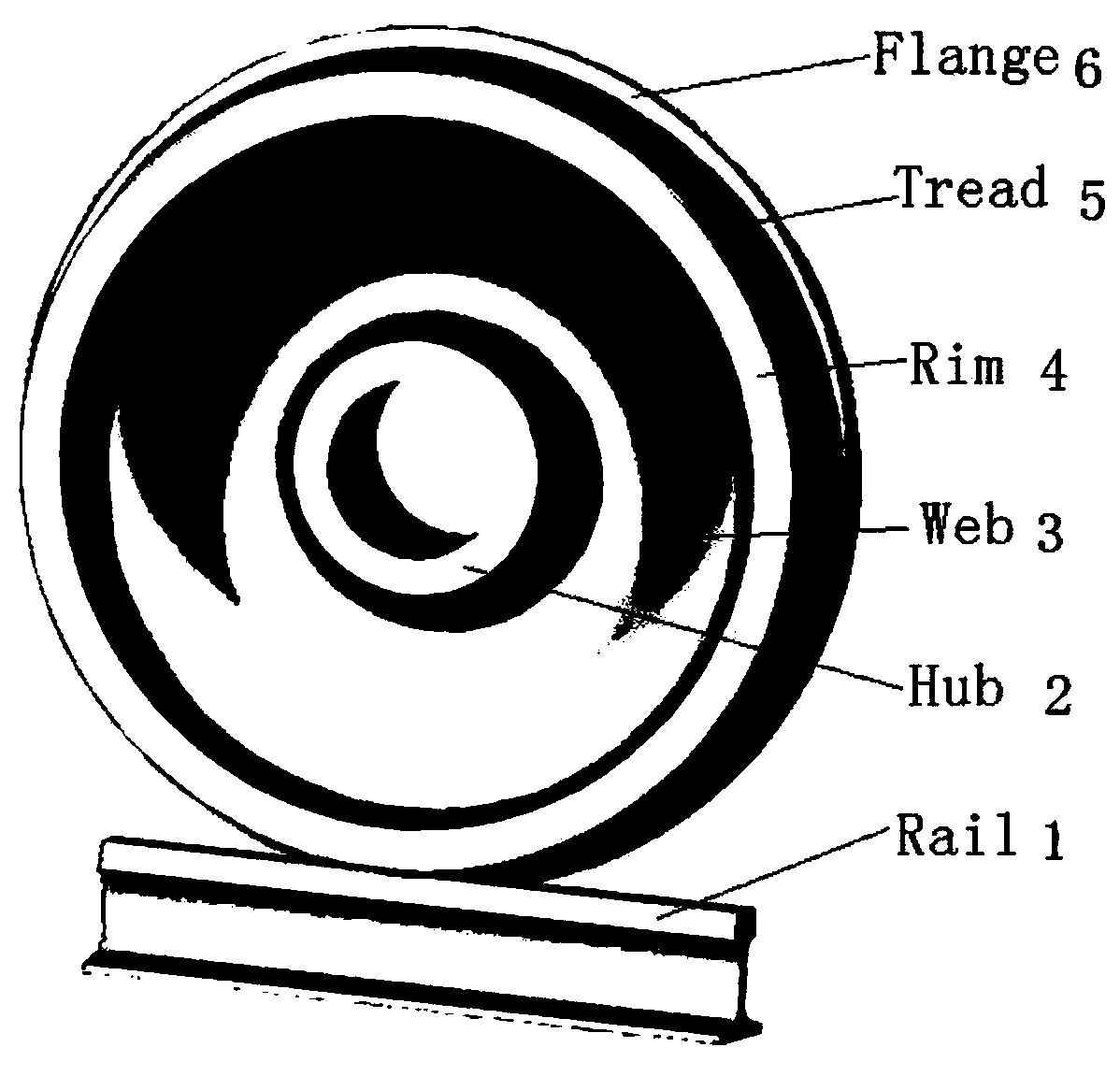

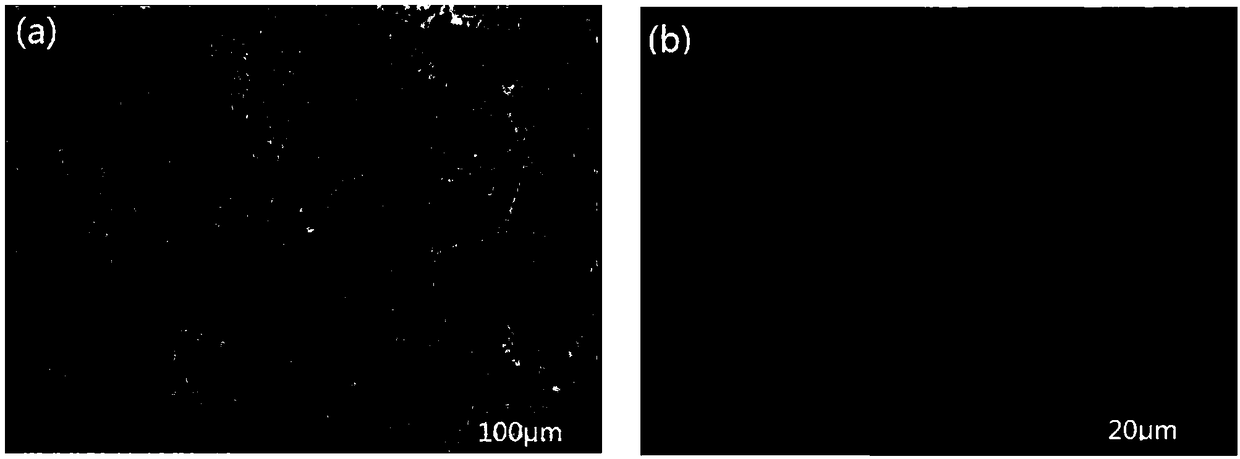

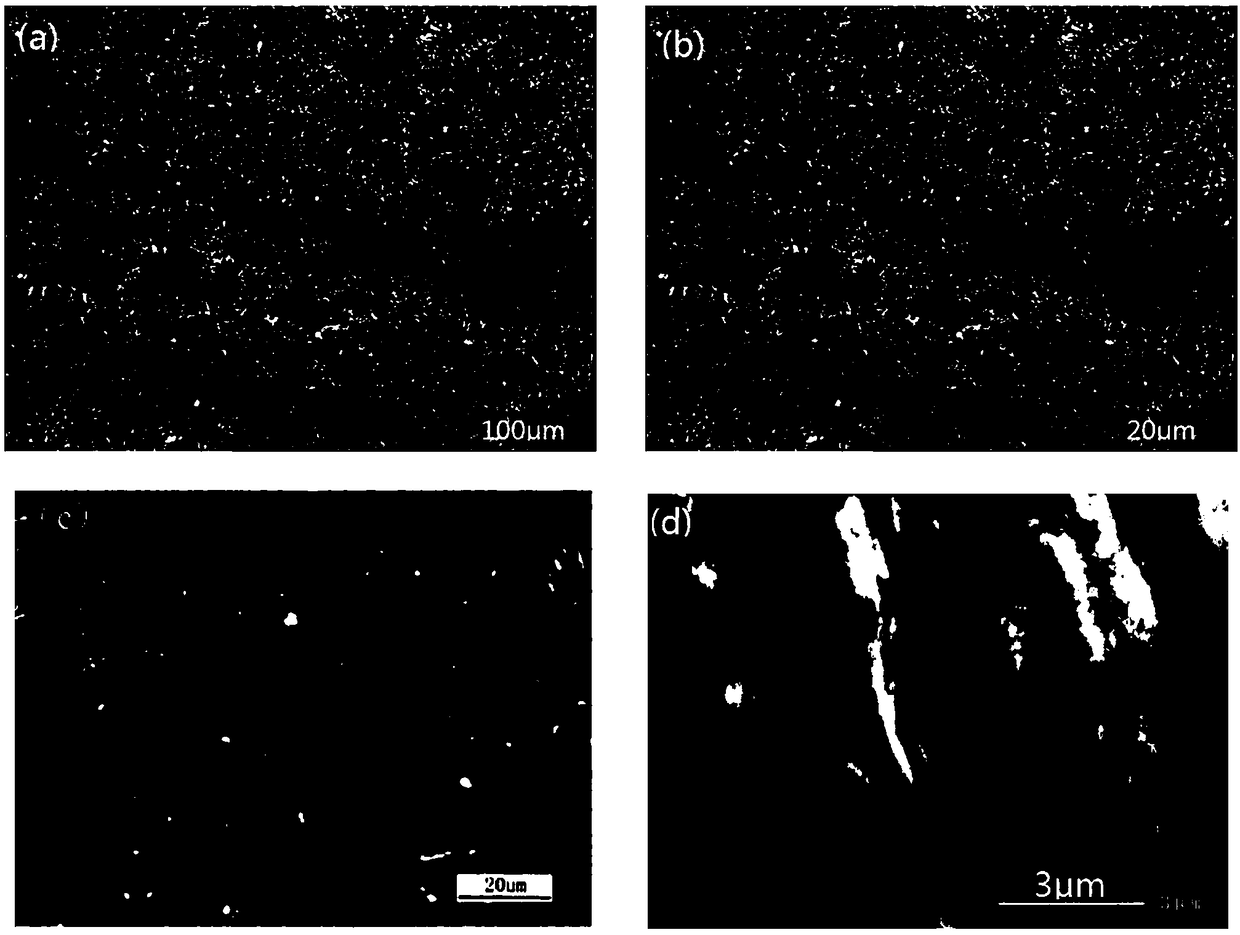

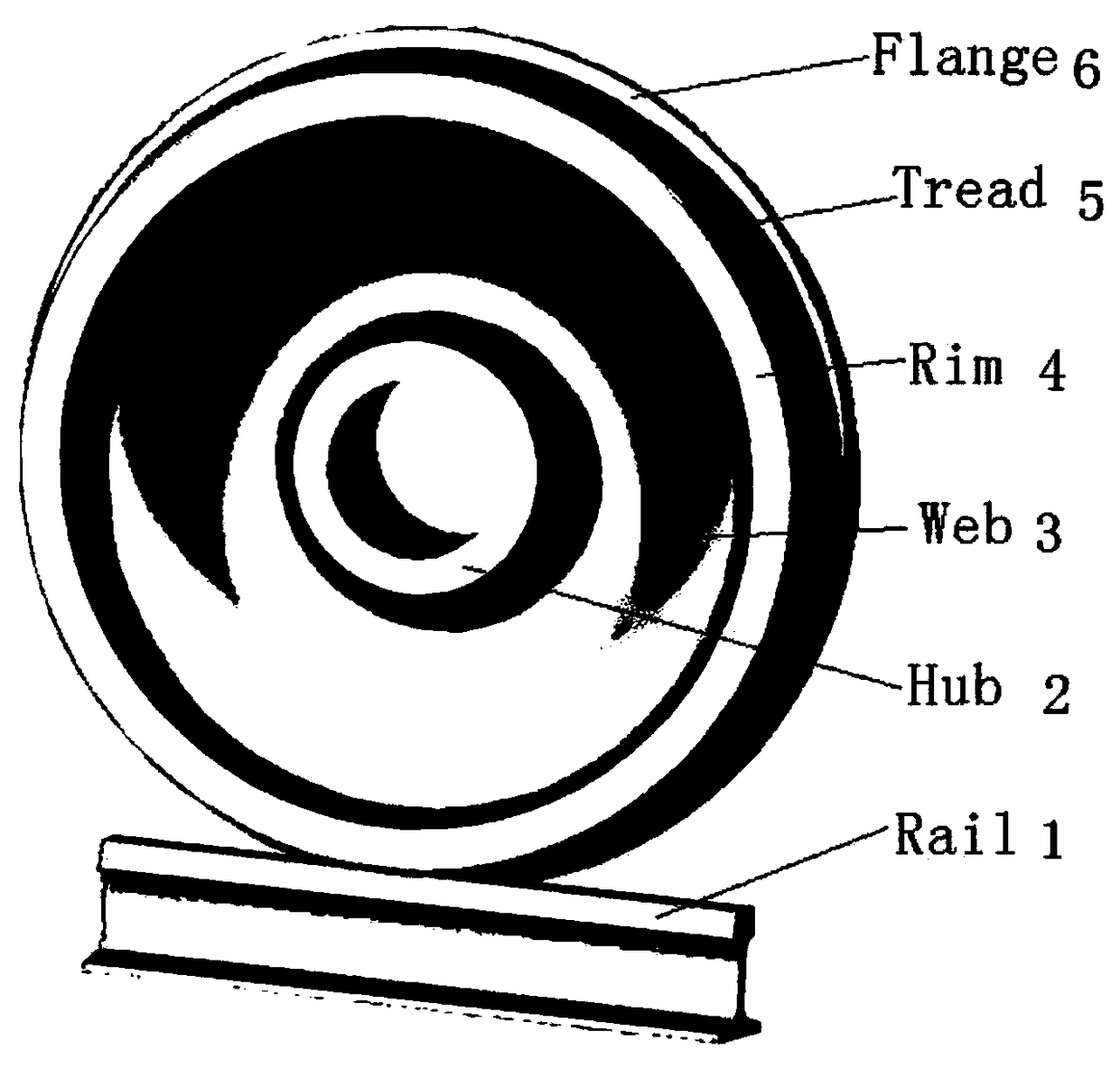

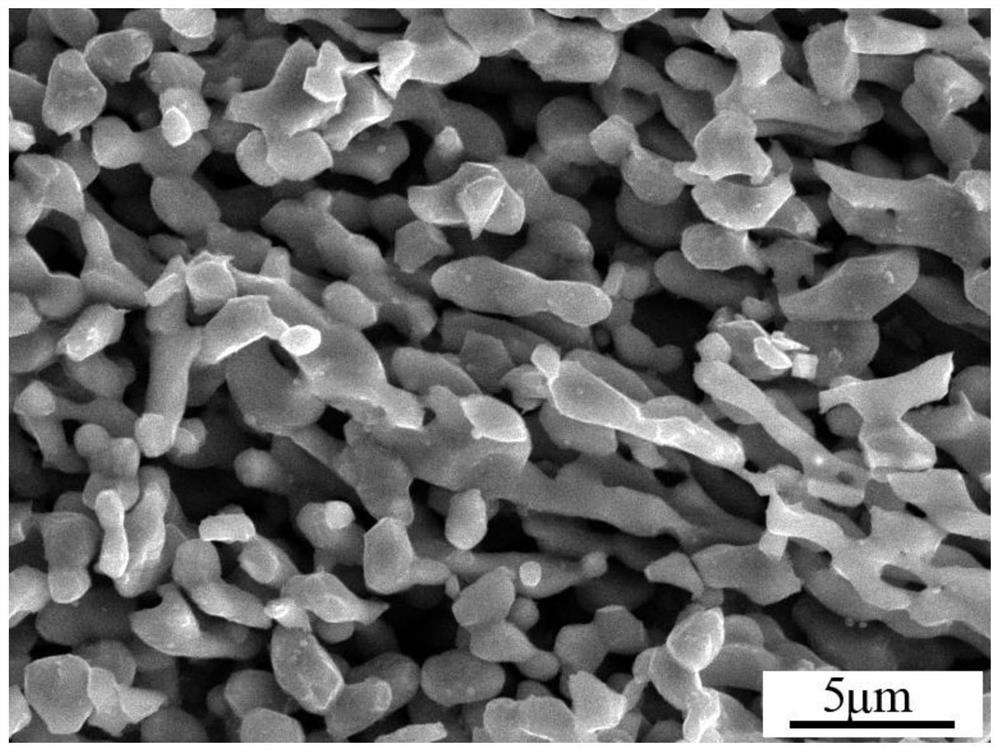

Common rail traffic bainite steel wheel used under cold and rigor service environment and manufacturing method of common rail traffic bainite steel wheel

InactiveCN108707831AHigh yield strengthHigh tensile strengthRail-engaging wheelsFurnace typesChemical compositionCommon rail

The invention discloses a common rail traffic bainite steel wheel used under the cold and rigor service environment and a manufacturing method of the common rail traffic bainite steel wheel. The common rail traffic bainite steel wheel comprises chemical components including 0.05%-0.30% of C, 0.50%-1.50% of Ni, 0.01%-1.20% of Cr, 0.70%-2.10% of Mn, 0.20%-1.00% of Si, 0.01%-1.00% of W, 0.05%-0.60% of Mo, 0.01%-0.80% of Cu, 0.01%-0.20% of V, 0.001%-0.20% of Nb, 0.0001%-0.0350% of B, 0.001%-0.040% of RE, not larger than 0.020% of P, not larger than 0.020% of S and the balance Fe and inevitable residual elements, wherein the sum of Mn and Cr is larger than or equal to 2.0% and smaller than or equal to 3.0%. By adopting a new alloy design system and alloying principle of C-Ni-Mn-Cr-Mo, after thewheel is molded, a rim obtained after advanced heat treatment obtains a carbide-free bainite organization structure, and the wheel has the excellent comprehensive mechanical property, decay resistance and service performance, in particular has the high low-temperature toughness and low-temperature breaking toughness, meets performance and service safety requirement under the low-temperature environment and is suitable for the cold zone under rigor conditions.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Bainitic steel wheel for rail traffic with capability of resisting against damp, hot and corrosive environments and manufacturing method thereof

InactiveCN109182920AHigh yield strengthHigh tensile strengthRail-engaging wheelsFurnace typesCarbideAlloy

The invention discloses a bainitic steel wheel for rail traffic with capability of resisting against damp, hot and corrosive environments and a manufacturing method thereof. The bainitic steel wheel comprises the following chemical components: 0.05-0.40% of C, 0.40-1.50% of Ni, 0.25-1.50% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% ofV, 0.001-0.20% of Nb, 0.0001-0.0350% of B, 0.001-0.040% of RE, less than or equal to 0.020% of P, less than or equal to 0.020% of S and the balance of Fe and inevitable residual elements, wherein Mn+Cr is more than or equal to 2.0% but less than or equal to 3.0%. The new alloy design system of C-Ni-Mn-Cr-Mo-Cu and alloying principle are adopted by the invention; after a wheel is formed, a rim after advanced thermal treatment is endowed with a carbide-free bainite structure; the wheel has excellent comprehensive mechanical property and service performance, especially, atmospheric corrosion resistance; the wheel is capable of resisting against damp, hot and corrosive environments and reducing the harmful influences of stress corrosion and medium corrosion; the service life and running safetyof the wheel can be further promoted.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

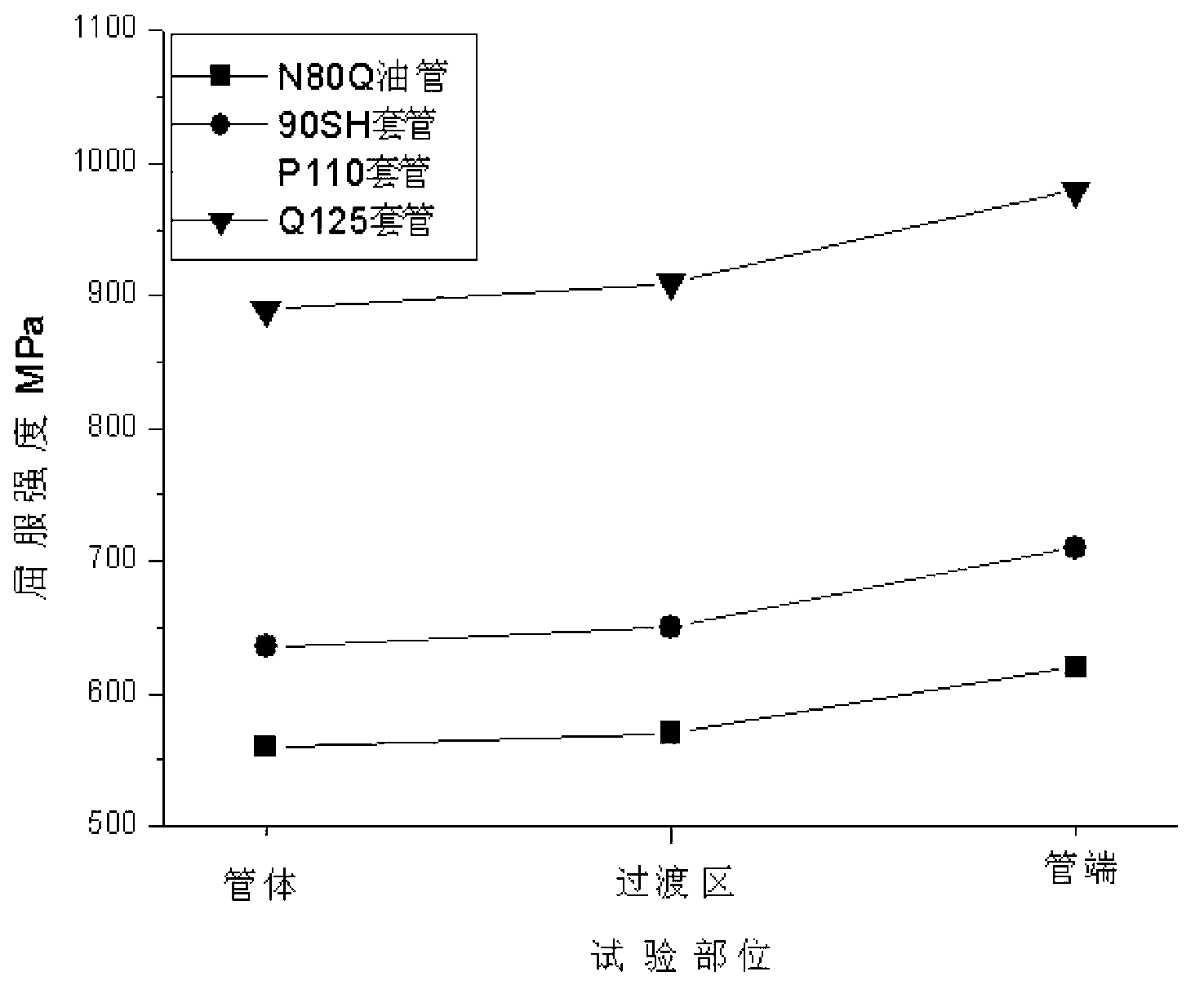

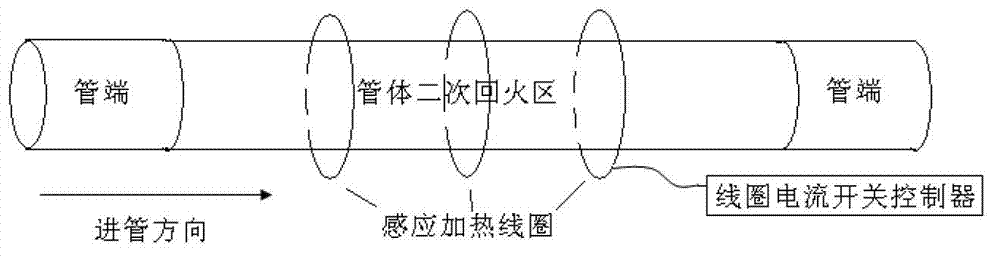

Strength mismatching heat treatment process for petroleum steel tube in hardened and tempered state

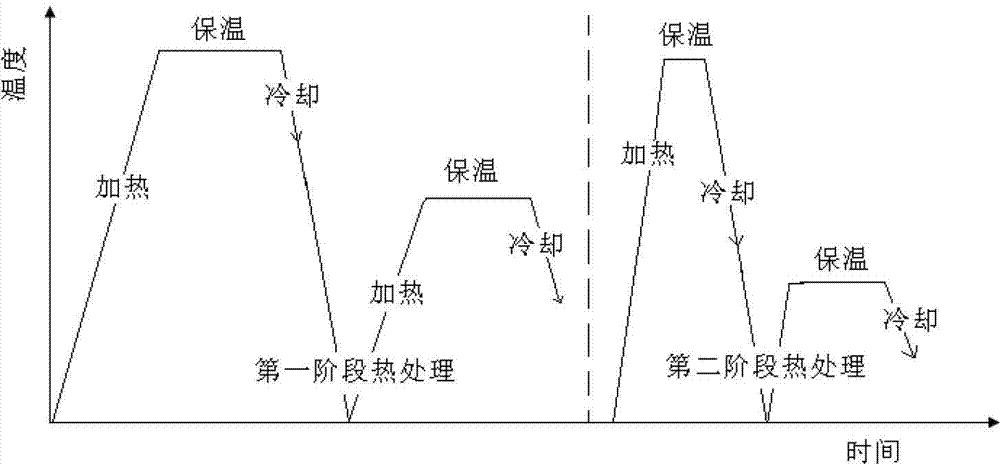

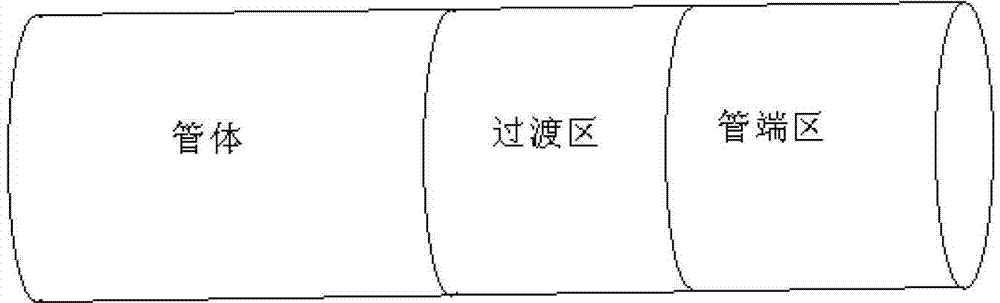

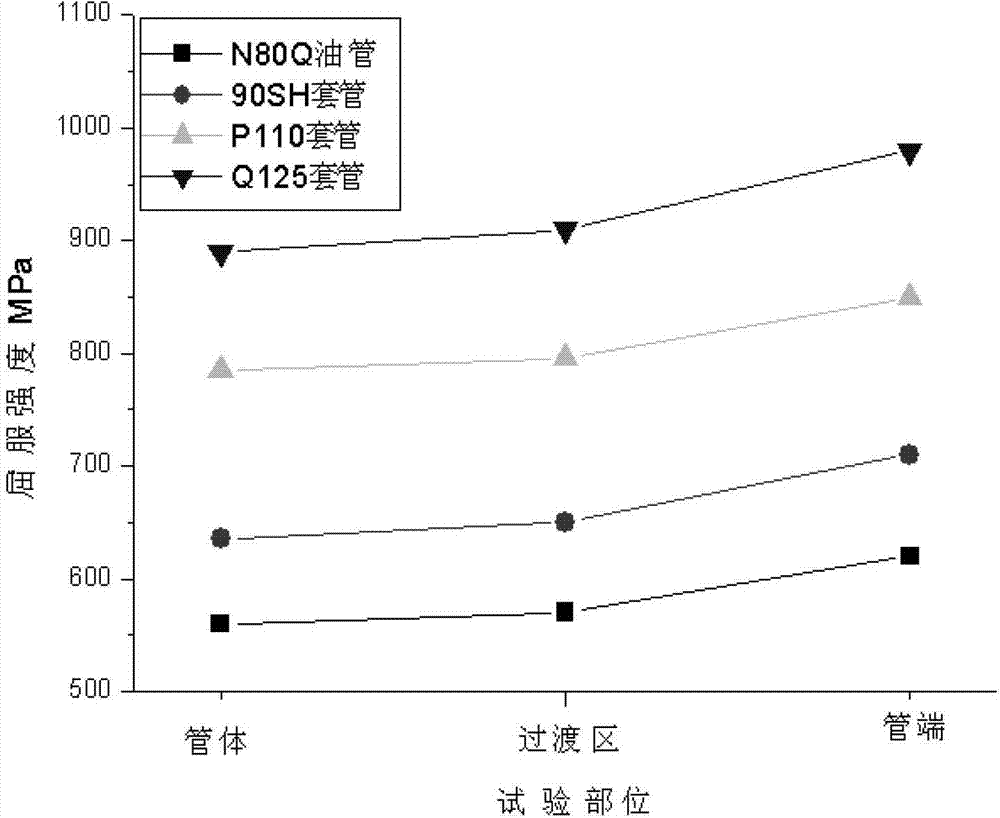

ActiveCN103266216AImprove service safetyHigh strengthFurnace typesHeat treatment furnacesStress concentrationUltimate tensile strength

The invention discloses a strength mismatching heat treatment process for a petroleum steel tube in a hardened and tempered state, belonging to the technical field of metal engineering materials. The process comprises first-stage whole tube hardening and tempering and second-stage tube end hardening and tempering. According to the process, the strength mismatching of the tube body and the tube ends of the petroleum steel tube in a hardened and tempered state can be realized, the strength and toughness of the tube ends are higher than those of the tube body, and the strength and toughness of transition zones between the tube ends and the tube body are higher than those of the tube body but lower than those of the tube ends, thus ensuring that the steel tube has the performance distribution of strength mismatching accompanied with the distribution of toughness mismatching. The distribution of strength mismatching eliminates the weak point that the tube ends of the existing product are prone to deform or even break due to stress concentration caused by thread structures, and improves the service safety of the steel tube.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Method for preparing oxide dispersion strengthened steel by adopting ultralow-temperature mechanical alloying technology

The invention relates to a method for preparing oxide dispersion strengthened steel by adopting an ultralow-temperature mechanical alloying technology. The method belongs to the technical field of special steel production, and is mainly characterized by mechanically alloying at the ultralow temperature of below -50 DEG C; through reducing ordering rearrangement speed of atoms during a mechanical alloying process, the impurity adsorption and the defect generation are reduced, and an entropy value of the oxide dispersion strengthened steel is improved, so that the impact ductility of the oxide dispersion strengthened steel is improved, the ductile-brittle transition temperature is remarkably reduced, and the use safety under the service conditions is improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method and apparatus for security algorithm selection processing, network entity, and communication system

ActiveUS8898729B2Improve service safetyImprove communication system performanceUser identity/authority verificationMultiple digital computer combinationsCommunications systemUser equipment

Embodiments of the present invention disclose a method and an apparatus for security algorithm selection processing, a network entity, and a communication system. The method includes: receiving a service request message sent by user equipment; and according to a security protection requirement of the service request message, selecting a security algorithm from a security algorithm list supported by both the user equipment and a network entity, where security algorithm lists supported by the user equipment and / or the network entity are set separately based on different security protection requirements, or security algorithm lists supported by the user equipment and the network entity are used for indicating security capability of the user equipment and the network entity respectively.

Owner:HUAWEI TECH CO LTD

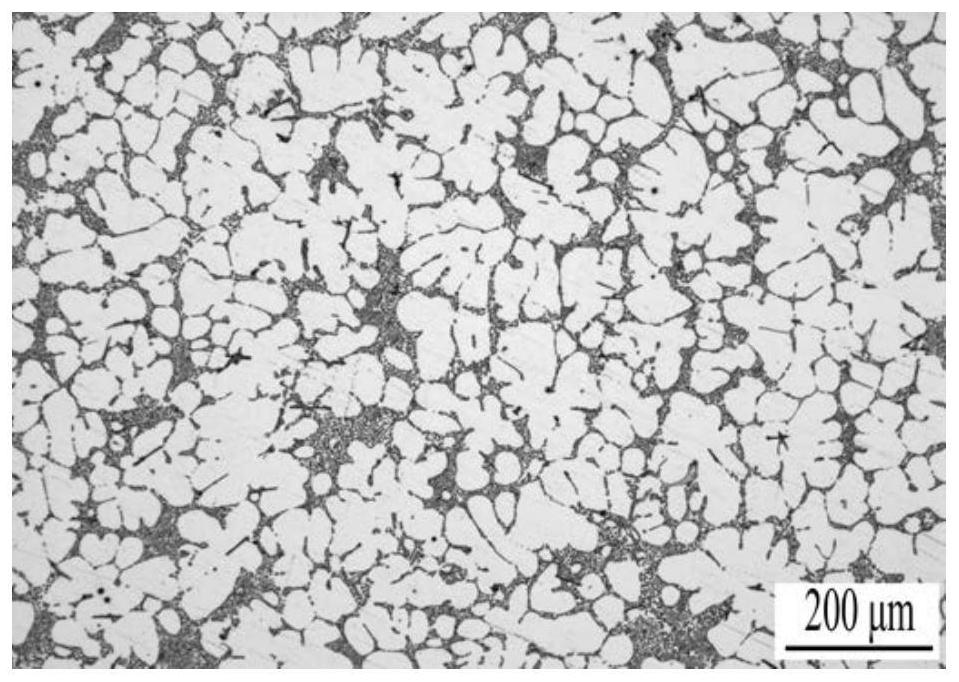

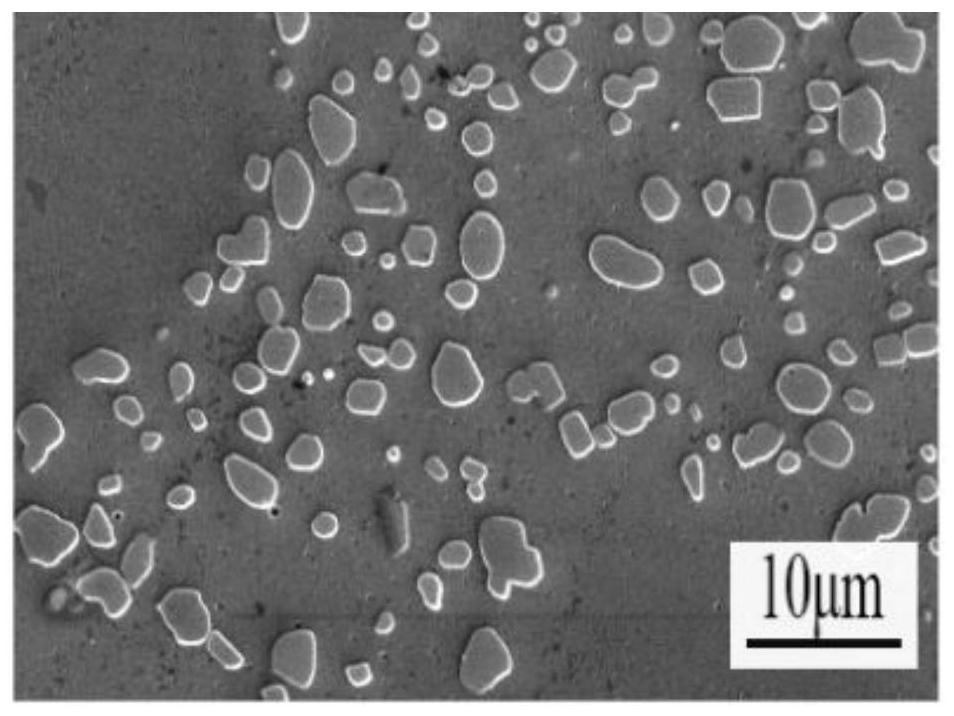

Aluminum alloy material for high-performance thin-wall 3D printing sand casting and preparation method thereof

InactiveCN111926220AImprove casting fluiditySolve the problem of difficult fillingSand castingUltimate tensile strength

The invention discloses an aluminum alloy material for high-performance thin-wall 3D printing sand casting and a preparation method thereof, and relates to the technical field of aluminum alloy production. The material comprises the following components of, in percentage by mass, 6.5%-8% of Si, 0.25%-0.45% of Mg, 0.05%-0.16% of Ti, 0.01%0-0.04% of Sr, 0.1%-0.2% of Fe, 0.16%-0.6% of Zr, 0%-0.4% ofSc, less than or equal to 0.10% of other inevitable impurity elements, and the balance Al. In addition, the invention further discloses the preparation method of the high-performance aluminum alloy. According to the alloy, the contents of Si, Mg, Sr, Ti, Zr and Sc are controlled, so that the alloy has good fluidity, a cast 3D printing sand mold casting is fine and uniform in structure, the strength and toughness of the alloy are remarkably improved, and the requirement of thin-wall 3D printing sand mold casting market development can be well met.

Owner:SOUTH CHINA UNIV OF TECH

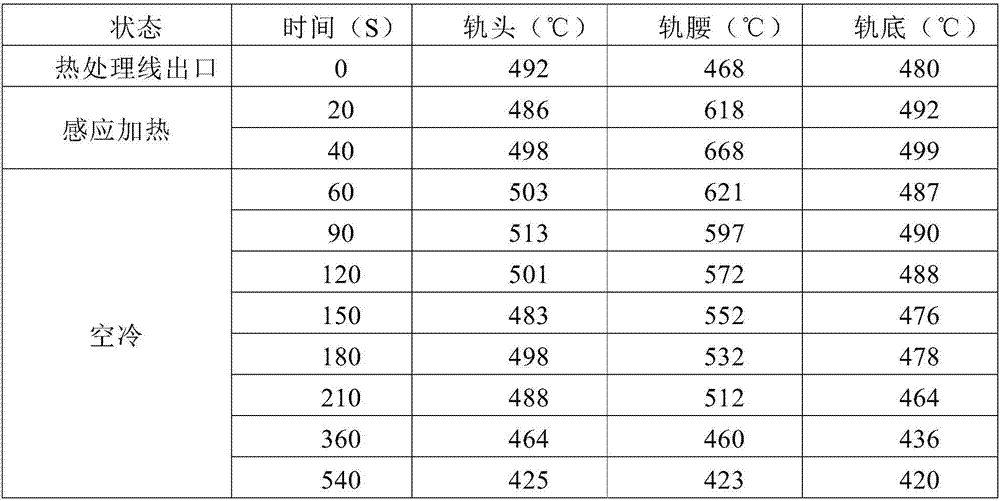

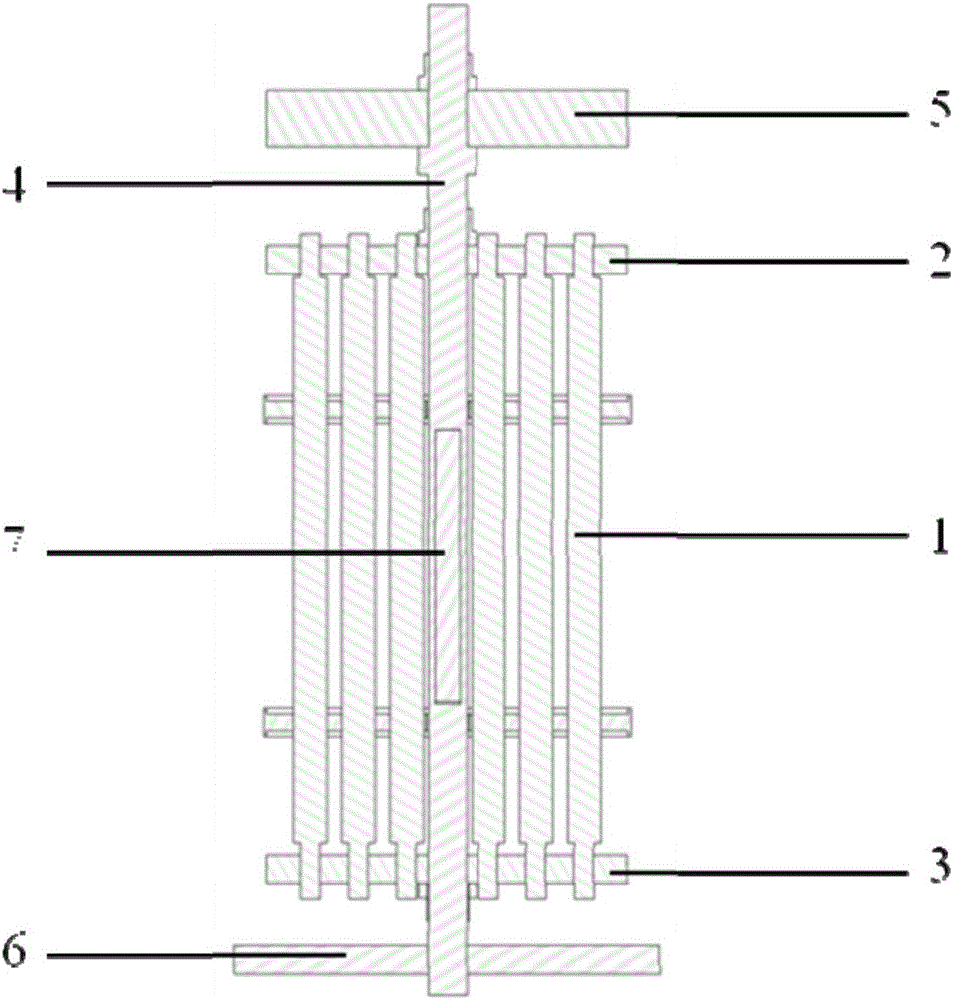

Steel rail online induction heating control method

InactiveCN107988464AElimination of abnormal tissueReduce stressFurnace typesIncreasing energy efficiencyTemperature differenceMartensite

The invention discloses a steel rail online induction heating control method. The steel rail online induction heating control method comprises the steps that induction heating is implemented to the steel rail web portion discharged out of the heat treatment line, and the heating temperature of the steel rail web portion ranges from 600 to 680 DEG C. According to the steel rail online induction heating control method, steel rail production is carried out, through the rail web compensation heating, the overcooling degree of the steel rail after online heat treatment is restrained, the staying time of the steel rail on the pearlite transition area can be prolonged, and generation of an abnormal martensite structure is avoided; through the rail web heating control, the temperature difference between the rail head and the rail bottom can be coordinated, the steel rail inner stress can be reduced, the steel rail straightening cracking risk is reduced, and the inner stress after steel rail straightening can be reduced. The method is easy and feasible and suitable for industrial production.

Owner:BAOTOU IRON & STEEL GRP

Fuel assembly available for integral replacement

ActiveCN106531232ARealize integrated refuelingFix fixNuclear energy generationFuel element assembliesInherent safetyHigh density

The invention discloses a fuel assembly available for integral replacement. By fixation of the fuel assembly and a top cover, axial fixation of the fuel assembly is realized, a fuel assembly fixation problem caused by a high-density cooling agent of a liquid-state lead-based reactor is solved, and integral replacement of the fuel assembly is realized. Since fuel elements with fixed upper ends and free lower ends are reinforced under the action of axial flushing force and buoyancy of the cooling agent, stability of the fuel elements in operation of the reactor is improved; owing to a moderator filled in each fixed rod, fission neutron moderation can be accelerated to improve reactivity of a reactor core and reduce the size of the reactor core. The fuel assembly has advantages of high safety, simple structure, small reactor core size and the like.

Owner:中科瑞华原子能源技术有限公司

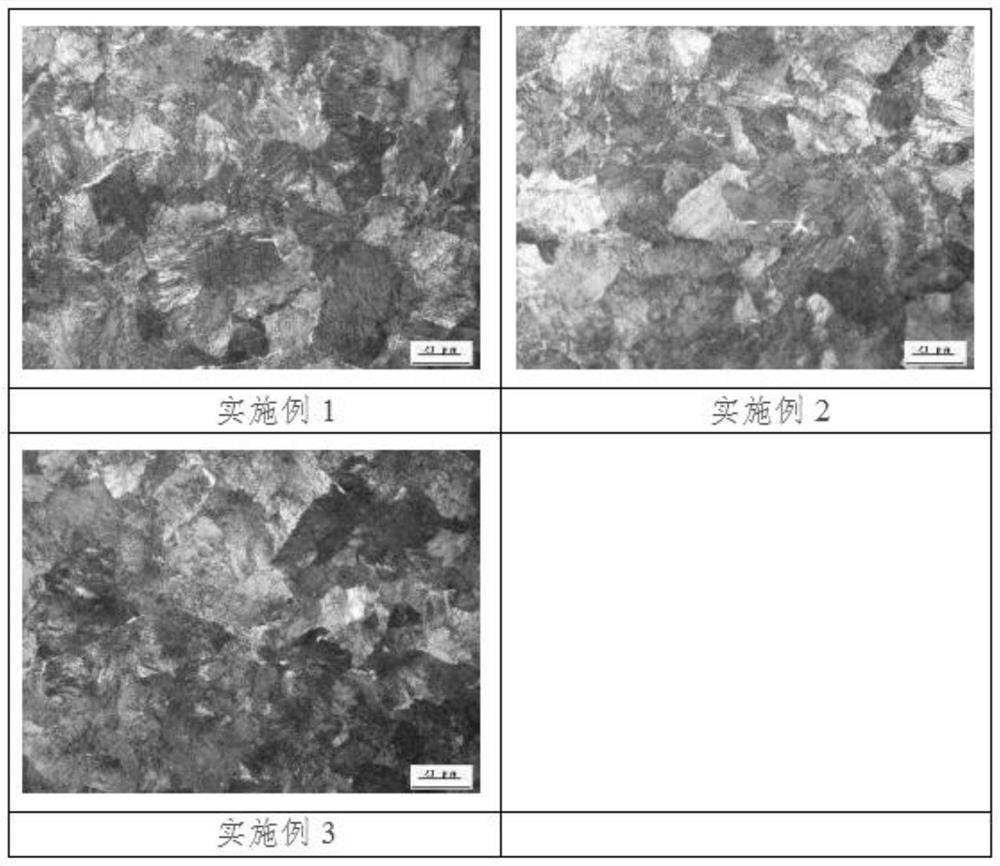

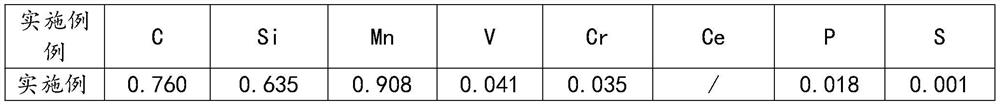

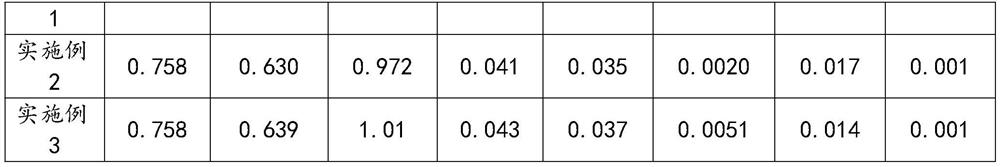

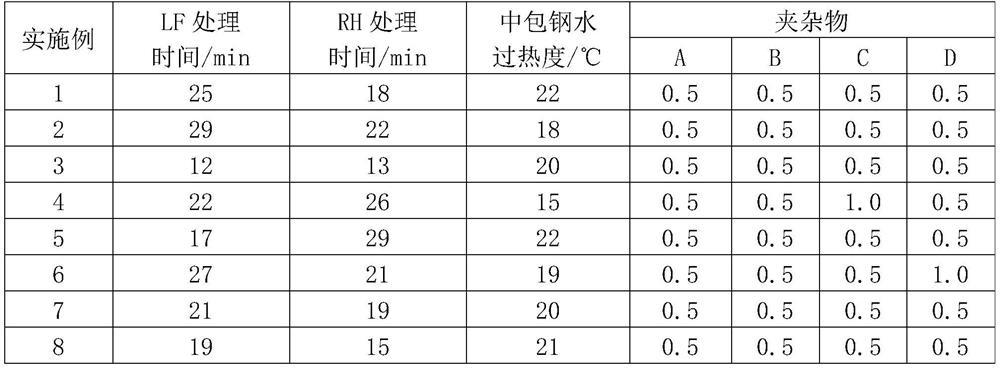

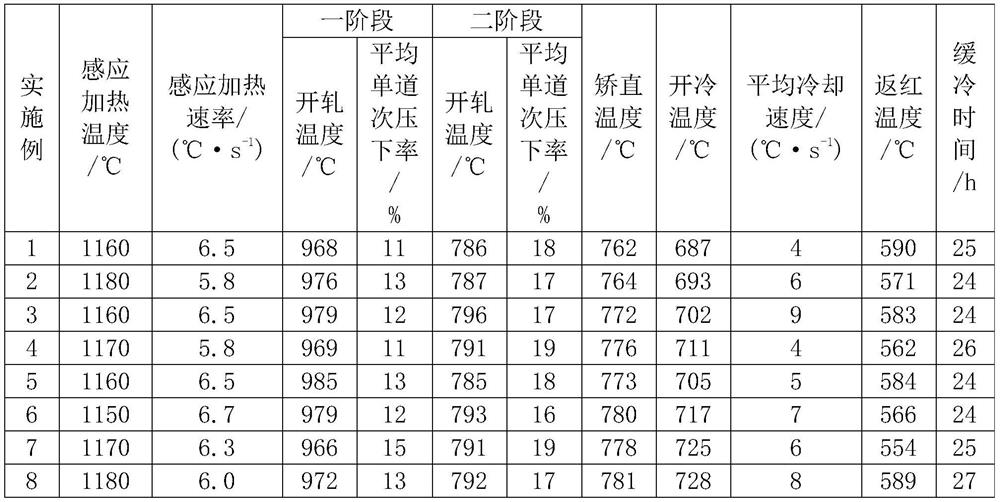

Manufacturing method for improving low-temperature toughness of hot-rolled U75V steel rail through rare earth elements

ActiveCN114855082AImprove low temperature toughnessHigh strengthProcess efficiency improvementMetal rolling arrangementsRare-earth elementUltimate tensile strength

The invention discloses a manufacturing method for improving the low-temperature toughness of a hot-rolled U75V steel rail by using rare earth elements, which is used for optimizing components and processes of the hot-rolled U75V steel rail and further improving the low-temperature toughness of the steel rail, so that the steel rail has excellent strength, hardness and welding performance at the same time. The rare earth Ce element is added for the hot-rolled U75V steel rail, so that the effects of refining grains, purifying steel and uniformly transforming structures can be achieved, and the low-temperature toughness of the steel rail is further improved while various mechanical properties of the steel rail are ensured. Therefore, low-temperature road steel rail service safety is improved, and line steel rail maintenance cost is reduced.

Owner:BAOTOU IRON & STEEL GRP

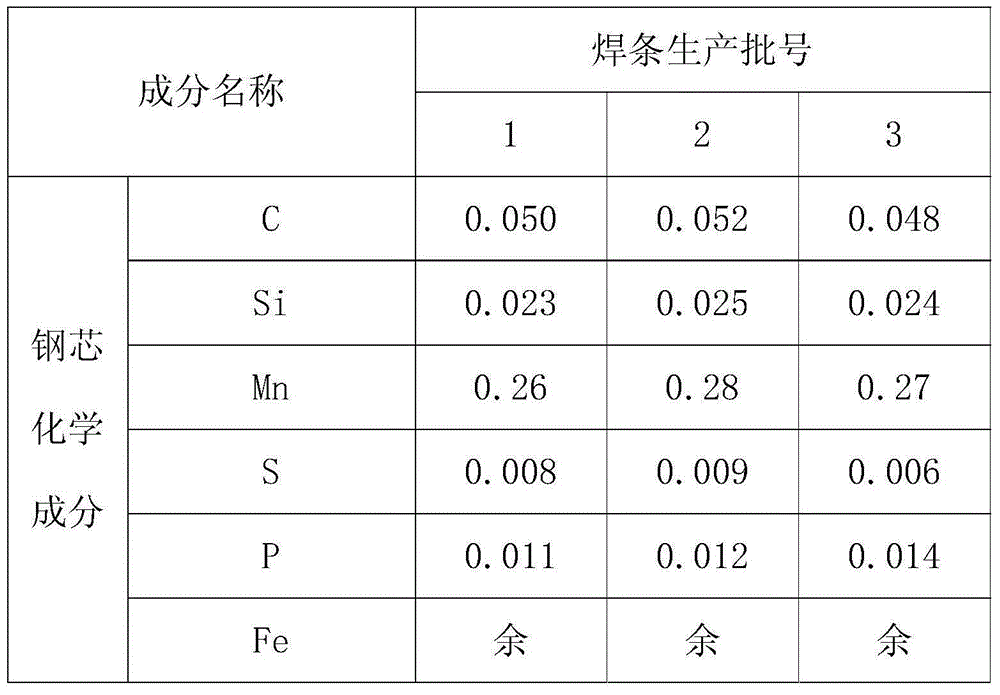

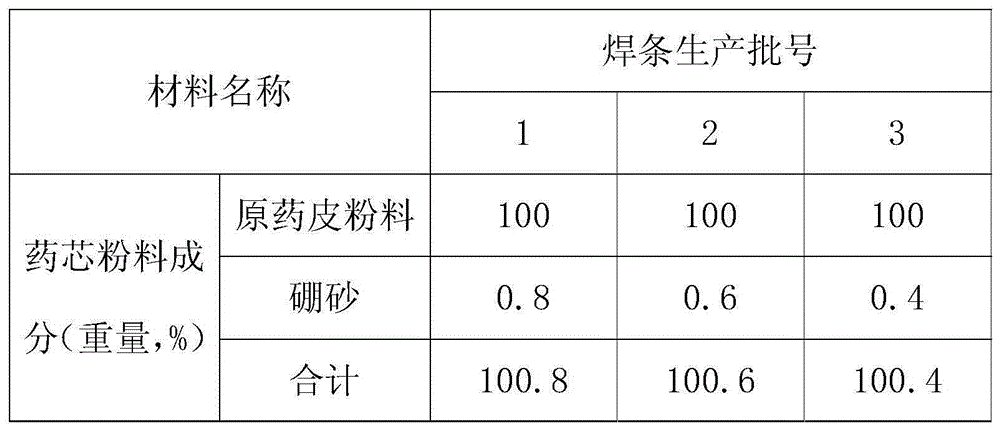

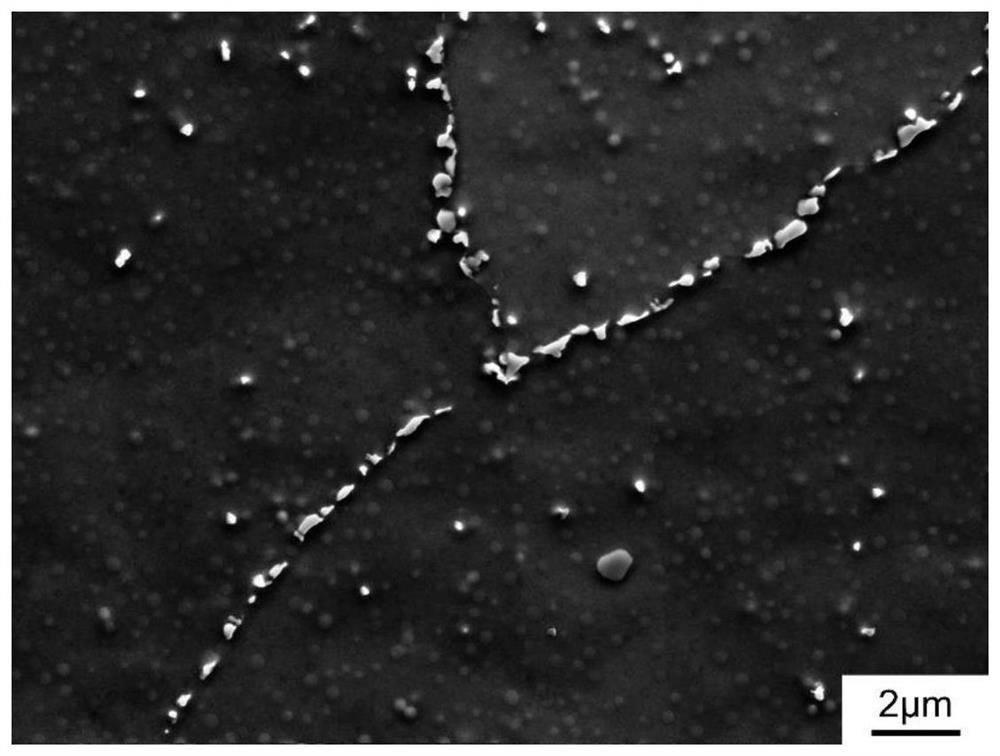

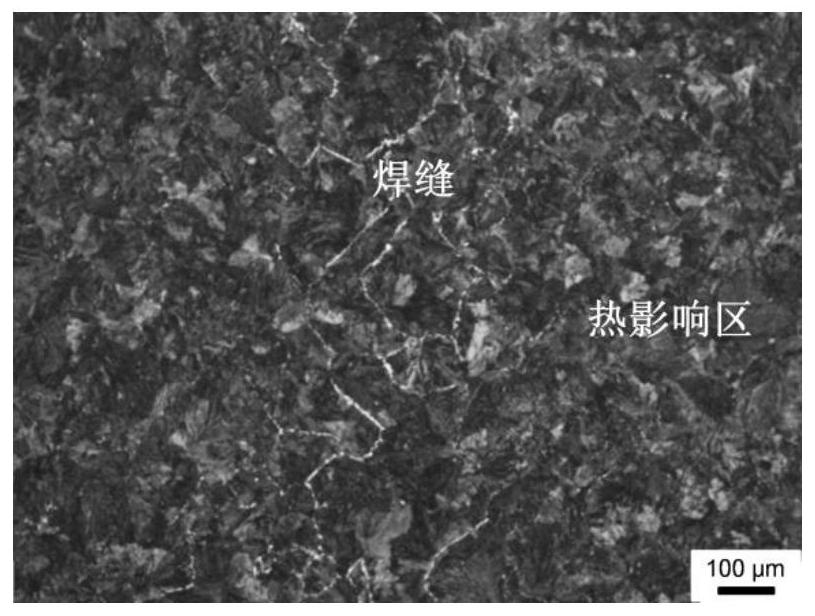

Method for doping trace boron element into weld metal and welding method

InactiveCN106513947AImprove toughnessImprove service safetyArc welding apparatusSolid state diffusion coatingBorideTrace element

The invention relates to a method for doping the trace boron element into weld metal and a welding method. The method for doping the trace boron element into the weld metal includes the step that the boride is added into a welding material, and the mass ratio of the boride to the welding material is 0.1-2:100. When the boride-containing welding material is used for welding, elemental boron can be decomposed in the welding arc space from the boride, and the elemental boron is doped into the weld metal. The welding material is a manual electrode coating or the flux-core of a flux-cored wire and submerged-arc welding flux.

Owner:江苏立新焊接材料有限公司

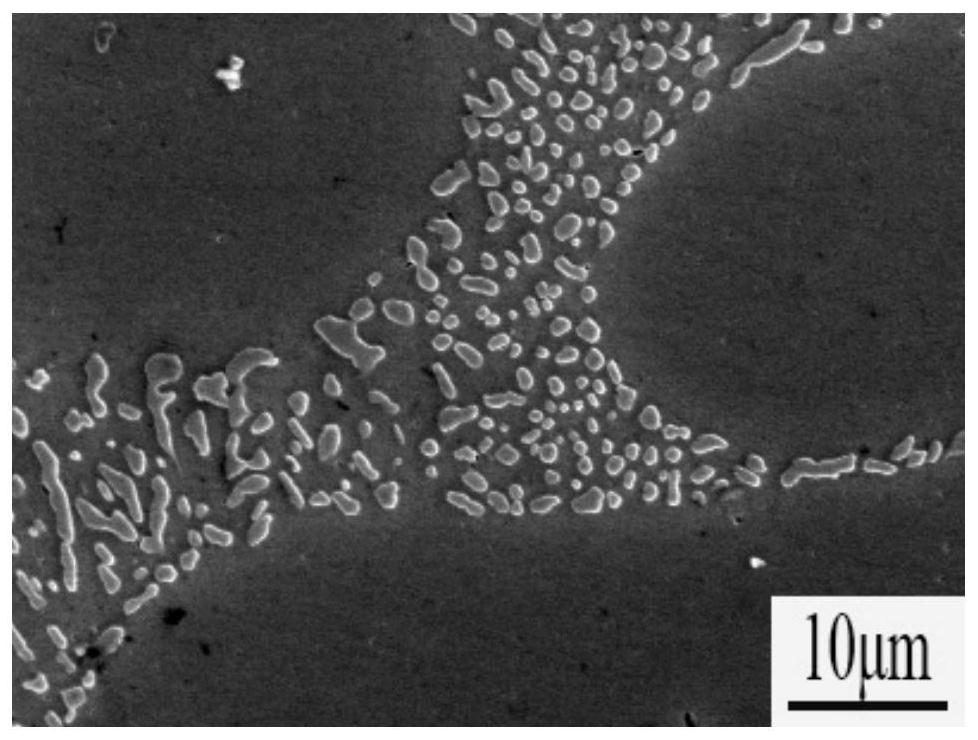

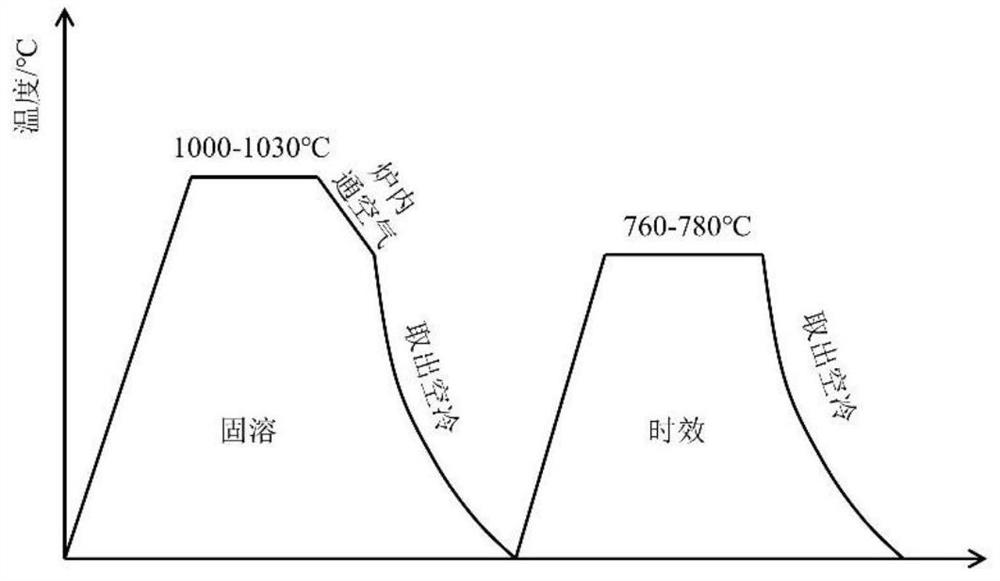

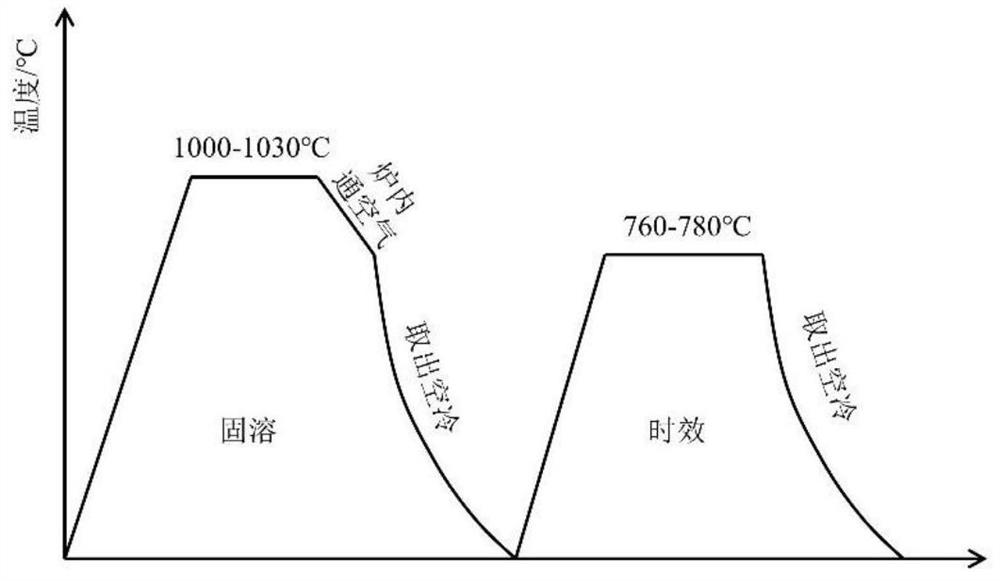

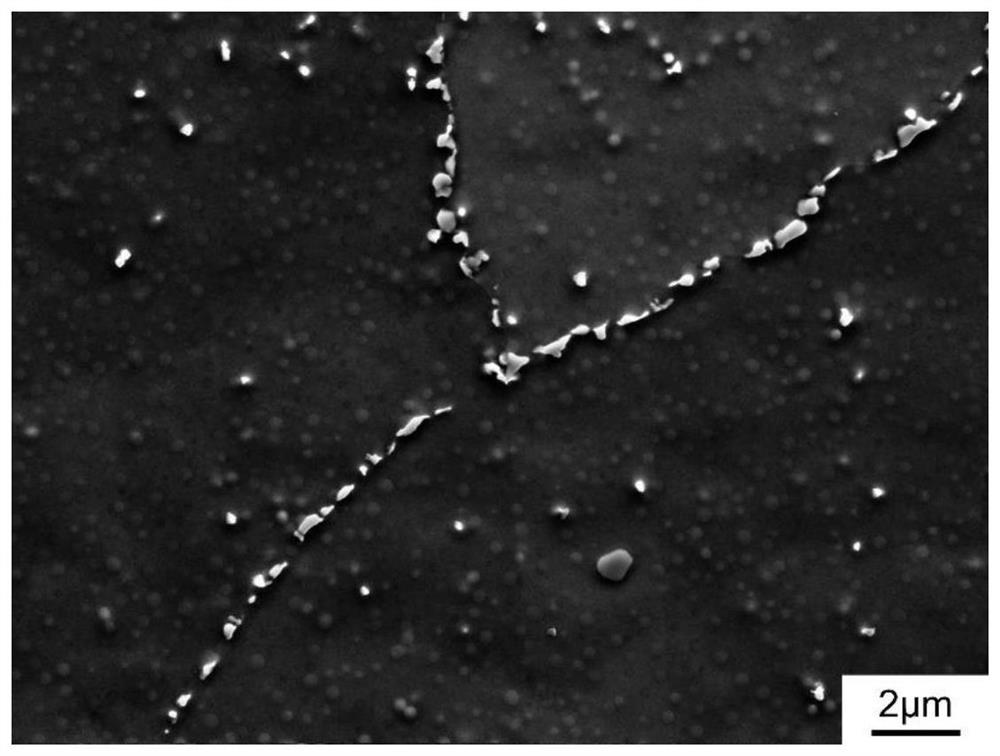

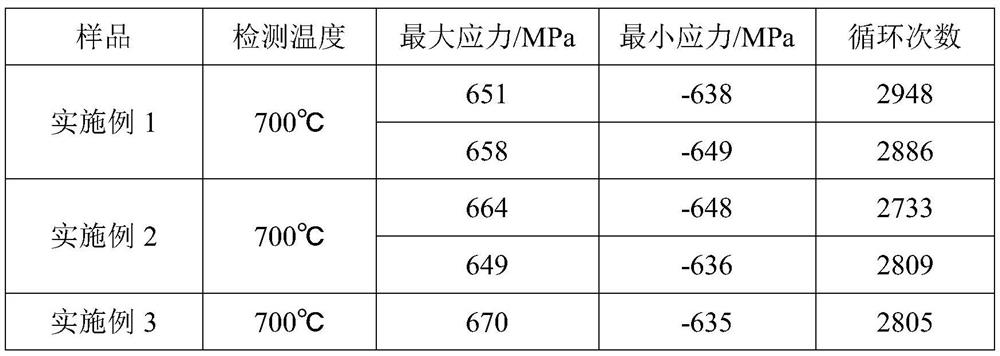

Heat treatment process for prolonging fatigue life of GH4738 alloy

The invention discloses a heat treatment process for prolonging the fatigue life of a GH4738 alloy, and belongs to the technical field of high-temperature alloy heat treatment. The process comprises the following steps that solution treatment is carried out on the GH4738 alloy under the condition that the temperature is 1000-1030 DEG C, and slow cooling and discharging air cooling are carried out in sequence; and then aging treatment is carried out at the temperature of 760-780 DEG C, and discharging air cooling is carried out to the room temperature. According to the heat treatment process, grain boundary carbide distribution in a matrix is optimized, the fatigue cycle of the alloy under the fatigue test condition is increased by 36% or above, the fatigue life of the GH4738 alloy is greatly prolonged, and then the service safety of alloy parts is improved. The heat treatment process is obvious in technical advantage and wide in market popularization prospect.

Owner:UNIV OF SCI & TECH BEIJING

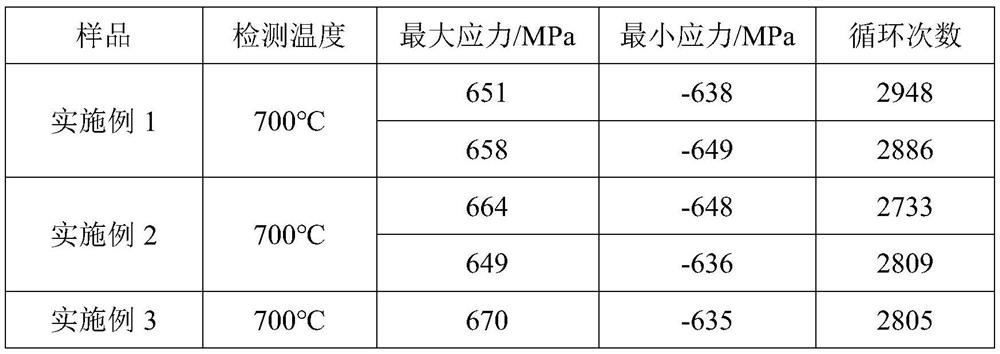

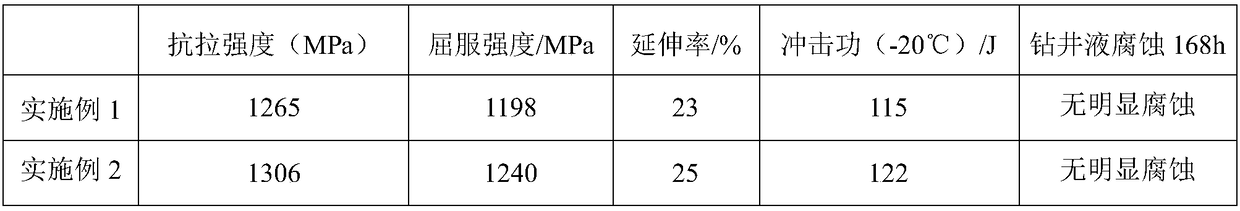

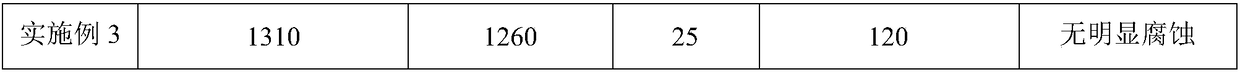

Nickel-containing corrosion-resistant steel pipe for ultrahigh-strength drill rod and manufacturing method of nickel-containing corrosion-resistant steel pipe

ActiveCN108411204AImprove service safetySimple manufacturing methodFurnace typesQuenching agentsSteel tubeCorrosion resistant

The invention relates to a nickel-containing corrosion-resistant steel pipe for an ultrahigh-strength drill rod and a manufacturing method of the nickel-containing corrosion-resistant steel pipe. Themanufacturing method comprises the following steps that a steel billet is smelted according to the following components of, by mass, 0.15 to 0.22% of C, 0.20 to 0.35% of Si, 0.8 to 1.2% of Mn, 0.6 to1.0% of Cr, 0.9 to 1.3% of Mo, 2.0 to 3.0% of Ni, less than or equal to 0.005% of S, less than or equal to 0.01% of P, and the balance iron and inevitable impurities; the steel billet is uniformly heated, and rolling and perforating are carried out to obtain a steel pipe; and heat treatment is carried out on the steel pipe, and then the steel pipe is cooled to room temperature to obtain the nickel-containing corrosion-resistant steel pipe for the ultrahigh-strength drill rod. According to the method, the chemical components of the steel pipe material are controlled, and all the components cooperate with one another; the drill rod has no obvious corrosion after placed in a drilling fluid for 168 service hours, so that service safety of the drill rod is greatly improved; and water is adoptedas a cooling liquid in a high-temperature tempering process, cooling speed is obviously higher than an air cooling speed currently used, so that the manufacturing period of the drill rod is greatly shortened.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

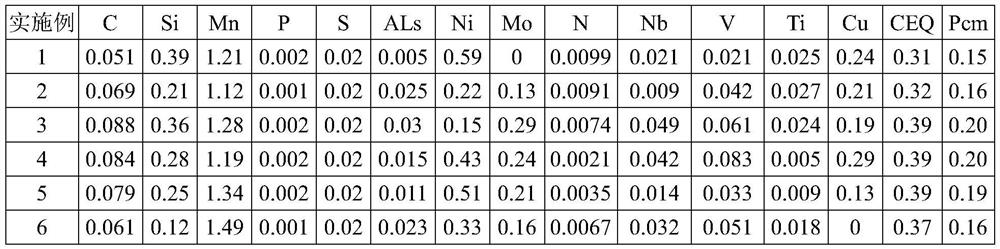

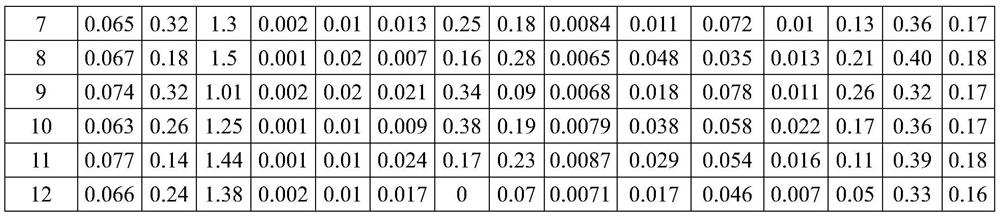

High-ductility EH36-grade ocean engineering steel and manufacturing method thereof

The invention relates to EH36-grade ocean engineering steel with high ductility, which is characterized by comprising the following chemical components in percentage by weight: 0.05%-0.08% of C, 0.10%-0.30% of Si, 1.00%-1.50% of Mn, 0.01%-0.04% of Nb, 0.02%-0.05% of V, 0.005%-0.02% of Ti, less than or equal to 0.01% of P, less than or equal to 0.01% of S, 0.01%-0.05% of Als and the balance of Fe and inevitable impurities. The chemical components of the steel are not added with precious alloy elements such as Ni; the microscopic structure and the grain size of the steel plate are regulated and controlled by controlling the content of sulfur and phosphorus and adopting continuous casting billet induction heating, two-stage controlled rolling, relaxation and controlled cooling processes, and the steel plate which is high in yield and stable in strength and toughness and particularly has high ductility is obtained.

Owner:ANGANG STEEL CO LTD

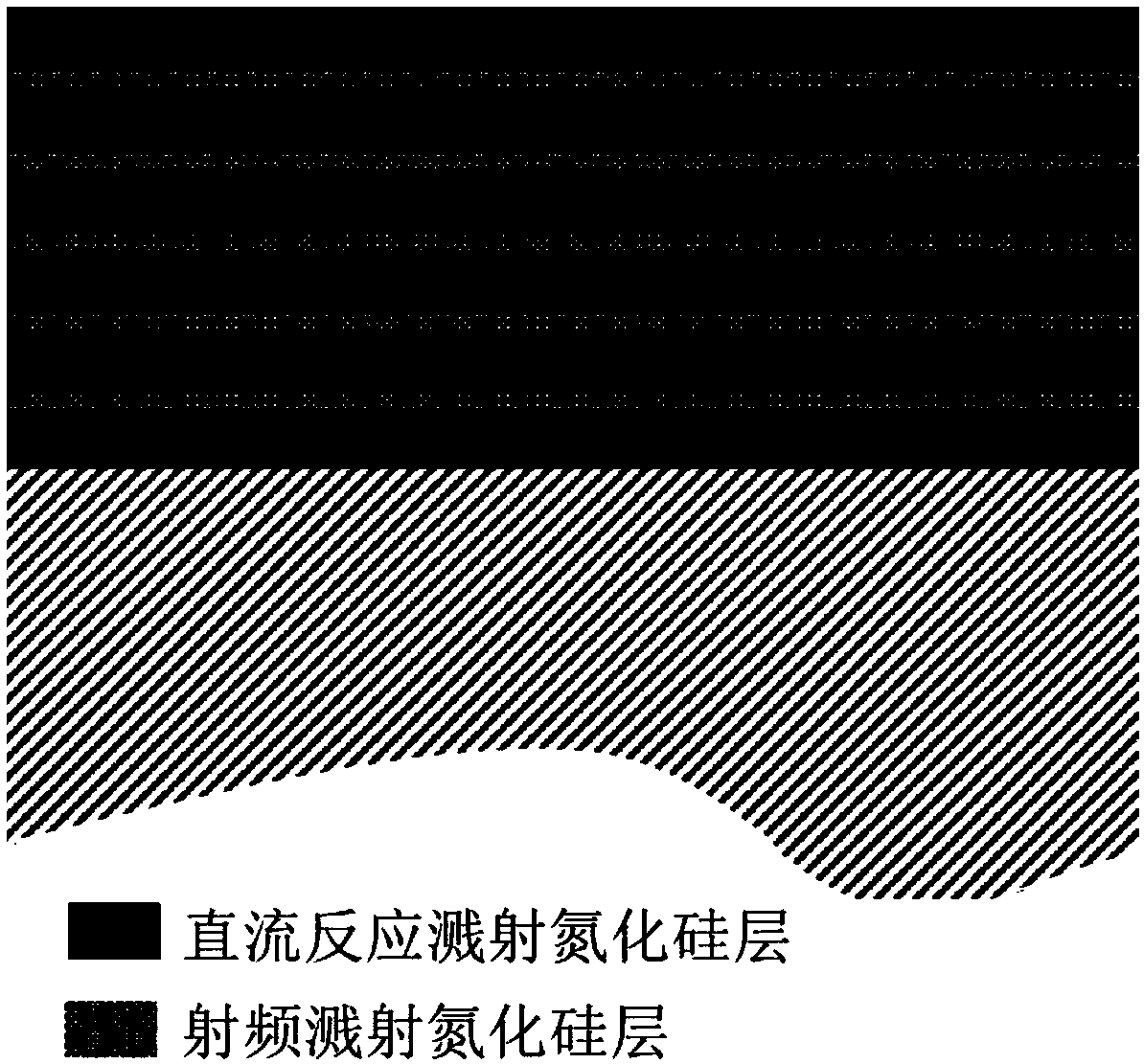

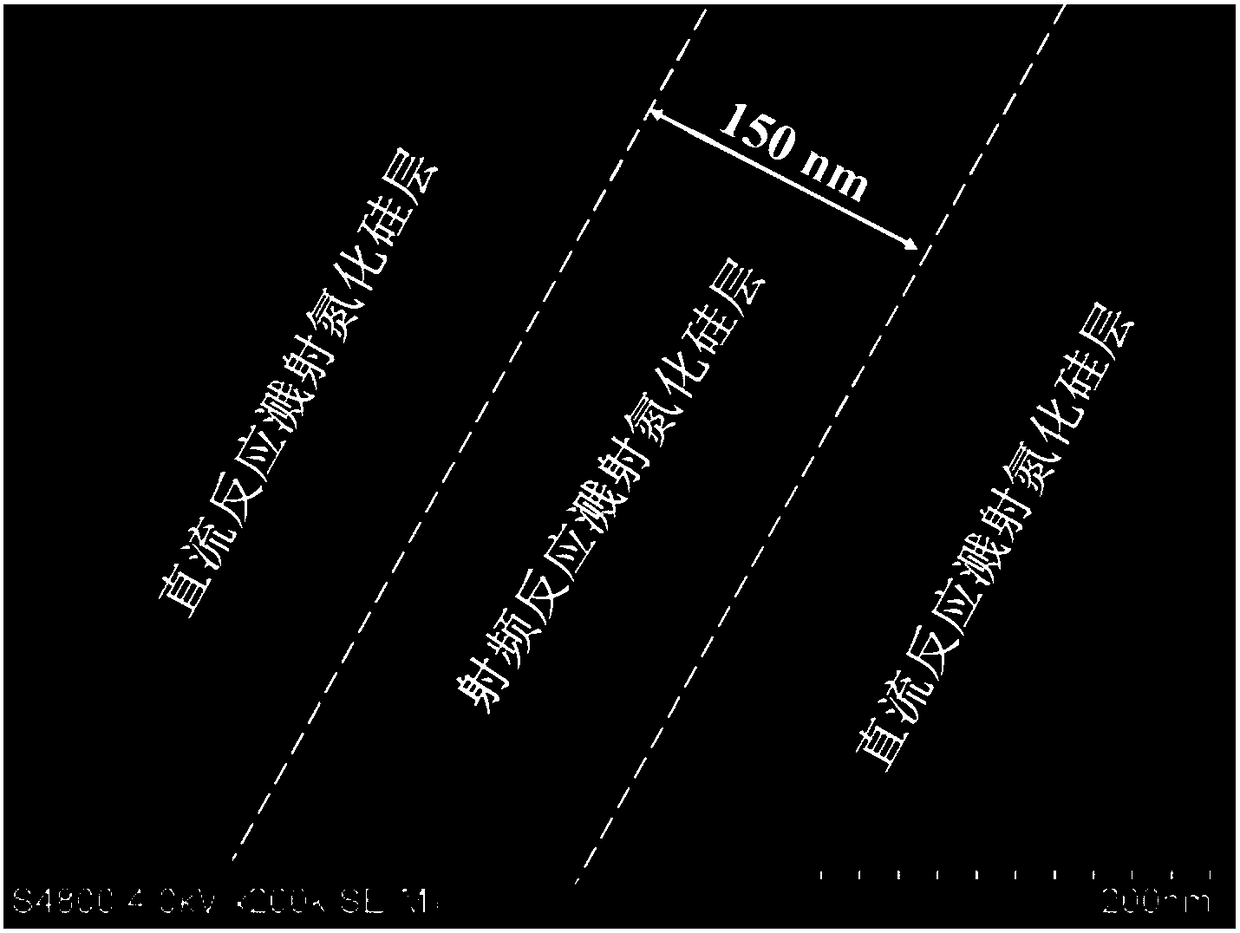

Nano multilayered silicon nitride ceramic coating and preparation method and application thereof

ActiveCN108265272AImprove bindingImprove toughnessVacuum evaporation coatingSputtering coatingElectrolysisCeramic coating

The invention discloses a nano multilayered silicon nitride ceramic coating and a preparation method and application thereof. The coating comprises a multilayered structure which is formed by direct-current reaction sputtering silicon nitride layers and radiofrequency sputtering silicon nitride layers which are alternately overlapped. The preparation method of the coating comprises the following step: depositing on a base material by taking a monocrystalline silicon target and / or a silicon nitride target as a cathode and taking inert gas and nitrogen as working gas and by a direct-current reaction sputtering technology and a radiofrequency sputtering technology to form the nano multilayered silicon nitride ceramic coating. The nano multilayered silicon nitride ceramic coating comprises direct-current reaction sputtering silicon nitride layers and radiofrequency sputtering silicon nitride layers which are alternately stacked. The nano multilayered silicon nitride ceramic coating is combined to a porous ceramic base material and the like well, has the advantages of compact structure, controlled thickness, high hardness, low internal stress, zero macroscopic defects and the like, andcan be applied to multiple fields of precise filtering and separation of various media, high-temperature wave transmitting / wave absorbing, electrolysis diaphragms and the like.

Owner:宁波海强装备科技有限公司

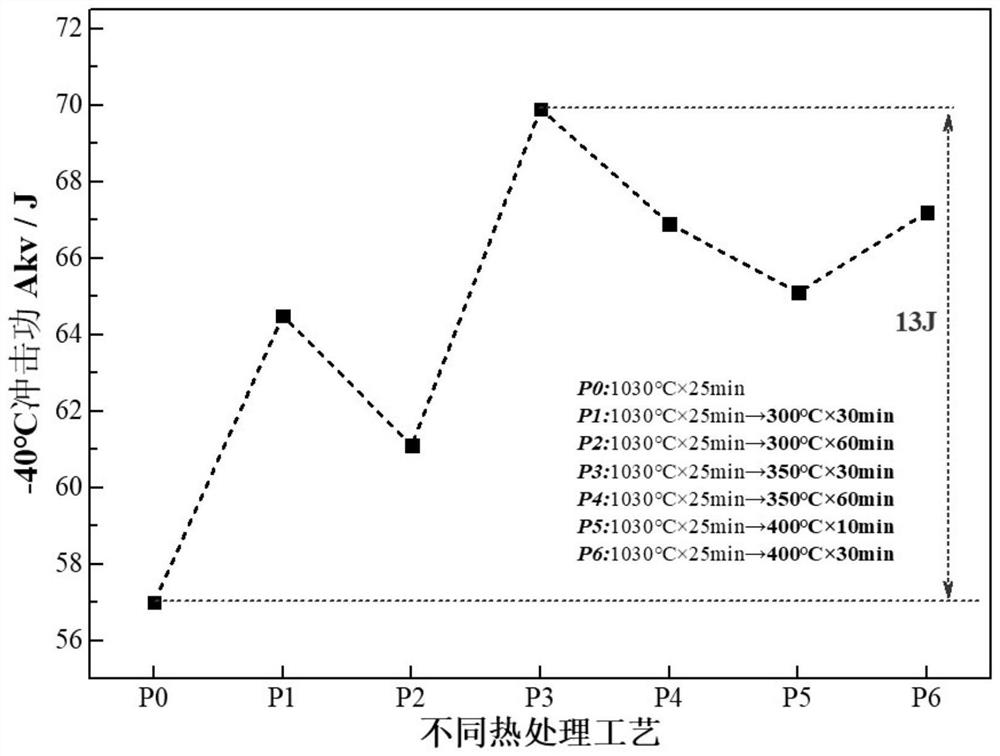

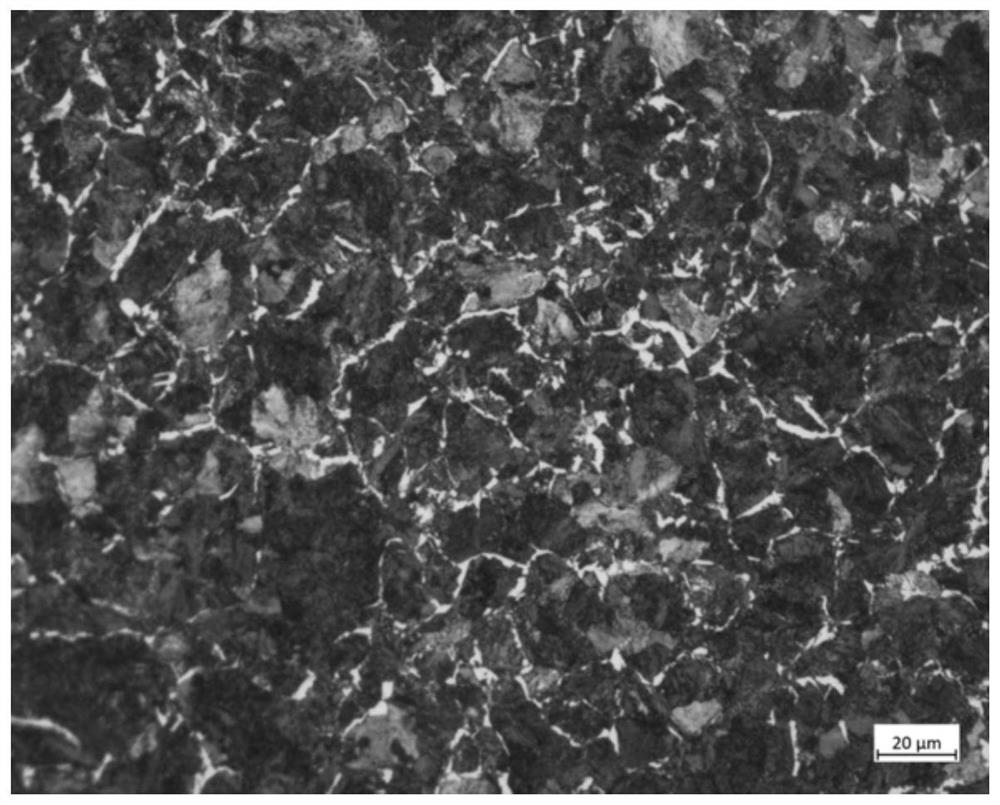

Method for improving low-temperature impact toughness of low-nickel ferrite-austenitic stainless steel

ActiveCN114045384AImprove low temperature toughnessHigh strengthFurnace typesHeat treatment furnacesTemperingSS - Stainless steel

The invention relates to a method for improving the low-temperature impact toughness of low-nickel ferrite-austenitic stainless steel. The method comprises the following steps that 1) hot rolling is conducted, specifically, the low-nickel stainless steel obtained after smelting is forged, and then hot rolling is conducted to obtain a hot-rolled material; 2) solid solution annealing is conducted, specifically, the hot-rolled material is subjected to solid solution annealing treatment, the solid solution temperature ranges from 1000 DEG C to 1100 DEG C, the heat preservation time ranges from 20 min to 40 min, and then water cooling is conducted; and 3) low-temperature tempering is conducted, specifically, the plate obtained after the step 2) is subjected to tempering, the tempering temperature ranges from 300 DEG C to 400 DEG C, the heat preservation time ranges from 10 min to 60 min, and then air cooling is conducted. According to the method, the low-temperature impact toughness is effectively improved while the strength of the low-nickel ferrite-austenitic stainless steel is guaranteed, so that the service safety of the low-nickel ferrite-austenitic stainless steel is improved, and the service life is prolonged.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

Steel for elastic wheel rim of tramcar as well as heat treatment method and production method of steel

ActiveCN113699452AImprove stabilityImprove service safetyFurnace typesProcess efficiency improvementUltimate tensile strengthHeat treating

The invention discloses steel for an elastic wheel rim of a tramcar as well as a heat treatment method and a production method of the steel. The steel for the elastic wheel rim of the tramcar comprises the following chemical components in percentage by weight: 0.55-0.67% of C, 0.25-0.60% of Si, 0.70-1.00% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, less than or equal to 0.35% of Cr, less than or equal to 0.20% of V and the balance of Fe and inevitable impurity elements. The strength and hardness levels of the wheel rim are equivalent to those of an LG61 wheel rim and a CL60 wheel, but the ductility and toughness are obviously improved, especially the low-temperature toughness is obviously improved, and the service safety of a wheel is improved.

Owner:MAANSHAN MAGANG JINXI RAIL TRANSPORT EQUIP

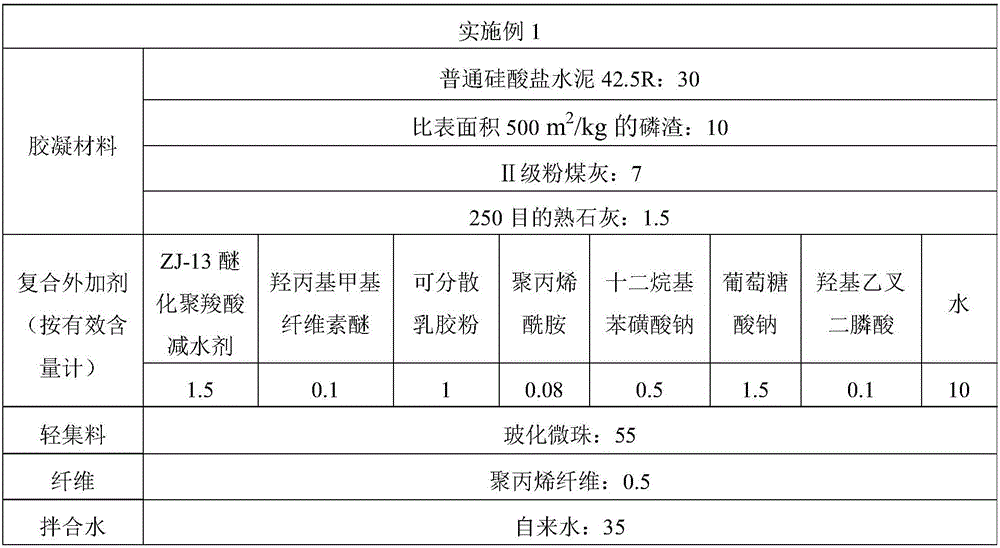

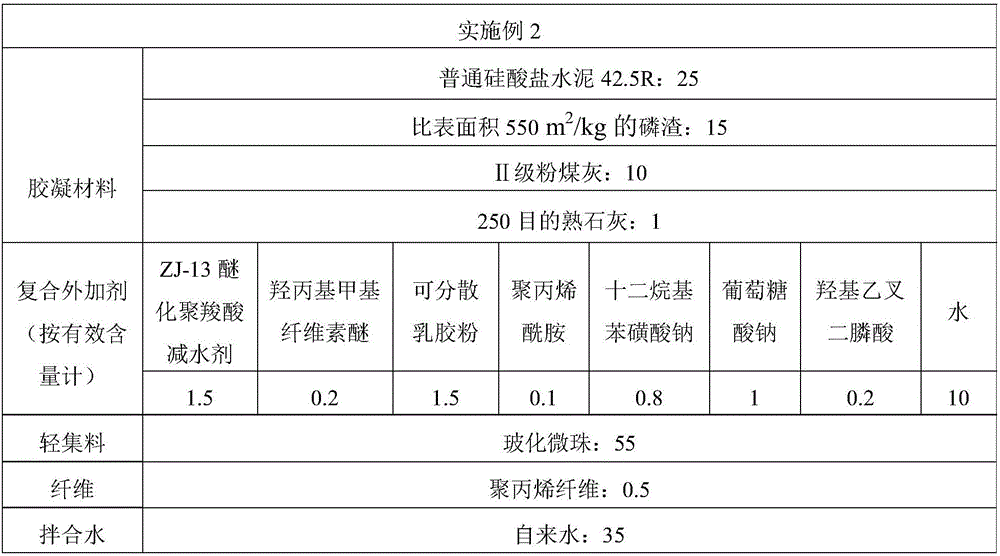

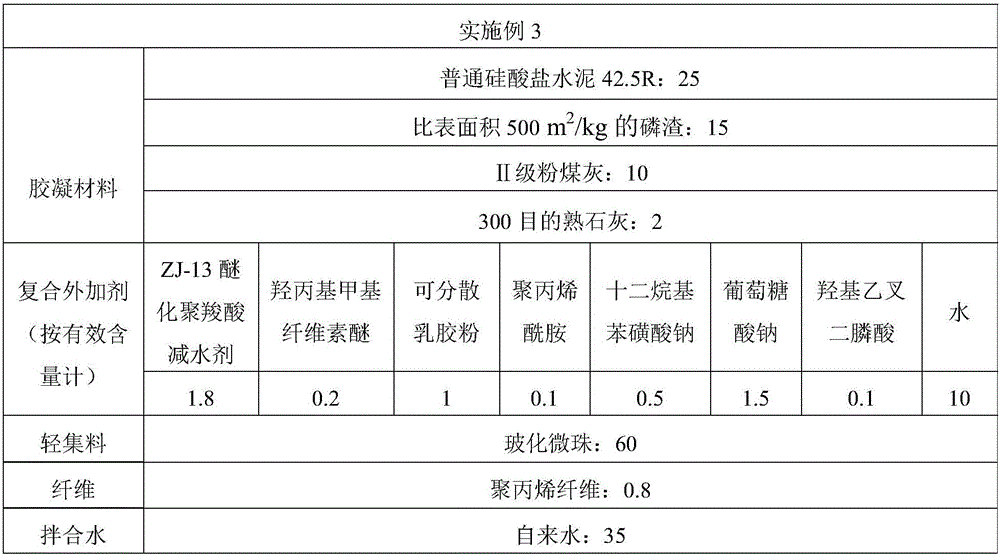

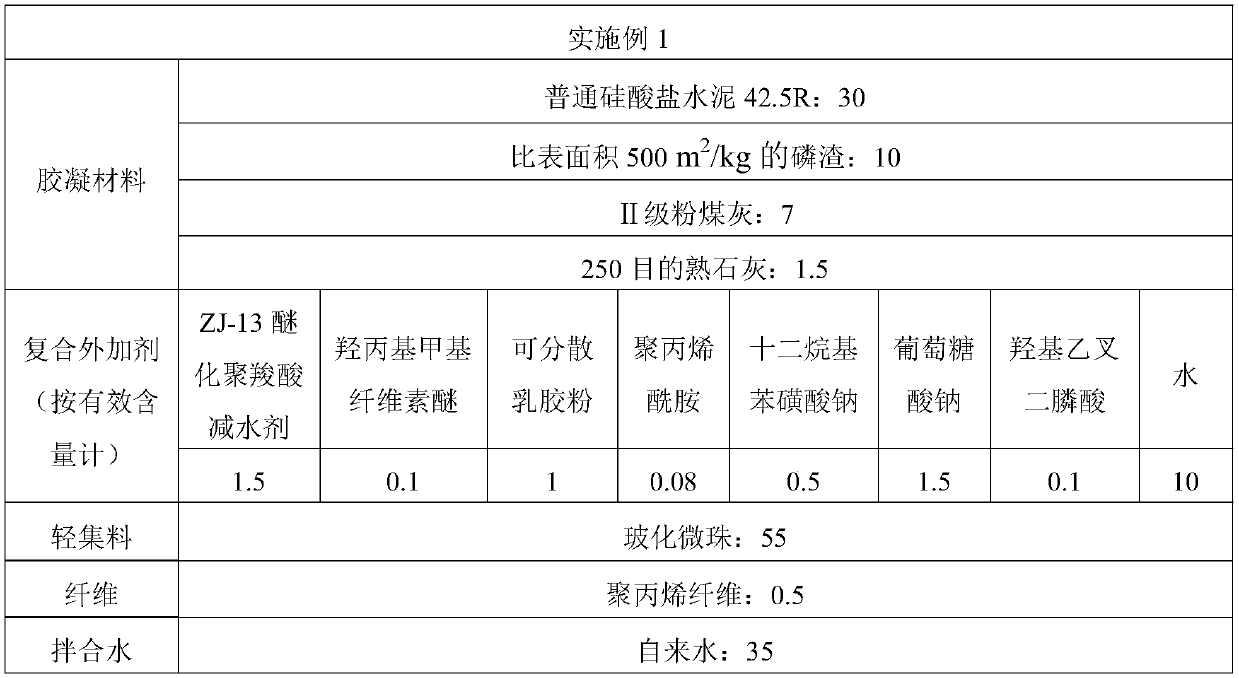

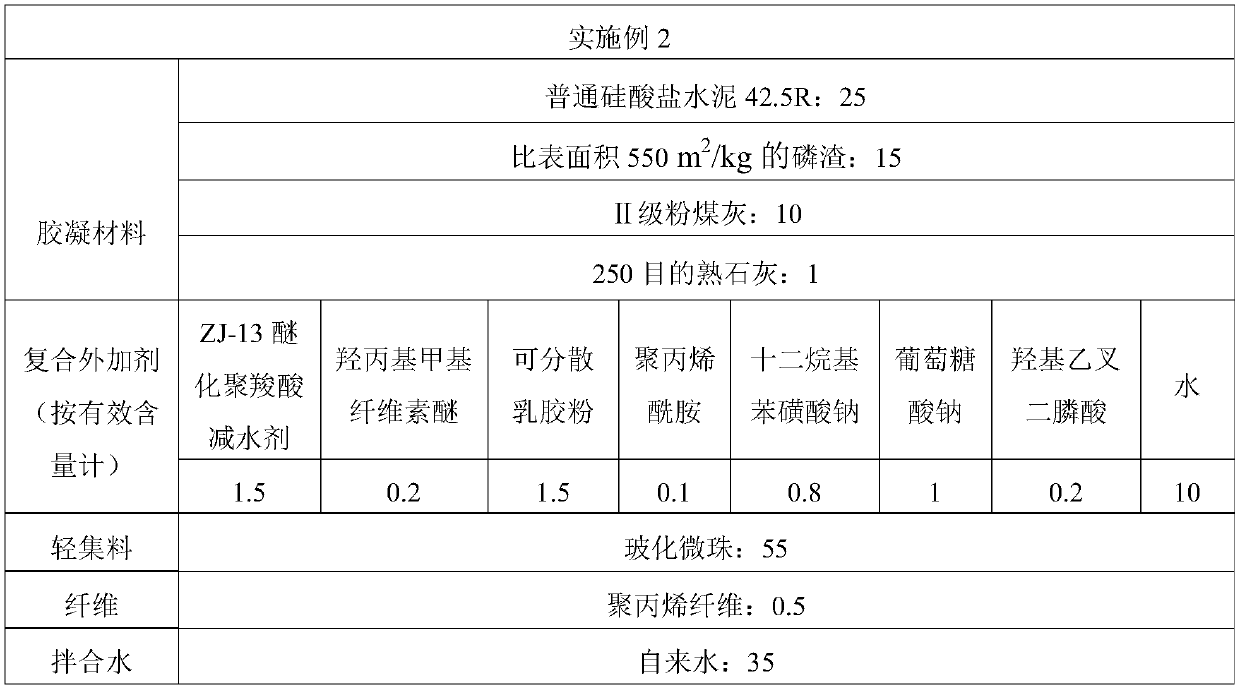

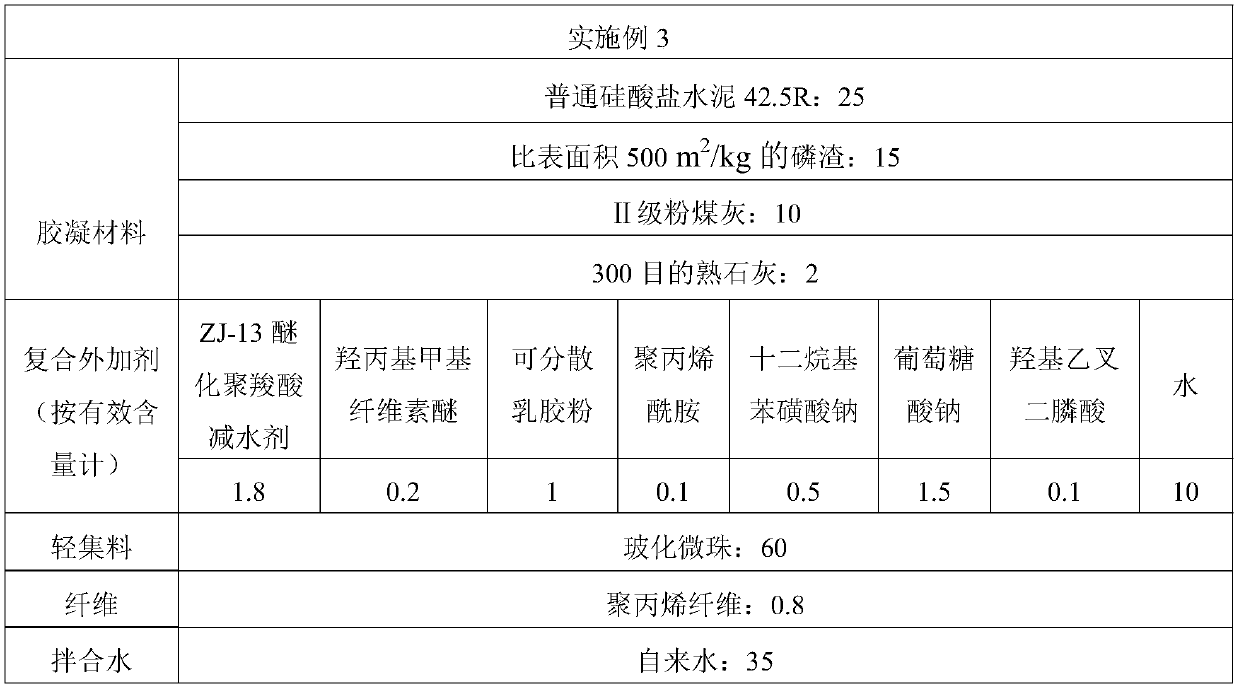

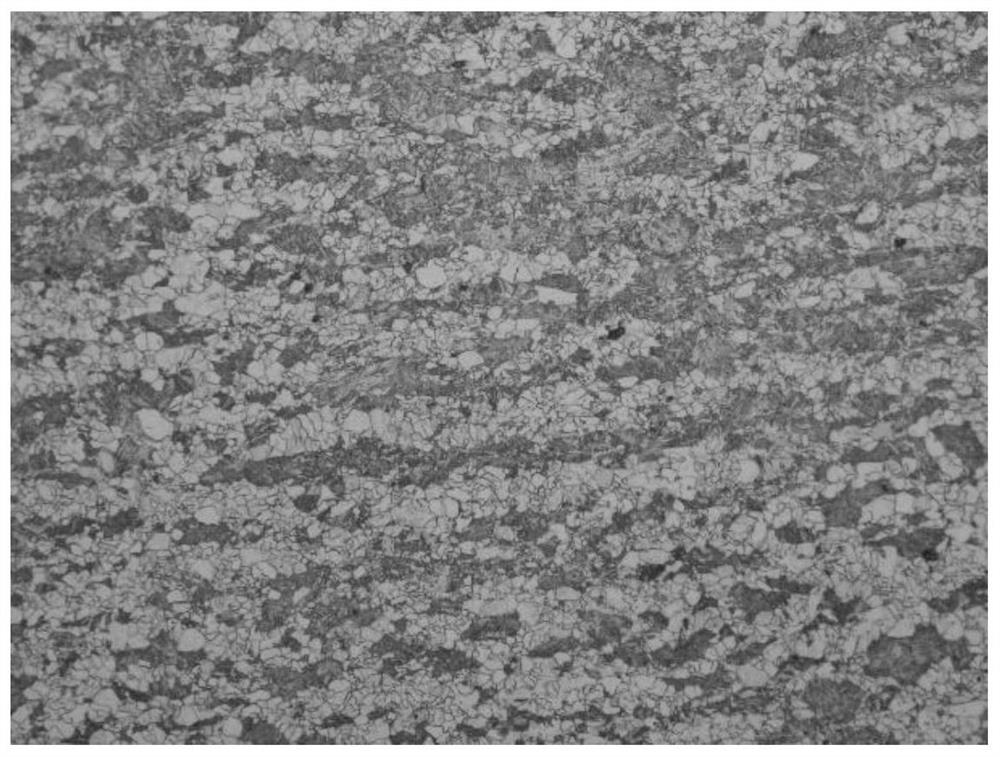

Wet-mixed thermal mortar doped with phosphorus slag and free of shrinkage and preparation method

ActiveCN106517952ASatisfy the requirements of coordinated construction operable timeImprove service safetyCelluloseFiber

The invention discloses wet-mixed thermal mortar doped with phosphorus slag and free of shrinkage. The wet-mixed thermal mortar is mainly prepared from cement, the phosphorus slag, fly ash, slaked lime, a composite admixture, lightweight aggregates, fibers and mixing water, wherein the composite admixture mainly comprises components as follows: an etherified polycarboxylate superplasticizer, hydroxyalkyl cellulose ether, dispersible latex powder, polyacrylamide, sodium dodecyl benzene sulfonate, sodium gluconate and etidronic acid. The wet-mixed thermal mortar effectively reduces construction intensity and has the characteristics that the construction operation time is superlong and controllable, the thermal mortar avoids air shrinkage and the like, furthermore, the wet-mixed thermal mortar is stable in performance in operable time of the construction, and the construction quality is excellent.

Owner:中建西部建设西南有限公司 +1

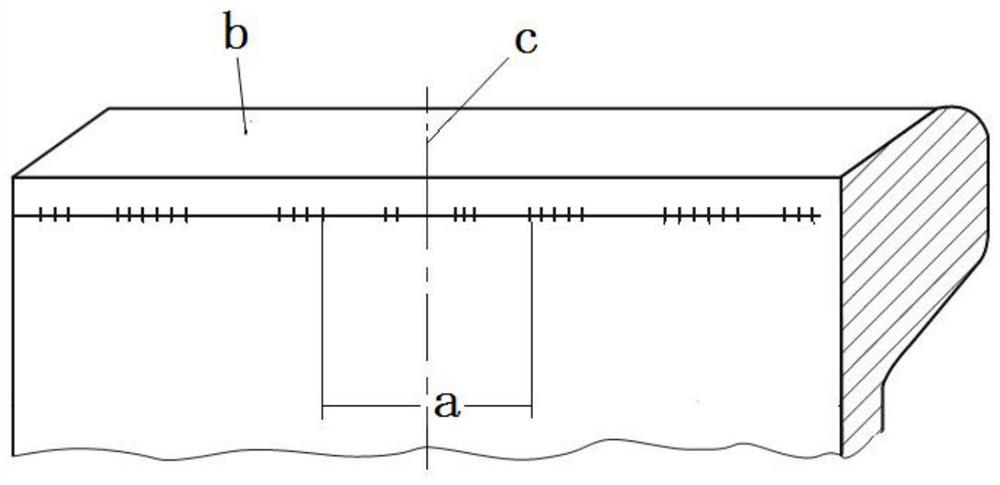

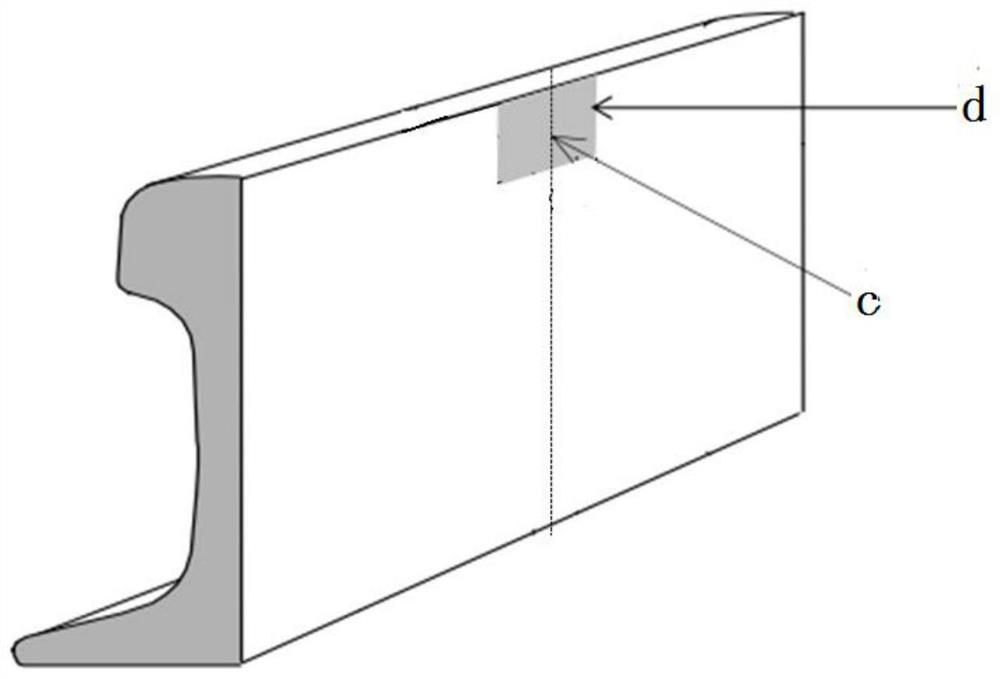

Welding method of copper-containing corrosion-resistant steel rails

ActiveCN113427109AReduce the chance of welding gray spotsImprove service safetyRailsWelding/cutting auxillary devicesPearliteCorrosion resistant

The invention discloses a welding method of copper-containing corrosion-resistant steel rails. The welding method comprises the following steps that (1) a copper-containing corrosion-resistant steel rail base material is prepared, the microstructure of the copper-containing corrosion-resistant steel rail base material is controlled to comprise 90%-100% of pearlite and 0%-10% of proeutectoid ferrite, and the copper-containing corrosion-resistant steel rail base material comprises, by mass, 0.20%-0.60% of Cu; and (2) the multiple steel rails made of the copper-containing corrosion-resistant steel rail base material in the step (1) are welded, the steel rail welding upsetting amount is controlled to be kept at 8.6-9.8 mm, the heat input amount of 4.0-8.2 MJ is adopted for welding, and after steel rail welding and overlap pushing are completed, the pressure maintaining pressure of 22-25 t is adopted for pressure maintaining. According to the welding method, the railway service safety can be improved by controlling the steel rail copper content, the welding heat input amount, the steel rail welding upsetting amount and the pressure maintaining operation in the overlap pushing stage.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

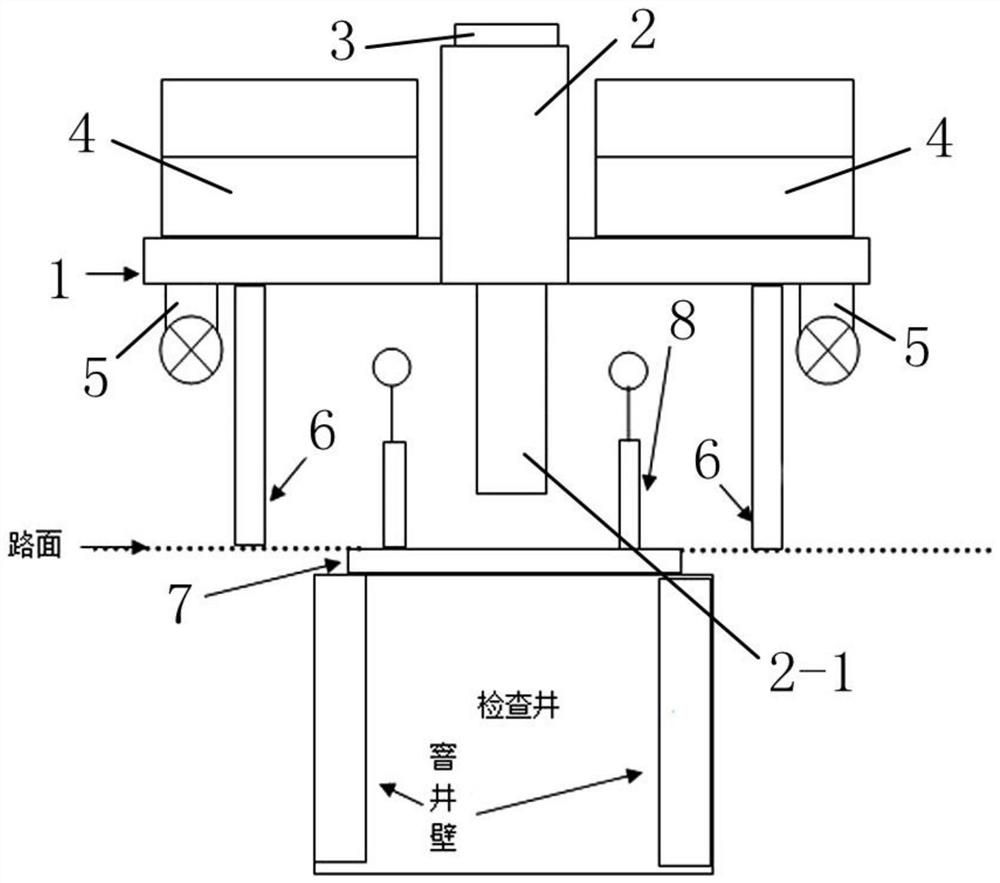

Field detection device for comprehensive bearing capacity of urban road inspection well system

PendingCN112982515AEasy to operateImprove service safetyArtificial islandsFoundation testingReliability engineeringReal-time computing

The invention belongs to the technical field of comprehensive detection equipment of an urban road inspection well system, and particularly relates to a field detection device for the comprehensive bearing capacity of the urban road inspection well system. The field detection device comprises a reaction frame, wherein loading equipment for applying a load to the urban road inspection well system is arranged in the middle of the reaction frame; a load sensor is arranged on the loading equipment; platforms on the reaction frame on the two sides of the loading equipment are used for placing balancing weights; walking wheels are mounted on the periphery of the lower side of the reaction frame; a telescopic support is further mounted on the lower side of the reaction frame; and the field detection device further comprises a displacement meter placed on an inspection well cover during detection. The detection device is simple and easy to operate, and detection data is accurate and reliable; and the field detection device is not limited to field detection of the comprehensive bearing capacity of the whole inspection well system, and can also independently perform a mechanical test on an inspection well cover product.

Owner:XUZHOU JIANKE TECH

Nanometer M2B reinforced iron-based wear-resistant coating and preparation method thereof

ActiveCN112981052AImprove wear resistanceApplicable to wear conditionsIncreasing energy efficiencyTemperingHigh energy laser

The invention discloses a nanometer M2B reinforced iron-based wear-resistant coating and a preparation method thereof. The method comprises the following steps of selecting cast Fe-B alloy as an original matrix, and polishing and derusting the surface of the original matrix; placing the treated original matrix in argon for preheating treatment; conducting surface melting treatment on the pretreated original matrix by utilizing high-energy laser; and conducting quenching and tempering heat treatment on the original matrix subjected to surface melting treatment, and preparing the surface wear-resistant coating of the nanometer M2B enhanced martensitic matrix on the surface of the original matrix. The prepared nanometer M2B reinforced iron-based wear-resistant coating has excellent wear resistance and can be used for the working condition of impact abrasive wear resistance, the wear resistance of the coating is improved by 3-7 times compared with the wear resistance of a cast Fe-B alloy, the traditional Fe-B wear-resistant alloy can be applied to the working condition of impact wear after being subjected to proper laser surface melting to prepare the coating, and the coating has important engineering application and popularization value.

Owner:XI AN JIAOTONG UNIV

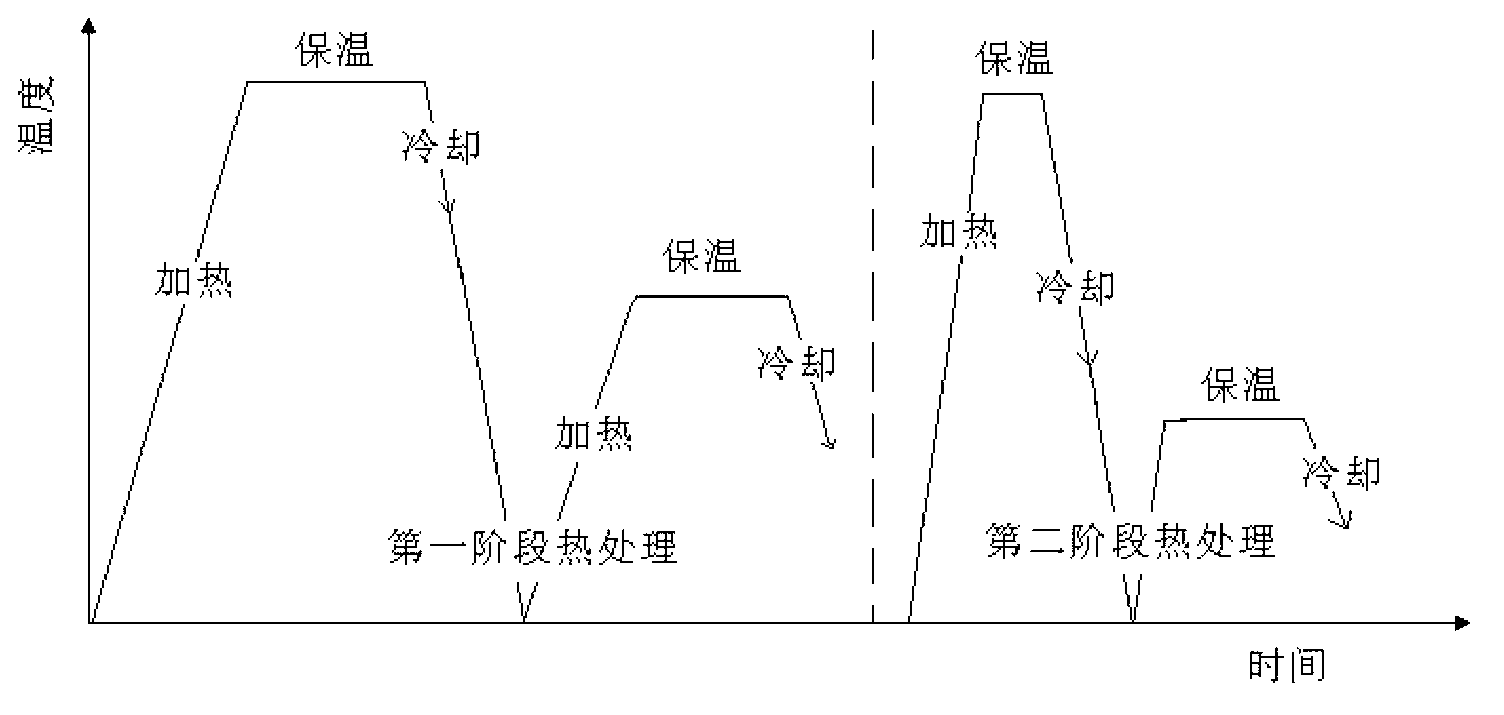

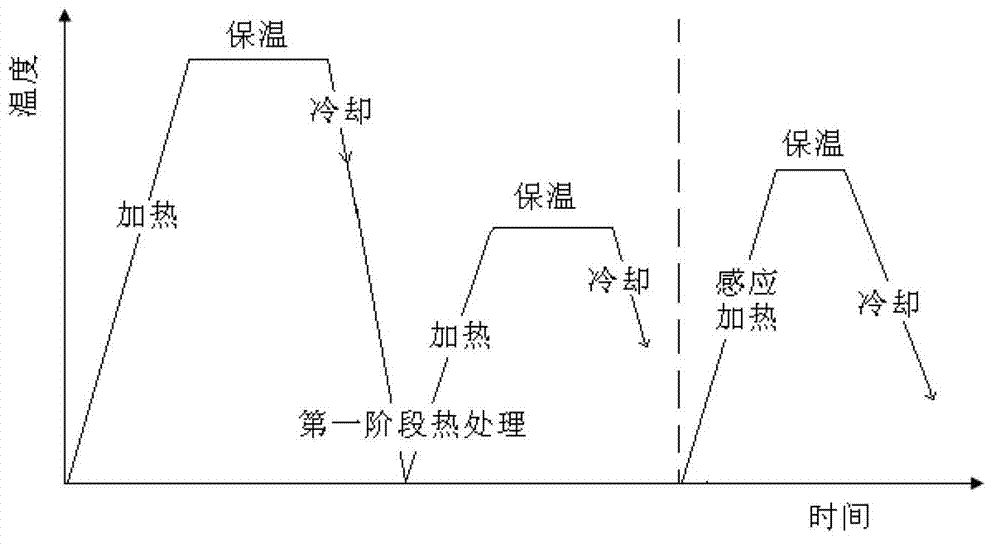

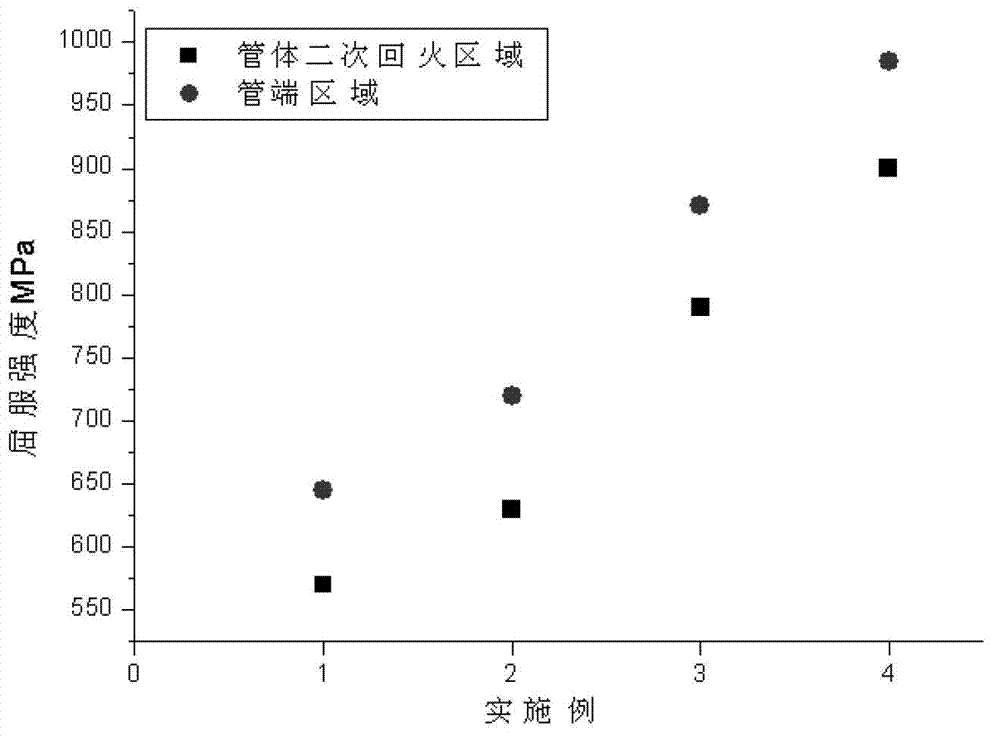

Reinforcing thermal treatment technology for pipe end of petroleum steel pipe in quenching and tempering condition

ActiveCN103266217BImprove service safetyReduce intensityFurnace typesHeat treatment furnacesStress concentrationUltimate tensile strength

The invention discloses a reinforcing thermal treatment technology for the pipe end of a petroleum steel pipe in a quenching and tempering condition. The technology comprises the following steps of: S1, performing the first-stage quenching and tempering treatment on the whole pipe; and S2, performing secondary tempering treatment on the middle part of the pipe body of the steel pipe obtained by the step S1. The secondary tempering treatment on the middle part of the pipe body of the steel pipe aims at reducing the strength of the middle part of the steel pipe and realizing the strength performance of a final product. The technology disclosed by the invention can realize strength mismatching between the pipe body and the pipe end of a petroleum steel pipe in a quenching and tempering condition, so that no obvious transition area exists between the pipe body and the pipe end of the steel pipe. According to the reinforcing thermal treatment technology for the pipe end of a petroleum steel pipe in a quenching and tempering condition, disclosed by the invention, the strength of the treated petroleum steel pipe is distributed in a mismatching manner, the weak point of easy deformation and even breakage caused by stress concentration of a threaded structure at the pipe end of an existing product can be eliminated, and the service safety of the steel pipe can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

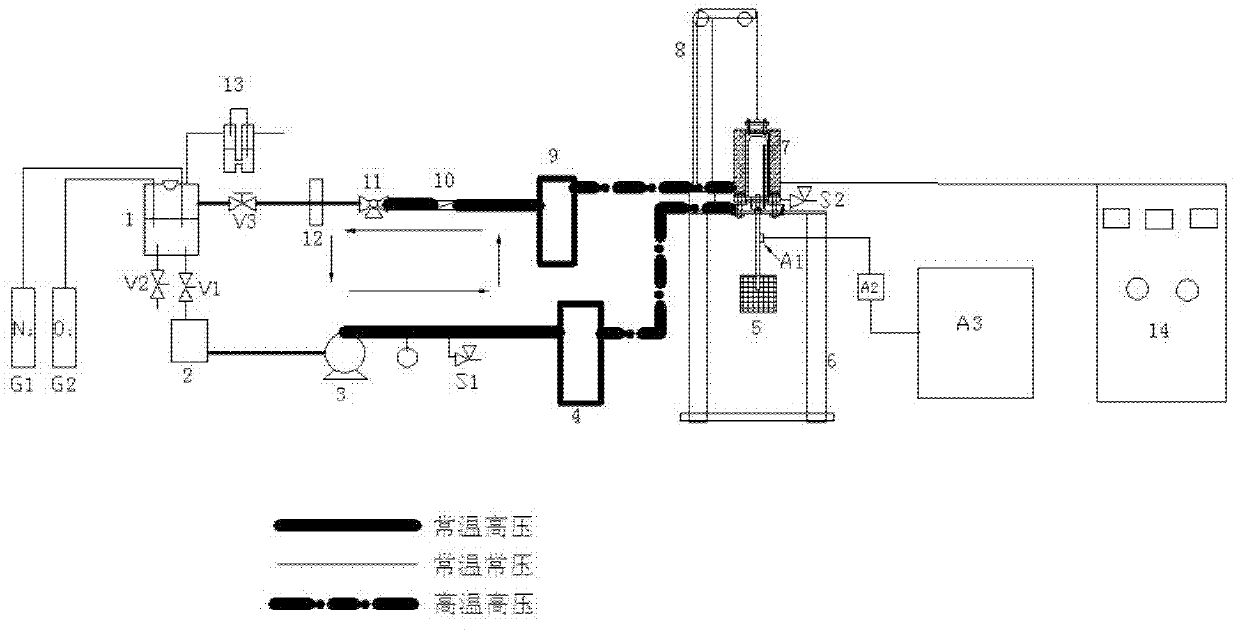

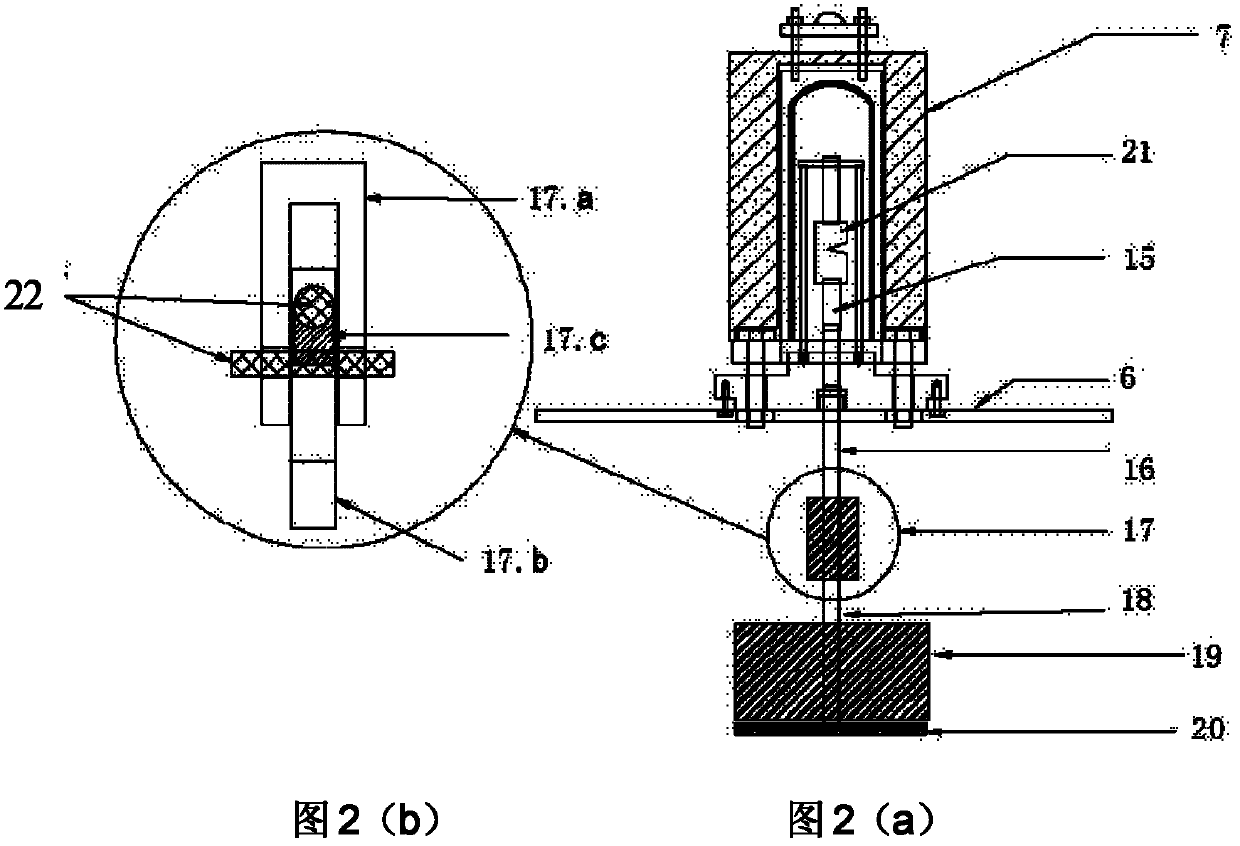

High-temperature and high-pressure circulating water constant-load extension experimental device with acoustic emission testing function

ActiveCN102288492BTemperature controlControl pressureMaterial strength using tensile/compressive forcesConstant loadAcoustic emission

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A Heat Treatment Process for Improving the Fatigue Life of gh4738 Alloy

The invention discloses a heat treatment process for improving the fatigue life of GH4738 alloy, which belongs to the technical field of high temperature alloy heat treatment. The process steps are as follows: the GH4738 alloy is subjected to solution treatment at 1000-1030°C, first slowly cooled and then air-cooled out of the furnace; then aged at 760-780°C, and air-cooled to room temperature after being out of the furnace. This heat treatment process optimizes the distribution of grain boundary carbides in the matrix, which increases the fatigue cycle of the alloy by more than 36% under fatigue test conditions, greatly improves the fatigue life of the GH4738 alloy, and further improves the service safety of alloy components. The technical advantage of this heat treatment process is obvious, and the market promotion prospect is broad.

Owner:UNIV OF SCI & TECH BEIJING

Air-cooling type 80H thermal production well casing based on strain design and production process thereof

InactiveCN103352176BImprove service safetySmall amount of plastic deformationDrilling rodsFurnace typesChemical constituentsMaterials science

The invention discloses an air-cooling type 80H thermal production well casing based on a strain design and production process thereof. The material of the air-cooling type 80H thermal production well casing comprises the following chemical constituents in percentage by mass: 0.20-0.22% of C, 1.0-1.25% of Mn, 0.40-0.50% of Si, less than 0.011% of P, less than 0.004% of S, 0.90-1.0% of Cr, 0.20-0.25% of Mo, 0.03-0.04% of Ni, 0.01-0.02% of Nb, 0.01-0.02% of Al, 0.001-0.0015% of B, and the balance of matrix element iron. The invention further discloses the production process for the casing. The production process comprises the following steps of: heat treatment and cooling. The resistance of the casing to high-temperature permanent deformation can be improved, and casing damages can be reduced, and then the safe reliability of the thermal production well casing during a service process can be improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Strength mismatching heat treatment process for petroleum steel tube in hardened and tempered state

ActiveCN103266216BImprove service safetyHigh strengthFurnace typesHeat treatment furnacesStress concentrationUltimate tensile strength

The invention discloses a strength mismatching heat treatment process for a petroleum steel tube in a hardened and tempered state, belonging to the technical field of metal engineering materials. The process comprises first-stage whole tube hardening and tempering and second-stage tube end hardening and tempering. According to the process, the strength mismatching of the tube body and the tube ends of the petroleum steel tube in a hardened and tempered state can be realized, the strength and toughness of the tube ends are higher than those of the tube body, and the strength and toughness of transition zones between the tube ends and the tube body are higher than those of the tube body but lower than those of the tube ends, thus ensuring that the steel tube has the performance distribution of strength mismatching accompanied with the distribution of toughness mismatching. The distribution of strength mismatching eliminates the weak point that the tube ends of the existing product are prone to deform or even break due to stress concentration caused by thread structures, and improves the service safety of the steel tube.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

A kind of non-shrinkage wet-mix thermal insulation mortar mixed with phosphorus slag and its preparation method

ActiveCN106517952BSatisfy the requirements of coordinated construction operable timeImprove service safetyCelluloseFiber

The invention discloses wet-mixed thermal mortar doped with phosphorus slag and free of shrinkage. The wet-mixed thermal mortar is mainly prepared from cement, the phosphorus slag, fly ash, slaked lime, a composite admixture, lightweight aggregates, fibers and mixing water, wherein the composite admixture mainly comprises components as follows: an etherified polycarboxylate superplasticizer, hydroxyalkyl cellulose ether, dispersible latex powder, polyacrylamide, sodium dodecyl benzene sulfonate, sodium gluconate and etidronic acid. The wet-mixed thermal mortar effectively reduces construction intensity and has the characteristics that the construction operation time is superlong and controllable, the thermal mortar avoids air shrinkage and the like, furthermore, the wet-mixed thermal mortar is stable in performance in operable time of the construction, and the construction quality is excellent.

Owner:中建西部建设西南有限公司 +1

A low yield ratio marine steel plate with good welding performance and its manufacturing method

ActiveCN110791702BPromote nucleationImprove high heat input welding performanceMaterials preparationYield ratio

The invention belongs to the field of steel material preparation, and particularly relates to a low-yield-ratio marine steel plate with good welding performance and a manufacturing method thereof. Thelow-yield-ratio marine steel plate comprises the following components of, by weight, 0.05%-0.09% of C, 0.1%-0.4% of Si, 1.0%-1.5% of Mn, less than or equal to 0.02% of P, less than or equal to 0.02%of S, 0.005%-0.03% of Als, 0%-0.6% of Ni, 0%-0.3% of Cu, 0.008%-0.05% of Nb, 0.005%-0.03% of Ti, 0.002%-0.01% of N, 0.02%-0.08% of V, 0%-0.3% of Mo, and the balance Fe and inevitable impurities, wherein the yield ratio of the steel plate is less than or equal to 0.80, the carbon equivalent Ceq is less than or equal to 0.41, and Pcm is less than or equal to 0.21. According to the low-yield-ratio marine steel plate with the good welding performance and the manufacturing method thereof, a certain content of N element is added, and second phase dispersion precipitation of V, Ti element is matched,so that the high-heat input welding performance and the low-temperature impact toughness of the steel plate are improved; and chemical components and the processes of high finish rolling temperature,low water inlet high red returning temperature and low cooling speed are combined, so that the high service safety with the yield ratio being less than or equal to 0.8 can be obtained, and a corresponding production process is formed while the high-service safety steel plate which is easy to weld with high heat input is obtained.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com