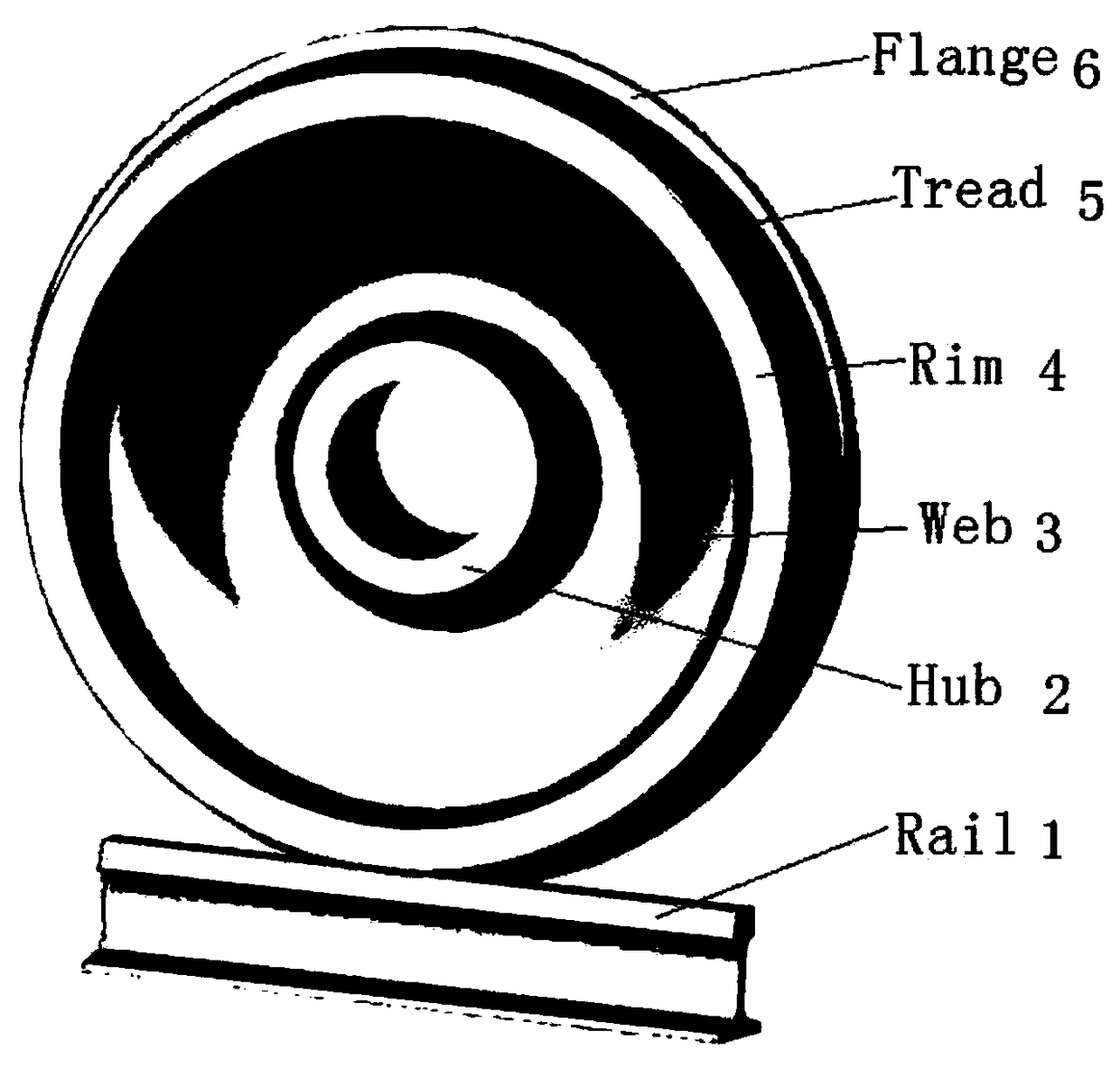

Bainitic steel wheel for rail traffic with capability of resisting against damp, hot and corrosive environments and manufacturing method thereof

A technology for corrosive environments and rail transportation, applied in the field of rail transportation, can solve problems such as corrosion of micro-batteries, poor hardenability, plastic deformation of wheels, etc., and achieve the effects of improving operating efficiency, reducing friction coefficient, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A bainitic steel wheel resistant to damp heat and corrosive environment, containing the chemical composition as described in Example 1 in Table 2.

[0073] The manufacturing method is as follows: the molten steel whose chemical composition is as shown in Example 1 in Table 2 is subjected to a steelmaking process, a refining process, a vacuum degassing process, a round billet continuous casting process, an ingot cutting process, a forging rolling process, a heat treatment process, processing, and finished product detection. process is formed. The heat treatment process is as follows: heating to 942°C for 4.3 hours, the rim tread is cooled to 200-350°C by program-controlled water spray, and air-cooled to room temperature, during which self-tempering is carried out by using the residual heat of the rim, web and hub; then Then heat to 250-350℃ for 4 hours at medium and low temperature, and then air-cool to room temperature after tempering.

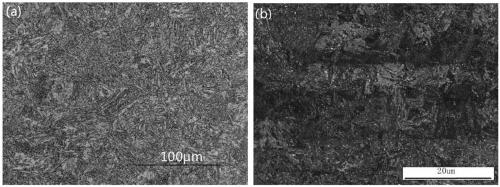

[0074] like figure 2 As shown...

Embodiment 2

[0076] A bainitic steel wheel resistant to damp heat and corrosive environment, containing the chemical composition as described in Example 1 in Table 2.

[0077] The manufacturing method is as follows: the molten steel whose chemical composition is as shown in Table 2 Example 2 is subjected to a steelmaking process, a refining process, a vacuum degassing process, a round billet continuous casting process, an ingot cutting process, a forging rolling process, a heat treatment process, processing, and finished product detection. process is formed. The heat treatment process is as follows: heating to 936°C for 3.8 hours, the rim tread is cooled to 200-360°C by program-controlled water spray, air-cooled to room temperature, during which self-tempering is carried out by using the residual heat of the rim, web and hub; then Then heat to 250-350°C for medium and low temperature tempering for 3.5 hours, and then air-cool to room temperature after tempering.

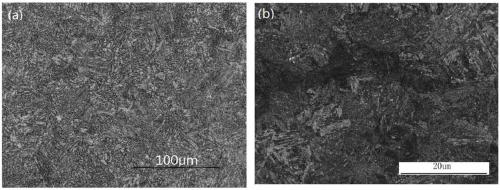

[0078] like image 3 As...

Embodiment 3

[0081] A bainitic steel wheel resistant to damp heat and corrosive environment, containing the chemical composition as described in Example 1 in Table 2.

[0082] The manufacturing method is as follows: the molten steel whose chemical composition is as shown in Table 2 Example 3 is subjected to a steelmaking process, a refining process, a vacuum degassing process, a round billet continuous casting process, an ingot cutting process, a forging rolling process, a heat treatment process, processing, and finished product detection. process is formed. The heat treatment process is as follows: heating to 943°C for 4.2 hours, the rim tread is cooled to 200-380°C by program-controlled water spray, air-cooled to room temperature, during which self-tempering is carried out by using the residual heat of the rim, web and hub; then Then heat to 300-400℃ for 4.2 hours at medium and low temperature, and then air-cool to room temperature after tempering.

[0083] like Figure 5 , 6 As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com